10 Jul Advantages of Using PVDF Paint Coating on ACP Panel

Table of Contents

When you choose PVDF paint coating for aluminium composite panels, you get outstanding durability and long-lasting beauty. PVDF coating on ACP panels stands up to tough weather, harsh chemicals, and daily wear. You can expect your panels to keep their color and gloss for more than 30 years, even in extreme conditions. The table below highlights how PVDF coating on ACP panels delivers superior weather resistance and longevity:

Feature | PVDF Coating on ACP Panels Value |

|---|---|

Outdoor usage duration | |

Passed neutral salt spray test | 3000 hours |

Temperature resistance range | -60 ℃ to 150 ℃ |

Color and gloss retention | Over 30 years, even in harsh climates |

You will see the benefits of PVDF coating every day, from easy cleaning to protection against fading and corrosion. PVDF paint coating makes your investment last.

Key Takeaways

- PVDF paint coating on ACP panels offers outstanding durability and keeps colors bright for over 30 years, even in harsh weather.

- This coating resists chemicals, UV rays, scratches, and corrosion, reducing maintenance and repair costs.

- PVDF coatings provide easy cleaning and prevent mold, making panels low-maintenance and long-lasting.

- Compared to other coatings like polyester, PVDF delivers better color retention, weather resistance, and overall protection.

- PVDF-coated ACP panels are ideal for building exteriors, signage, and industrial uses, offering safety, strength, and lasting beauty.

PVDF Paint Coating Overview

What is PVDF Coating

You may wonder what makes PVDF paint coating special. PVDF stands for polyvinylidene fluoride, a high-performance fluoropolymer. Manufacturers use PVDF-based coatings, such as Kynar and Kynar coating, to protect surfaces from harsh environments. These coatings have a unique chemical structure with alternating -CH2- and -CF2- groups. This structure gives PVDF coating on ACP panels excellent resistance to chemicals, UV rays, and weather.

The properties of PVDF coating set it apart from other options. You get a melting point between 117°C and 172°C, and the coating stays stable up to 150°C. PVDF-based coatings also have high tensile strength, flexibility, and a V-0 flammability rating, which means they resist fire and produce little smoke. The table below shows some key properties of PVDF coating:

Property | Typical Value / Description |

|---|---|

Melting Point | 117 – 172 °C |

Maximum Service Temp | 150 °C |

Flammability Rating | V-0 (self-extinguishing) |

Tensile Strength | 14 – 55 MPa |

Elongation at Break | 20 – 800 % |

Chemical Resistance | High (acids, bases, solvents) |

Weather Resistance | Excellent |

You will often see PVDF paint coating used in construction, automotive, and industrial projects. The PVDF Fluorocarbon Coatings Market Research Report 2033 shows that the market for PVDF-based coatings is growing fast. In 2023, the market size reached about USD 1.2 billion, and it is expected to grow to USD 2.1 billion by 2032. This growth comes from the demand for durable, high-quality PVDF paint and sustainable building materials.

Why Use PVDF on Aluminium Composite Panels

When you choose PVDF coating on ACP panels, you get more than just a surface finish. You get a solution that protects and enhances your investment. PVDF aluminium composite panels offer many advantages over other coatings. Here are some reasons why you should consider PVDF-based coatings for your project:

- PVDF coating on ACP panels gives you outstanding durability and chemical resistance.

- You get excellent protection from extreme weather, UV rays, and pollution.

- The color and gloss of your panels stay vibrant for decades, resisting fading.

- PVDF-based coatings, including Kynar, make your panels more resistant to scratches and impacts.

- You spend less time and money on maintenance because PVDF coating on ACP panels is easy to clean.

- PVDF paint coating is ideal for buildings in harsh environments, such as coastal areas or industrial zones.

The benefits of PVDF coating go beyond protection. You also get a beautiful, long-lasting finish that keeps your building looking new. The properties of PVDF coating, such as thermal stability and chemical resistance, make it the top choice for architects and builders who value quality. When you select PVDF coating on ACP panels, you invest in performance, safety, and style.

