03 Aug A Complete Guide to ACM Metal Panel Specifications and Pricing in 2025

Table of Contents

When you pick acm metal panel systems in 2025, you notice that things like thickness, core type, finish, and fire rating can change how the panels work and how much they cost. Thicker acm panels, special coatings, and more detailed systems usually cost more money. For example:

Specification Aspect | Details / Range |

|---|---|

Thickness | |

Finish | PVDF, powder, wood, stone |

Pricing Range | $30–$80/sq m |

You can choose acm panels with different aluminum composite panel systems. These can have simple sealed joints or more advanced rain screens. This lets you pick the aluminum composite material that fits your budget and project needs.

Key Takeaways

Pick ACM panels that fit your project. Think about the core type, thickness, and finish. This helps you balance price, strength, and fire safety.

Fire-rated cores like mineral-filled panels give better safety. They also meet strict building rules. These are important for tall or business buildings.

Standard panel sizes cost less and are faster to put in. Custom sizes work for special designs but cost more.

Finishes change how the panels look and last. Choose coatings that protect from weather. Make sure they match your style and budget.

Good installation and following fire safety rules stop expensive problems. They also keep your building safe and looking nice for a long time.

ACM Metal Panel Overview

What Is Aluminum Composite Material?

Aluminum composite material is used a lot in new buildings. It has three layers. Two thin aluminum sheets are stuck to a core. The core is made from polyethylene or mineral fillers. Both sides of the aluminum have special coatings. These coatings protect and decorate the panel. This makes the panels light, strong, and flat. They are stiffer and thicker than single aluminum sheets. The core can be solid polyethylene or a mix with minerals. This setup makes the panels easy to move and put in place. You can pick from many finishes and colors for your design.

The main parts of aluminum composite panels:

Two painted aluminum sheets

A core made from polyethylene or mineral fillers

Coatings on both sides for protection and looks

All these parts make a strong and useful material for many jobs.

Types of ACM Panels

You can pick different acm panels for your project. The two main types are PE core and fire-rated (FR) core panels. PE core panels use polyethylene. This makes them light and bendy. FR core panels use mineral fillers. These help the panel resist fire. You can see how they are different in the table below:

Attribute | PE Core ACM Panels | FR Core ACM Panels |

|---|---|---|

Core Color | Usually black | Light or dark grey |

Weight | Light | Heavier |

Rigidity | Not as stiff | Stiffer |

Fire Performance | Burns fast, thick black smoke | Chars, better at stopping fire |

You should check the core type for safety and rules. FR core panels are better for tall buildings and places with strict fire laws.

Common Applications

You can find aluminum composite panels in many places. They are light and bend easily, so they work for tricky shapes and updates. Here are some ways people use them:

Outside walls for homes and businesses

Curtain walls and building fronts

Inside walls and room dividers

Roof and ceiling panels

Furniture and decorations

You can use aluminum composite material for outside and inside jobs. ACM panels are easy to put up, come in many finishes, and last a long time. Aluminum cladding makes buildings look modern and keeps out bad weather. You can trust aluminum composite panels for many design needs in new and old buildings.

ACM Panel Specifications

Thickness Options

Thickness Options

When you pick aluminum composite material, check the panel thickness. Most panels are between 2 mm and 6 mm thick. The most common are 3 mm, 4 mm, and 6 mm. Alucobond panels have two thin aluminum sheets with a polyethylene core. Dibond panels are similar but use thinner aluminum layers.

Thickness Range (mm) | Thickness Range (inches) | Notes/Examples | |

|---|---|---|---|

Corrugated Plastic Core | 3 mm to 25 mm | ~1/8″ to ~1″ | Double-sided aluminum, USA made |

Solid Core | 2 mm to 6 mm | ~5/64″ to ~1/4″ | Polyethylene core, lightweight |

Plywood Core | 6.35 mm (1/4″) and 12.7 mm (1/2″) | 1/4″ and 1/2″ | Exterior-grade plywood core |

Insulated/Foam Core | 15.875 mm (5/8″) to 88.9 mm (3-1/2″) | 5/8″ to 3-1/2″ | Foam core with stabilizers |

OEM Composite Panels | 2 mm to 25 mm | ~5/64″ to 1″ | Various finishes and colors |

Thicker acm panels, like 4 mm or 6 mm, are stronger. They can handle more hits and work well outside. You use thinner panels, like 3 mm, for signs or inside walls. Thicker panels cost more because they use more material. Heavy panels also need better support, which can make installation cost more.

