23 Feb How to Choose the Best Aluminum Cladding Type for Your Project

Table of Contents

Choosing the best aluminum cladding types starts with understanding your project’s specific needs. Consider how you plan to use the building and take into account the weather conditions in your area. Your design ideas also play a crucial role. Selecting the right aluminum cladding types not only enhances the building’s appearance but also improves its performance. Many businesses prefer aluminum cladding because it offers excellent thermal insulation and fire resistance, along with easy maintenance. The impact of aluminum cladding types on buildings is reflected in the table below:

Metric | Data |

|---|---|

$6,355.9 million | |

Projected Market Size (2031) | $10,352.9 million |

Compound Annual Growth Rate (2022-2031) | 5.0% |

Aluminum cladding types protect the exterior of your building, helping to reduce energy costs and promote eco-friendly construction. Every project benefits when you choose the right aluminum cladding types. Keep your goals, budget, and local safety regulations in mind. The following sections will guide you in selecting the best aluminum cladding types for your building.

Key Takeaways

Pick aluminum cladding by thinking about your building’s use. Think about the local weather and your design goals too. This helps keep your building safe and looking good.

Learn about the main aluminum cladding types. These are solid panels, composite panels, ribbed panels, and profiles. Choose the type that works best for your project.

Look at fire safety rules and local codes before you pick cladding. This keeps your building and the people inside safe.

Think about how long the cladding will last. Think about energy use, how easy it is to clean, and the cost over time. This helps you get the most for your money.

Use a checklist and buy from trusted suppliers. This helps you compare choices and make smart decisions for your project.

Aluminum Cladding Types

When you look at cladding for your project, you will see a few main aluminum cladding types. Each type has its own features, uses, and style. If you know the differences, you can pick the best panels for your building.

Solid Aluminum Panels

Solid aluminum panels are made from one sheet of aluminum. These panels are strong and last a long time. They do not rust or get damaged by weather. They are good for busy places and buildings that need more protection. You can pick from many colors and finishes to make your building look special. These panels can be shaped into cool designs and patterns. You often find them in new offices, schools, and hospitals. They are simple to clean and stay nice for years.

