29 Jul A Complete Guide to Aluminium Composite Panel Sheets for 2025

Table of Contents

Metric | Value | Timeframe |

|---|---|---|

Market Size | $7.02 billion | 2025 |

Units Sold | 650 million | 2025 |

You can trust acp because it is light but strong. It looks modern and comes in new finishes. These features fit well with green building trends.

Key Takeaways

Aluminium composite panels are light and strong sheets. They have two thin aluminum layers. The middle part can stop fires. This makes them safe and tough for many jobs.

ACP panels are used a lot for building outsides, signs, and inside spaces. People also use them in transportation. They do not get damaged by weather, fire, or rust. They come in many colors and looks.

When picking ACP panels, look at fire safety, thickness, and core quality. Also check design choices and if the supplier is reliable. This helps you get safe, stylish, and long-lasting panels.

ACP panels are easier and cost less to put up than solid aluminum. They are also cheaper than other cladding materials. You only need simple cleaning and care to keep them looking good and strong.

Always buy ACP panels with the right certificates and warranties. Work with trusted suppliers who give good help and make sure of quality.

What Is an Aluminium Composite Panel Sheet?

Structure and Materials

An aluminium composite panel sheet has a special sandwich design. It uses two thin aluminum layers on the outside. The middle core is not made of aluminum. Most acp panels have a core of polyethylene or a fire-retardant mineral. Many new acp panels use fire-retardant (FR) cores. These FR cores help the panels meet tough safety rules. They help the panels pass fire tests like NFPA 285 and ASTM E84. The aluminum skins are made from strong alloys. They are usually 0.5mm to 0.8mm thick. These skins make the panels strong and steady when it gets hot or cold.

The top of acp panels gets a special coating. You might see PVDF, polyester, or nano finishes. These coatings protect the panels from UV rays, water, and pollution. The panels stay bright and do not fade for a long time. Most aluminum composite panel sheets can be recycled. This helps cut down on waste and supports green building trends.

Tip: Always look for certifications like ASTM or EN on acp panels. These show the panels meet world safety and quality standards.

Common Uses

Aluminium composite panels are used in many ways. Builders use acp panels for the outside of buildings, like facades. The panels are also good for walls, ceilings, and inside design. You can find acp panels in airports, hotels, and stores. The transportation industry uses these panels too. Makers use aluminum composite panels for train, bus, and truck bodies. The panels are light and strong, so they work well.

Acp panels are also used for signs. The panels have a flat, smooth surface. This makes signs look clear and sharp. Acp panels are popular for ads and displays. More people want aluminum composite panel sheets now. Places like China and India use them a lot because they are building more.

Application Sector | Key Usage Examples |

|---|---|

Facades, exterior cladding, ceilings, partitions, interior decoration | |

Transportation | Vehicle bodies for trains, buses, trucks |

Signage & Display | Advertising boards, signage, displays |

Features of Aluminium Composite Panels

Durability and Weather Resistance

You want acp panels that last a long time. These panels are strong and light. This makes them easy to move and put up. You can use acp outside because they stand up to rain, wind, and sun. The panels have a hard aluminum skin and a tough core. This helps them stay strong in bad weather.

Many acp panels have fire-retardant cores. These cores help keep buildings safer from fire. This is very important for tall or busy buildings. New tests give better fire safety results. You can trust these panels follow strict safety rules. The panels also have PVDF coatings. These coatings block UV rays and keep colors bright. Thicker panels, like 6mm, are better for wind and last longer outside.

Note: Even though acp panels are strong, hail or flying things can dent thin panels. Pick thicker panels if you live where storms are common.

You will see that aluminum composite panel sheets are strong and light. This makes them a good pick for many uses inside and outside.

Surface Finishes and Colors

Acp panels come in many finishes and colors. You can choose glossy, matte, metallic, or even wood and stone looks. This lets you match the panels to any style. There are new finishes like anodized aluminum. These give a modern look and more protection.

