05 Sep What Makes Fire-rated ACP Essential for Modern Curtain Wall Applications

Table of Contents

Modern buildings must focus more on fire safety now. This is very important for tall and public buildings. Some recent disasters show the dangers:

The Grenfell Tower fire in London killed many people.

The Sharjah fire in 2020 made rules for building cladding change.

Fires in Milan, Hong Kong, and Islamabad caused deaths and damage.

These events made people want fire-rated acp more in building work. Builders, architects, and owners now choose fire-rated acp for curtain wall systems. They do this to follow new safety rules and keep people safe.

Key Takeaways

Fire-rated ACP panels have a special mineral core. This core stops fire and keeps flames from spreading. It helps make buildings safer.

These panels follow strict fire safety rules. They help protect people by slowing down fire, smoke, and heat in emergencies.

Fire-rated ACPs are strong and can handle bad weather. They come in many colors and textures. This lets people design creative and lasting buildings.

Picking certified fire-rated ACP and putting them in the right way with fire barriers gives strong protection. It also follows the law.

Cleaning and checking fire-rated ACP panels often keeps them working well. This helps keep the building safe for a long time.

Fire-rated ACP in Curtain Walls

Aluminum Composite Panel Structure

Aluminum composite panel technology has changed how curtain walls are built. Each panel has two thin aluminum sheets with a core in the middle. Standard panels use a core made of polyethylene. Polyethylene burns easily and does not protect buildings well in a fire. Fire-rated ACP panels use a mineral-filled core instead. This core does not burn and can handle heat and flames much better.

Panel Type | Core Composition | Fire Resistance | Typical Applications |

|---|---|---|---|

Polyethylene (PE) core | Basic fire resistance | Interior walls, signs, low-risk areas | |

Fire-Rated ACP | Mineral-filled core | High fire resistance | Tall buildings, hospitals, schools |

Fire-rated ACP panels have a mineral core made from things like magnesium hydroxide and aluminum trihydroxide. These minerals do not catch fire and help the panel stay strong in high heat. The mineral core also stops toxic smoke and melted drops from forming, which can happen with standard panels. This design helps fire-rated aluminum panels pass tough fire safety tests like ASTM E84 and NFPA 285. They can resist fire for up to 120 minutes.

Modern curtain wall buildings need more than basic fire resistance. Old systems with float glass and regular aluminum frames do not work well in fires. Float glass breaks, and aluminum melts at about 660°C. Sealants and gaskets at joints often fail, letting fire and smoke get through. Weak spots between curtain walls and other parts of the building let fire spread fast. Without good fire-stopping, flames can move between floors and through air spaces, putting people and property in danger.

Note: Fire-rated ACP panels fix these problems by making a strong, fire-resistant barrier. They help keep the curtain wall safe during a fire and protect people inside.

Fire Retardant ACP Core Materials

The core of a fire retardant ACP is important for fire safety. Makers use different minerals and inorganic materials to get the right fire resistance. The most common fire retardant ACP core materials are:

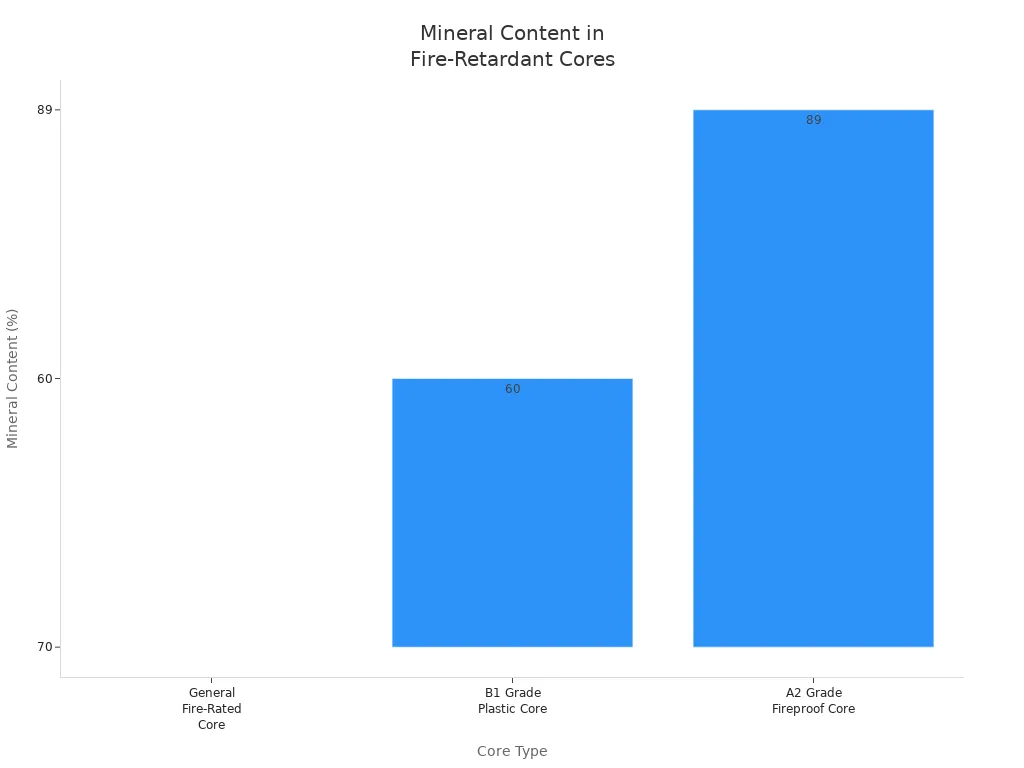

Mineral/Inorganic Components | Mineral Content (%) | Additional Notes | |

|---|---|---|---|

General Fire-Rated Core | Calcium Hydroxide, Magnesium Hydroxide, Aluminium Hydroxide, Magnesium Oxide | ~70% or more | Mixed with polymers (~30%), halogen-free, self-extinguishing, smoke suppression |

B1 Grade Plastic Core | Aluminum Oxide (Al₂O₃), Magnesium Oxide (MgO) | 55% – 65% | Flame retardant content mainly aluminum and magnesium oxides |

A2 Grade Fireproof Core | Aluminium Hydroxide (Al(OH)₃), Magnesium Hydroxide (Mg(OH)₂) | 88% – 90% | Higher mineral content, better fire resistance, halogen-free, environmentally friendly |

A2 grade fireproof cores have up to 90% mineral content. This makes them the best choice for tall and public buildings. These cores are halogen-free, put out their own flames, and stop smoke. Fire retardant ACP panels with these cores meet the highest fire and environmental safety standards.

Fire-rated ACP panels for curtain walls must meet strict fire ratings. In China, panels are sorted as Class A (non-combustible), Class B1 (flame retardant), Class B2 (combustible), or Class B3 (flammable). Most fire-rated ACP panels get a B1 rating, which means they slow down fire and resist flames. Some panels reach Class A for even more protection. These ratings match building codes that say wall materials must be Class A or B1 for fire safety.

New ways to make fire-rated ACP have made them safer and better looking. Makers now use new coatings and better core materials for more fire resistance and strength. They offer more colors and textures, so fire-resistant aluminum-plastic plates fit many building styles. Green manufacturing uses recycled materials to help the environment.

Better fire-retardant properties and strength from improved core materials.

More color choices and textured finishes for design.

Greener manufacturing with recycled materials and better recycling.

Use of mineral or non-combustible cores to meet tough fire rules.

Panels are now used for more than just facades, like inside walls and partitions, because of new rules and green trends.

Fire-rated ACP panels are now very important in curtain wall building. They mix fire safety, strength, and design choices, making them needed for modern buildings. Architects and builders use these panels to follow safety codes and keep people safe from fire.

Benefits of Fire-rated ACP

Fire Resistance and Safety

Aluminum composite panels help stop fires in buildings. Each fire-rated ACP has a core with minerals that do not burn. This core slows down fire and keeps it from starting easily. The panels are good for building walls and facades. The fireproof core stops flames from spreading fast on the outside. In tall buildings, hospitals, and schools, this helps keep people and things safe.

Fire-rated aluminum composite panels follow strict building rules. They pass tests like NFPA 285 and ASTM E119 for fire safety. The panels stay strong during a fire and do not fall apart. They are light, so workers can install them easily. Fireproof cladding also helps building owners avoid legal trouble.

Fire-rated ACPs keep fire in one place. This gives people more time to leave and helps firefighters do their job.

Using the cassette system makes fire resistance better. This method protects the edges and keeps panels in place during a fire. Fire barriers and fire stopping behind the panels add more safety. They stop fire from moving between floors or behind the cladding. All these features make aluminum composite panels a great choice for fire safety in curtain walls.

Smoke and Heat Control

It is important to control smoke and heat in a fire. Aluminum composite panels with fireproof cores limit smoke and heat when they burn. The mineral core does not catch fire, so less toxic smoke forms. This helps people leave safely and lowers the risk of breathing in smoke.

Tests show fire-rated aluminum composite panels work well in fires. The oxygen index test checks how panels handle heat and flames. Cement plastering may control smoke better, but fire-rated panels are still much safer than regular ones. Building codes say these panels must meet tough smoke and heat rules.