Thickness | Structural Performance Impact | Cost and Installation Impact |

|---|---|---|

Lightweight, flexible, easy to cut and shape; good for signage and interior use | Lower cost; easy installation due to less weight | |

4mm | Balanced durability and flexibility; good for exterior cladding | Moderate cost; needs standard support |

6mm | Maximum strength and impact resistance; best for large projects | Higher cost; needs strong support and complex installation |

Tip: Pick the right acm panel thickness for your job. Thicker panels last longer outside. Thinner panels save money for indoor use.

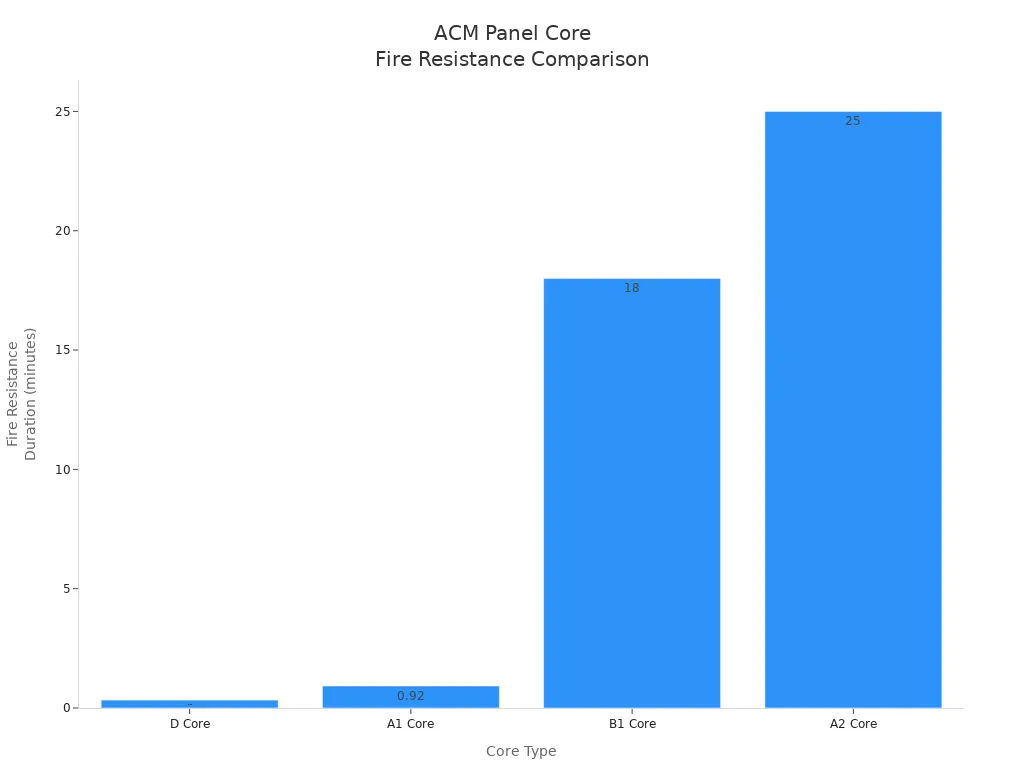

Core Types and Fire Ratings

The core inside your aluminum composite panel is important for safety. You can choose from different core types. The main ones are polyethylene (PE) core, fire-retardant (FR) core, and mineral-filled core. Each type changes how the panel acts in a fire.

