13 Aug Weighing the Pros and Cons of Aluminium Composite Panel Cladding

Table of Contents

Aluminium composite panel cladding has many good points for new buildings. Many architects pick aluminium cladding because it stands up to bad weather, rust, and fire. It stays strong for a long time and does not need much care. Builders also like that it is easy to design with and saves energy. But aluminium cladding can get dents if something hits it hard. If it gets damaged, you might have to replace the whole panel. Some places do not allow it because of fire safety rules. Knowing the good and bad sides of aluminium composite panel cladding helps people make smart choices for their building projects.

Main benefits:

Lasts a long time and needs little care

Easy to recycle and saves energy

Many design choices and finishes

Main drawbacks:

Gets dents easily and hard to fix

May not be allowed in some buildings

Key Takeaways

Aluminium composite panels stay strong for a long time. They do not get damaged by weather or rust. They need little care, so you save time and money. These panels are light and simple to put up. This makes building cheaper and faster. Aluminium cladding comes in many colors and designs. You can make buildings look special and creative. The panels help stop fires and save energy. This makes buildings safer and better to use. But aluminium panels can get dents easily. Some places do not allow them because of fire rules.

What Is Aluminium Composite Panel Cladding

Structure and Materials

Aluminium composite panel cladding is made from panels with many layers. Each panel has two thin aluminum sheets on the outside. These sheets are about 0.5 mm thick. The sheets are stuck to a core in the middle. The core is made from safe polyethylene or a mineral-filled material. This core makes the panel strong but still light. A strong glue holds all the layers together. The outside aluminum sheets are often made from alloys like 3003, 3105, or 5005. These alloys make the panels bend easily and stop rust. The surface has a special coating like PVDF or polyester. This coating keeps the panels safe from weather, stains, and sunlight. Because of this structure, the panels are strong, bendy, and last a long time. The design also helps keep buildings cool in summer and warm in winter.

Note: Using different materials in aluminum composite panel cladding makes it tough and saves energy. That is why many people pick it for building projects.

Common Uses

Aluminium cladding is used in many new buildings. Builders put aluminum composite panels on the outside of buildings. They use them for facades, curtain walls, and ventilated facades. These panels are also good for inside walls, feature walls, and false ceilings. Many stores use these panels for signs and displays because they look nice and last long. When fixing old buildings, aluminum composite panel cladding can make them look new and keep heat in. Some furniture makers use these panels in kitchens and cabinets. They do this because the panels do not get damaged by water, stains, or heat. The panels are light, so they are easy to put up and do not make buildings heavy. There are many finishes, so architects can make each project look special. Aluminum composite panels are good for the environment because they can be recycled and do not need much care.