Aspect | Performance of Fire-rated ACPs |

|---|---|

Fire Spread and Smoke Control | |

Flammability Characteristics | Mineral core reduces risk of rapid fire growth |

Testing Standards | Meets or exceeds NFPA 285, ASTM E84, and oxygen index |

Fire Safety Measures | Works best with fire barriers and non-combustible layers |

Fire-rated aluminum composite panels cannot stop all smoke and heat by themselves. Fire barriers and insulation behind the panels are needed for full safety. Together, these systems help keep fire, smoke, and heat under control.

Durability and Aesthetics

Aluminum composite panels last a long time on curtain walls. They do not get damaged by weather, rust, or fading. Special coatings protect them from sun, pollution, and scratches. This means less work to keep them looking good and saves money over time.

Fireproof cladding lets designers be creative. Aluminum composite panels come in many colors, textures, and shapes. Architects can pick finishes that look like wood, stone, or metal. The panels are light but strong, so they can make big shapes without heavy supports.

Facade Material | Durability & Maintenance | Long-term Aesthetics & Design Flexibility |

|---|---|---|

Fire-rated ACPs | Wide range of colors, textures, and shapes; mimics wood and stone | |

Solid Aluminum | Corrosion and weather resistant | Less design flexibility compared to ACPs |

Wood | Prone to warping, rotting, pest damage; high maintenance | Natural, timeless appeal but limited finishes |

Stone | Very durable but heavy; requires robust support | Stone-like finishes available on ACPs |

Cleaning the panels with soap and water keeps them nice. Checking them often helps find damage early and keeps fire safety strong. The panels are light, so moving and installing them is easier and better for the environment. Many aluminum composite panels use recycled materials and can be recycled later. This helps green building projects.

Fire-rated ACPs mix fire safety, strength, and design choices. They are a smart pick for modern curtain wall systems.

Standards and Certifications

EN13501 and IS 17682:2021

Fire safety standards help builders pick safe materials. EN13501 is a rule used in Europe. It checks how building products react to fire. Materials get ranked from A1 to F. A1 means the material does not burn. F means it burns easily. A class a fireproof metal composite panel gets the best fire rating. These panels do not spread flames much. They also do not make a fire worse. The rating checks for smoke and burning drops too. This helps people leave safely if there is a fire.

IS 17682:2021 is a rule used in India. It checks how metal composite panels react to fire. The tests are like the ones in EN13501. Both rules say a grade fr metal composite panel must pass hard fire tests. If panels meet these rules, buildings can get legal approval. This keeps people inside safe.

Using a class a fireproof metal composite panel helps buildings follow strict codes. It also lowers risks if there is a fire.

ASTM E2307 and Local Codes

In the United States, ASTM E2307 is an important rule. It checks fire safety for curtain walls. The test looks at how well fire barriers work. It uses a special machine to see if the barrier stops flames and heat. The test is for systems with a grade fr metal composite panel.

ASTM E2307 gives two scores:

F-rating: How long fire is stopped.

T-rating: How long the other side stays cool.

The International Building Code says buildings need these tests.

Local rules often use IBC and may add more fire checks.

A class a fireproof metal composite panel with a strong core helps meet these rules. This makes sure curtain walls keep people and things safe during a fire.

Applications of FR ACP

Curtain Walls and Facades

Curtain Walls and Facades

Aluminum composite panel technology has changed how buildings look. These panels give strong fire protection. That is why they are used for tall building walls. Many places like malls, offices, hotels, and airports use these panels. The panels are light but also very strong. This helps builders make safe and nice-looking walls.

High-rise office buildings

Hotels

Exhibition centers

Airports

Other public buildings

Architects pick fire retardant cladding because it stops fire and follows safety rules. For example, the Kimpton Pittman Hotel in Dallas used over 1,000 special aluminum composite panel units with a fire-rated core. The project used new ways to make and put up the panels. This made sure the building was safe and looked good. The Marina Bay Sands Hotel in Singapore also uses fireproof wall panels outside. This shows that aluminum composite panel systems can make curved walls and keep people safe from fire.

Project Name | Location | Description | Key Features | Architect | Size (sq ft) | Services Provided |

|---|---|---|---|---|---|---|

Kimpton Pittman Hotel | Dallas, Texas | Old building fixed up with a new part using fire-rated core aluminum composite panels for 1,000 custom metal panels. | Used 3D laser scanning, custom making, KSC 2100 rain-screen system, and special louvers. Careful planning for busy city area. | Perkins + Will | 12,000 | Design Help, 3D Scanning, Custom Making, Installation |

ALUCOBOND® PLUS panels passed the NFPA 285 fire test. They meet the 2022 NYC Building Code. This lets architects use these panels for tall building walls and follow fire safety rules.

