11 Aug Aluminium Composite Panel Cladding Specifications and Key Technical Details

Table of Contents

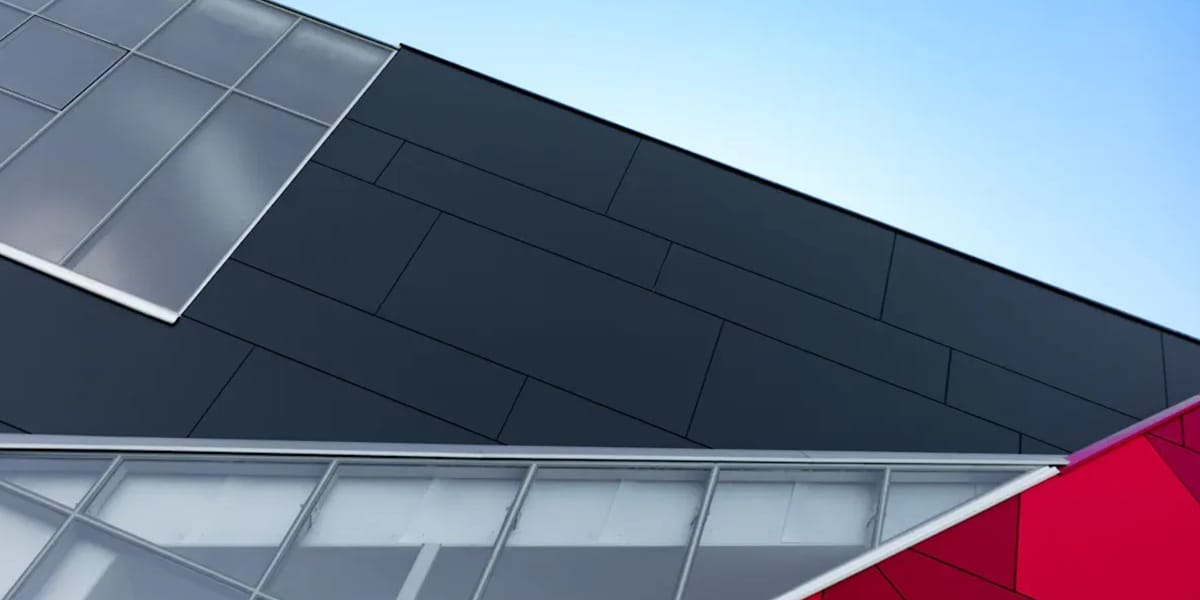

Aluminium composite panel cladding is popular for new buildings. It is strong, flexible, and looks smooth. Architects and builders need to know some important details. These include core composition, thickness, fire ratings, coatings, and how to install it. This helps make sure the panels work well and are safe. The acp market is growing fast. In 2024, it made USD 37.8 billion. It may double by 2034.

Metric | Value (2024) | Projected Value (2034) | CAGR (%) |

|---|---|---|---|

Aluminum Composite Panels (ACP) Revenue | USD 37.8 billion | USD 72.8 billion | N/A |

Overall Aluminum Cladding Market Size | USD 56.5 billion | USD 108.7 billion | 6.8% |

This fast growth shows why picking the right aluminium composite panel cladding is important for every project.

Key Takeaways

Pick the correct core material to follow fire safety rules. This is very important for tall buildings. – Use 4mm thick panels for most projects. This gives a good mix of strength, weight, and cost. – Choose PVDF coatings to protect panels from the sun and rain. This helps the color last and keeps the panels strong. – Install panels with care using the right sealants and mounting systems. This stops water and air from getting inside. – Clean the panels gently every few years to keep them looking nice. This also helps them last up to 40 years or more.