Key Benefits of PVDF Coating on ACP Panels

Chemical and Weather Resistance

Chemical and Weather Resistance

You want your cladding to last, even in harsh weather conditions. PVDF coating on ACP panels gives you excellent weathering resistance. This means your panels resist acids, solvents, and bases. You do not have to worry about corrosion or damage from pollution. PVDF paint coating forms a strong barrier that blocks UV rays and keeps your building safe from sunlight and rain.

- PVDF aluminium composite panels show strong weather resistance.

- The coating stands up to boiling water for two hours without peeling.

- You get anti-UV and anti-nuclear radiation protection.

- PVDF coating on ACP panels resists chalking and fading.

Laboratory tests confirm these results. PVDF coatings contain over 70% fluorocarbon resin. When you wipe the surface with butyl ketone 200 times, the substrate stays protected. The coating meets the AAMA 2605 standard, which tests for color retention and film integrity after long exposure to Florida weather. You can see the chemical resistance of PVDF in the table below:

Chemical | Concentration | Temperature | PVDF Suitability |

|---|---|---|---|

Acetic Acid | 80% | 80°C | OK |

Acetic Acid | 80% | 120°C | X |

Sulfuric Acid | 98% | 80°C | OK |

Sodium Hydroxide | 50% | 80°C | OK |

Hydrochloric Acid | 36% | 80°C | OK |

Nitric Acid | 70% | 80°C | △ |

PVDF coating on ACP panels gives you pollution resistance and durability, even in tough environments.

Durability and Abrasion Resistance

You need your cladding to stay strong for years. PVDF coating on ACP panels delivers high durability. The coating resists scratches, impacts, and daily wear. You get high peel-off strength and waterproofing. PVDF paint coating keeps your panels looking new, even after many years.

Tensile tests show that PVDF composites with metal phosphate fillers have more than double the Young’s modulus of regular PVDF. This means your panels are stiffer and stronger. The coating also increases tensile strength and flexibility at moderate filler levels. PVDF coating on ACP panels stands up to repeated use and mechanical stress.

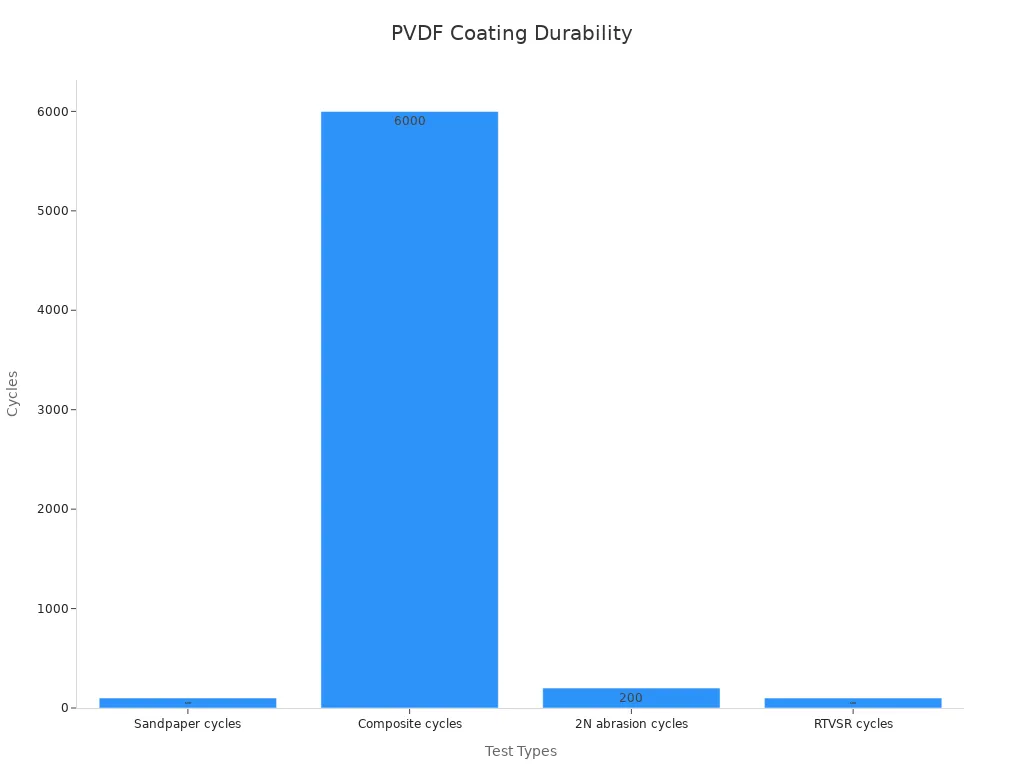

The table below shows how PVDF coatings perform in abrasion tests:

Test/Measurement Type | Value/Result | Description/Significance |

|---|---|---|

Sandpaper abrasion cycles | 100 cycles | Maintains superhydrophobicity after abrasion |

Load during abrasion test | Up to 10 N | Durable under heavy loads for 6000 abrasion cycles |

Pencil hardness | 5H – 6H | High mechanical hardness and abrasion resistance |

Abrasion cycles survived (composites) | 6000 cycles | High mechanical durability |

PVDF coating on ACP panels also resists corrosion, so you do not have to worry about rust or damage from chemicals. This durability means your cladding will last longer and need fewer repairs.

Color and Gloss Retention

You want your building to look bright and fresh for many years. PVDF coating on ACP panels offers high colour retention and superior fade performance. The panels keep their color and gloss, even after decades of sunlight and rain. You get long-term fade resistance, so your cladding does not lose its shine.

PVDF-based coatings, such as Kynar and Kynar coating, protect against UV rays and prevent chalking. The coating resists pollution and keeps your panels looking clean. You will notice that PVDF coating on ACP panels provides a matte finish or a glossy look, depending on your choice. The finish stays smooth and does not slip, making it safe for many uses.

PVDF coating on ACP panels gives you good weather resistance and sunlight resistant surfaces, so your building always looks its best.

Maintenance and Cleaning

You save time and money with PVDF coating on ACP panels. The surface is easy to clean. Dirt, dust, and stains do not stick to the panels. You can wash them with water or mild soap. The coating resists corrosion, so you do not need special cleaners or treatments.

PVDF paint coating also prevents mold and mildew. The panels do not chalk or fade, so you do not have to repaint them often. This low maintenance is one of the main benefits of PVDF coating. You get more value and less work over the life of your cladding.

Functional Properties

PVDF coating on ACP panels gives you more than just a pretty surface. The coating has many functional properties that improve safety and performance. You get fire resistance, antistatic features, and antibacterial protection. The properties of PVDF coating make your panels safer and cleaner.

Tests show that PVDF coatings with MoO3 nanowires stop the growth of bacteria like Staphylococcus epidermidis. The coating also meets ISO and EN standards for adhesion, hardness, and mold resistance. PVDF coating on ACP panels gives you a strong, safe, and reliable cladding solution.

Performance Aspect | Standard / Test Method | Description / Result Summary |

|---|---|---|

Adhesion | ISO 4624:2016 (Pull-Off Test) | High pull-off strength and strong bonding |

Blue-Stain Fungal Resistance | EN 152 (Wood Preservatives) | No surface staining after 8 weeks |

Mould Resistance | E24-12 (Mold Growth) | No mold growth with MoO3 nanowires |

Coating Hardness | ISO 1522:2006 (Pendulum Damping Test) | Hard, durable film |

Antibacterial Property | Experimental with MoO3 nanowires | Stops growth of Staphylococcus epidermidis |

You can trust PVDF coating on ACP panels to deliver quality, durability, and safety for your building. The benefits of PVDF coating include resistance to weathering, corrosion, and fading. You get long-lasting cladding that stands up to harsh weather conditions and daily use.

PVDF Coating vs Other Options

PVDF vs Polyester Coatings

When you compare pvdf coatings to polyester coatings, you see clear differences in performance. You get much better resistance to fading and chalking with pvdf. The strong carbon-fluorine bond in pvdf helps your panels last longer and keeps colors bright. Polyester coatings cost less, but they do not protect as well against UV rays or harsh weather. You may notice uneven fading or chalking on polyester-coated panels after a few years.

Here is a quick comparison:

Performance Aspect | PVDF Coating | Polyester Coating |

|---|---|---|

Coating Thickness | ≥ 25 µm | ~16 µm |

Color Retention | Excellent | Fair |

UV Resistance | High | Low |

Abrasion Resistance | High | Moderate |

Chemical Resistance | High | Low |

Warranty | Up to 30 years | 10-15 years |

You get longer-lasting color, better protection, and higher durability with pvdf coatings on your aluminium composite panels.