Other Uses in Building Design

FR ACP is used for more than just outside walls. Builders use aluminum composite panel products inside too. They work for wall covers, room dividers, columns, and signs. These fire resistant panels help keep halls and public spaces safe. Hospitals and schools use aluminum composite panel systems for safety and design choices.

Fire retardant cladding is also good for soffits, canopies, and balconies. The panels do not burn, rust, or get damaged by weather. This makes them good for inside and outside jobs. Designers use aluminum composite panel systems to make bold shapes and bright colors for entrances and special walls. FR ACP is used for both safety and decoration. It helps architects follow fire rules and be creative.

Tip: Check and clean aluminum composite panel cladding often. This keeps fire safety strong and makes walls look new.

Aluminum composite panel products help green building. Many panels use recycled materials and can be recycled again. This makes fireproof wall panels a smart pick for eco-friendly projects.

Selection and Installation

Choosing the Right Fire-rated ACP

Picking the right fire-rated aluminum composite panel is very important for safety. Architects and builders need to think about many things before they decide.

The project’s needs are important. Some buildings need panels that are strong and light. Other projects care more about saving money.

The weather matters too. Panels with PVDF coatings do not rust or fade in the sun. These are good for places with tough weather.

Fire safety is a big deal. Panels with mineral-filled cores protect better and follow strict rules.

Being eco-friendly is also important. Panels made from recycled stuff help green building projects.

How much money and time you have can change your choice. Modular systems help save both time and money.

What the panel is made of, how thick it is, and its fire rating all matter for how well it works and how much it costs. Good brands and certified panels keep people safe for a long time. Most panels are 3 to 6mm thick. This makes them strong but not too heavy. Special coatings like PVDF or anodized finishes help the panels last in bad weather. Using prefabricated systems means less waste and faster building. Aluminum does not rust, so it works well near the ocean or in wet places. It is important to meet fire safety ratings like A2-s1, d0 for many jobs.

Makers test panels to meet rules like ASTM D1929 and EN 13501-1. They use outside labs to check fire resistance. These steps make sure panels are safe and follow the law.

Tip: Always look for certifications and make sure panels follow the rules before using them for curtain walls.

Integration with Building Systems

Making sure fire-rated ACP works well with other building parts is key for fire safety. The first step is picking the right materials. Builders use fire-resistant things like fiber cement, metal cladding, and mineral wool insulation to make a strong wall system.

Use the right way to put up panels. Fasten them with good anchors and seal every joint with fire-resistant sealant. This stops fire from getting through weak spots.

Follow all building codes and rules. Using standards like the International Building Code and NFPA keeps the building safe and legal.

Plan the system early. Architects and engineers should work together from the start. This helps fire-rated panels fit with other building parts and avoids problems later.

Check and fix the panels often. Looking for damage or bad seals keeps the system strong and safe from fire.

Makers spend time and money on research and testing to keep up with new fire safety rules. They make panels with mineral-filled cores that slow down fire, smoke, and bad gas. These new ideas make fire-rated ACP a good pick for many uses, like tall building walls or inside dividers.

Note: Checking panels often and putting them in the right way keeps buildings safe from fire and helps curtain walls last longer.

Fire-rated aluminum composite panels are important for curtain walls. They help stop fires and follow safety rules. These panels can handle bad weather and do not need much care. This saves time and money for building owners. Architects like them because they can make cool shapes and finishes. Owners should check the core and fire rating before buying. They need to pick certified panels and follow local rules. Cleaning the panels often and putting them in right keeps buildings safe and nice.

FAQ

What is the difference between fire-rated ACP and standard ACP?

Fire-rated ACP has a core filled with minerals. This core helps stop fire. Standard ACP uses a polyethylene core. Polyethylene burns fast and is not safe in fires. Fire-rated panels keep buildings safer. They also follow strict safety rules.

How can someone identify certified fire-rated ACP panels?

Manufacturers put labels on certified fire-rated ACP panels. These labels show ratings like A2 or B1. Buyers should look for certifications such as EN13501, ASTM E2307, or IS 17682:2021. Always ask for test reports from trusted labs.

Can fire-rated ACP panels be used for interior walls?

Yes, fire-rated ACP panels are good for inside walls. They work for partitions and columns too. These panels give fire protection and last a long time. They also let designers choose different looks. Hospitals and schools use them to keep people safe.

Do fire-rated ACP panels require special maintenance?

Clean panels with mild soap and water to keep them nice. Check panels every year for damage or loose seals. Taking care of panels helps keep fire safety strong and makes them last longer.

Curtain Walls and Facades

Curtain Walls and Facades