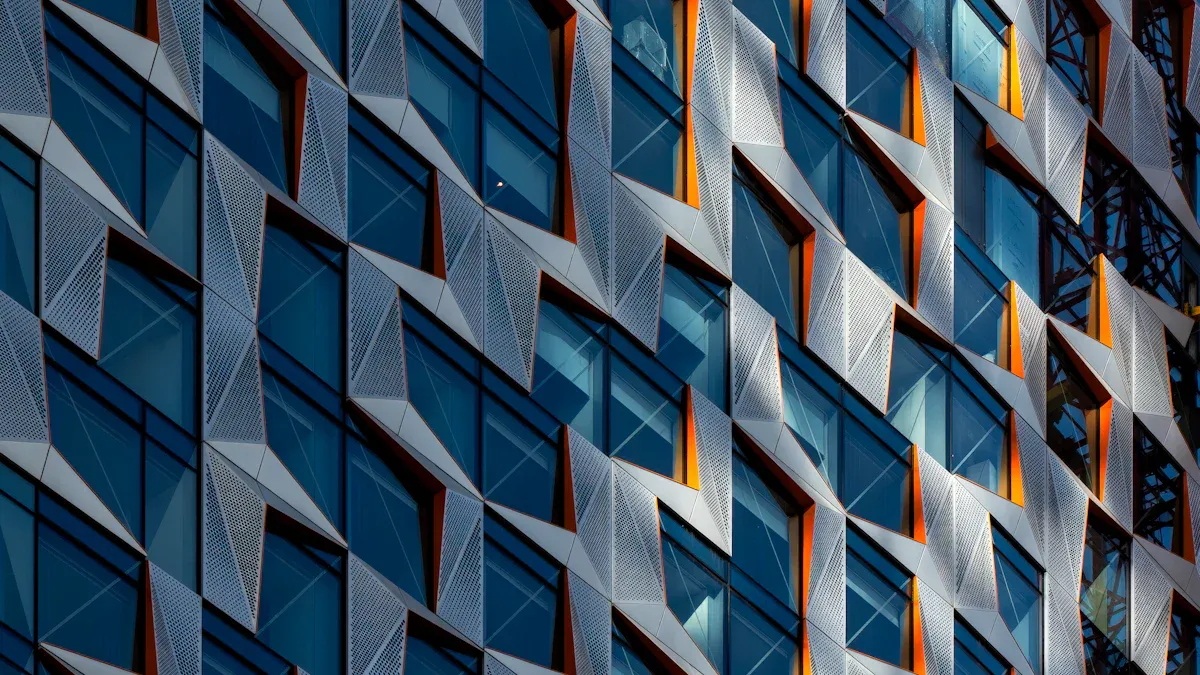

Aluminum Composite Panels

Aluminum composite panels have two thin aluminum sheets with a core in the middle. This makes the panels light but still strong. Many architects like these panels because they are easy to use and look modern. You can bend them into curves or angles and choose from lots of colors and finishes. Some famous buildings, like the VanDusen Botanical Garden Visitor Centre and MassArt Residence Hall, use these panels for their energy savings and design.

Benefits include:

Light weight and easy to put up

Fire resistance with special cores

Stand up to weather and save energy

Help with green building certifications

Risks include:

Damage can be hidden after impacts

Hard to fix if broken

Some places do not allow them on tall buildings

Do not last as long if installed badly

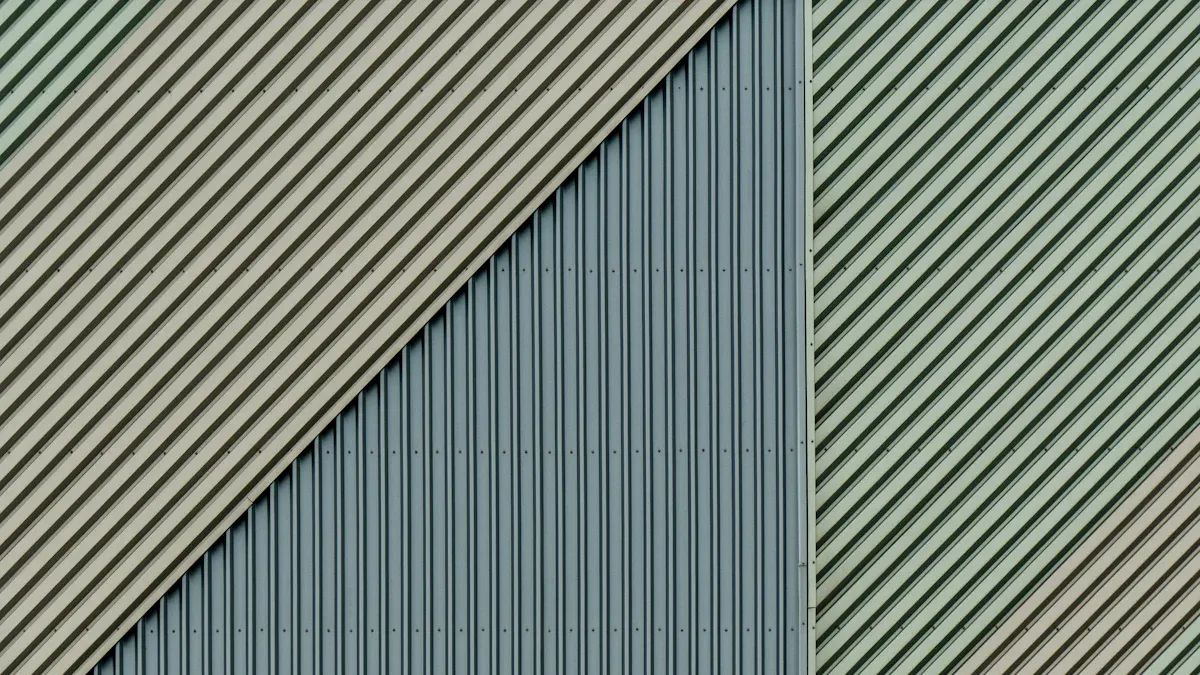

Ribbed and Corrugated Panels

Ribbed and corrugated panels give buildings a bold, bumpy look. These aluminum panels have waves or ridges that make them stronger. You often see them on warehouses, factories, and homes. Ribbed panels help water run off and do not dent easily. They also work well as insulated metal panels to keep buildings warm or cool.