PVDF vs FEVE and Acrylic

You might also consider FEVE or acrylic coatings. FEVE coatings offer good weather resistance, but pvdf still leads in long-term color retention and chemical resistance. Acrylic coatings are affordable, but they do not last as long outdoors. You will find that pvdf coatings keep your panels looking new for decades, even in tough environments. The smooth surface of pvdf also makes cleaning easier and reduces maintenance.

Cost and Performance

You may pay more for pvdf coatings at first, but you save money over time. The strong adhesion of pvdf reduces the need for extra adhesives or repairs. You spend less on maintenance because the coating resists scratches, stains, and corrosion. In performance tests, pvdf coatings show excellent results for wear resistance and weatherability. For example, pvdf coatings maintain color for over 15 years, while standard powder coatings show changes in just a few years.

Metric | PVDF Coating Value | SMP Coating Value |

|---|---|---|

Fading Units (Hunter ΔE) | 5 (lower is better) | 7 for roofs, 5 for walls |

Chalking Rating | 8 (higher is better) | 6 for roofs, 8 for walls |

Film Adhesion Warranty | 40 years | 40 years |

You get a smart investment with pvdf. The coating’s durability and low maintenance help you save money and keep your building looking great for years.

Applications of PVDF Coating on Aluminium Composite Panels

Building Facades and Exteriors

You see PVDF coating on ACP panels used widely in building facades and exteriors. This coating protects your building from harsh weather, UV rays, and pollution. You get a surface that resists fading, chalking, and corrosion. PVDF coatings meet strict standards like AAMA 2605, so you know your cladding will last for decades.

- PVDF coatings keep color and gloss for up to 30 years.

- You spend less time and money on maintenance.

- The panels stay strong against acid rain, hail, and sunlight.

- PVDF coatings help your building meet green standards and energy codes.

The global market for aluminium composite panels is growing fast. More builders choose PVDF-coated panels because they want durable, lightweight, and attractive exterior cladding applications. You find these panels on office towers, hotels, and homes around the world.

Signage and Branding

You want your signs to look bright and professional for years. PVDF coatings help you achieve this. The coating keeps colors vivid and prevents fading, even in direct sunlight. You can clean the panels easily, so your signs always look fresh.

- PVDF-coated ACPs are lightweight and easy to shape.

- You can use them for outdoor signs, billboards, and branding displays.

- The panels resist graffiti, stains, and scratches.

Many companies choose PVDF-coated panels for their branding because they want a long-lasting, low-maintenance solution. You get a sign that stands out and stays beautiful.

Specialized and Industrial Uses

You find PVDF coatings in many specialized and industrial settings. These coatings protect panels in chemical plants, airports, and factories. PVDF resists acids, alkalis, and solvents, so your panels do not degrade or discolor.

- PVDF coatings pass tough abrasion and impact tests.

- The panels work well in harsh climates, from deserts to coastal areas.

- New PVDF technologies add self-cleaning and antimicrobial features.

