23 Jul What Are the Main Types of Aluminum Cladding and Their Features

Table of Contents

Aluminum cladding types are composite panels, solid panels, aluminum siding, anodized finishes, powder-coated finishes, perforated panels, folded panels, and standing seam systems. Each type of aluminum cladding has special features for outside walls. These features include strength, design choices, and protection from weather. Builders and architects pick these cladding types for different project needs. The world market for aluminum composite panels is getting bigger. This is because more people live in cities and want light, recyclable outside walls. Picking the right aluminum cladding helps projects look good and work well.

Key Takeaways

Aluminum cladding has three main types. These are composite panels, solid panels, and siding. Each type has its own strength, look, and lasting power.

Special finishes like anodized and powder-coated help protect aluminum cladding. They keep it safe from weather, rust, and fading. These finishes also add color and style.

There are different cladding systems like perforated, folded, and standing seam panels. These systems let you be creative with design. They also give strong protection from wind and rain.

Picking the right aluminum cladding depends on a few things. You should think about how long it lasts, the price, energy savings, and building style. This helps make sure you get good and lasting results.

Aluminum cladding is light and easy to take care of. It saves energy and works well for many buildings. This makes it a smart pick for new construction.

Aluminum Cladding Types

Aluminum wall cladding comes in a few main forms. Each type has special features for outside walls. The most common types are composite panels, solid aluminum panels, and aluminum siding. These types give different levels of strength, design choices, and how well they work.

Composite Panels (ACM/ACP)

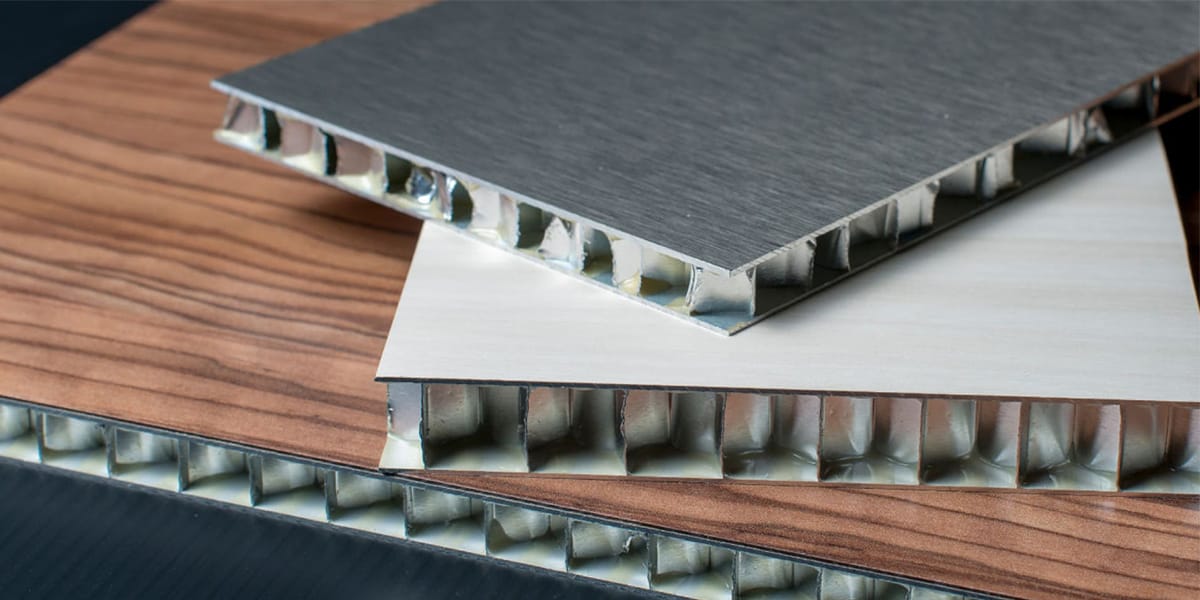

Aluminum composite panels are also called ACM or ACP. They have two thin aluminum sheets stuck to a core that is not aluminum. This makes the panel light but strong. Aluminum composite panels have a smooth look and come in many colors. Builders use them for modern buildings, business fronts, and signs.