Aluminum Cladding Profiles

Aluminum cladding profiles come in many shapes and sizes. You can pick profiles that fit your design, from flat strips to fancy patterns. These profiles help you make special walls and show off building features. Many designers use aluminum cladding profiles to add shadows and depth to walls. You can mix profiles with other cladding types for a custom look. Profiles also hide joints and keep out bad weather.

Tip: Use aluminum cladding profiles to make your building stand out and work better.

Each aluminum cladding type gives you different ways to protect and decorate your building. If you know about the types, you can make better choices for your project.

Key Factors for Choosing Aluminum Cladding

When you pick cladding for your building, you need to think about a few key things. Each one helps you find the best aluminum cladding for your building, safety needs, and local weather. Let’s look at what you should think about before you decide.

Building Use

How you use your building changes what cladding you need. A hospital, school, or tall apartment needs more safety than a small shop or warehouse. Some buildings need extra fire protection. In the last 25 years, fires from flammable cladding have caused big problems, especially in tall buildings.

The Grenfell Tower fire in London and a fire in a Shanghai apartment showed how dangerous the wrong cladding can be.

After these fires, many buildings changed unsafe panels to fire-safe aluminum or non-combustible aluminum composite panels.

Fire safety rules now help decide which cladding you can use, based on what your building is for.

Tests check how cladding acts in fire and heat, so you can pick the safest one for your building.

You should always check local rules and fire safety standards before you pick aluminum cladding. This keeps your building and everyone inside safe.

Climate and Weather

Your local weather changes how well your cladding works. In hot places, stone cladding can help lower cooling bills more than aluminum composite panels. But you can make aluminum cladding safer and better at saving energy by using special insulation like mineral fiberglass or glass wool.

If you live where fires are common, you need cladding and insulation that do not burn easily.

Tip: Always pick cladding that matches your area’s temperature, rain, and fire risk. This helps your building last longer and saves energy.

Aesthetic Preferences

You want your building to look nice and match your design ideas. Aluminum cladding comes in many colors, shapes, and finishes. You can choose smooth panels for a modern look or ribbed panels for a bold style. Decorative profiles let you add shadows and depth to your building.

Some people mix different cladding types to make a special look.

You can use architectural aluminum cladding to show off special parts or entrances.

Think about how your building will look from the street and how it fits with other buildings nearby.

Budget and Cost

Your budget is important when you pick cladding. Many people think metal cladding costs too much at first. This can make some projects skip aluminum cladding, even though it has many good points.

A market study found that high material and installation costs often make builders pick cheaper choices, especially when money is tight. Even though new technology is making prices lower, aluminum cladding still costs more than some other materials.

Another study showed that aluminum cladding can make your energy bills go up because it needs more cooling in hot weather. But, aluminum is easy to recycle, which can save money over time.

Note: Always look at both the starting price and the long-term costs, like energy and upkeep, when you pick cladding.

Structural Compatibility

You need to make sure your aluminum cladding works with your building’s frame. The right fasteners keep your cladding strong and safe.

Use fasteners made from the same metal as your cladding to stop rust.

Do not use galvanized steel fasteners with aluminum, as they can cause rust.

Stainless steel hardware works well with aluminum cladding, especially in wet or salty places.

If you use wood frames, pick special nails and add barriers to keep both the wood and metal safe.

Engineers use computer models to test how cladding and fasteners hold up under stress, wind, and weather. They look for weak spots and make sure your building stays safe and strong.

Wind Load Capacity

Wind can push hard on your building cladding, especially on tall buildings or in stormy places. You need to pick aluminum cladding that can handle strong winds without bending or breaking.

Engineers use tests and computer models to see how cladding reacts to wind. They check how the panels attach to the building and make sure the whole system stays safe.

Always follow local building codes for wind load. This keeps your building safe during storms.

When you think about all these things—how you use the building, the weather, the look, the cost, the structure, and the wind—you can pick the best aluminum cladding for your project. Matching your cladding to your needs and local rules helps you build a safe, good-looking, and long-lasting building.

