11 Apr Understanding 3mm Aluminium Composite Panels: Benefits, Applications, and Installation

Introduction to Aluminium Composite Panels

Aluminium Composite Panels (ACPs) have gained prominence in modern architectural applications due to their unique composition and versatility. ACPs consist of two thin layers of aluminium enclosing a non-aluminium core, which can be made of materials such as polyethylene or mineral-filled cores. This structure provides a combination of durability, aesthetic appeal, and lightweight characteristics, making ACPs an optimal choice for a variety of uses. Among the various thicknesses available, 3mm ACPs are particularly sought after for their balance of functionality and affordability.

The 3mm thickness of aluminium composite panels is favored in diverse applications, ranging from interior decorative panels to external cladding solutions. It delivers significant structural integrity while remaining lightweight, allowing for ease of handling and installation. This specific thickness does not compromise strength; rather, it ensures that the panels maintain their shape and withstand environmental stresses effectively. Consequently, 3mm ACPs have become a preferred material in both commercial and residential constructions.

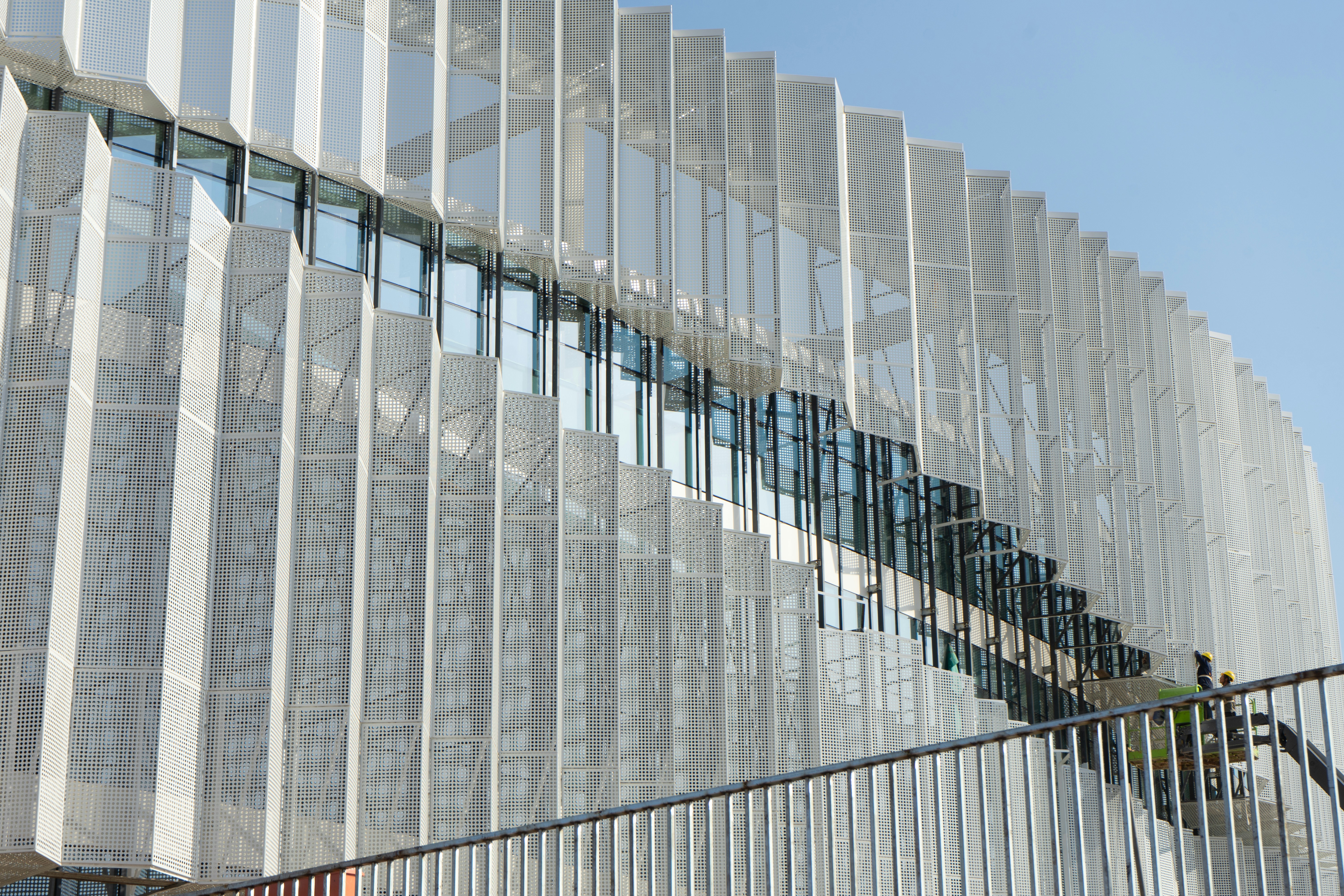

The aesthetic qualities of 3mm ACPs also contribute to their widespread use. Available in numerous colors, finishes, and textures, these panels enable architects and designers to achieve striking visual effects without the need for extensive structural reinforcements. Additionally, the flexibility of ACPs allows for the creation of complex shapes and designs that can enhance the overall appeal of buildings. The combination of design versatility with functional advantages, such as resistance to weather and easy maintenance, positions 3mm aluminium composite panels as a leading choice in the construction industry.

This blog post will delve deeper into the benefits, applications, and installation processes associated with 3mm ACPs, providing valuable insights into how this material can be utilized effectively in modern construction projects.

Key Features of 3mm Aluminium Composite Panels

The 3mm Aluminium Composite Panels (ACPs) exhibit a multitude of defining features that contribute to their ubiquity in various construction and design projects. One notable characteristic is their lightweight nature, which significantly eases the handling and installation processes. The lightweight composition allows for easier transport and less strain on supporting structures, making 3mm ACPs an optimal choice for both large-scale and smaller architectural endeavors.

Durability is another essential feature that sets 3mm aluminium composite panels apart. They are resistant to corrosion and weather effects, thereby maintaining their performance and appearance over time. Unlike traditional materials that may degrade, 3mm ACPs promise longevity with minimal maintenance requirements. This durability ensures that surfaces will remain intact, even in challenging environmental conditions such as exposure to extreme temperatures and moisture.

Aesthetic appeal is also a key feature of 3mm ACPs, providing a sleek finish that can greatly enhance the overall design of a building or structure. Available in a wide array of colors and finishes, these panels can mimic materials such as wood or stone, offering flexibility for architects and designers aiming for a specific look without sacrificing practicality. Additionally, their smooth surface allows for easy customization through printing and fabrication, increasing their versatility in various applications.