Composition

Core Materials

Aluminum composite panels have different core materials. These materials help the panels work for many building needs. The main types are polyethylene, low-density polyethylene, and mineral-filled fire-resistant cores. Each type changes how the panel handles fire, its weight, and where it can be used. The table below lists the main core types and their fire ratings:

Core Material Type | Mineral Content | Polyethylene Content | Fire Class | Key Characteristics |

|---|---|---|---|---|

PE (Polyethylene) Core | 0% | 100% | B2 | Lightweight, flexible, combustible |

LDPE Core | ~45% | ~55% | B1 | Flame retardant, slows flame spread |

Mineral-Filled Core | 10-30% | A2/A | Non-combustible, high fire resistance |

Mineral-filled cores use safe compounds like magnesium hydroxide and aluminum trihydroxide. These cores help panels get top fire safety ratings. Many tall buildings need these ratings. Some acp sheets use aluminum honeycomb or corrugated cores. These types make the panels strong and stiff.

Aluminum Skins

The outside layers of aluminum composite material are called skins. Skins are important for how long the panels last and how they look. Makers use alloys like 3003, 5052, and AA1100 for these skins. The skin thickness is usually between 0.06 mm and 0.5 mm. Some heavy-duty skins can be up to 0.8 mm thick. Most acm panels are 2 mm to 6 mm thick. Special sizes can be made for unique building needs. Skins can have finishes like brushed, mirror, mill finish, or prepainted. These finishes help the panels stay dry and strong.

Note: Chromate treatment puts a protective layer on the aluminum skin. This layer helps stop rust and makes paint stick better. It also lets the panels fix small scratches by themselves. This keeps the panels looking good for a long time.

Coatings

Coatings keep aluminum composite material safe from weather, sun, and chemicals. The two main types are PVDF and polyester. PVDF coatings protect against sun and keep colors bright. They help panels look new for over 30 years, even in tough weather. Polyester coatings cost less but only last 10-15 years. They can fade faster. The table below shows how the two coatings compare:

Performance Aspect | PVDF Coating | Polyester Coating |

|---|---|---|

Coating Thickness | 25 micrometers or more | ~16 micrometers |

Color Retention | Excellent | Fair |

UV Resistance | High | Low |

Abrasion Resistance | High | Moderate |

Chemical Resistance | High | Low |

Warranty | Up to 30 years | 10-15 years |

Picking the right coating helps panels last longer and work better. PVDF coatings are the best choice for most outside uses in aluminum composite panels and acp projects.

Specifications

Thickness

Thickness

Aluminum composite material comes in many thicknesses. Most panels are between 2mm and 6mm thick. Panels used outside are usually 4mm thick. This thickness gives good strength and is not too heavy. It also helps save money. For inside uses like signs or wall covers, 3mm panels are common. The thickness of the aluminum skins is important too. Good acm panels have skins at least 0.21mm thick. Some skins can be as thick as 0.5mm. Thicker skins make the panel stronger. They also help the panel stand up to wind and hits. This makes them good for tough places.

Common aluminum composite panel thicknesses:

4mm: Industry standard for both interior and exterior cladding.

6mm: Used for specialized exterior projects needing extra strength.

In building projects, the 4mm aluminum composite panel is very useful. It works for many designs and is easy to put in place. It is strong but not too hard to handle.

Panel Thickness | Structural Performance and Properties | Application Suitability |

|---|---|---|

3mm | Flexible, easy to shape, lower strength | Indoor walls, ceilings, signage |

4mm | Balanced strength, good impact resistance, lightweight | Exterior and interior cladding, facades, partitions |

6mm | Highest strength, extra rigidity, heavier | Curtain walls, high-impact exterior areas |

Dimensions

Aluminum composite material is made in standard sizes. This helps save time and materials. The most common size is 1220mm x 2440mm (4ft x 8ft). Other sizes are 1250mm x 3200mm and 1500mm x 3050mm. Special sizes can be made for special building needs. But these can cost more and be harder to install.

Standard panel sizes help stop waste and make work faster.

Custom panels let you make special designs but need more planning.

Factory-made acm panels are cut to the right size. This helps them fit better when installed.

Using standard aluminum composite panels helps keep projects on track and saves money. Custom sizes should only be used if really needed for the design.