Advantages of Aluminium Composite Panel Cladding

Durability

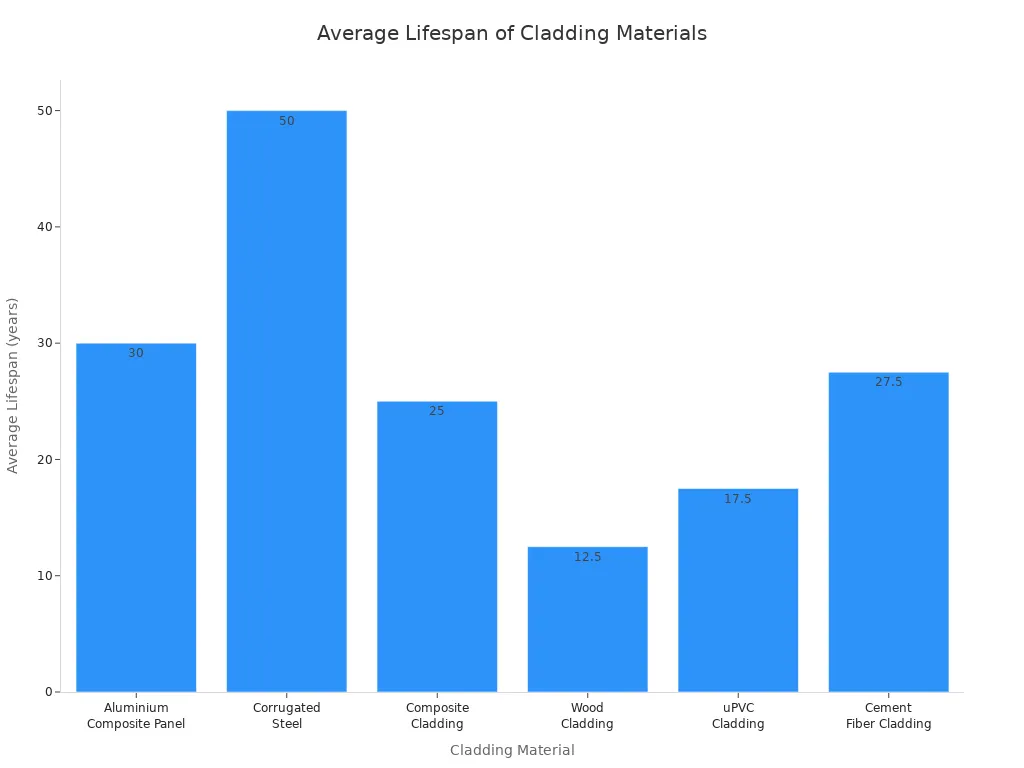

Aluminium cladding is strong against weather, rust, and stains. The powder-coated surface keeps rain, sun, and dirt away. This helps the panels last many years with little harm. Aluminium composite panel can last up to 30 years. That is longer than some other materials. The table below shows how long different cladding lasts:

Cladding Material | Average Lifespan | Notes on Durability and Maintenance |

|---|---|---|

Aluminium Composite Panel | Up to 30 years | Powder-coated aluminum; requires maintenance to prevent corrosion, especially in coastal areas |

Corrugated Steel | About 50 years | Long lifespan but needs regular inspection and repair |

Composite Cladding (wood/plastic) | 25 years or more | Durable, low maintenance, resistant to moisture, insects, UV, temperature fluctuations |

Wood Cladding | 10-15 years | Requires regular maintenance; prone to rot and warping |

uPVC Cladding | 15-20 years | Low maintenance but prone to cracking, discoloration, and fading |

Cement Fiber Cladding | 25-30 years | Good fire, water, and weather resistance; may require re-caulking |

Stone, Glass, Brick Cladding | Long lifespan (varies) | High durability and low maintenance |

Aluminium composite panels keep their shape and color for years. This makes them a good pick for new and old buildings.

Fire Resistance

Fire resistance is a big plus for aluminum composite panel. Many panels pass tough safety tests like ASTM E84. Most panels with a polyethylene core get a B1 rating. This means they slow down flames. The aluminum layers help stop the core from burning by blocking air. This makes the panels safer for schools, hospitals, and tall buildings. Building codes often ask for at least a B1 or Class A rating. Aluminium cladding helps keep people and buildings safe during a fire.

Note: Always check your local fire safety rules before picking cladding.

Low Maintenance

Aluminium cladding is easy to care for each year. Most owners clean the panels once or twice a year. They use mild soap and water. The natural oxide layer stops rust, so no repainting is needed. This saves about 30% on care costs compared to steel. Cleaning steps are simple:

Rinse the panels with water.

Wipe with a soft cloth and mild soap.

Rinse again to wash off dirt.

Repeat if there are tough spots.

These steps keep the panels looking nice and help them last longer. Low maintenance means you save time and money over the years.

Lightweight and Easy Installation

Aluminium composite panels are very light, about 2.5 pounds per square foot. This makes them easy to move and put up. Installing aluminum composite panel is faster and needs less work than stone or brick. The table below shows how heavy materials compare:

Material | Weight Characteristics | Installation Impact |

|---|---|---|

Aluminium Composite Panels (ACP) | Lightweight (~2.5 lbs/sq ft), easy to handle and install | Faster installation, less labor-intensive |

Plywood | Heavier than ACP | Requires stronger support, harder to install |

Wood Plastic Composite (WPC) | Heavier than ACP | Needs stronger support |

High Pressure Laminate (HPL) | Heavy, requires special fittings | More complex installation |

PVC | Lightweight but less durable, mostly for interiors | Easier to handle but limited exterior use |

Natural Stone | Very heavy, expensive to install | Difficult and labor-intensive installation |

Cement Boards | Heavy, fire-resistant but less design flexibility | Harder to install |

Because they are light, aluminium cladding panels do not put much weight on buildings. This can lower building costs and make projects finish faster.