Aluminum Cladding Material Performance

Durability

You want your building to last a long time. High-performance aluminum cladding material can handle tough weather. It stands up to acid rain, strong sun, and heavy rain. Special coatings and alloys help stop corrosion. They also help the panels deal with temperature changes. This design lets your cladding last up to 25 years. It also lowers how much you spend on repairs. Galvalume aluminum cladding lasts longer than old galvanized coatings. In salt spray tests, Galvalume does better than other coatings by 20 to 40 times. If you live where hail falls, studies show aluminum cladding panels can take many hits. You can use these results to plan repairs before damage gets worse.

Fire Safety

Fire safety is very important for any building. You should pick aluminum cladding material with third-party certifications. These include the British Board of Agrément (BBA) and fire ratings like Euroclass A1 or A2-s1,d0. These ratings mean the cladding does not burn or burns very little.

Non-combustible cladding helps stop fire from spreading.

Certifications like CCPI show the product data is clear and honest.

Always check fire rules for your building’s type and height.

Being part of industry groups shows a focus on safety.

Independent tests prove your aluminum cladding material meets strict fire rules.

Energy Efficiency

Aluminum cladding can help your building use less energy. Hybrid systems that mix aluminum with polycarbonate save over 4% energy. Energy tests show the right cladding and design can lower energy bills. You can use computer models and machine learning to pick the best aluminum cladding material for your weather. Good insulation and shiny coatings also help keep your building comfy.

Maintenance

You want cladding that is easy to take care of. Aluminum cladding only needs regular cleaning and sometimes a little paint. Extruded aluminum trim costs less to keep up than galvanized steel or PVC. Life Cycle Cost Analysis (LCCA) shows aluminum’s strength and resistance to rot and wear save money over time. You can use tools like spreadsheets or One Click LCA to guess your building’s total maintenance costs.

Sustainability

Sustainable aluminum cladding helps green building goals. Many systems last over 50 years and use recycled metals. When they get old, you can recycle the panels again. Environmental Product Declarations (EPDs) and Life Cycle Assessments (LCAs) show aluminum cladding has less impact when you recycle it. Some studies compare aluminum to ceramic panels and find recycling uses less energy and makes less pollution. New recycling methods make aluminum cladding material even more earth-friendly.

Choosing the Right Aluminium Cladding Material

Grades and Thickness

When picking aluminium cladding material, look at grade and thickness. Different grades give different strength and resistance. Grades like 3003 and 5005 are common. They do not rust easily and are simple to shape. If your building faces bad weather, use a stronger alloy for more protection.

Thickness is important, too. Most aluminium cladding material is between 2mm and 6mm thick. Thicker panels are better for busy places or strong winds. For example, Alcotex® panels are 4mm thick and have a PVDF coating. This coating protects from sun, acid rain, and salt spray. It also keeps its color for at least 10 years, even in tough places. Fire safety matters, so always check if the aluminium cladding material meets rules like NFPA 285-23 or ASTM E 119.

Tip: Thicker panels and good coatings help your building last longer and stay safe.

Workability and Installation

You want aluminium cladding material that is easy to use. Good panels bend and cut without breaking. This helps you make curves or special shapes for your building. Lightweight aluminium panels make installation faster and safer. You need fewer workers and finish sooner.

Installers like aluminium cladding material because it fits many building types. You can put panels on steel, concrete, or wood frames. Use the right fasteners and follow the maker’s instructions. This keeps your panels safe and helps them last longer.

Pick panels that fit your building’s needs.

Use the right tools for cutting and shaping.

Always check for quality certifications before starting.

Cost-Effectiveness

Aluminium cladding material gives good value over time. It costs more at first than vinyl or wood, but you save money on repairs and care. The table below shows how aluminium compares to other materials:

Material | Initial Cost | Maintenance & Durability | Installation Complexity & Cost | Energy Efficiency & Other Benefits |

|---|---|---|---|---|

Aluminum | Higher than vinyl/wood | Low maintenance; resists rot, pests, weather, fire | Lightweight; reduces installation time and cost | Superior thermal insulation and reflectivity; recyclable and sustainable |

Wood | Moderate | High maintenance; sealing, staining needed; prone to rot and pests | Moderate | Renewable but less durable; higher maintenance costs over time |

Vinyl | Low | Prone to cracking; frequent repairs increase long-term costs | Easy installation | Low durability; not recyclable; environmental concerns |

