09 Mar A Comprehensive Guide to Exterior Aluminium Composite Panels in 2025

Table of Contents

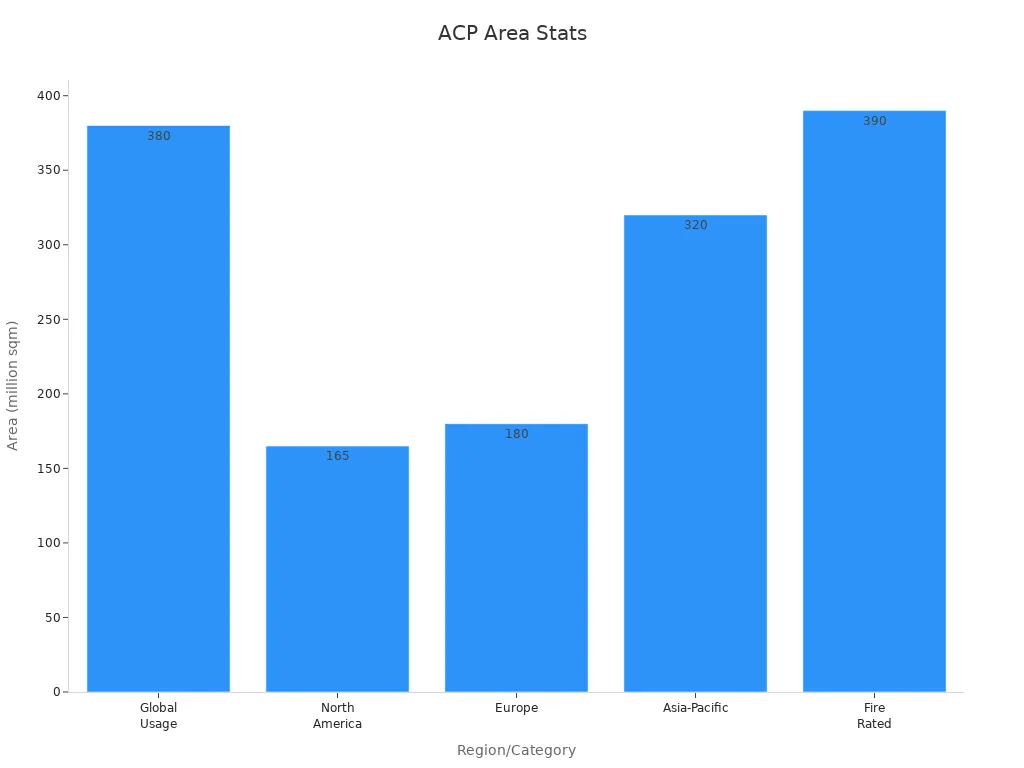

Exterior aluminium composite panels are new solutions for building outsides. Each panel has two aluminum sheets and a strong core. This makes aluminum composite panels light, tough, and able to handle bad weather. The market for aluminum composite panels is growing quickly. This happens because more people live in cities and want better building materials. In 2025, new rules and green labels make people use exterior acp sheets more. These sheets help with fire safety, saving energy, and letting people choose different designs. Many architects pick aluminium composite panels for outside walls and signs. They do this because the panels can be used in many ways and are easy to take care of.

Aluminum composite panels now use recycled materials, better coatings, and smart features. This helps builders follow eco-friendly trends.

Key Takeaways

Exterior aluminium composite panels are tough and light. They do not get damaged by weather. This makes them great for outside walls of buildings.

These panels help save energy. They keep buildings warm in winter. They keep buildings cool in summer. This helps lower heating and cooling bills.

Many panels have fire-resistant cores. This makes buildings safer, especially tall ones. They follow strict fire safety rules.

Panels come in many colors and finishes. They also come in different shapes. Architects can make cool and new designs with them.

If you install panels the right way, they last a long time. Cleaning them is easy. They can look good and work well for over 20 years.

What Is an Exterior Aluminium Composite Panel?

Structure and Materials

An exterior aluminium composite panel has a sandwich-like build. It has two thin aluminum sheets on the outside. These sheets cover a strong core in the middle. The core is usually made from polyethylene or a fire-safe mineral. This setup makes the panel strong but not heavy. The aluminum sheets are about 0.5 mm thick. Makers glue the sheets to the core with special glue. This makes the panel solid and steady.