Design Flexibility

Aluminium cladding comes in many finishes and colors. Big brands offer over 30 colors, like solid, metallic, and woodgrain. Custom colors are also possible for special jobs. Some companies have more than 50 finishes around the world. Architects use these panels to make bold, modern designs inside and outside. Composite panels can be bent into curves, angles, or cool shapes. This lets designers be creative and helps buildings look unique.

ACPs are used for sunshades, canopies, and louvers.

Panels are good for inside walls, ceilings, and even furniture.

The surface can show logos and graphics for branding.

This design freedom and good insulation help architects meet style and energy needs.

Cost Efficiency

Aluminium composite panel cladding is a smart choice for saving money. The cost per square meter is $2 to $10, depending on finish and place. This is cheaper than copper, zinc, or steel, but a bit more than vinyl or wood. Because the panels are light, it costs less to put them up. The table below compares labor costs for different cladding:

Cladding Type | Labor Cost Factors | Labor Intensity & Skill Requirement |

|---|---|---|

Aluminum Composite Panel | Installation is relatively straightforward | Lower labor costs due to simpler installation |

Stone Cladding | Requires specialized skills | Labor-intensive, higher labor costs |

Brick Veneer | Skilled labor required | Labor-intensive, leading to higher labor costs |

Aluminium cladding also saves money over time because it needs little care and lasts long. The panels insulate well, which can lower heating and cooling bills. Picking quality aluminum composite panel gives value now and in the future.

Disadvantages of Aluminium Composite Panel Cladding

Impact Damage and Denting

Aluminium cladding is light, but this can be a problem. The panels can get dents or scratches if hit hard. Some common damage types are:

Hail or strong winds can make dents, especially on thin panels.

Scratches can happen if sharp things are dragged across the surface.

Vandalism or falling things like branches or balls can cause damage.

Scientists tested these panels by shooting ice balls at them. They found that hail can leave dents that do not go away. These dents look bad and can lower a building’s value. Thicker panels do better against dents, but very thick ones might not take hits well. Fiber cement is dense and does not dent easily. Aluminium cladding shows damage more than fiber cement. Steel panels can also dent, but fiber cement stays strong.

Tip: If you live where storms or lots of people pass by, think about dents before picking aluminium cladding.

Waterproofing and Sealing

Aluminium cladding alone does not stop water. The panels need a barrier behind them to keep water out. If this barrier is not put in right, water can get inside the wall. Some common water problems are:

Gaps or weak spots in the barrier.

Bad drainage or not enough air behind the panels.

Bad sealing in places with lots of moisture.

Water can build up behind the panels and weaken the glue. This can make the panels bend, peel, or get stains. Builders use waterproof glue or sealant on all gaps to stop water. They cover panel edges with varnish or tape to protect the core. Joints and edges must be sealed well. Installers add drains and use flashing around windows and doors. Checking the panels often helps find and fix bad seals.

Note: Good installation and regular checks help keep aluminium cladding waterproof.

On-Site Modification Challenges

It can be hard to work with aluminium cladding at the building site. Installers face some problems:

Curved panels might straighten out if not bent right.

Joints can bulge, crack, or bend if the sealant is not flexible.

Uneven surfaces or gaps can show up if the frame does not fit.

Very hot or cold weather can cause blisters or glue to fail.

These problems mean installers need special tools and must follow steps closely. Mistakes can slow the job and cost more money. Changing panels at the site often needs extra planning and skill.

Callout: Changing aluminium cladding at the site takes careful work and skill to avoid mistakes.