The combination of lightweight properties, exceptional durability, and aesthetic versatility makes 3mm aluminium composite panels a highly regarded choice for installations in a range of environments. Whether utilized in facades, signage, or interior applications, the features of these panels contribute significantly to their growing popularity in contemporary architecture and design. Their ability to balance functionality with appealing design elements positions 3mm ACPs as an asset in both commercial and residential projects.

Advantages of Using 3mm Aluminium Composite Panels

3mm aluminium composite panels (ACP) have gained significant popularity in various construction and design applications due to their numerous advantages. One of the primary benefits is the ease of installation. These panels are lightweight compared to traditional building materials, which simplifies handling and reduces labor costs during installation. Moreover, the panels can be easily cut or shaped on-site, allowing for a high level of customization without lengthy preparations. Consequently, this convenience makes ACP suitable for both residential and commercial projects.

Another distinct advantage of 3mm aluminium composite panels is their cost-effectiveness. While the initial investment may vary depending on specific designs and finishes, their longevity and durability result in substantial savings over time. ACP is resistant to corrosion and weathering, minimizing the need for repairs or replacements. Additionally, their ability to withstand harsh environmental conditions means that property owners can avoid incurring unexpected costs from damage repairs.

Maintenance requirements for 3mm aluminium composite panels are relatively low. Unlike traditional materials, which may require frequent painting or sealing, ACP can typically be cleaned with simply mild soap and water. This feature suits busy professionals and businesses that want to maintain an aesthetically pleasing exterior without investing excessive time or resources into upkeep. Furthermore, the smooth surface of these panels significantly reduces the accumulation of dirt and grime, ensuring a clean appearance year-round.

Another noteworthy benefit is the thermal insulation properties of 3mm aluminium composite panels. They serve as effective barriers, helping to regulate temperature within a building. By minimizing heat transfer, ACP contributes to improved energy efficiency, potentially lowering heating and cooling expenses. Such attributes highlight the role of these panels in creating sustainable and environmentally friendly building designs.

Common Applications of 3mm Aluminium Composite Panels

3mm Aluminium Composite Panels (ACPs) have gained significant traction across various industries due to their versatile characteristics and aesthetic appeal. Their lightweight nature combined with durability makes them ideal for a multitude of applications. In the construction industry, 3mm ACPs are often used for facades, cladding, and interior partitions. They provide an attractive finish while also offering excellent thermal insulation and weather resistance, which are essential in building designs.

