18 Jun Aluminum Composite Panel Advantages Every Builder Should Know

Table of Contents

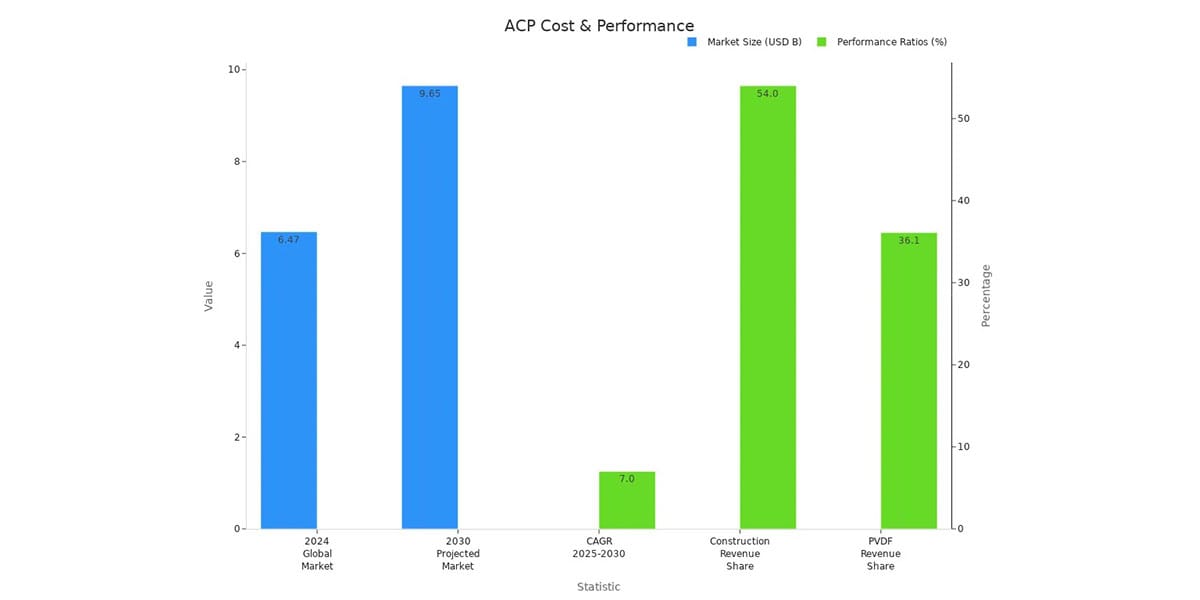

You want building materials that save you money, speed up your work, and last for years. Aluminum composite panels deliver all these benefits. Builders across the world trust aluminium composite panels for their lightweight structure and easy handling. In 2024, the global market for aluminum composite panels reached $6.47 billion, showing strong demand.

Aluminium composite panel advantages include greater durability and design flexibility. These panels help you manage project costs while meeting modern safety standards. You can rely on aluminium composite panels for practical solutions in every build.

Key Takeaways

- Aluminum composite panels save money by lowering both upfront and long-term costs through durability and low maintenance.

- These panels are lightweight, making them easy to handle and install, which speeds up construction and reduces labor expenses.

- They resist weather, stains, corrosion, and fire, ensuring buildings stay safe and look good for many years.

- Aluminum composite panels offer great design flexibility with many colors, finishes, and shapes to create unique and modern buildings.

- Using these panels improves energy efficiency and supports sustainable building by reducing energy use and environmental impact.

Aluminium Composite Panel Advantages

Aluminum composite cladding stands out as a smart choice for builders. You get a material that saves money, reduces weight, and speeds up installation. These main advantages make aluminum composite panels a favorite for modern construction projects. Let’s look at how these benefits work for you on real job sites.

Cost Savings

You want to keep your project within budget. Aluminum composite panels offer a cost effective solution for both small and large builds. The panels require less maintenance over time, which means you spend less on repairs and replacements. When you choose aluminum composite cladding, you also lower your life cycle costs. Studies show that using these panels can reduce economic costs by over 6% and life cycle costs by more than 13%. Recycling and material substitution strategies can cut emissions by up to 77%, making this an economical solution for sustainable building.