Tip: Aluminum composite panels are simple to cut and shape. This makes them great for creative building designs.

Aluminum composite panels help keep buildings warm or cool. This can lower energy bills. They do not rust or let water in, so they are good for outside walls. They do not need much care over time. Many architects use aluminum composite panels for new buildings and fixing old ones.

Solid Aluminum Panels

Solid aluminum panels use one thick sheet of aluminum. These panels are very strong and last a long time. They do not dent as easily as aluminum siding. They also stop rust and water very well. Designers use solid aluminum panels in busy places and tough spots.

Material | Rust Resistance | Dent Resistance | Water Resistance | Life Expectancy | Weight |

|---|---|---|---|---|---|

Solid Aluminum Cladding | Excellent | Good | Excellent | Light | |

Aluminum Composite Panels | Good | Good | Good | Durable | Light |

Aluminum Siding (Vinyl) | Excellent | Poor | Good | 15-25 years | Light |

Solid aluminum panels can last more than 40 years if cared for. They need little work to keep looking nice. Some projects use solid aluminum panels on tall buildings or in public places. These panels also look good inside as wall panels.

Aluminum Siding

Aluminum siding uses long strips of aluminum. These strips can go across or up and down. This type covers many houses and short buildings. Aluminum siding is light and easy to put up. It does not rust or let water in, so it keeps buildings safe from bad weather.

Aluminum siding comes in many colors and looks. Homeowners like it because it costs less and is easy to care for. But aluminum siding dents easier than solid panels or aluminum composite panels. It usually lasts from 15 to 25 years.

Note: Aluminum siding is best for homes and small business buildings.

Advantage Category | Description |

|---|---|

Lightweight | Aluminum cladding, especially ACPs, is light and easy to use. |

Durability | Aluminum wall cladding stands up to bad weather and lasts long. |

Corrosion Resistance | All types of aluminum facade cladding stop rust and corrosion. |

Fire Resistance | Aluminum melts at high heat and does not burn fast. |

Energy Efficiency | Aluminum composite panels help save on heating and cooling. |

Versatility | Aluminum wall cladding comes in many shapes, colors, and finishes. |

Cost-Effectiveness & Maintenance | Aluminum siding and panels need little care and save money over time. |

The main types of aluminum wall cladding—composite panels, solid panels, and siding—each have their own good points. Aluminum composite panels are flexible for design and save energy. Solid aluminum panels are strong and last a long time. Aluminum siding is a good choice for saving money on homes. These types of aluminum facade cladding help builders and architects with different needs.

Types of Aluminum Wall Cladding Finishes

Anodized Aluminum

Anodized Aluminum

Anodized aluminum makes the surface hard and strong. This finish uses electricity to change the metal. The process makes the outside layer thicker. Anodized finishes do not peel or chip off. They do not scratch easily and keep their color for years.

Builders like anodized aluminum because it lasts a long time. It works well in places with tough weather. The finish protects from rain, sun, and dirty air. Anodized aluminum does not rust. This is good for buildings near the ocean.

Anodized aluminum wall cladding stays nice for many years. It does not fade or turn chalky, even after a long time outside.

AAMA 611-14 is the rule for anodized finishes. This rule says the finish must be tough and keep its color. Anodized aluminum passes hard salt spray and weather tests. It gets very little pitting after 3,000 hours of salt spray. The finish keeps its color and shine after 10 years in Florida sun. Class I anodized finishes are at least 18 microns thick. This thick layer gives more protection outside.