Makers keep adding new colors and textures for your needs. You can find panels that look natural or bold for your project. Tests show these finishes stay bright and do not fade, even after years in the sun and rain. This makes acp panels a great choice for creative designs inside and outside.

Finish Type | Description | Best Use |

|---|---|---|

Glossy | Shiny and smooth | Signs, displays |

Matte | Soft, non-reflective | Modern facades |

Metallic | Sleek, metal look | Exterior cladding |

Wood/Stone | Natural textures | Interior panels |

You can use acp panels for many things because they are strong, light, and stand up to weather. The panels give you lots of design choices for inside and outside projects.

Pros and Cons of Aluminum Composite Panels

Main Advantages

Main Advantages

There are many good reasons to pick acp for your project. These panels give you lots of benefits. They are popular and save money. The table below shows how acp panels compare:

Performance/Cost-Benefit Aspect | Description/Advantage |

|---|---|

Lightweight | Reduces building weight, lowers power use, and helps vehicles move faster. |

Strength-to-weight ratio | Gives you strong panels without adding extra weight. |

Fire resistance and non-flammability | Improves fire safety and meets building codes. |

Corrosion resistance | Stands up to weather, pollution, and chemicals. |

Thermal and acoustic insulation | Keeps buildings and vehicles comfortable and energy efficient. |

Ease of assembly and fabrication | Makes installation faster and cuts costs. |

Environmental friendliness | Supports green building goals; some brands use recycled aluminum. |

Technological advancements | New coatings like PVDF boost durability and lower long-term costs. |

Market growth and demand | High demand in Asia Pacific and North America shows strong economic value. |

Application versatility | Works well in construction, transportation, advertising, and more. |

You can use acp in many ways. It is easy to cut and shape. The panels are simple to put up. This saves time and money. Many builders like acp panels because they last a long time. New ways to make them, like autoclave curing, help the panels work better and be greener.

🏆 Tip: If you want a modern look that is light and strong, acp is a smart pick.

Potential Drawbacks

It is important to know the limits of acp. These panels have many good points, but there are some problems too.

Physical vulnerability: acp can get dents in storms or if hit hard. Fixing dents is tough and may not look perfect.

Raw material costs: The price of aluminum and other parts can change a lot. Sometimes, this makes acp less cheap.

Fire safety concerns: Some acp cores can burn fast. Always check the fire safety rating before you buy.

Repair technology costs: New ways to fix panels cost a lot of money.

Market growth limits: High prices and not enough supply can slow down the market, even if many people want acp.

Issue Category | Description | Impact / Statistical Data |

|---|---|---|

Physical Vulnerability | Panels can dent in storms and are hard to fix without losing looks. | Repairs take time and cost more; damage can weaken the structure. |

Raw Material Costs | Prices for aluminum and coatings go up and down. | In India, prices rose 7-10% in 2021; shortages can make panels hard to find. |

Fire Safety Concerns | Some acp cores are flammable, leading to strict rules. | Raises compliance costs and limits use in some places. |

Repair Technology Costs | New repair tools are costly. | Adds to the total price and makes repairs less common. |

You should think about these problems and the good points. Always check the core type and fire safety rating before you pick acp panels. This helps you get the right mix of safety, strength, and value for your project.

Choosing the Right Composite Panel

When you pick the right composite panel, you need to think about a few things. These things are fire resistance, thickness, core quality, design choices, and if your supplier is reliable. Each thing helps you get the best safety, look, and use for your building or sign.

Fire Resistance and Safety

You should always check how well acp panels stop fire and keep heat out. Fire safety is very important for tall buildings or crowded places. In Europe, some aluminum composite panels can stop fire for 30 minutes or more. This depends on the core and how thick the panel is. Mineral core panels are better at stopping fire than polyethylene cores. Many countries now want non-combustible or fire-retardant cores for public and tall buildings. These rules help keep people safe and make companies build safer panels.

Makers test acp panels with rules like EN 13501-1 in Europe and NFPA 285 in the USA. These tests check how fast fire spreads, how much smoke comes out, and how easy the panel burns. New coatings, like intumescent types, can help stop heat and flames from spreading. When you pick acp panels, always look for safety certificates and test results. This makes sure your project follows local building rules and keeps everyone safe.