Each panel gets a special coating on the surface. Some coatings are PVDF, polyester, or nano coatings. These coatings help the panel stand up to weather, sun, and rust. Panels come in different thicknesses like 3mm, 4mm, and 6mm. Builders pick the thickness that fits their needs. There are many colors and finishes to choose from. Some finishes are shiny, flat, brushed metal, or mirror. Some panels even look like wood or stone.

Here is a table that lists the main features of an exterior aluminium composite panel:

Feature | Description |

|---|---|

Structure | Three-layer sandwich: two pre-painted aluminum sheets with a polyethylene or mineral core |

Thickness Range | 3 mm to 6 mm |

Dimensions | Common sizes: 48 in x 96 in to 60 in x 120 in |

Surface Finishes | High Gloss, Matte, Brushed Metal, Mirror |

Color Options | White, Black, Metallic, Red, Yellow, Blue, Green, and more |

Grades | Fire-Rated, DIBOND®, Polymetal™, KOMAALU®, Omega-Bond® |

Performance | Rigid, lightweight, easy to fabricate, good dimensional stability |

Fire Rating | Meets UL 94V-0, ASTM E-84 Class 1 or Class A materials |

Applications | Exterior/interior signage, architectural cladding, displays, kiosks |

The panel’s build makes it easy to cut and bend. This helps builders put up the panels fast. The panels are also good for the environment. Many use recycled aluminum and can be recycled again.

Core Purpose

The main job of an exterior aluminium composite panel is to protect and decorate buildings. These panels keep out wind, rain, hail, and sun. The strong core and aluminum layers make the panel tough. The panel can handle bad weather and daily use.

Exterior acp sheets help save energy in buildings. They keep buildings cool in summer and warm in winter. This can cut energy bills by over 30% when used in ventilated facades. The panels also block some outside noise. This makes rooms inside quieter.

Fire safety is another big plus. Many acp sheet types have fire-safe cores. These panels meet strict fire safety rules like ASTM E84 and EN 13501-1. Builders use these panels on tall buildings to make them safer.

Design choices are a big reason people like these panels. Exterior acp sheets come in many colors, textures, and finishes. Architects can make buildings look modern, bold, or natural. The panels fit many shapes and sizes. They work for new buildings and for fixing old ones.