In commercial settings, 3mm ACPs are frequently employed for signage and branding. Businesses utilize these panels for shopfronts, directional signs, and promotional displays because of their ease of maintenance and capability to withstand harsh environmental conditions. The ability to print vibrant graphics directly onto the surface of ACPs further enhances their appeal as a medium for effective visual communication.

Residential applications also benefit from the use of 3mm Aluminium Composite Panels. Homeowners often opt for these panels in outdoor applications such as patio enclosures, decorative wall cladding, and even in garage doors. Their smooth finish and various color options allow homeowners to personalize their spaces while enjoying the advantages of long-lasting materials.

In public infrastructure, 3mm ACPs are used in bus shelters, railway stations, and airport terminals, providing not only a durable solution but also enhancing the aesthetic values of public spaces. The robust composition of ACPs makes them resistance to impacts and extreme weather, ensuring longevity even in high-traffic areas. Overall, the adaptability and visual appeal of 3mm Aluminium Composite Panels make them an exceptional choice for various applications, catering to both functional and aesthetic needs across multiple sectors.

Installation Process of 3mm Aluminium Composite Panels

Installing 3mm aluminium composite panels requires careful planning and execution to ensure a successful outcome. The process begins with preparation, which includes selecting the right materials and tools. Essential tools for installation typically include a measuring tape, level, utility knife, drill, and appropriate fasteners. Safety gear, such as gloves and goggles, is also recommended to protect against sharp edges and debris.

Once the tools are gathered, the next step involves accurate measurement of the installation area. It is crucial to measure the surface where the panels will be installed, taking note of any obstacles or irregularities that may require adjustments. Marking the dimensions on the wall or substrate helps streamline the subsequent steps. Correct measurement is vital to avoid wasting materials and ensure seamless fitting.

After measurements are confirmed, proceed to cut the 3mm aluminium composite panels to the appropriate sizes. Using a utility knife, score the panel along a straight edge and then break it along the cut line for a clean edge. For intricate cuts, a jigsaw or circular saw may be used, ensuring to adjust the speed to avoid damaging the panel. Precision in cutting is essential to achieve a polished final appearance.

With the panels ready, the mounting process can begin. Start from the bottom and work upwards, securing the panels to the substrate using screws or adhesive, depending on the installation method chosen. It is advisable to use a level to ensure each panel is straight before fastening. For added durability, consider spacing the fasteners adequately and applying a sealant at the edges to prevent moisture ingress.

Throughout the installation, maintaining safety protocols is essential. Make sure the workspace is free of hazards and that all tools are used according to manufacturer guidelines. By adhering to these steps, both DIY enthusiasts and professionals can successfully install 3mm aluminium composite panels, resulting in a resilient and aesthetically pleasing finish.

Maintenance and Care of 3mm Aluminium Composite Panels

The maintenance and care of 3mm aluminium composite panels are essential to ensure their longevity and aesthetic appeal. Regular upkeep not only preserves their appearance but also enhances their durability. To maintain your panels effectively, it is important to adopt specific cleaning methods, avoid potential damage, and address common wear and tear promptly.

Cleaning aluminium composite panels should be approached with care to avoid scratching or damaging their surface. A mild detergent mixed with warm water is generally sufficient for routine cleaning. Using a soft cloth or sponge, gently wipe down the panels to remove dirt, grime, or any residues. For tougher stains or built-up dirt, a non-abrasive cleaner can be utilized, but caution is advised to prevent scratching the finish. Rinsing the panels thoroughly with water after cleaning is essential to prevent soap residues from causing discoloration.

In addition to regular cleaning, it is crucial to avoid damage to the panels. This includes protecting them from harsh chemicals or abrasive materials that can wear down the surface. Additionally, using protective covers during extreme weather conditions can prevent potential degradation from localized damage. It is advisable to inspect the panels periodically for signs of wear and tear, such as dents or scratches, which can be repaired early to prevent further deterioration.

Addressing wear and tear is vital for maintaining the integrity of 3mm aluminium composite panels. Minor scratches can be touched up with specialized paint designed for aluminium finishes, ensuring a seamless appearance. For more significant damage, it may be necessary to consult with a professional for proper repair or replacement of the affected panels. By following these maintenance practices, you can preserve the functionality and aesthetics of 3mm aluminium composite panels, contributing to their longevity and overall performance in various applications.

Environmental Impact of 3mm Aluminium Composite Panels

Aluminium composite panels (ACPs), including the widely used 3mm variant, have garnered attention for their environmental implications. One of the principal advantages of 3mm aluminium composite panels is their recyclability. The core material of these panels can be efficiently recycled, significantly reducing waste and minimizing the demand for virgin materials. Consequently, when end-of-life management is executed properly, aluminium can be reclaimed and repurposed, contributing to a circular economy.