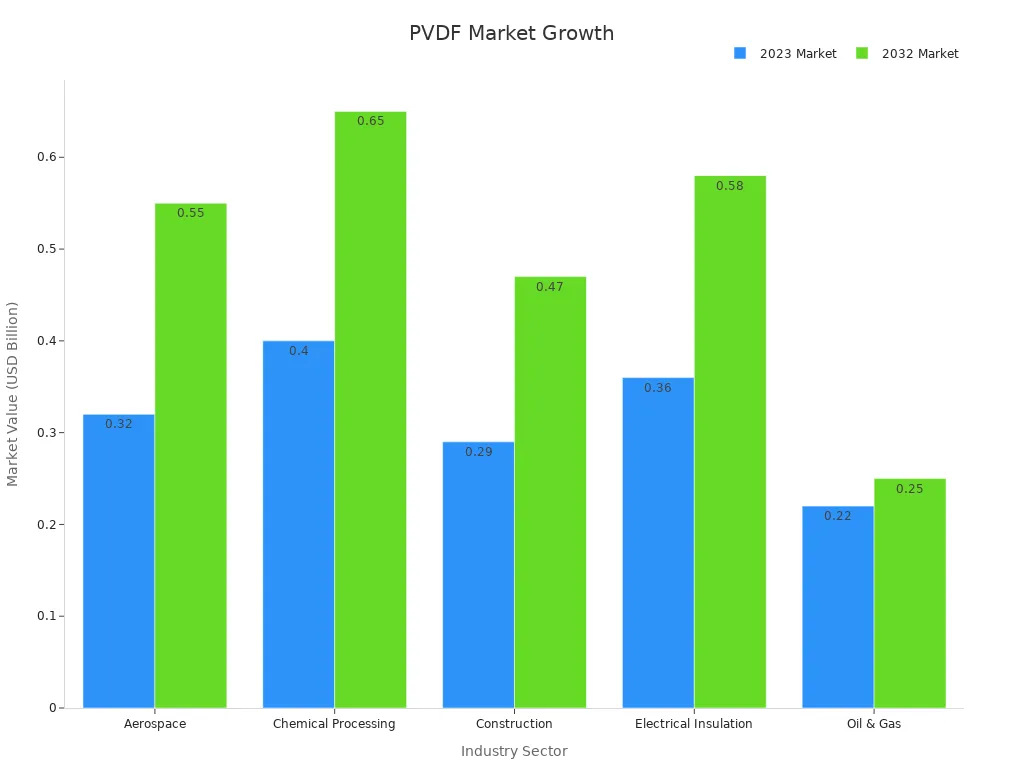

Here is a table showing how PVDF coatings benefit different industries:

Industry Sector | Market Value 2023 (USD Billion) | Projected Market Value 2032 (USD Billion) | Key Benefits of PVDF Coatings in Sector |

|---|---|---|---|

Aerospace | 0.32 | 0.55 | Lightweight, chemical resistance, durability for aircraft components |

Chemical Processing | 0.40 | 0.65 | Corrosion resistance, protection under extreme conditions |

Construction | 0.29 | 0.47 | Durability, environmental protection, aesthetic appeal |

Electrical Insulation | 0.36 | 0.58 | Exceptional electrical insulation, safety, and efficiency |

Oil & Gas | 0.22 | 0.25 | Resilience in harsh environments, maintaining integrity |

You can trust PVDF coating on ACP panels to deliver strong performance in every environment. The combination of durability, easy care, and safety makes PVDF a top choice for cladding in many industries.

You gain many benefits when you choose PVDF-coated ACP panels. These panels offer strong protection, long-lasting color, and easy maintenance. The market keeps growing because builders trust their performance. You see high demand in construction, especially for fire-resistant and eco-friendly options. The table below highlights why more people select these panels for both homes and businesses:

Feature | Value for You |

|---|---|

Market Growth | Fast, with more buildings using ACPs |

Safety | Meets strict fire and safety standards |

Maintenance | Needs less cleaning and repairs |

Innovation | New coatings add extra protection and value |

Choose PVDF-coated ACP panels for lasting value and a smart investment in your property.

FAQ

What makes PVDF paint coating better for aluminium composite panels?

You get excellent weathering resistance and high colour retention with PVDF paint coating. This coating protects aluminium composite panels from corrosion and fading. You see long-term fade resistance and superior fade performance, even in harsh weather conditions. PVDF-based coatings also offer strong weather resistance and durability.

How does PVDF coating on ACP panels help with maintenance?

You spend less time cleaning PVDF aluminium composite panels. The surface resists dirt and stains. You only need water or mild soap. PVDF coating on ACP panels prevents mold and chalking. You do not need to repaint often. This saves you money and effort.

Can PVDF-based coatings withstand pollution and chemicals?

Yes, PVDF coating on ACP panels gives you pollution resistance and durability. The properties of PVDF coating block acids, bases, and solvents. You get protection from industrial pollution. Kynar and Kynar coating also help your cladding stay strong in tough environments.

Where can you use PVDF aluminium composite panels?

You can use PVDF aluminium composite panels for exterior cladding applications, signage, and industrial buildings. The panels offer good weather resistance, sunlight resistant surfaces, and chalking resistant finishes. You get quality and longevity for your projects.

Chemical and Weather Resistance

Chemical and Weather Resistance