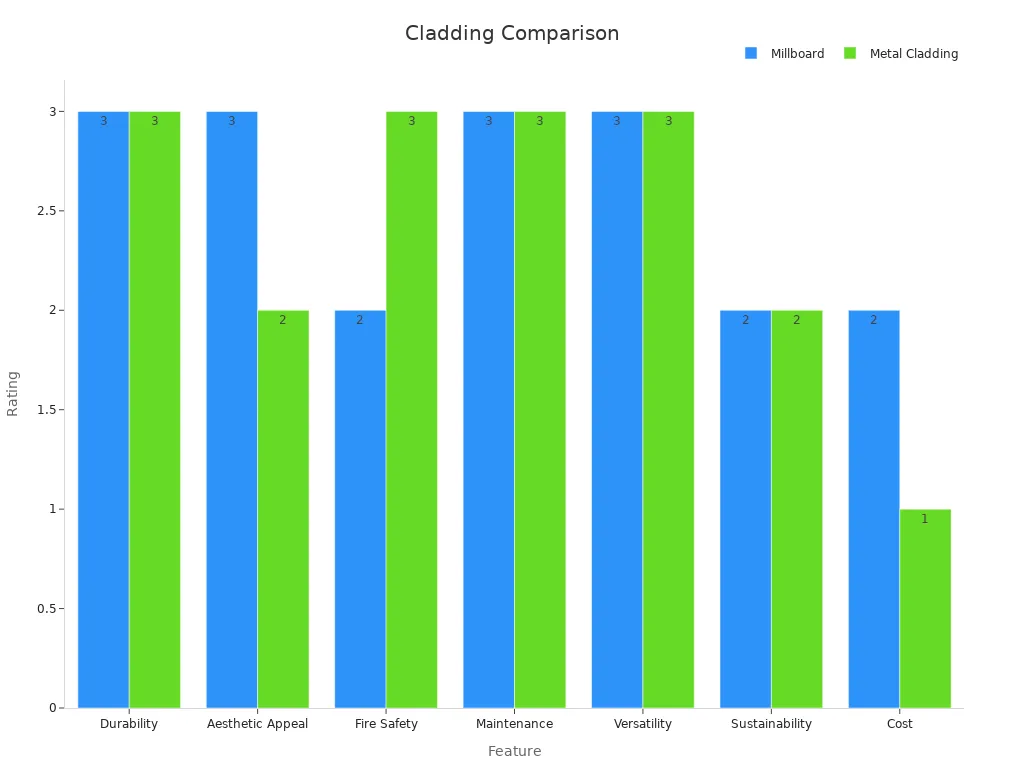

Here is a table that compares aluminium composite panels to other cladding materials:

Feature | Wood | Stone | Concrete | Aluminium Composite Panels (ACP) |

|---|---|---|---|---|

Initial Cost | Moderate | High | Moderate | Moderate |

Long-Term Cost | High (maintenance, replacement) | High (maintenance) | Moderate | Low (minimal maintenance) |

Durability | Low | High | High | High |

Aesthetics | High (natural beauty) | High (natural beauty) | Moderate (monotonous) | High (versatile, customizable) |

Weight | Low | High | High | Low |

Installation Cost | Moderate | High | High | Moderate |

Environmental Impact | High (deforestation) | High (quarrying) | Moderate (cement production) | Low (recyclable materials) |

Fire Resistance | Low | High | High | High |

Water Resistance | Low | High | High | High |

Sound Insulation | Moderate | High | High | Moderate |

Maintenance | High (regular painting, sealing) | Low (minimal) | Low (periodic cleaning) | Low (minimal cleaning) |

Tip: Picking aluminium composite material for outside walls can save money on upkeep and help with green building goals.

Exterior acp sheets are strong, safe, and look good. The panels last a long time and do not need much care. Their build and acp sheet features make them a top pick for new buildings.

Aluminium Composite Panel Features

Durability & Weather Resistance

Aluminium composite panels are very strong and can bend without breaking. They use alloy AW5005, which is both light and tough. This alloy does not rust easily, even near the ocean. These panels can take hits from hail many times. Tests with gas guns show they do not get big dents. The panels keep out wind, rain, and sun. They are light, so builders can put them up fast. This also means buildings do not get too heavy. These acp sheet features help buildings stay safe and look nice for a long time.

Insulation & Energy Efficiency

Aluminum composite panels help save energy in buildings. They stop heat from leaking out through the walls. This keeps rooms warm in winter and cool in summer. People do not need to use heaters or air conditioners as much. The acp sheet features also block noise, so rooms are quieter. Studies show that panels with solar heating and insulation can cut energy use by up to 65%. These features help builders follow green rules like LEED. They also make it easier to meet strict energy laws.

Fire Resistance & Safety

Fire resistance is an important acp sheet feature. Not all aluminum composite panels are safe from fire. Some have a core that burns easily. Others use a special core that stops fire from spreading. Fire-rated panels are safer and follow building rules. Real events, like the Grenfell Tower fire, show why fire safety matters. Builders now pick panels that do not burn fast. They also add sprinklers to keep people and buildings safe. These acp sheet features make them better for tall or busy buildings.

Design Flexibility

Design flexibility is a top acp sheet feature. Aluminum composite panels come in almost 40 colors and many finishes. Some finishes are matte, shiny, metallic, or look like wood. They can even look like copper or zinc. The panels are light but strong, so builders can bend or shape them. They can make curves, domes, or cool patterns. Famous places like the VanDusen Botanical Garden use these panels for special looks. The acp sheet features let architects design modern, bold, or natural styles. These panels work for new buildings or fixing old ones.

Aluminum Composite Panels Applications

Aluminum composite panels are used in many building projects. Their special build makes them a favorite for lots of jobs. These panels are light, strong, and simple to shape. Builders and architects use them to make buildings work better and look nicer.