Performance Metric | Result/Specification | Test Standard |

|---|---|---|

Salt Spray Resistance | ASTM B-117 | |

Humidity Resistance | 1000 hours pass | ASTM D 2247 |

Gloss Level | 15-25 @ 60° | – |

Chemical Resistance | Excellent | – |

Recommended Bake Cure | 10 minutes @ 340°F metal temperature | – |

Anodized aluminum wall cladding looks shiny and metallic. The finish can be silver, bronze, black, or other colors. Many architects use anodized finishes for new building styles. The finish lets the real look of aluminum show. It makes buildings look smooth and modern.

Powder-Coated Aluminum

Powder-coated aluminum adds color and protects the metal. This finish uses dry powder that sticks to the surface. The powder melts and makes a smooth layer when baked. Powder coating covers the aluminum all over. It hides small marks and gives even color.

Powder-coated finishes come in many colors. Builders can pick bright or soft colors. The finish can be matte or shiny. Powder-coated aluminum wall cladding fits many building styles.

Powder-coated finishes stop scratches, chips, and fading. They do not rust and can handle bad weather. The AAMA 2600 series is the rule for powder-coated aluminum. This rule says the finish must be tough and keep its color. Powder-coated aluminum passes 3,000 hours of salt spray tests. It keeps its color and shine after many years outside. The finish also passes tests for saving energy from the sun.

Finish Type | Standard(s) | Key Performance Tests & Outcomes |

|---|---|---|

Anodized Aluminum | AAMA 611-14 | – Abrasion resistance (Michael Clarke Test) |

Powder-Coated Aluminum | AAMA 2600 series | – Abrasion resistance |

Tip: Powder-coated aluminum wall cladding is great for projects that need special colors or finishes.

Both anodized and powder-coated finishes help aluminum wall cladding last longer. They protect buildings from weather, dirt, and daily use. The best finish depends on how you want the building to look and work.

Different Types of Aluminum Cladding Systems

Perforated Panels

Perforated panels are made from aluminum plate with lots of small holes. These holes let air and light move through the panel. The panels still protect the building from outside things. Architects like perforated panels for modern buildings. They make cool shadows and patterns on the walls. Perforated panels help air flow and can keep buildings cooler inside. You often see this system on parking garages, schools, and offices.

Perforated panels have many good points for aluminum cladding systems. They make the wall lighter and let designers be creative. The holes can be round, square, or special shapes. This makes every project look different. Tests show that thicker panels are stronger. Wide panels might not be as strong as thick ones.

Folded and Cut Panels

Folded and cut panels are made by shaping aluminum plate into forms. Machines cut and bend the plate to make sharp lines or 3D shapes. This system gives buildings a bold and modern style. Folded panels can hide where two panels meet. This makes the wall look smooth. Designers use these panels on museums, airports, and shopping centers.

This system has many good points for aluminum cladding systems. Folded panels can cover corners and edges without extra pieces. They also make the wall stronger. Studies show that how you fold the panels changes how much weight they hold. The right design keeps the building safe in strong winds.

Tip: Folded and cut panels are great for projects that need special shapes or patterns.

Standing Seam Panels

Standing seam panels use long strips of aluminum plate with raised edges. The edges lock together to keep water out. This system works for both walls and roofs. Standing seam panels look clean and modern. They last a long time.

Builders like standing seam panels for many aluminum cladding systems. They are easy to put up and do not need much care. The raised seams help water run off fast. Tests show these panels meet tough rules for wind and rain. The BS 5427–1:1996 guideline helps builders check if the panels will stay strong in bad weather.

Standing seam panels, folded and cut panels, and perforated panels are all types of aluminum cladding systems. Each system uses aluminum plate in a special way to meet design and safety needs.

