06 Jun What Are the Key Advantages of PVDF Coating on ACP Panels for Exterior Cladding

Table of Contents

PVDF Coating ACP Panel Advantages for Exterior Cladding stand out due to several clear advantages. ACP panel cladding with PVDF coating offers excellent durability in harsh outdoor conditions. These ACP panels resist fading, corrosion, and damage from weather, which keeps buildings looking new. Many architects choose ACP for exterior application because the panels maintain color and require little maintenance. The advantages of ACP panels make them a reliable solution for any modern facade.

Key Takeaways

- PVDF coatings protect ACP panels from harsh weather, UV rays, and chemicals, keeping buildings strong and colorful for over 20 years.

- These coatings reduce corrosion and damage, making panels more durable and reliable in tough outdoor environments.

- PVDF-coated ACP panels need less cleaning and maintenance due to their smooth, self-cleaning surfaces, saving time and costs.

- The panels offer excellent thermal insulation, helping buildings stay comfortable and lowering energy bills.

- ACP panels with PVDF coatings are lightweight, eco-friendly, and easy to install, making them a smart choice for modern, sustainable construction.

PVDF Coating Overview

What Is PVDF Coating

PVDF coating is a special type of finish made from polyvinylidene fluoride. This material forms a strong, protective layer on surfaces like aluminium composite panels. PVDF coatings have a unique chemical structure that gives them high resistance to weather, chemicals, and UV rays. These coatings also provide a smooth, glossy surface that looks attractive on buildings.

The table below shows how PVDF coating compares to powder coating in several important areas:

Property | PVDF Coating | Powder Coating |

|---|---|---|

Film Thickness | 60-120 μm | |

Service Life | > 20 years | 7-8 years |

Durability | More durable | Less durable |

Weather Resistance | High (UV, chemicals) | Lower |

Color Retention | Better color adhesion and gloss retention | Mostly matte finish, fades over time |

This data shows that PVDF coatings last longer and keep their color better than other finishes. PVDF aluminium composite panels use this coating to protect buildings and keep them looking new for many years.

Why PVDF for ACP Panels

PVDF coatings offer many key benefits of using pvdf coatings on acp. These coatings protect aluminium composite panels from harsh weather, sunlight, and pollution. PVDF coatings resist strong acids, bases, and many organic solvents. The table below lists some physical and chemical properties of pvdf:

PVDF coatings offer many key benefits of using pvdf coatings on acp. These coatings protect aluminium composite panels from harsh weather, sunlight, and pollution. PVDF coatings resist strong acids, bases, and many organic solvents. The table below lists some physical and chemical properties of pvdf:

Property Category | Specific Metrics and Values |

|---|---|

Density | |

Temperature Resistance | -30°C to 150°C; melting point ~177°C |

Mechanical Properties | High tensile strength, impact resistance, abrasion and scratch resistance |

Durability and Aging | Can last over 50 years without loss of properties; excellent UV and weather resistance |

Chemical Resistance | Resistant to acids, bases, oxidizers, reducers, organic solvents |

Surface Properties | Very low surface energy; non-stick; low surface roughness |

PVDF coatings help acp panels stay strong and bright even in tough climates. PVDF aluminium composite panels do not fade or crack easily. These key benefits of using pvdf coatings make them the top choice for exterior cladding. Many architects trust pvdf coating for acp because it keeps buildings safe and beautiful. Aluminium composite panels with pvdf coatings give long-lasting protection and value.

PVDF Coating ACP Panel Advantages for Exterior Cladding

Weather and UV Resistance

PVDF coating acp panel advantages for exterior cladding begin with outstanding weather and UV resistance. PVDF coatings protect ACP from sunlight, rain, and temperature changes. These panels keep their strength and appearance even after years outdoors. The following table shows how PVDF-coated ACP panels perform in key areas:

Performance Indicator | Rating |

|---|---|

UV Resistance | Excellent |

Weather Resistance | Excellent |

Impact Resistance | High |

Heat Insulation | Excellent |

Surface Treatment | PE/PVDF Coating |

PVDF coatings provide excellent weathering resistance and anti-uv resistant qualities. This extremely durable coating helps ACP panels last longer in harsh climates. The panels do not fade or crack, even under strong sunlight or heavy rain. PVDF coatings also meet strict standards for outdoor use, making them a top choice for building exteriors.

