13 Mar Aluminium Composite Panel Texture Trends Everyone Loves In 2025

Table of Contents

- 1 Key Takeaways

- 2 Texture Trends 2025

- 3 Aluminium Composite Panel Texture Types

- 4 Choosing Aluminum Composite Panels

- 5 Real-World Examples

- 6 FAQ

- 6.1 What makes 3D and fluted aluminium composite panels popular in 2025?

- 6.2 Are aluminium composite panels eco-friendly?

- 6.3 How do metallic finishes differ from other panel textures?

- 6.4 Can aluminium composite panels mimic natural materials?

- 6.5 What should someone consider when choosing a panel texture?

Popular aluminium composite panel texture choices in 2025 include 3D and fluted surfaces, offering a tactile experience that designers prefer over flat panels. Metallic colors such as copper and titanium remain favorites, along with dual-tone styles and customizable patterns. Eco-friendly finishes are increasingly popular, reflecting a growing demand for sustainable options. Advances in technology have introduced new ways to utilize aluminum composite panels, including eco-friendly coatings and innovative designs. Additionally, many projects now incorporate stone finishes ACP panel surfaces to achieve a natural and sophisticated look.

Key Takeaways

3D and fluted aluminium composite panels make buildings look cool. They catch light and shadow. This adds depth and style. It helps buildings look modern and interesting.

Metallic and dual-tone finishes stand out. They make bold designs that grab attention. These finishes last a long time. They work well inside and outside.

Customizable textures help architects make special building looks. These looks can match brands or creative ideas. This boosts creativity and identity.

Eco-friendly panels use recycled materials. They save energy and last a long time. They help meet green building needs. They also help reduce waste.

Aluminium composite panels are strong and light. They are easy to put in place. This makes them popular for many projects. People use them for commercial, residential, and public buildings.

Texture Trends 2025

3D and Fluted Panels

Architects and designers like using 3D and fluted aluminium composite panel textures. These panels, like Mirage Fluted and Elemento, have grooves or raised patterns. The patterns catch light and shadow, making walls look interesting. More people want textured and 3D surfaces now. This is because modern buildings need materials that look good and work well.

Market research shows why this trend is growing:

- Cities are growing, so new buildings need better materials.

- Laminating coatings are popular for their nice look and eco-friendly benefits.

- Digital printing lets people make custom designs and textures.

- Laminated panels can look like wood, stone, or metal, giving more choices.

- These panels are light, strong, and easy to clean, so they fit many uses.

Here is a table comparing two types of fluted panels:

Panel Type | Design Features & Materials | Performance Characteristics | Price Range (per m²) | Suitable Applications & Notes |

|---|---|---|---|---|

Aluminum Alloy Fluted | Has grooves going up and down or across; can look like wood, painted, or sandblasted; made with CNC and laser cutting | Stands up well to weather, does not rust, keeps out water, blocks UV rays, lasts long, needs little care | Good for tough outdoor places, fancy buildings, and modern or industrial styles | |

Composite Fluted | Made from mixed materials like wood powder, plastic, or stone powder; looks like wood, resists water and sun | Handles weather well, protects the environment, resists water and sun, needs some care | $28 – $113 | Used for outside walls, balconies, and as a cheaper choice than wood or aluminum alloy |

These panels look good and work well, so they are very popular for 2025.

Metallic Finishes

Metallic finishes are still a top pick for aluminium composite panel textures. Designers like copper, rose gold, and titanium for a modern and fancy look. These finishes shine and make spaces feel special. People want metallic textures because they stand out and look bold.

Laminating coatings help make metallic effects look even better. This technology gives panels a shiny and even color, and makes them last longer. Metallic finishes can handle bad weather, sunlight, and rust, so they work inside and outside. Many architects use these panels in business buildings for a high-end look.

Dual Tone Designs

Dual tone aluminium composite panel textures are getting more popular. These panels mix two colors or finishes, sometimes with a sharp line or a smooth blend. The surface looks different when you look at it from different angles or in different light.

Designers use dual tone panels to make parts of a building stand out or look like they are moving. This trend lets people pick custom designs and textures. Dual tone panels fit both new and old styles, so they are flexible for many designs.

Customizable Textures

Custom designs and textures are now very important for aluminium composite panel textures. Digital printing and new laminating methods give endless options. Architects can order panels that match a brand, a pattern, or even artwork.