Weight and Physical Properties

Aluminum composite panels are much lighter than other wall coverings. Most acm panels weigh between 3 and 8 kg for each square meter. The weight depends on how thick the panel is and what is inside. Because they are light, these panels are easy to move and put up. This means less work and less support is needed.

Material | Average Weight (kg/m²) | Notes |

|---|---|---|

Aluminum Composite Panels | 3 to 8 | Standard thickness panels |

Fiber Cement Siding | ~16.9 | More than twice heavier than ACP |

Stone Cladding | Heavier | Requires more structural support |

Wood Cladding | Heavier | More installation complexity |

Aluminum composite material keeps its shape well. It does not bend or twist much, even when it gets hot or cold. The thermal expansion is about 2.4 mm for every meter if the temperature changes by 100°C. The flexural strength is about 120–143 MPa. These features help acm panels stay strong and keep their shape for a long time, even in bad weather.

Fire Ratings

Fire safety is very important for aluminum composite panel cladding. How well a panel handles fire depends on what is inside and how thick it is. Panels with mineral-filled or inorganic cores get the best fire ratings. These are called A2 or A in many countries. These panels can last up to two hours in a fire. This makes them good for tall buildings and places where many people go.

Aspect | Details |

|---|---|

Applicable Standard | |

Certification Scheme | BIS Product Certification Scheme (ISI Mark) |

Mandatory Compliance | Yes, for legal marketing and consumer safety |

Key Fire-Related Tests | Limiting oxygen index, Smoke density rating, Ignitability, Flame spread, Non-combustibility |

Other Tests | Dimensions, Tensile strength, Peel strength, Coating thickness, Adhesion, Weather resistance, Chemical resistance |

Certification Importance | Ensures safety, quality, and legal compliance for ACPs in India |

IS 17682:2021 is the rule for aluminum composite material in India. It covers fire safety and how long the panels last. Only acm panels with BIS certification can be sold or used in buildings. The rule checks fire safety, strength, weather resistance, and coating quality. Mineral cores and good coatings help panels pass tough fire tests. This helps aluminum composite panel cladding meet strict safety rules.

Picking the right core and following IS 17682:2021 makes sure aluminum composite panels are safe and work well for any wall covering project.

Aluminium Composite Panel Cladding Systems

Mounting Systems

Mounting Systems

Aluminum composite material cladding uses different ways to attach panels. These ways help keep the panels safe from wind and rain. Each system has special parts that help the panels stay in place.

Shims help line up the panels and set the space between them.

Furring makes a flat area for the panels to sit on.

Fasteners keep the panels tight and are often hidden.

Gaskets and sealants stop water from getting in the joints.

Flashing adapters and masking move water away and protect the edges.

Panel stiffeners make big or bendy panels stronger.

Each mounting system has its own good points. Hanging systems let the panels move a little when it gets hot or cold. They are easy to fix and work well for big walls. Male-female interlocking systems snap together and make the joints smooth. They also help the panels stand up to strong winds. Riveted systems use strong fasteners and are good for places with lots of wind. Glued systems hide the joints and keep out water. Some systems, like the ACM 3000 Dry & Wet System, pass tough tests for strength and water safety.

Joints and Sealing

Good joints are very important for aluminum composite material cladding. Joints must keep out water, air, and dust. There are different sealants for aluminum composite panels.

Polyurethane (PU) sealants stick well and bend easily. They can last up to 20 years.

MS polymer sealants are great in bad weather and last at least 15 years.

Silicone sealants are very strong against sun and chemicals. They can last up to 40 years.

Acrylic sealants work well between metal and concrete. They also block the sun.

Installers use foam strips behind the sealant to help fill the gap. Gaskets made from strong rubber or plastic go between the panels to stop leaks. These things help the panels work well inside and outside.

Tip: Always pick fasteners and gaskets that match the panel finish. This stops rust and helps the panels last longer.