Corrosion and Chemical Protection

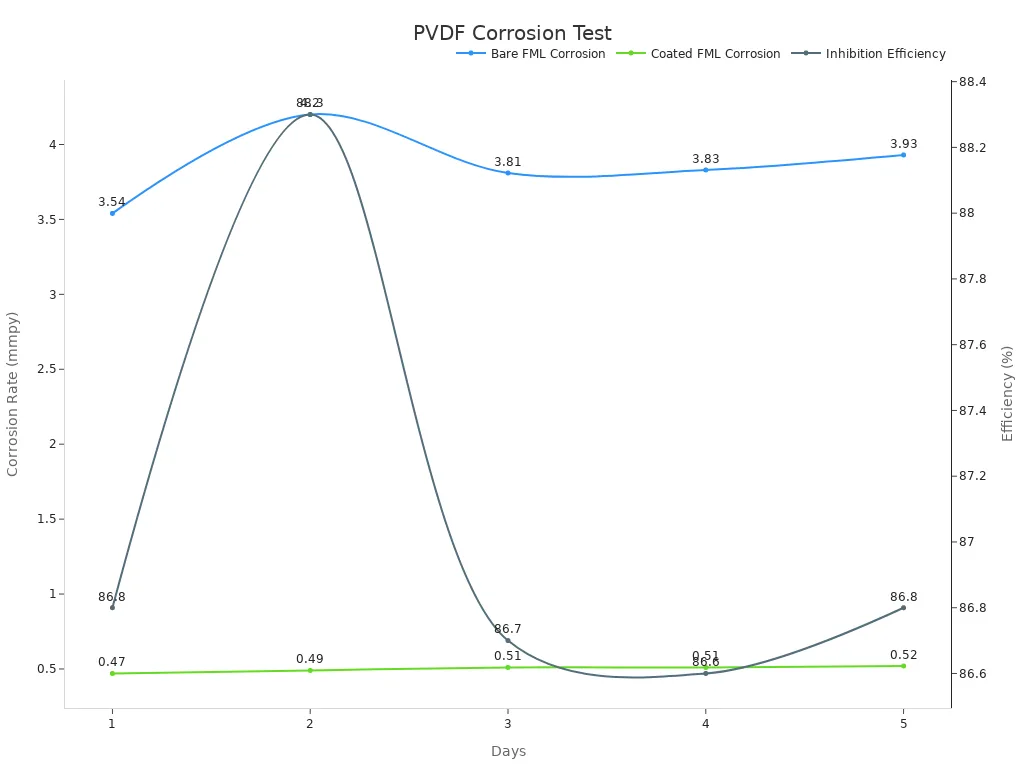

PVDF coating acp panel advantages for exterior cladding include strong anticorrosion and chemical protection. PVDF coatings shield ACP from acids, bases, and pollution. The table below shows how PVDF coatings reduce corrosion rates:

Days | Corrosion Rate of Bare FML (mmpy) | Corrosion Rate of Coated FML (mmpy) | Inhibition Efficiency (%) |

|---|---|---|---|

1 | 3.54 | 0.47 | 86.8 |

2 | 4.20 | 0.49 | 88.3 |

3 | 3.81 | 0.51 | 86.7 |

4 | 3.83 | 0.51 | 86.6 |

5 | 3.93 | 0.52 | 86.8 |

Average | ~3.86 | ~0.50 | 87.0 |

PVDF coatings lower corrosion rates by almost ten times compared to uncoated panels. They also show high adhesion, which means the coating stays attached even in tough chemical environments. This excellent protection keeps ACP panels safe from rust and chemical damage, supporting long-term durability.

Color Retention and Surface Finish

PVDF coating acp panel advantages for exterior cladding also include superior color retention and a smooth surface finish. PVDF coatings use a special fluorocarbon bond that resists fading and keeps colors bright. These coatings protect ACP panels from acid rain, salt fog, and industrial pollution. Some key points include:

- PVDF coatings allow ACP to last over 20 years outdoors without losing color.