Custom textures have many good points:

- They help brands look different with special building fronts.

- They let people be creative in public places.

- They give both style and function.

This trend shows that people want building materials that are unique and new. Custom designs and textures let you get any look, from woodgrain to cool, modern patterns.

Sustainable Surfaces

Sustainability is shaping the future of aluminium composite panel textures. Builders want eco-friendly materials that are better for the planet. ACP panels can be recycled, including the aluminum, plastic, and minerals inside.

- These panels last a long time, so there is less waste.

- They help keep buildings warm or cool, saving energy.

- ACP sheets do not get as hot as glass, so buildings stay cooler.

- Makers use recycled or carefully sourced aluminum to help the environment.

- Life Cycle Assessment (LCA) checks how each panel affects the planet, so people can make better choices.

Sustainable surfaces look good and work well. They help meet green building rules and answer the need for eco-friendly solutions. Because of this, sustainable aluminium composite panel textures are now very important for many projects.

Aluminium Composite Panel Texture Types

Brushed Metal

Brushed Metal

Brushed metal aluminium composite panels have lines that go in one direction. This look is modern and a bit industrial. Many architects like brushed metal because it looks clean. It also hides fingerprints and small scratches well. The panels use powder coating, anodizing, or micro-textured embossing for different looks. These finishes can even look like carbon fiber or wood grain.

Powder-coated aluminum sheets are now used in over 40% of commercial cladding. They are strong against UV rays and keep their color for years.

Manufacturers use waterjet cutting and perforation for custom designs. This lets them make special shapes and cool effects.

Brushed metal panels are light and do not rust. They are used in buildings, cars, and electronics.

Many companies use recycled materials and eco-friendly coatings to help the environment.

Antimicrobial surface treatments are used more now, growing at 8.2% each year. These treatments help keep buildings clean and safe.

Woodgrain

Woodgrain aluminium composite panels look like real wood but are as strong as metal. The surface can show patterns like oak, walnut, or maple. This texture is popular for people who want a natural look without wood problems.

Woodgrain panels are light, so they are easy to put up and do not make buildings heavy.

Special coatings protect the panels from sun and rain, so they last longer.

These panels can be recycled, which helps the planet.

They come in many sizes and shapes, so architects can design freely.

The panels also keep heat in or out, which saves energy.

Woodgrain panels do not cost much and meet fire safety rules. They are easy to care for and last a long time, so people use them for new buildings and fixing old ones.

Matte

Matte aluminium composite panels have a flat surface that does not shine. This finish gives buildings a soft and modern look. Matte textures do not show fingerprints or smudges easily, so they are good for busy places.

Matte panels use special coatings that stop scratches and stains.

They come in many colors, so designers can be creative.

The panels are often made with recycled materials, which is good for the earth.

Matte finishes cut down glare, so they work inside and outside.

New technology, like nano-coatings, makes matte panels stronger and better. Builders pick matte finishes because they are simple and easy to keep clean.

High-Gloss

High-gloss aluminium composite panels are shiny and reflect like a mirror. This finish makes colors look bright and bold. Designers use high-gloss panels to make buildings stand out.

The Great Northern Way Pavilion in Vancouver uses a high-gloss red finish to get noticed. PVDF and FEVE coatings help these panels stay shiny and keep their color for up to 30 years. These coatings also protect against sun, chemicals, and bad weather.

High-gloss finishes are used in restaurants, banks, and offices. The ACP market is growing fast, reaching $6.9 billion in 2023 and could hit $11.7 billion by 2033. This growth is because people want advanced finishes, like high-gloss, that look good and last long.

Stone and Marble

Stone and marble aluminium composite panels look like real stone or marble but are much lighter and easier to use. These panels give a classic and fancy style for inside and outside.

Evidence Aspect | Description |

|---|---|

Market Recognition | Used in famous buildings in the Middle East, Europe, and Australia, showing they are popular. |

Lightweight | Much lighter than real stone, so they are easy to move and install. |

Durability | Stands up to weather, rust, and hits. Good for many uses. |

Aesthetic Appeal | Looks like real stone with many colors and finishes for design choices. |

Versatility | Can be cut and shaped for things like wall cladding and facades. |

Easy Installation | Simple to put up, often with special tools. |

Long Lifespan | Can last 40 to 60 years if cared for. |

Marble finishes give a timeless look with special lines and patterns. Advanced coatings, like PVDF, help the panels handle weather and stay looking new. These panels cost less than real marble and are easier to care for.