Tip: Always ask for fire test papers and check if the acp panels have a mineral-filled core for the best fire safety.

Thickness and Core Quality

The thickness and core quality of acp panels decide how strong and tough they are. Thicker panels are stronger and last longer. Thinner panels bend more and work for curved shapes. The core material is important too. A solid, good core with no air holes or foam works better and is safer.

You can use the table below to see what to check:

Specification Aspect | Details | Why It Matters |

|---|---|---|

Solid, no air spaces, no foamed insulation | Prevents weak spots and defects | |

Aluminum Face Sheet Thickness | About 0.50 mm (0.0197 inch) | Ensures even strength |

Thickness Tolerance | +/- 0.008 inch (0.20 mm) for 3 mm to 6 mm panels | Keeps panels consistent |

Bond Integrity Testing | ASTM D1781 standard, no adhesive failure allowed | Makes sure the panel stays together |

Environmental Resistance | Works from -55°F to +175°F, stable under temperature changes | Good for all climates |

You should always check if the acp panels meet these rules. Good acp sheets will last longer and work better, even in bad weather.

Design and Aesthetic Options

You have many choices for how acp panels look and feel. New styles include 3D wave panels, curved cladding, and finishes that look like wood or stone. Some companies make special finishes or green wall systems for nature-friendly design. These choices help you make a cool style and support green goals.

Design Trend / Material Category | Examples / Companies | Key Features / Benefits |

|---|---|---|

Parametric Geometry | 3D Wave Panels, Curved ACP | Unique shapes, custom designs |

Biophilic Design | Green Walls, Planter ACP | Better comfort, extra insulation |

Sculptural Finishes | Etched Stone, Custom Cladding | Sophisticated look, material depth |

Recycled Aluminum | Topbright, M-CITY | Low environmental impact, strong |

Ventilated Facade Systems | Barefoot, Dongjie | Energy-efficient building designs |

You can also pick from many colors and textures. Digital tools like BIM and 3D printing help you see your design before you build. This makes it easier to match your project’s style and brand.

Note: Picking the right acp panels with the right finish and color can make your building stand out and help the planet.

Supplier and Warranty

Picking a good supplier is just as important as picking the right panel. You want a supplier who answers fast, delivers on time, and gives strong warranties. Good suppliers have certificates like ISO 9001 or CE. They let you check where materials come from and how good the product is.

Supplier Name | Certifications/Quality Checks | Warranty Availability | Reorder Rate | |

|---|---|---|---|---|

Singer-Ruser(hz) Building Materials | ≤2h | Customization certifications | Not specified | 17% |

Weifang Jyd Steel Co., Ltd. | ≤1h | QA/QC inspectors, traceability | Not specified | 16% |

Hdt Tubing Co., Ltd. | ≤3h | Warranty available | Yes | 63% |

You should look for suppliers with a good name, happy customer reviews, and a record of on-time delivery. Warranties show the supplier trusts their product to last. Always ask about after-sales help and support. This helps you fix problems fast and keeps your project going.

Check for certificates and test data.

Read what customers say about delivery and quality.

Ask about warranty details and what is covered.

Visit the factory or ask for samples if you can.

🛠️ Tip: A good supplier will help you with how to install, care tips, and quick answers if you have questions.

When you focus on these things—fire safety, thickness, core quality, design, and supplier trust—you make a smart choice. Picking the right composite panel helps you build safe, nice-looking, and energy-saving projects that last.

Composite Panel Materials Compared

ACP vs. Solid Aluminum

ACP vs. Solid Aluminum

When you look at composite panel materials, you can see big differences between ACP and solid aluminum panels. ACP has two thin aluminum sheets with a plastic or mineral core in the middle. Solid aluminum panels are made from one thick sheet of aluminum. This makes them different for cladding and facades.