- The panels keep their shine and smooth finish, even after exposure to wind, rain, and pollution.

- American research shows PVDF coatings stay stable and durable up to 80% longer than other coatings.

- PVDF coatings pass tough salt spray tests and keep their look after 30 years in harsh weather.

- The panels resist scratches, impacts, and extreme temperatures from -60°C to 150°C.

These advantages make PVDF-coated ACP panels ideal for buildings that need to look good for many years.

Mechanical Strength and Durability

PVDF coating acp panel advantages for exterior cladding extend to mechanical strength and long-term durability. PVDF coatings protect ACP from scratches, impacts, and bending. The multi-layer coating process adds extra strength and shields the panel from damage. PVDF coatings meet or exceed standards like AAMA 2605, which proves their high performance in outdoor settings.

- PVDF coatings give ACP panels long-term resistance to weather, UV, and physical stress.

- The panels do not chalk, peel, or break easily.

- Compared to powder coatings, PVDF coatings offer better UV stability and durability.

This exceptionally durable coating ensures that buildings stay safe and attractive for decades.

Self-Cleaning and Low Maintenance

PVDF coating acp panel advantages for exterior cladding also include self-cleaning and low maintenance. PVDF coatings have a self cleaning quality because of their superhydrophobic surface. Water droplets roll off easily, taking dirt and dust with them. The surface energy is very low, so stains and grime do not stick.

PVDF coatings keep their self-cleaning ability even after bending, peeling, or exposure to heat and UV. In real-world use, PVDF-coated surfaces need less cleaning and cost less to maintain. For example, PVDF membranes in water treatment show high resistance to fouling and can process large amounts of water at a low cost. This means less work and lower costs for building owners.

Thermal Insulation Benefits

PVDF coating acp panel advantages for exterior cladding also include thermal insulation. The polyethylene core inside ACP panels acts as a thermal barrier. This helps keep buildings cooler in summer and warmer in winter. PVDF coatings add another layer of UV protection, which keeps the panels strong and helps control indoor temperatures.

High-quality ACP cladding systems lower energy use for heating and cooling. They prevent heat from passing through walls and stop condensation. This leads to lower energy bills and better comfort inside the building.

PVDF coatings on ACP panels provide a complete package of advantages: excellent weathering resistance, anti-uv resistant properties, anticorrosion, long-term durability, and self-cleaning. These features make PVDF-coated ACP panels the best choice for exterior cladding in any climate.