Stone and marble ACPs make buildings look better and are easy to use and last a long time.

Choosing Aluminum Composite Panels

Design Goals

Design Goals

Every project begins with a clear plan. Architects want panels that fit their ideas and are safe. Aluminium composite panels come in many finishes, colors, and shapes. These choices help designers be creative and make buildings look special.

Panels have aluminum sheets and different core materials. This makes them strong, tough, and safe from fire.

Companies test panels for fire safety, strength, and weather resistance.

Certifications from groups like ASTM and EN show the panels are safe and good quality.

Using recycled materials and saving energy are important for new designs.

Trusted brands give detailed guides to help pick the right panels.

Studies say panels with polymeric cores can stop hail and hard hits. This helps architects pick panels that keep buildings safe from bad weather. Research also says it is important to think about how long panels last, how much they cost, and how well they keep heat in or out. Machine learning and parametric modeling help make buildings use less energy. These tools help save money over time.

Environment and Durability

Builders want materials that last long and help the planet. Aluminium composite panels are strong and good for the environment.

Panels do not rust or get damaged by weather, so they are great outside.

Lightweight panels are easy to move and put up, saving time and money.

Many panels use recycled stuff, which is good for green building.

Fire-resistant panels are safe for tall and public buildings.

People care about saving energy and being green. Panels help keep buildings warm or cool, so they use less energy. New coatings like Nano PVDF make panels last longer and look nice. These features make panels a smart pick for many uses, like building walls or buses.

Brand Identity

Companies use building design to show who they are. Aluminium composite panels help businesses get noticed.

New cutting tools make special shapes and patterns possible.

Graphic design software helps match brand colors on panels.

Panels work inside and outside, so they are very useful.

Custom finishes and textures can show a company’s style.

People want materials that look good, work well, and help the planet. Digital printing lets companies put logos or pictures on panels. Social media and websites show off these cool designs, helping brands get more attention. Panels also help keep buildings quiet and save energy, which is good for budgets and the environment.

Real-World Examples

Commercial Projects

Many businesses use aluminium composite panel textures on their buildings. These panels can be very big, sometimes up to five meters long. This helps make walls look smooth and modern. Companies pick these panels because they last a long time, about 40 to 50 years. They do not need much care. The panels meet tough coating rules, so they do not get damaged by sun, rust, or chemicals. This makes them a smart choice for many uses.

Some famous buildings show how designers use these panels in cool ways:

Southern Connecticut State University’s College of Health and Human Services has special panels with laser-cut holes.

100 Hood Park Drive in Massachusetts uses a wall system with shaped aluminum fins for air flow and fire safety.

Meta’s Facebook office campus in Bellevue, WA, uses a dual-tone metal system that meets LEED rules.

These examples show that aluminium composite panels are flexible and save money. They are light, so putting them up is easier. They can also be recycled, which helps the planet.

Residential Spaces

People now use aluminium composite panels in homes too. These panels can look like wood, stone, or metal. This gives houses a modern or classic look. Builders use them for outside walls, balconies, and even inside rooms. The panels help keep homes warm or cool by giving good insulation.

In tall buildings, designers use panels with holes and textures to make them look interesting. For example, the Rose Hill tower in Manhattan has chevron shapes and water jet-cut patterns. These designs make the building stand out and also look like old styles. The panels last a long time and are easy to take care of, so they are great for homes.

Public Installations

Public buildings use aluminium composite panels in many ways. The Lagos Park Building in Madrid used these panels for walls that let air move. This helped cut electricity bills by up to 75%. The panels also made the building more comfortable and gave it a top energy rating.

Project | Use of ACP | Result |

|---|---|---|

Lagos Park Building, Madrid | Ventilated facades | Lowered energy bills, better comfort, long-lasting look |

Parking Garage | Noise reduction panels | Dropped noise from 92 dB to quiet levels |

Office Building | Façade restoration | Panels resisted fading, lasted over 20 years |

Other public places, like the Austin Central Library, use panels that are anodized and have holes for strength and design. These uses show that aluminium composite panels can handle bad weather, lower noise, and keep looking good for many years.

