Products

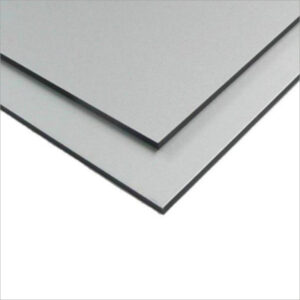

A2 Fireproof Aluminum Composite Panel 4mm, 5mm for Exterior

Standard Size: 1220*2440mm

Width:1000,1250,1500,1570mm

Length: (max length can be 6000mm )

Panel Thickness: 3mm,4mm,5mm,6mm

Aluminum Thickness: 0.01~0.50mm

Color Coating: any color

Coating: PE/PVDF Coating

MOQ: 800 SQM/Color

A2 Fireproof Aluminum Composite Panel is a kind of a popular wall decorative composite material that is widely used today. With its superb mechanical strength and very good toughness, it is one of the most lightweight materials used for wall decorations today. However, A2 aluminum composite cladding is not used only for wall decorations. It has very good mechanical properties and therefore has other areas of the application too. It has an extreme rigidity, both very low and rather high-temperature resistance, as well as super peel strength. Moreover, its excellent surface flatness and smoothness are the reasons why this material is highly recommended for use in many different areas of application. To sum it up, the A2 aluminum composite cladding is a material of high quality and affordable price that has a wide area of application.

All of the materials that belong to this group, i.e. the A2 aluminum composite cladding products, are made from two aluminum sheets that are coupled or bonded upon a thick internal core. The core is made from fire-retardant materials. It also contains a small percentage of polyethylene (PE). Such a composition accounts for peculiar features of this type of aluminum composite panels.

Reviews

There are no reviews yet.