Advantages of Using ACP Cladding in Practice

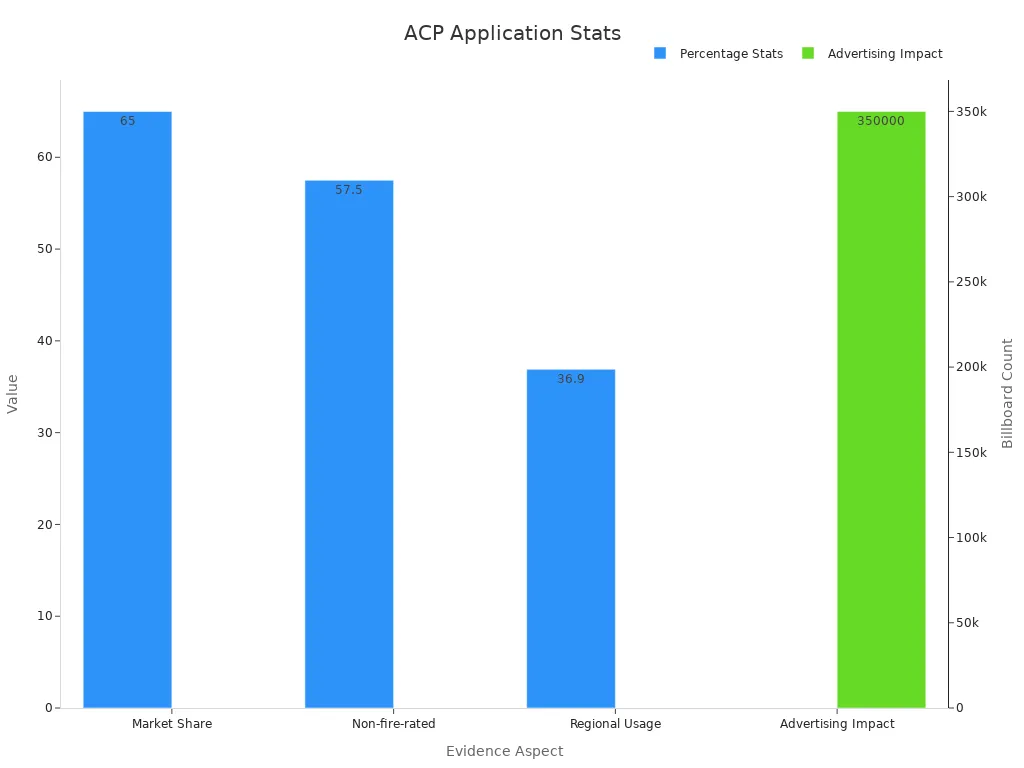

Applications in Architecture

Architects and builders use aluminium composite panels in many types of projects. These panels appear on high-rise buildings, commercial centers, and homes. Their lightweight nature makes installation faster and reduces the load on building structures. The wide range of colors and finishes allows designers to create modern and attractive facades. Fire-rated panels meet strict safety codes, making them a safe choice for public spaces. The table below shows how ACP cladding fits into different architectural needs:

Evidence Aspect | Details |

|---|---|

Building Applications | High-rise, commercial, and residential buildings benefit from lightweight and fire resistance. |

Architectural Appeal | Many colors and finishes; combines durability with aesthetics. |

Weight Advantage | Reduces structural load and construction time. |

Industry Innovations | Self-cleaning, anti-bacterial, and fire-resistant coatings enhance utility. |

Suitability for Harsh Environments

Aluminium composite panels perform well in tough climates. They resist water, chemicals, and temperature swings. Advanced coatings like PVDF add extra protection against UV rays, dirt, and moisture. In cities like Toronto, where buildings face hot summers and snowy winters, ACP panels keep their color and shape. Fire-retardant cores improve safety for exterior cladding applications. Builders follow rainscreen guidelines to prevent leaks and maintain performance.

- Chemically and water resistant

- Withstand high humidity and temperature changes

- Fire-retardant and water-repellent coatings

- Low maintenance due to anti-dirt surfaces

Long-Term Value and Sustainability

The advantages of using acp cladding include long-term savings and eco-friendly benefits. ACP panels last for decades without fading or warping. Their durability means fewer repairs and less frequent replacements. Aluminum is fully recyclable, which supports green building trends. Many government programs encourage the use of sustainable materials. The suitable application of pvdf-coated acp panels helps buildings stay beautiful and strong while reducing environmental impact.

ACP cladding offers a smart solution for modern construction. It combines strength, safety, and style with long-term value.

PVDF-coated panels offer outstanding performance for exterior cladding. These panels resist sunlight, corrosion, and chemicals, which helps buildings keep their color and shine for many years.

- They require little maintenance and remain cost-effective over time.

- The panels use lead-free paints and support green building goals.

Many builders choose PVDF-coated panels because they are easy to install and shape. Their long-lasting beauty and strength make them a smart choice for any project.

FAQ

What makes PVDF-coated ACP panels better for outdoor use?

PVDF-coated ACP panels resist sunlight, rain, and pollution. They keep their color and strength for many years. Builders choose them for long-lasting building exteriors.

How often do PVDF-coated ACP panels need cleaning?

Most PVDF-coated panels need cleaning only once or twice a year. Their smooth surface helps rain wash away dirt. This reduces maintenance time and cost.

Can PVDF-coated ACP panels handle extreme weather?

Yes. These panels stay strong in hot summers and cold winters. They resist cracking, fading, and corrosion. Many architects use them in cities with harsh climates.

Are PVDF-coated ACP panels eco-friendly?

Aluminum in ACP panels is recyclable. PVDF coatings use lead-free paints. Many builders pick these panels for green building projects.

Is it easy to install PVDF-coated ACP panels?

Installers find these panels lightweight and simple to cut or shape. This makes installation faster and safer. Most projects finish on time with less effort.