Tip: Choosing aluminum composite panels helps you save on both upfront and long-term expenses. You also help the environment by reducing your project’s carbon footprint.

Here’s a quick look at the cost and sustainability benefits:

Advantage Aspect | Empirical Findings |

|---|---|

Carbon Footprint | 5874.20 kg CO2-eq per ton of aluminum-plastic composite panels |

Emission Reduction | Up to 77.46% reduction via recycling and material substitution strategies |

Human Health Impact | Reduced by 46.36% with optimized strategies |

Ecological Impact | Reduced by 77.14% |

Resource Use | Reduced by 52.10% |

Economic Costs | Life cycle costs reduced by 13.56%, economic costs by 6.22% |

Future Projections | Power grid decarbonization could further reduce emissions by 76.42% by 2050 |

Lightweight Benefits

Aluminum composite cladding is known for being lightweight and durable. You can handle and transport these panels with ease. This reduces labor costs and speeds up your workflow. When you compare aluminum composite panels to traditional materials like stone or concrete, the difference is clear.

Material | Weight |

|---|---|

Wood | Low |

Stone | High |

Concrete | High |

ACP | Low |

Aluminum composite panels weigh about the same as wood but much less than stone or concrete. This means you can use them for building facades and cladding without adding extra load to your structure. In railway vehicle design, aluminum alloys and composite panels have shown a 35.5% weight reduction compared to steel panels. You get the strength you need without the heavy weight.

Note: Lighter panels mean less strain on your building’s framework and easier handling for your crew.

Easy Installation

You want materials that make your job easier. Aluminum composite cladding offers easy installation thanks to its lightweight nature and flexible design. You can cut, bend, and shape the panels to fit any project. This saves time and reduces labor costs.

- Aluminum composite panels are easy to install compared to traditional materials.

- The lightweight property allows for quick handling and placement.

- Product guides and case studies show that even large projects, like admin buildings and factories, benefit from faster installation times.

- Detailed installation guidelines help you avoid mistakes and ensure a smooth process.

The panels’ structure also supports sound insulation, which adds value to your projects. Builders have found that using aluminum composite panel sheet systems improves acoustic performance and energy absorption. This makes them ideal for both commercial and residential buildings.

Pro Tip: Use aluminum composite panels for projects where speed and efficiency matter. You will finish faster and keep your clients happy.

Durability and Resistance

Weather Resistance

You want your building to stand strong against the elements. Aluminum composite cladding gives you weather-resistant protection for any project. Manufacturers test these panels with bend and peel strength machines to make sure they hold up under stress. These tests follow strict international standards like ASTM, ISO, and EN. You can trust that aluminum composite cladding will not crack or peel, even after years of sun, rain, or wind. The panels work well for external facades because they keep their color and shape. This means you get long-lasting durability and fewer repairs over time.

Stain and Corrosion Resistance

Aluminum composite cladding is both stain-resistant and corrosion-resistant. You do not have to worry about rust or ugly stains ruining your building’s look. Companies use SGS testing and other quality checks to make sure the panels resist chemicals, acids, and even mortar. Paint testing covers flexibility, hardness, gloss, and resistance to acids and alkalis. You get panels that stay clean and bright, even in tough environments. Here are some of the main tests and standards:

Test Aspect | Test Standard(s) | Durability/Resistance Confirmation |

|---|---|---|

Color Uniformity | AAMA 2605 | Ensures consistent dry-film thickness and color stability |

Specular Gloss | ASTM D 523 | Confirms surface gloss within specification limits |

Dry Film Hardness | ASTM D 3363 | Minimum hardness level (HB) without film rupture |

Flexibility (T-Bend) | ASTM D 4145 | Coating flexibility without cracking |

Adhesion (Dry, Wet, Boiling Water) | ASTM D 3359 | Coating adhesion remains intact after cuts and tape test |

Impact Resistance | ASTM D 2794 | Coating withstands mechanical impact without detachment |

Abrasion Resistance | ASTM D 968 | Minimum abrasion coefficient value ensures surface durability |

Mortar Resistance | ASTM C 207 | No loss of film adhesion or visual change after mortar exposure |

Chalk Resistance | ASTM D 659 | Limits chalking to acceptable rating |

Chemical Resistance | ASTM D 1308, D 2244 | No loss of adhesion or visual change after acid exposure tests |

You save time and money on cleaning and maintenance when you choose aluminum composite cladding for your projects.