Composition / Description | Fire Behavior and Duration under Direct Flame | |

|---|---|---|

D Core | Polyethylene (PE) core | Ignites after ~20 seconds; intense smoke and dripping plastic |

B1 Core | Non-contributing to fire | Resists flame for ~18 minutes; does not ignite but disintegrates |

A2 Core | Mineral / Non-combustible core | Remains intact for ~25 minutes; acts as fire barrier; only outer skin falls with some smoke |

A1 Core | Solid aluminum with no core | Melts after ~55 seconds; hot liquid aluminum drips |

A2 mineral cores give the best fire protection. Many places now want A2 or better for tall buildings. In the UK and Europe, you must use A2-rated panels for most new jobs. Polyethylene cores burn fast and make a lot of smoke. You should not use them in risky places. Fire-retardant cores help you follow safety rules and keep people safe.

Note: Always check your local building codes before picking a panel. The wrong core can cause legal problems and extra costs.

Finishes and Colors

You have lots of finish and color choices for aluminum composite material. These help you match your building’s style or brand. Popular finishes in 2025 are:

Metallic finishes for a modern look, like brushed aluminum or stainless steel

Wood and stone finishes for a natural or classic feel

Glossy finishes for bright, shiny surfaces

Matte finishes for a soft, elegant look

Standard colors such as red, blue, gray, and white

Custom colors for unique designs or branding

Special coatings like anti-graffiti or reflective finishes for extra protection

The finish you pick changes how your panels look and last. Extra coatings protect your panels from water, dents, sun, and fire. These coatings help your panels stay new and strong for years. Custom colors and special finishes cost more, but give you more design choices.

Protective finishes add waterproofing and UV resistance.

Special coatings make panels easier to care for.

Custom colors and finishes raise the price.

Tip: Pick finishes that work for your weather and design. Glossy and metallic finishes stand out. Matte and wood finishes blend in.

Standard Sizes

You can buy aluminum composite panels in standard sizes to save time and money. Most panels come in sheets from 48 inches by 96 inches up to 60 inches by 120 inches. The usual thickness is between 2 mm and 4 mm. Some companies make custom sizes, but these take longer and cost more.

Aspect | Custom Size Impact | |

|---|---|---|

Standard Dimensions | 3 mm thickness x 48 in width x 120 in length | Custom dimensions must be specified precisely |

Cutting Costs | Not applicable for standard sheets | Additional cutting costs apply |

Saw Kerf (Material Loss) | Saw blade width approx. 0.187 in; can accept undersized pieces | Saw kerf causes slight undersizing, affecting fit and installation precision |

Cut Tolerance | Standard tolerance +/- 0.030 in | Custom cuts require precise instructions; tolerance affects installation |

Installation Impact | Easier due to consistent size and fit | May complicate installation due to size tolerances and fit issues |

Standard sizes make planning and installing easier. You get lower prices and faster delivery. Custom sizes help with special shapes but cost more and take longer. Always check if you can use standard panels before ordering custom ones.

Note: Standard sizes help you avoid mistakes and delays. Custom sizes are best for special shapes or big projects.

Aluminum Composite Panel Pricing 2025

Price Ranges by Core and Thickness

ACM panel prices in 2025 can be very different. The price changes based on the core type and thickness you pick. FR core panels cost more than PE core panels. Thicker panels also cost more because they use more material and are stronger.

Here is a table that shows the average cost for each core and thickness:

Core Type | Thickness | Price Range (per sq ft) |

|---|---|---|

PE Core | 3mm | $15 – $20 |

PE Core | 4mm | $18 – $25 |

FR Core | 4mm | $22 – $30 |

FR Core | 6mm | $28 – $35 |

ACM panels usually cost more than regular siding. This is because they have a special design and extra safety features. FR cores give you better fire safety and last longer, so they cost more.

Note: Check your local building rules. Some jobs need FR core panels for safety.

Finish and Customization Costs

The finish and custom options you pick can change your project’s price. Standard colors and finishes are cheaper. If you want metallic, woodgrain, or stone looks, you will pay more. Custom colors and special coatings also raise the price.

Choosing custom thickness, color, or size can save time and money when you install. Prefinished panels with many paint choices and custom sizes mean you do not need to paint or cut much on site. Some brands, like Vitraplate®, make many finishes and build panels in the USA. This means you get your panels faster and pay less for shipping.