Feature | Aluminium Composite Panels (ACP) | Solid Aluminum Panels |

|---|---|---|

Composition | Two thin aluminum sheets with a core | Single, thick aluminum sheet |

Weight (4mm thickness) | 6.3 kg/m² | 10.8 kg/m² |

Decorative Options | Many colors and textures | Fewer options |

Flatness | Excellent | Good |

Fire Resistance | Can be fire-retardant | Excellent |

Recyclability | Recyclable | Fully recyclable |

Cost | About half the price | Double the price |

Fabrication | Easy, flexible | Harder, less flexible |

Applications | Facades, interiors, signage | High-impact, fire-sensitive areas |

ACP is lighter than solid aluminum. It is also easier to put up. You do not need as much help or support when you use ACP. Solid aluminum costs more money. It is stronger and better at stopping fire. People use solid aluminum where safety is very important, like on canopies or outside walls.

📝 Tip: Pick ACP if you want to save money and make creative designs. Choose solid aluminum if you need the best fire safety and strength.

ACP vs. Other Cladding

You have lots of cladding choices, like wood, stone, concrete, and high-pressure laminates. ACP is special because it gives you good value, lasts long, and lets you pick many designs. The table below shows how ACP matches up with other cladding:

Feature | Wood | Stone | Concrete | ACP |

|---|---|---|---|---|

Initial Cost | Moderate | High | Moderate | Moderate |

Long-Term Cost | High (maintenance) | High (maintenance) | Moderate | Low (minimal maintenance) |

Durability | Low | High | High | High |

Aesthetics | High (natural beauty) | High (natural beauty) | Moderate | High (customizable) |

Weight | Low | High | High | Low |

Installation Cost | Moderate | High | High | Moderate |

Environmental Impact | High | High | Moderate | Low (recyclable) |

Fire Resistance | Low | High | High | High |

Water Resistance | Low | High | High | High |

Sound Insulation | Moderate | High | High | Moderate |

Maintenance | High | Low | Low | Low |

You can use ACP for outside walls, inside walls, and signs. ACP does not need much care compared to wood or stone. It stands up to water, fire, and bad weather. You get more design choices with ACP. Many architects like ACP for modern buildings because it is light and easy to shape. If you want something that looks good, works well, and does not cost too much, ACP is a smart choice for many projects.