Rigidity and Strength

Aluminum composite cladding gives you the strength you need for safe, modern buildings. Engineers design these panels to balance strength and flexibility. Research shows that special grain structures and reinforcements, like graphene, make the panels tough and ductile. You get panels that do not bend or break easily. Studies on aluminum alloys prove that these materials work well under heavy loads and changing temperatures. You can use aluminum composite cladding for columns, beams, and facades. The panels offer durability and versatility, making them a smart choice for many building types.

Aluminum composite cladding stands out for its durability, strength, and resistance to damage. You get peace of mind knowing your building will last.

Design Flexibility

Modern Architectural Uses

You see aluminum composite panels in some of the world’s most famous buildings. Architects choose these panels for their strength, light weight, and modern look. Here are a few examples:

The Shard in London uses aluminum in its tall, glass-covered structure. This shows how strong and stable aluminum can be in skyscrapers.

One World Trade Center in New York City features aluminum composite panels on its exterior. These panels give the building a shiny, modern appearance and help it stand out.

The Eden Project in Cornwall uses aluminum in its lightweight frames for large, dome-shaped biomes. This proves that aluminum composite panels work well for creative and unusual designs.

Aluminum composite panels help you create buildings that look new and exciting. You can use them for facades, signs, and even inside spaces. Their weather resistance and fire safety make them a smart choice for many projects.

Customization Options

You want your building to look unique. Aluminum composite panels give you many ways to customize your design. You can pick from different sizes, shapes, and finishes. Market research shows that you can tailor these panels to fit your needs, whether you are working on furniture, signs, or interior walls. Many surveys and studies show that customers like having choices. You can match your panels to your brand or style. The flexibility in color options lets you create a look that fits your vision. This makes aluminum composite panels popular with both architects and designers.

Tip: Use custom finishes or printed graphics to make your project stand out from the rest.

Aesthetic Variety

Aluminum composite panels offer a wide variety of colors and textures. Designers use them for everything from lamps and furniture to murals and art installations. For example, Italian designers have made lamps from single sheets of aluminum composite material. In New York, artists have created large murals using these panels. You can also find them in custom bike frames, retail displays, and even trade show booths. This wide range of uses shows how creative you can get with aluminum composite panels. You can choose glossy, matte, metallic, or even wood-like finishes to match any style.

You can trust aluminum composite panels to bring your creative ideas to life, no matter the project.

Safety and Maintenance

Fire Resistance

You want your building to be safe in case of fire. Aluminum composite panels offer strong fire resistance, making them a reliable fireproof exterior option. Manufacturers design these panels with non-combustible or mineral-filled cores, which help slow down ignition and stop flames from spreading. Fire-resistant panels often meet B1 or A2 ratings, showing they are difficult to ignite or even non-combustible. During production, companies follow strict fire safety standards and use special coatings to improve protection.

Australian fire services and building inspectors check fire alarm systems, emergency lighting, and sprinkler systems in buildings with aluminum composite cladding. They also test smoke alarms, fire doors, and hydrants to make sure everything works. Installers use fire-rated sealants and sometimes add extra fireproof materials behind the panels. Regular inspections and maintenance keep your building safe and up to code.

Tip: Choose aluminum composite panels for a fireproof solution that meets modern safety standards and gives you peace of mind.

Low Maintenance

You save time and money with aluminum composite panels because they require very little upkeep. The panels resist stains, corrosion, and weather damage, so you do not need to clean or repair them often. Building owners benefit from these maintenance benefits, as the panels keep their color and finish for years. Quality assurance teams check the installation, panel alignment, and joints to make sure everything stays in top shape.

- Panels stay clean with simple washing.

- No need for repainting or frequent repairs.

- Regular inspections ensure long-term durability.

You can trust that your building will look good and stay strong with minimal effort.

Thermal Insulation

Aluminum composite panels help you control the temperature inside your building. These panels reduce heat transfer, which means your building stays cooler in summer and warmer in winter. This thermal insulation lowers your energy bills and supports green building goals. Market studies show that composite panels with insulation can save up to 65% in energy use. Some panels even include solar heating features, raising indoor temperatures by over 40°C on sunny days.