Making panels in a factory can cut build time in half. You need fewer workers and less equipment at your site. If you plan early and talk with your supplier, you can keep your project on budget. But if you want rare finishes or shapes, you may wait longer and pay more. Problems with supplies can also slow delivery and raise costs.

Tip: Pick your finishes and sizes early. This helps you avoid delays and keeps your budget right.

Volume and Installation Factors

The total price for your ACM panel job depends on how much you need and how you put it up. Buying more panels at once often gives you a lower price per square foot. Big jobs can also save on shipping.

Installation prices can change a lot. Here are some things that affect the cost:

Labor costs in your area

How tricky the building shape and support is

Extra work like sealing, painting, or getting the surface ready

Local market prices (North America and Europe cost more than Asia-Pacific)

If you need special cuts or shapes

ACM panels are lighter than steel panels. You need less support and fewer workers to put them up. You can save about 30% on installation compared to steel. The panels are easy to move, so labor and shipping cost less. Most jobs in 2025 have installation costs between $40 and $55 per square foot for both materials and labor.

ACM panels last a long time and do not need much care. They stand up to wind, rain, sun, and rust. Over time, you save money because you do not need to fix or replace them often.

ACM panels cost more at first than wood, vinyl, or brick, but they last longer and look better.

Special coatings help stop water damage, dents, and fading.

Panels are tested for wind, fire, and weather safety.

Note: Always check with different suppliers and get full quotes. This helps you find the best quality and price for your job.

Factors Affecting ACM Panels Cost

Material and Core Selection

When you pick aluminum composite material, the core and type matter for cost. You can choose from different cores like polyethylene or fire-rated mineral blends. Fire-rated cores cost more, but they help you follow safety rules for outside walls. The quality of the aluminum sheets also changes the price. Thicker aluminum layers make the panel stronger, but they cost more. Some brands use special polyethylene blends to make their panels last longer and work better.

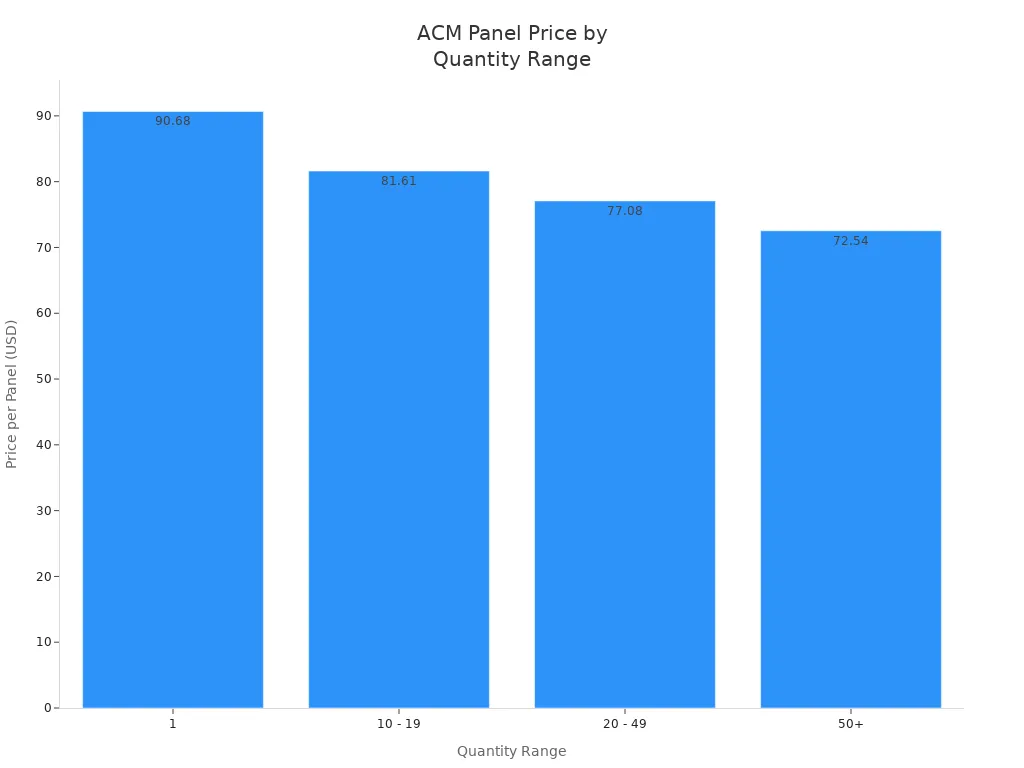

Size and Thickness

The size and thickness of your aluminum composite panels change the price a lot. Bigger panels and thicker aluminum layers use more material, so they cost more. If you buy more panels, the price for each one goes down:

Quantity Range | Price per 3mm 4×8 ft Panel (USD) |

|---|---|

1 | $90.68 |

10 – 19 | $81.61 |

20 – 49 | $77.08 |

50+ | $72.54 |

The 4mm aluminum composite panel is the most common for outside walls. It gives a good mix of price and strength. Thicker 6mm panels are heavier and cost more to put up, but they do not always work better for most jobs. Picking the right acm panel thickness helps you stay on budget.

Finish and Brand

The finish and brand you pick for your aluminum composite material also change the price. Some finishes, like metallic or woodgrain, cost more than plain matte. Brands with longer warranties, like a 30-year Duranar® finish, usually charge more. For example, ALCLAD II insulated ACM panels have a longer finish warranty than other brands, so you pay more for extra strength. Aluminum composite panels made in America may cost more, but they can be better quality and give more help.

Brand / Product Name | Finish Type | Warranty Details | Manufacturing Location | Core Material Quality |

|---|---|---|---|---|

Matte/Matte | 10-year bond integrity warranty; 10-year indoor finish; 5-year outdoor finish | Houston, Texas, USA | Premium polyethylene blend (LDPE & HDPE) | |

ALCLAD II Insulated ACM | Not specified | Duranar® 30-year finish warranty | Not specified | Not specified |

Tip: Longer warranties and special finishes add value, but you should check if they fit your project needs.

Accessories and Installation

Accessories and how you put up the panels can change the total cost a lot. You need moldings, clips, and caulks to finish the job. Some ways to install let you make changes on site, which can save time and work. Shop-made systems need more planning and can cost more if you need to change things later. The fasteners and moldings you use change how the panels look and what they cost. You should also think about testing, insulation, and delivery times. Always look at the full cost to put up the panels, not just the price of the material. This helps you see the real cost and how low care needs can save money over time.

Field-made systems save time and work.

Shop-made systems may cost more if you need changes.

Accessories and how you install affect looks and price.

Testing and insulation add to the total cost.

Note: The main things that change acm panel costs are material, size, finish, and how you put them up. Plan well to get the best value from your aluminum composite panels.

Choosing ACM Panels

Commercial vs. Residential

When you pick composite panels, think about your building type. Commercial buildings, like malls or hotels, often use panels with special coatings. These coatings, like spectra coating, make the building stand out. Many homes cannot use these coatings because of local rules. Houses need to look like others in the area. Fire safety is very important for all buildings. Commercial buildings need panels with high fire-retardant ratings, such as A2 or B1. You must check your local building codes before choosing aluminum cladding. These rules help you avoid trouble during setup and when people use the building.

Commercial jobs use thicker panels and advanced finishes outside.

Homes focus on matching nearby styles and fire safety rules.

Both need to follow local codes for cladding and setup.

Climate and Durability

You want your panels to last through any weather. Aluminum composite panels handle sun, heat, and storms well. These panels can last over 50 years, which is as long as many buildings. The coatings on aluminum cladding stop rust and corrosion. This means you do not need to do much work to keep them nice. Composite panels also help keep your building warm in winter and cool in summer. They lower heat loss through the walls. This makes them a smart choice for many climates. If you live where there are earthquakes or strong winds, the panels are light and put less stress on your building.

Composite panels stand up to sun, rain, and wind.

You save energy and get panels that last a long time.

Aluminum cladding needs little care and keeps looking good.

Balancing Cost and Performance

You can find a good mix of price and quality by matching panel features to your needs. Think about how you will use the panels first. For outside walls, pick panels that last and resist weather. Choose the core material with care, since it changes cost and safety. Pick finishes that fit your design and budget. Buying more panels at once can lower your price. Well-known brands may cost more, but they last longer and have better warranties. Always look at the total life of the panels, not just the first price. This helps you get the most from your money.