Brick | High | Very durable; minimal maintenance; natural insulation | Labor-intensive and costly installation | Excellent longevity and energy efficiency |

Fiber Cement | Moderate | Durable; resists rot, pests, fire; requires repainting | Moderate | Good balance of cost and performance |

Stone | Very high | Extremely durable; minimal maintenance | Labor-intensive and expensive | Premium aesthetic and longevity |

Steel | Moderate | Durable but requires coatings to prevent rust; maintenance needed | Heavier; installation more complex and costly | Requires added insulation; less energy efficient than aluminum |

You can save up to 30% on care costs over 20 years compared to wood. Aluminium cladding material is also recyclable, which adds value over time. Its energy efficiency helps lower heating and cooling bills. Lightweight panels make installation faster and cheaper, so your project costs less.

Decision Checklist for Aluminum Cladding

Assessing Project Needs

You want to pick the best cladding for your building. A checklist helps you compare choices and avoid errors. Use these steps to help you decide:

1. See if the cladding makes your building look better and keeps out bad weather. 2. Make sure new cladding can swap with old materials and still save energy. 3. Pick cladding that does not let heat pass through easily to lower energy bills. 4. Check that the cladding follows fire safety rules and local codes. 5. Ask about the warranty and how much care the cladding will need. 6. Get experts or trusted groups to approve your cladding choice. 7. Choose cladding that is good for the planet and has green labels. 8. Look up the supplier to make sure they are honest.

A multi-criteria analysis helps you look at all these things. This way, you can see how each cladding type works over time, how much care it needs, and what it costs. This method helps you pick cladding that matches your goals and budget.

Tip: Write down what your project needs and use this checklist to compare each choice. This helps you make a smart and careful decision.

Supplier and Compliance

You must check that your supplier and cladding follow all rules. Good suppliers give you papers that show their products are safe and high quality. The table below lists some important papers and what they mean for your project:

Publication Name | Purpose and Content Description | Relevance to Cladding Form Factors Verification |

|---|---|---|

Light Green Sheets | Registration record for clad aluminum alloy products; includes registered designations, component alloys, cladding location, and other details. | Needed to check what the cladding is made of and its shape. |

Gray Sheets | Contains designations, chemical composition limits, and color codes for aluminum hardeners. | Shows the chemical limits needed for checking if the cladding is right. |

Pink Sheets | Designations and chemical composition limits for aluminum alloys in castings and ingot form. | Helps check if the alloy mix is correct for cladding. |

Tan Sheets | Lists tempers for aluminum and aluminum alloy products registered by producers. | Used to check the temper details for cladding products. |

Teal Sheets | International alloy designations and chemical composition limits for wrought aluminum alloys. | Gives more data for checking alloy types and mix for rules. |

Ask your supplier for these papers before you buy anything. This step helps you avoid trouble with building checks and keeps your project moving. Good suppliers also give you test results and certificates. You can trust their products to be safe and high quality.

You can boost your building’s look and strength by choosing cladding that fits your project goals and budget. Experts say that matching finishes and installation to your needs improves durability, energy use, and design. Real projects show that the right cladding helps buildings last longer and look better. Use the checklist and talk to suppliers or experts for the best results.

FAQ

What is the lifespan of aluminum cladding?

Aluminum cladding can last from 25 to 50 years. If you install it right and clean it often, it lasts longer. Special coatings help stop rust and fading.

Can you paint or refinish aluminum cladding?

You can paint or refinish aluminum cladding if you want. Pick paint made for metal. Clean the panels before you start. Always follow the maker’s steps for the best results.

Is aluminum cladding safe in a fire?

Aluminum cladding with non-combustible cores is safe in fires. Look for certifications like Euroclass A1 or A2. These ratings mean the cladding resists fire and helps keep people safe.

How do you clean aluminum cladding?

Use mild soap and water to wash aluminum cladding. Rinse with clean water after washing. Do not use strong chemicals or rough tools. Clean the panels once or twice a year to keep them looking good.

Does aluminum cladding help with energy efficiency?

Aluminum cladding helps save energy when you use good insulation. Reflective coatings help keep buildings cool inside. The right system can lower your heating and cooling bills.