Installation Guidelines

To install aluminum composite material cladding, you need to plan first. Workers measure and mark where each panel will go. They cut and shape the panels with special tools to make the joints fit well. Panels are fixed to the building with glue, fasteners, or clips. Installers follow the maker’s rules.

Here are the main steps for putting up the panels:

Seal all joints, corners, and edges with the right sealants or gaskets.

Keep the space and level the same across the whole wall.

Use trim and flashing to cover edges and make it look nice.

Check gaskets and fasteners for any problems before using them.

Tighten bolts in a cross shape to spread the pressure.

After the panels are up, check and clean them often. Take off the plastic film after the sealant dries to stop stains. Getting help from experts keeps the panels looking good for a long time.

Performance and Maintenance

Durability

Durability

Aluminium composite panel cladding lasts a long time. Most panels stay good for 25 to 40 years. This depends on how good the materials, coatings, and installation are. If the panels use strong alloys and PVDF coatings, they can last even longer. Sometimes, panels last up to 70 years if you take care of them. Companies often give warranties for 20 to 30 years. This shows they trust their product. If you clean and check the panels often, they can handle bad weather, pollution, and saltwater. In places near the ocean or factories, you may need extra protection to keep the panels strong.

Tip: Check and clean the panels often to help them last as long as possible.

Insulation

Aluminium composite panels help keep heat and noise out. The core between the aluminum layers blocks heat and sound. These panels reflect up to 95% of heat from the sun. This keeps buildings cool in summer and warm in winter. You do not need to use as much heating or cooling. This saves energy and money. The panels also stop outside noise, so rooms are quieter. Unlike old materials, aluminium composite cladding does not change shape much when it gets hot or cold. This means the insulation works well all the time. The panels are good for green buildings and can help get green building awards.

Main insulation benefits:

Keeps indoor temperatures steady

Uses less energy

Stops moisture and fire

Cleaning

Cleaning aluminium composite panel cladding helps it look nice and work well. Dirt and dust can build up over time. Start cleaning at the top and move down. Use soft sponges or microfiber cloths with gentle soap. Do not use strong chemicals like bleach or acids. These can hurt the panel’s surface and coating. Do not use rough pads or hard brushes. Jet washing and steam cleaning are safe if you are careful. For big or tall buildings, you can hire cleaning experts. Clean the panels every 3 to 5 years. If the area is very dirty, clean them more often.

Note: Always try any cleaner on a small spot first to make sure it does not damage the surface.

Choosing aluminum composite panel cladding means you need to think about some important things:

The core material and fire rating should follow building rules, especially for tall buildings.

The thickness, finish, and how you put up the panels change how safe, strong, and nice they look.

Panels must move a little when it gets hot or cold and let water vapor out.

Experts say you should look at technical data sheets and talk to professionals for every project. Groups like SGS and ASTM give certifications to show the panels are safe and good quality. If you need more help, ask certified suppliers or technical support teams.

FAQ

What is the lifespan of aluminum composite panel cladding?

Most aluminum composite panels last from 25 to 40 years. If the panels have PVDF coatings, they can last even longer. Cleaning and checking the panels often helps them last more years.

Can aluminum composite panels be recycled?

Yes, aluminum composite panels can be recycled. Factories can take off the aluminum skins from the core. The recycled aluminum can be used to make new things. This makes ACPs a good choice for the environment.

Are aluminum composite panels waterproof?

Aluminum composite panels keep water out. If you install them right and seal the joints, water cannot get in. Flashing also helps stop leaks and keeps the building safe from water damage.

How do you repair scratches or dents on ACP cladding?

You can polish small scratches or use touch-up paint to cover them. If there is a dent or big damage, you need to change the panel. Always use the repair steps from the manufacturer.

Do aluminum composite panels require special cleaning products?

No, you only need mild soap and water to clean them. Do not use strong chemicals or rough tools. Use a soft cloth or sponge to wipe the panels. Try any cleaner on a small spot first to make sure it does not hurt the surface.

Thickness

Thickness Mounting Systems

Mounting Systems Durability

Durability