Building Facades & Cladding

Aluminum composite panels are often used on building outsides. They keep out wind, rain, and sun. These panels help buildings stay comfy and save energy. Many tall and business buildings use them because they are easy to put up and clean. The panels come in lots of colors and styles, so architects can make cool designs. Because they are light, they do not make buildings heavy. This also lets workers finish faster than with old materials. These panels also follow fire and green building rules.

Signage & Branding

Aluminum composite panels are great for making signs. Their smooth top lets pictures and words look sharp and bright. Stores and companies use these panels for signs that are easy to see. Studies show that simple, bold signs on these panels help people remember brands. The panels do not rust or fade, so signs stay nice for a long time. They are easy to wash and need less care than wood or plastic. Fire-safe cores and recycled parts make them safe and good for the planet.

ACP signs cost less and last a long time.

Panels can be cut into many shapes for fun signs.

Signs shine and can be seen even when it is dark.

Architectural Design

Architects use aluminum composite panels in creative ways. The panels fit flat or curved spots, so buildings can have cool shapes. Designers use them for window edges, decorations, and art. The panels are strong like steel but much lighter, so buildings do not need big supports. They help keep rooms warm or cool, which saves money. Many projects use recycled panels, so they are better for the earth. New building styles use these panels because they are flexible, tough, and make buildings look special.

Note: Aluminum composite panels help green building because they can be recycled and help save energy.

Types & Finishes

Core Materials

Aluminum composite panels can have different core materials. These cores help the panels be safe and work well. The first panels used polyethylene cores. These made the panels light and simple to put up. But polyethylene cores can burn fast. Many places do not allow them in tall buildings now. Makers now use fire-retardant cores instead. These cores have minerals or special plastics inside. Fire-retardant cores slow down fire and make panels stronger. Some brands mix minerals and plastics for better safety. Others use honeycomb shapes for more strength and insulation. Inorganic cores are the safest and do not make toxic smoke.

Core Material Type | Fire Safety | Weight | Insulation | Use Case |

|---|---|---|---|---|

Polyethylene (PE) | Low | Light | Poor | Low-rise, signage |

Fire-Retardant (FR) | High | Moderate | Good | High-rise, public areas |

Inorganic (Mineral) | Very High | Light | Excellent | Hospitals, schools |

Tip: Always look at local rules before picking a core material for aluminum composite panels.

Surface Finishes

Surface finishes keep panels safe and make them look nice. PVDF coatings last a long time outside. They protect against sun, rain, and dirt. Polyester finishes cost less and are good for inside walls. Laminating coatings make panels shiny and add extra protection. Oxide film panels do not rust and last longer. New finishes can stop germs and scratches. Some panels block UV rays or keep bacteria away. Designers can pick metallic, wood-grain, mirror, or matte styles.

PVDF: Best for outside, strong against weather.

Polyester: Good for inside walls, saves money.

Oxide film: Very tough, stops rust.

Laminating: Extra shine and protection.

Customization

Aluminum composite panels can be made in many ways. Builders can pick the coating, panel type, and finish. Some panels have digital prints for special looks or logos. Others have coatings for hospitals or schools. Fire-resistant and antibacterial panels are made for safety. Panels come in many colors, textures, and sizes. Some brands use new tech for custom shapes and patterns. People want panels that are safe, green, and easy to clean.

Customization Option | Example Uses |

|---|---|

Digital Printing | Storefronts, branding signs |

Antibacterial Coating | Hospitals, clinics |

Wood-Grain Finish | Offices, homes |

Custom Shapes | Art walls, curved facades |

Note: Custom aluminum composite panels help architects reach any design or safety goal.

Installation & Maintenance

Installation Basics

Aluminium composite panels need careful work when put up. Trained workers usually do the job for the best results. ACPs are light, so they are easy to move and place. Workers can cut and shape them at the building site. This helps the panels fit many building styles. Installers use special brackets and fasteners to hold the panels tight. This keeps the panels safe during strong winds or heavy rain.

Good installation stops problems later. If panels are not lined up right, gaps can show up. Water or dust can get in through these gaps. Installers must leave space for the panels to grow or shrink with heat or cold. In wet or seaside places, experts may use special coatings for extra protection. Good work helps the panels last longer and look nice.