Moreover, the production process of aluminium composite panels is increasingly becoming energy efficient. Manufacturers are adopting advanced technologies that minimize energy consumption while adhering to strict environmental regulations. This progress not only lessens the carbon footprint associated with the manufacturing of ACPs but also aligns with global initiatives aimed at reducing greenhouse gas emissions. As energy-efficient production techniques become more widespread, the environmental impact of these panels continues to diminish.

3mm aluminium composite panels also play a pivotal role in contributing to green building certifications, such as LEED (Leadership in Energy and Environmental Design). The lightweight nature of these panels can lead to reduced transportation emissions as they require less energy to transport compared to heavier materials. Additionally, their durability and low maintenance requirements mean that less frequent replacements are necessary, further alleviating environmental strain over time.

Additionally, incorporating aluminium composite panels into building designs can enhance energy efficiency. They can act as insulating layers, helping maintain indoor temperatures, leading to decreased reliance on heating and cooling systems. This characteristic not only reduces energy consumption but also supports sustainable architectural practices.

By considering the recyclability, energy efficiency in production, and their contribution to green building practices, it becomes evident that 3mm aluminium composite panels offer an environmentally responsible choice in construction and design. The continued innovation in this field suggests even greater sustainability improvements in the future.

Comparison of 3mm Aluminium Composite Panels vs Other Materials

When considering construction and design materials, 3mm aluminium composite panels (ACP) stand out for their unique combination of properties. To effectively evaluate their advantages, a comparative analysis against other widely used materials such as wood, polyvinyl chloride (PVC), and glass is essential.

In terms of performance, 3mm ACPs excel due to their lightweight yet robust structure, making them easier to handle and install compared to glass or wood. The thermal and acoustic insulation properties of aluminium composite panels are superior, providing energy efficiency and soundproofing that rival traditional materials. For example, while wood may warp or expand with moisture, ACPs maintain their integrity, enhancing longevity.

Cost is another critical factor in choosing construction materials. While the initial investment for 3mm aluminium composite panels can be higher than that of PVC, they prove economical over time. Their durability reduces maintenance costs, unlike wood, which requires regular treatment against decay and pests. Moreover, the resistance of ACPs to fading, cracking, and denting can lead to lower replacement costs, making them a cost-effective option in the long run.

Durability is a hallmark of 3mm ACPs, outperforming materials like wood and PVC in various environments. The composite panels are resistant to harsh weather conditions, UV radiation, and chemical exposure. In contrast, wood can suffer from decay, while PVC may become brittle over time. Glass, while aesthetically appealing, is prone to breakage and requires careful handling during installation.

Aesthetically, 3mm aluminium composite panels offer a sleek, modern appearance that can be customized in various colors and finishes. This versatility allows for excellent design possibilities that enhance visual appeal without compromising structural integrity. While natural wood offers warmth, it may not accommodate the contemporary designs achieved through ACPs. Ultimately, the selection of materials should align with specific project requirements and desired outcomes.

Conclusion and Future Trends in Aluminium Composite Panels

In summary, 3mm aluminium composite panels (ACP) have emerged as a versatile building material, favored for their lightweight, durability, and aesthetic appeal. The numerous benefits discussed, including ease of installation, low maintenance requirements, and excellent thermal insulation properties, have contributed to their widespread use in both residential and commercial applications. These panels are seen in facades, signage, and interior design due to their ability to be customized in style and finish, providing an attractive solution that meets diverse architectural needs.

Looking ahead, the aluminium composite panel market is poised for continuous growth as innovations and sustainability concerns shape industry practices. The advancement of manufacturing technologies has introduced new possibilities for creating ACPs that not only enhance performance but also reduce environmental impact. For instance, eco-friendly materials and sustainable practices are gaining traction in the production of these panels, complying with global standards for reducing carbon footprints. This shift towards green building solutions is expected to drive demand for aluminium composite panels that align with sustainable architectural practices.

Furthermore, as the construction industry embraces smart technology, aluminium composite panels are anticipated to integrate features such as smart sensors for monitoring structural integrity or energy consumption. This intersection of advanced technology and materials science could lead to multifunctional panels that provide enhanced value to builders and architects alike. The move towards customization will also continue to proliferate, with manufacturers developing panels that can adapt quickly to changing design trends while maintaining their functional benefits.

As we reflect on the current state of aluminium composite panels, it is clear that they will remain a central figure in the construction industry. By keeping an eye on emerging trends and technological developments, stakeholders can prepare to capitalize on future opportunities within this evolving market.