You get a comfortable indoor space and save on heating and cooling costs. Aluminum composite panels make your building more energy efficient and eco-friendly.

Benefits of Aluminium Composite Panels in Construction

Versatility in Application

Versatility in Application

You can use aluminium composite panels in many ways across construction projects. Their flexibility and strength make them a top choice for builders. Here are some common uses:

- Ventilated façades help improve insulation and lower carbon emissions. Specialized systems like T-CH-PRO and T-SZ-PRO make installation easier and faster.

- Both interior and exterior cladding benefit from aluminum composite cladding. You get modern looks and strong protection for commercial, residential, and public buildings.

- Roofs and suspended ceilings use these panels for a uniform and durable finish. Their light weight makes handling simple.

- Indoor and outdoor signage stands out with these panels. You can create long-lasting, high-visibility signs for any business or event.

- Aluminum composite cladding offers fire resistance, UV resistance, and durability. These features support many architectural needs.

You can trust aluminum composite cladding to meet the demands of different projects, from large buildings to detailed signage.

Energy Efficiency

You want your building to save energy and lower costs. Aluminium composite panels help you reach this goal. Builders use energy modeling tools to test and improve the performance of walls made with these panels. The panels provide excellent thermal insulation, which keeps buildings cooler in summer and warmer in winter. You can optimize insulation layers to reduce energy use and costs. Lower Energy Use Intensity (EUI) values show that buildings with aluminum composite cladding use less energy. New production methods, such as SMART rotomolding, also save up to 30% more energy during manufacturing. These advances make aluminum composite panels a smart choice for energy-efficient construction.

Tip: Choose aluminum composite cladding to help your building meet energy codes and reduce utility bills.

Sustainable Building

You support sustainability when you choose aluminium composite panels. These panels have high recyclability and a long lifespan, which means less waste over time. Many manufacturers use recycled aluminum and eco-friendly coatings to meet green building standards. You also lower heating and cooling costs because the panels improve insulation. Industry trends show a move toward products with lower carbon footprints and better recyclability. The lightweight nature of aluminum composite cladding reduces transportation costs and material use. You can find brands that focus on eco-friendly and sustainable products for your projects. Compared to steel, wood, or concrete, aluminum composite cladding needs less maintenance, which further supports sustainable building goals.

- High recyclability and long lifespan

- Improved insulation for lower energy use

- Eco-friendly materials and coatings

- Less maintenance and reduced environmental impact

- Ideal for indoor and outdoor signage in green buildings

You help protect the environment and meet sustainable building goals by using aluminum composite cladding.

Aluminum composite panels give you many benefits for modern construction. You get lightweight panels that reduce structural load and save money. These panels offer strong fire resistance, UV protection, and high durability.

- ACPs work well for both budget projects and high-rise buildings.

- You can choose panels with recycled content to support green building goals.

- The market for these panels keeps growing because of their toughness and energy efficiency.

Consider aluminum composite panels for your next project. You will see better performance, safety, and design flexibility.

FAQ

What are aluminum composite panels made of?

Aluminum composite panels have two thin aluminum sheets. A non-aluminum core sits between them. This design gives you strength, light weight, and flexibility. You get a material that works well for many building projects.

Can you use aluminum composite panels outdoors?

Yes, you can use aluminum composite panels outside. These panels resist weather, sunlight, and rain. You get a strong and long-lasting surface for building exteriors, signs, and facades.

How do you clean aluminum composite panels?

You can clean these panels with mild soap and water. Use a soft cloth or sponge. Avoid harsh chemicals or rough brushes. This keeps your panels looking new and bright.

Tip: Clean panels regularly to prevent dirt buildup and stains.

Are aluminum composite panels safe in a fire?

Manufacturers design many aluminum composite panels to resist fire. You should look for panels with fire ratings like B1 or A2. These ratings show the panels slow down flames and help keep your building safe.

Do aluminum composite panels help save energy?

Yes, these panels provide good thermal insulation. You use less energy for heating and cooling. This helps lower your energy bills and supports green building goals.

Versatility in Application

Versatility in Application