Tip: Always pick skilled workers for ACP jobs. This lowers the chance of damage and helps the panels work well for a long time.

Maintenance Tips

ACPs do not need much care, but cleaning keeps them nice. Most panels need cleaning once or twice each year. In busy or dirty places, clean two times a year to get rid of dirt. In cities or near the sea, one cleaning a year is enough. Use water or mild soap for most cleaning jobs. For hard stains, use gentle cleaners like ethanol or methanol.

Scratches or dents can happen sometimes. Use soft cloths and do not use strong chemicals. If you see damage, fix it fast to stop bigger issues. ACPs do not rust because of their special coatings. In very wet places, use extra care or coatings.

ACPs can last over 20 years with simple care.

Warranties from makers can last up to 25 years.

Cleaning often gets rid of dust, stains, and dirt.

Good care helps panels keep their color and shine.

Here is a table with easy steps for ACP care:

Task | Frequency | Tools Needed |

|---|---|---|

Water Rinsing | 1-2 times a year | Hose, soft cloth |

Mild Soap Cleaning | As needed | Mild soap, sponge |

Solvent Cleaning | For tough stains | Ethanol, methanol |

Surface Inspection | Yearly | Visual check |

Note: Cleaning and good installation help ACPs save energy, block noise, and stay beautiful for many years.

Compliance & Sustainability

Safety Standards

Safety Standards

Aluminium composite panels follow tough safety rules for buildings. Builders and architects trust these panels because they pass fire tests. The NFPA 285 test checks how wall panels act in a fire. Panels with fire-resistant cores use minerals like alumina trihydrate or magnesium oxide. These minerals let out water vapor when they get hot. This helps stop fires from spreading. The metal skins on the panels bounce heat away and slow down flames. If a fire starts, the core can help put out the fire after the flame is gone. Labs test these panels and write reports to show they pass NFPA 285 and other codes. These reports prove aluminium composite panels help keep people safe in buildings.

Tip: Always look for NFPA 285 approval when picking panels for tall or busy buildings.

Environmental Impact

Aluminium composite panels are good for the environment in many ways:

Makers use recycled aluminum and plastic in the panels.

Panels can be recycled when they are old, so less trash goes to landfills.

ACPs last a long time, so you do not need to fix or replace them often.

Panels do not give off bad gases when used.

Making and putting up panels uses less energy than many other materials.

ACPs help buildings get LEED credits and green awards.

Weather-resistant panels protect buildings and lower storm damage.

Good insulation means less heating and cooling, so energy is saved.

ACPs have a smaller carbon footprint than cladding that cannot be recycled.

Light panels use less fuel to move and install.

Less care is needed, so fewer chemicals and less water are used.

ACPs help cities stay healthy by lowering harm to nature and helping plants and animals.

Note: Picking aluminium composite panels helps green building and makes cities safer and better for everyone.

In 2025, aluminium composite panels are very popular in building. These panels are strong and last a long time. They can be used in many ways and are safe. Builders like them because they help save energy and last for years. The market for these panels is growing fast all over the world. Experts say to pick the best panel for each job and ask professionals for help. Hospitals and famous places use these panels and show they work well even in hard weather.

FAQ

What is the lifespan of exterior aluminium composite panels?

Most aluminium composite panels last between 20 and 25 years. Cleaning and taking care of them helps them stay nice. Many companies give warranties for up to 25 years.

Can aluminium composite panels be recycled?

Yes, these panels are made with recycled aluminum and plastic. When they get old, workers can recycle them again. This cuts down on waste and helps green building.

Are aluminium composite panels safe for tall buildings?

Panels with fire-retardant or mineral cores follow strict safety rules. Builders use these panels on tall buildings to help stop fires from spreading.

How do you clean aluminium composite panels?

Use water and mild soap to clean the panels. For tough stains, use a soft cloth and gentle cleaner. Do not use strong chemicals so the finish stays nice.

Do aluminium composite panels come in custom colors and shapes?

Manufacturers make panels in many colors, textures, and shapes. Architects can order special panels for unique designs, logos, or patterns.

Safety Standards

Safety Standards