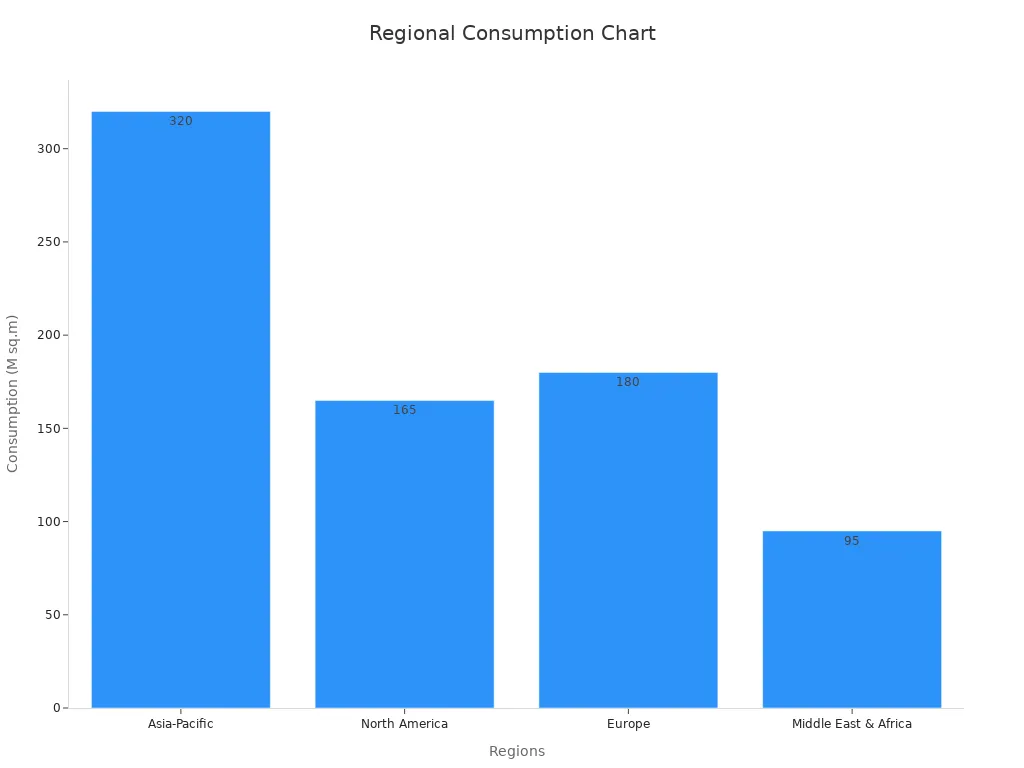

Aluminium composite panel textures are growing fast in 2025. Designers pick 3D, metallic, dual-tone, customizable, and eco-friendly finishes. These finishes look good and work well. The market was about $7.5 billion in 2024. It might reach $12.2 billion by 2033. Asia-Pacific uses the most panels, with 320 million square meters. New technology gives us panels that can be recycled. Some panels even clean themselves.

Statistic Category | Details / Values |

|---|---|

Market Size (2024) | About USD 7,494.72 million |

Market Size (2033 Projection) | About USD 12,238.57 million |

CAGR (2020-2023) | Around 5.6% |

Regional Consumption (2024) | Asia-Pacific: 320 million sq. meters |

Technological Innovations | Recyclable panels, nano-coated self-cleaning surfaces, bio-based core materials |

Designers can look at real projects for ideas. Picking the right texture helps make buildings special and strong.

FAQ

What makes 3D and fluted aluminium composite panels popular in 2025?

Designers like 3D and fluted panels because they look cool. These panels have shapes that stick out or go in. They catch light and make buildings look special. Many architects use them to make walls more interesting.

Are aluminium composite panels eco-friendly?

Many companies now use recycled stuff in aluminium composite panels. These panels last a long time and help save energy in buildings. Picking eco-friendly finishes helps the planet and supports green building.

How do metallic finishes differ from other panel textures?

Metallic finishes, like copper or titanium, are shiny and bright. They reflect light and look modern. These panels do not rust and can handle bad weather. Designers use them in business buildings to make them stand out.

Can aluminium composite panels mimic natural materials?

Yes, some panels look just like wood, stone, or marble. They give the nice look of real materials but are strong and easy to clean. Many people use them inside and outside their homes.

What should someone consider when choosing a panel texture?

Tip: Think about how the building looks and where it is. Some textures hide dirt or scratches better. Others shine or make spaces feel warm. Pick a texture that fits what you want for your project.

Brushed Metal

Brushed Metal Design Goals

Design Goals