Choosing the Right Aluminium Cladding

Key Selection Factors

Key Selection Factors

Picking the best aluminium cladding means looking at many things. Architects and builders check how long it lasts and how much it costs. They also look at how well it saves energy and how easy it is to take care of. The way the cladding looks on the building is important too. The table below gives facts and numbers to help make a good choice:

Selection Factor | Numerical Guideline / Data Point | Explanation / Impact |

|---|---|---|

Energy Optimization | Hybrid cladding (10% polycarbonate + 90% aluminum) achieves 4.58% better energy optimization than pure aluminum | Shows improved energy efficiency and sustainability for certain blends |

Life-cycle Cost Analysis | Polycarbonate has lower initial cost, but hybrid balances initial cost with long-term energy savings | Highlights the need to weigh upfront costs against future savings |

Maintenance Modeling | Multi-criteria analysis includes service life, maintenance frequency, and cost trade-offs | Helps plan for long-term care and cost management |

Predictive Modeling | Multivariate Polynomial Regression (MPR) predicts energy use and material costs | Gives data-driven support for design decisions |

Multi-criteria Decision Making | Weighting durability, performance, and maintenance can shift preferred cladding choice by 17% or more | Shows that many factors together can change the best choice |

Durability and Maintenance | Durable materials reduce maintenance frequency and costs over time despite higher initial costs | Points to the value of long-lasting aluminium cladding |

Tip: Builders should always make sure the cladding is safe from fire and water. This is extra important for big business buildings.

Typical Applications

Aluminium cladding works for many kinds of buildings. Designers put aluminum facade cladding on tall offices, schools, and hospitals. It is good for new buildings and for fixing old ones. The table below shows how different cladding types do in real projects:

Cladding Type | Numerical Data / Performance Metric | Implication for Selection |

|---|---|---|

Stone Cladding | Reduces cooling load by 4% vs aluminum panel, 1.5% vs plaster systems | Best for energy savings in hot climates |

Polyurethane Board | Reduces cooling load by 3.8% compared to sandstone with polystyrene | Good for thermal performance |

Fire Risk | Aluminum panel fire risk mitigated by high ignition point insulation | Fire safety remains a top priority |

Recommended System | Gravel gray stone with cavity and mineral fiberglass insulation | Balances thermal and fire performance for commercial building |

Aluminium cladding is flexible and fits many uses. Builders like it for business buildings because it is light and strong. It is also easy to put up. Aluminum facade cladding is used on schools, malls, and apartments too. It does not need much care and lasts a long time. Many architects pick aluminium cladding for its modern style and energy savings. Water-resistant cladding like aluminum helps keep rain and bad weather out.

Note: Always pick the cladding type that fits the building and local weather for the best results.

Aluminum cladding comes in different types. Each type has its own good points. Composite panels are light and strong. They also help stop fires. Solid panels are even stronger for busy places. Siding is a good choice for houses. Special finishes like anodized and powder-coated protect the panels. These finishes also add color.

Builders like aluminum cladding because it does not rust. It is easy to clean and saves energy.

Architects can pick many colors and textures for their designs.

More tall buildings use aluminum cladding because it is light and good for the planet.

To get the best results, pick the right cladding for your building. Ask an expert for help if you are not sure.

FAQ

What is the main benefit of aluminum cladding?

Aluminum cladding keeps buildings safe from rain and wind. It makes buildings look new and stylish. Builders like it because it lasts many years and does not rust. People also like that it is easy to take care of.

Can aluminum cladding be used with other materials?

Yes, designers sometimes use aluminum cladding with glass, stone, or brick. This makes buildings look special and different. Using more than one material can help save energy and make buildings stronger.

How does aluminum cladding help with energy efficiency?

Aluminum cladding panels can bounce sunlight away. This helps keep the inside cooler. Some panels have insulation inside them. These panels help lower heating and cooling bills.

Is aluminum cladding safe in a fire?

Aluminum melts only when it gets very hot. It does not catch fire fast. Many systems use special cores or insulation that resist fire. Builders should always follow local fire safety rules.

How long does aluminum cladding last?

Most aluminum cladding stays good for more than 30 years. If you take care of it, it can last even longer. Special finishes like anodized or powder-coated help stop fading and damage.

Anodized Aluminum

Anodized Aluminum Key Selection Factors

Key Selection Factors