Installation and Maintenance

Installation Tips

Installation Tips

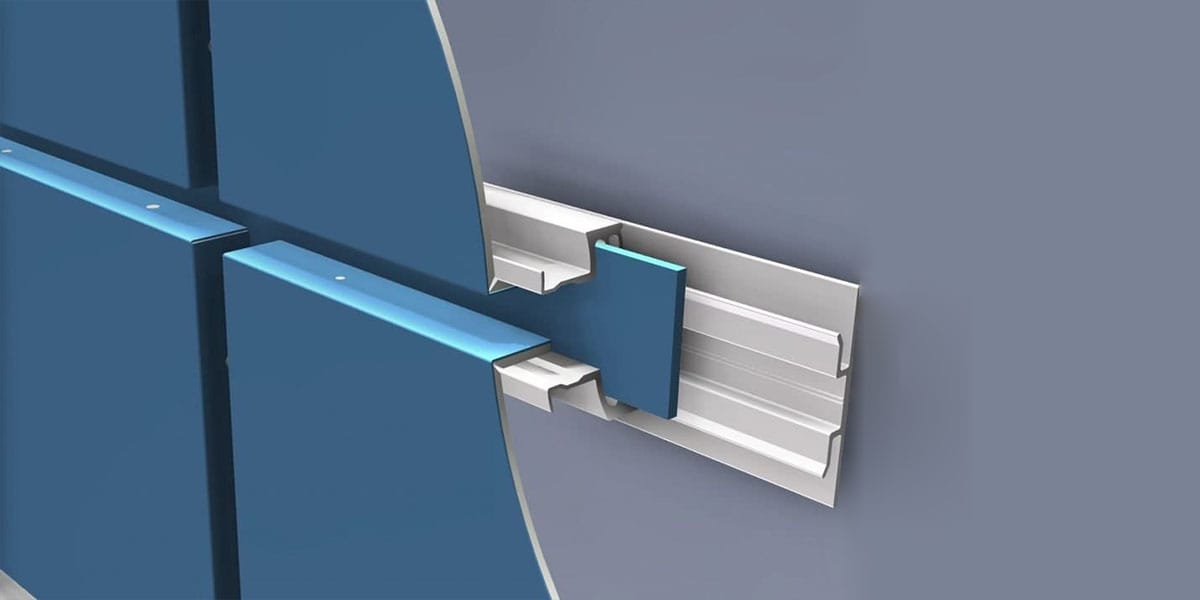

You can get the best results with aluminium composite panels by following some easy steps. First, make a strong base using metal or wood. Make sure all the support pieces are straight and even. Drill holes in the panels and supports before you put them together. This stops the panels from cracking.

Use the right tools, like saws or special cutters, to cut the panels. Always wear safety gear to keep yourself safe. After cutting, smooth the edges with sandpaper or a file. This keeps you from getting hurt and makes the edges look neat. Take off the protective film as soon as the panels get to the site. This stops glue from sticking and keeps the panels clean.

Follow the arrows on the protective film when you install the panels. This helps the color and finish look the same. Use the hanging method so the panels can move when it gets hot or cold. Leave a gap of 10-15 mm between each panel. Fill the gap with a silicone-based sealant. Do not use caulk for sealing. Use the right tools to put on the sealant. Never use your fingers for this job.

Here are some extra tips to help you install panels:

Use a sealant shaped like an hourglass that is twice as wide as the gap.

Pick a backer rod that is about 25% bigger than the gap.

Make joint sizes four times bigger than the movement you expect.

Put oil on moving parts and tighten nuts in a cross pattern.

Check gaskets for problems and put them between panels with care.

Check your work with a level while you install the panels. After you finish, look for any gaps or panels that are not straight. Clean up your work area and throw away waste the right way.

🛠️ Tip: Do not make mistakes like measuring wrong, not cleaning surfaces, or skipping safety steps. These tips help you install panels safely and smoothly.

Cleaning and Care

You can keep your aluminium composite panels looking nice with simple cleaning. Wipe the panels often with a soft cloth and mild soap. Do not use strong chemicals or rough tools that can scratch the panels. Rinse with clean water and dry with a soft towel.

Check the seals and joints at least once a year. Look for cracks or spaces and fix them if needed. Never use high-pressure water, as it can damage the coating. If you see stains, clean them right away so they do not stay.

Taking care of your panels helps them last longer and look bright. This also protects your money and makes sure the panels work well in any weather.

When picking aluminium composite panels in 2025, think about fire safety first. Make sure the panels are strong and last a long time. You also want panels that can fit many styles. Always check if the supplier is good and follows safety rules. Look at the table to see what is most important:

Key Factor | Why It Matters |

|---|---|

Fire Resistance | Keeps buildings safe |

Lightweight Build | Easy to install and handle |

Design Options | Matches many styles |

Supplier Support | Ensures quality and warranty |

This guide helps you pick the right panels for your project. You can feel sure about your choice and get good results.

FAQ

What is the best thickness for ACP sheets?

You should pick 4mm or 6mm thick panels for most building exteriors. Thicker panels give you more strength and last longer. For signs or indoor use, 3mm panels work well.

How do you clean aluminum composite panels?

Use a soft cloth and mild soap. Rinse with clean water. Do not use harsh chemicals or rough tools. You keep the panels looking new with regular cleaning.

Can you recycle ACP sheets?

Yes, you can recycle most ACP sheets. Many brands use recycled aluminum. This helps the environment and supports green building goals.

Are ACP panels waterproof?

ACP panels resist water very well. You can use them outside in rain or snow. Always seal the joints properly for the best results.

How long do ACP panels last?

Most ACP panels last 15 to 20 years. Good care and cleaning help them last longer. Check the warranty from your supplier for more details.

Main Advantages

Main Advantages ACP vs. Solid Aluminum

ACP vs. Solid Aluminum Installation Tips

Installation Tips