Fading Over Time

Aluminium cladding can lose color after years in the sun. Some things that cause fading are:

Different quality of materials used.

Not cleaning or treating the panels right before coating.

Using cheap core materials or films.

If the factory does not check quality, the panels may fade or change color faster. This can make a building look old or patchy. Picking panels from good brands and checking for quality can help stop fading.

Initial Cost

The first cost of aluminium cladding is in the middle compared to other materials. The table below shows how it compares:

Material | Initial Cost (per sq ft) | Lifecycle Cost Characteristics |

|---|---|---|

Aluminium Composite Panel | $5 to $15 | Medium first cost; low long-term cost because it lasts long, needs little care, and saves energy |

Traditional Aluminum | $10 to $30 | Higher first cost; higher long-term cost than ACP |

Stone Cladding | $15 to $30 | High first cost; high long-term cost because it is hard to install and care for |

Wood | $3 to $25 | Cost can change; high long-term cost because it needs care and replacement |

Vinyl | $3 to $16 | Low to medium first cost; medium long-term cost with little care needed |

Aluminium cladding costs less than stone or traditional aluminum but more than some wood or vinyl. But it lasts longer and needs less care, so it can save money over time. The price of aluminum and polyethylene can change fast. This can make it hard to plan project costs. If there is not enough supply or prices go up, projects can be delayed.

Note: Even if the first cost is high, aluminium cladding can save money later because it lasts and needs little care.

Applications

Commercial Buildings

Commercial Buildings

Aluminium cladding is important in commercial building projects. Architects use it for office towers, malls, and hotels. It gives buildings a modern look and strong protection. The panels keep out rain, wind, and sunlight. This helps buildings last longer. Many projects use aluminium cladding for curtain walls and facades. These panels can cover big areas and make bold designs. Owners like that the panels need little care and save energy. The panels also follow strict fire safety rules. This makes them safe for busy public places.

Residential Projects

Cities are using more aluminium cladding in homes. Many tall apartments and condos use these panels. They are light, easy to put up, and look nice. The panels help keep homes warm in winter and cool in summer. In cities like New York and Shanghai, new apartments often have aluminium cladding. More people want to live in cities and want modern, green homes. This makes the market for these panels grow. Some mid-rise buildings use fiber cement or engineered wood to save money. But aluminium cladding is still popular in city homes. It has many design choices and meets building codes.

Industrial Uses

Factories and warehouses use aluminium cladding on their outside walls. The panels protect buildings from bad weather and rust. Industrial places need materials that can handle chemicals and heavy use. Aluminium cladding is strong and easy to clean. Many sites use the panels for column covers and roof edges. Some even use them on machine control panels. The panels help keep heat in or out, which saves money on energy. In cleanrooms and labs, aluminium cladding gives a safe, tough surface. It stands up to hard use. These uses show that aluminium cladding works well in many industries.

Aluminium composite panel cladding is tough and easy to take care of. It also comes in many styles and colors. Some buildings might have problems like dents or higher starting costs. Every project should think about things like how it handles weather, fire, and how it looks.

Make sure the panels can stand up to local weather.

Think about price, how much work it needs, and if the supplier is trusted.

Local laws and future plans help people pick the best cladding for their building.

FAQ

What is the main benefit of aluminum composite panel cladding?

Aluminum composite panels last for many years. They do not need much care. These panels can handle rain, stains, and rust. Builders like them because they are light. They are also simple to put up.

Can aluminum composite panels be recycled?

Yes, you can recycle aluminum composite panels. The aluminum sheets and some cores go to recycling places. This helps cut down on trash. It is good for green building.

How do you clean aluminum composite panel cladding?

Use soft soap and water with a gentle cloth. Rinse the panels well after washing. Do not use strong cleaners or rough brushes. Clean the panels once or twice each year. This keeps them looking nice.

Are aluminum composite panels safe in a fire?

Many panels have special cores that slow fire. These panels meet safety rules. Always check the fire rating before you pick panels.

Commercial Buildings

Commercial Buildings