Products

Showing 1–12 of 24 results

-

2mm Interior Aluminium Composite Panel

-

3mm ACP Aluminium Composite Panel

-

4mm Exterior Aluminium Composite Panel

-

5mm Aluminium Plastic Composite Panel

-

Interior ACP Panel PE Coating Wall Panel

-

Exterior ACP Sheet PVDF Coating

-

Non-combustible A2 aluminium composite sheet

-

B1 Fire Rated Aluminium Composite Panel

-

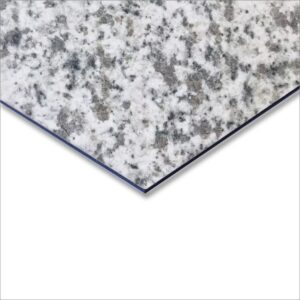

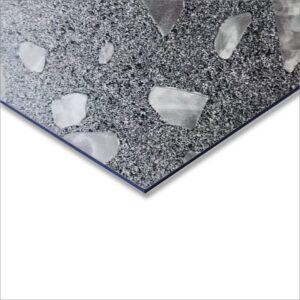

QSJ-0069 Marble ACP Sheet

-

QSJ-0068 Marble ACP Aluminium Panel

-

QSJ-0063 Marble Aluminum Composite Panel

-

QSJ-0061 Marble Composite Panel Aluminium