Match panel specs to your design needs.

Pick finishes and cores that fit your project.

Focus on panels that last and need little care.

Tip: Think of aluminum composite panels as a smart buy for your building. They are strong, look good, and save energy for many years.

Common Mistakes with Aluminum Composite Panels

Overlooking Fire Ratings

Not all acm panels keep you safe from fire. Some panels have better fire ratings than others. Picking the wrong fire rating can be dangerous. Many fires have spread fast because the wrong panels were used. In 2015, a fire in Azerbaijan killed 16 people. The flames moved up the building’s cladding very quickly. Fires in Dubai, France, and South Korea also show this risk. It is important to check if your panels meet local fire rules. The right fire-rated panel helps keep people and buildings safe.

Date | Location | Consequence |

|---|---|---|

2015-05-19 | Azerbaijan | 16 deaths, 63 injuries, fire spread on cladding |

2012-05-14 | Roubaix, France | 1 death, 20 apartments destroyed |

2015-02-21 | Dubai, Marina Torch Tower | 7 injuries, cladding charred on upper floors |

Tip: Always get proof of fire rating before you buy composite cladding.

Ignoring Installation Standards

You must follow the right steps to install acm panels. If you skip steps or use the wrong parts, problems can happen. Using the wrong fasteners or sealants can make panels bend or fall off. Water can get behind the cladding and cause mold or rust. If you do not let panels move with heat, they can crack or come loose. Always follow the maker’s instructions and best practices. Good installation keeps your panels safe and looking nice for a long time.

Use the right fasteners and sealants that stop water.

Let panels move a little so they do not bend.

Check that panels line up and seal well at every step.

Note: Panels last longer and need fewer repairs when installed the right way.

Misunderstanding Panel Types

There are many kinds of composite panels, but they are not all the same. Using indoor panels outside is a mistake. Indoor panels can fade, age fast, or break down outside. Some panels need special glue or base materials. For example, using wood as a base outside can make panels bend and make noise. Always pick the right panel type for your project.

Common Mistake | Explanation | Consequence |

|---|---|---|

Indoor panels do not have coatings for weather | Fading, less strength | |

Wrong adhesive or base material | Glue or wood base does not work outside | Panels can fall off or bend |

Poor gluing technique | Not using tape makes seams look bad | Weak joints, looks messy |

Remember: Pick the right panel and install it the right way. This helps you avoid mistakes and keeps your cladding strong and safe.

If you know about ACM panel specs, you can make better choices. This helps you:

Choose the best panel type, finish, and way to install for your project.

Spend less on workers and finish your job faster with strong, light panels.

Follow fire safety rules and avoid paying extra for fixes.

Help the environment and spend less on repairs over time.

Always look at specs and prices before you buy anything. Ask experts or suppliers if you need help. Keep this guide handy for your next aluminum composite panel project.

FAQ

How do you clean ACM panels?

You can clean ACM panels with mild soap and water. Use a soft cloth or sponge. Avoid harsh chemicals or abrasive pads. Rinse with clean water. Dry with a soft towel for best results.

Can you cut ACM panels on-site?

Yes, you can cut ACM panels on-site. Use a circular saw with a fine-tooth blade. Always wear safety gear. Measure carefully before cutting. Cutting on-site helps you fit panels to unique shapes.

Are ACM panels safe for fire zones?

Fire-rated ACM panels, like those with an A2 or FR core, offer strong fire resistance. Always check your local building codes. Choose panels with the right fire rating for your project’s safety needs.

What finishes can you choose for ACM panels?

You can pick from many finishes, such as metallic, matte, woodgrain, or stone. Custom colors are also available. Special coatings, like anti-graffiti or UV protection, help your panels last longer.

Do ACM panels need much maintenance?

ACM panels need very little maintenance. You only need to clean them a few times a year. The panels resist rust, fading, and stains. Regular cleaning keeps them looking new.

Thickness Options

Thickness Options