03 Sep What Does ACP Panel Mean in Construction

Table of Contents

An acp panel in construction is a flat panel. It has two thin aluminum sheets stuck to a core that is not aluminum. An aluminium composite panel is strong and light. It works well for building surfaces. Many architects like acp panels. They do not rust. They come in many colors. They help keep buildings cool or warm. You can use these panels for looks and for how they work. This makes them popular for modern projects.

Key Takeaways

ACP panels are strong and light. They come in many colors. This makes them popular for outside and inside buildings. The panels have a sandwich design. They use aluminum sheets and a core. This design changes their strength, fire safety, and thickness. ACP panels can resist weather, rust, heat, and sound. They are easy to put up and take care of. You just need to clean them often. Picking the right core is important for fire safety. Mineral-filled cores protect better than polyethylene cores. ACP panels are good for the environment because you can recycle them. They also save money because they last long and need little care.

ACP Panel Overview

What Is an ACP Panel

You might ask what an acp panel is. In construction, an acp panel means aluminium composite panel. This panel has a sandwich shape. Two thin aluminum sheets are on the outside. These sheets stick to a core that is not aluminum. The core is usually polyethylene. This makes the panel strong and light. Aluminium composite panels come in many shapes and looks. They work for both style and use.

The usual size for an acp panel is 1220mm by 2440mm. You can pick different thicknesses for your project. The table below shows common sizes and thicknesses for different jobs:

Application Type | Aluminum Sheet Thickness (mm) | Total Panel Thickness (mm) | Standard Panel Size (mm) |

|---|---|---|---|

Exterior wall decoration / Advertising | ≥ 0.2 | ≥ 4 | 1220 x 2440 |

Indoor panels | ≥ 0.1 (generally ~0.2) | ~3 | 1220 x 2440 |

Curtain wall panels | ≥ 0.5 | > 4 | 1220 x 2440 |

Different acp panel types fit different needs. Thicker panels are stronger for outside walls. Thinner panels are good for inside use.

ACP in Construction

Aluminium composite panels are used a lot in new buildings. These panels cover outside walls, decorate inside spaces, and make signs. The world market for aluminium composite panels was about USD 6.47 billion in 2024. The building industry used more than half, about USD 3.49 billion. Experts think this market will grow quickly. The main reasons are eco-friendly features, insulation, and no rust.

Using an acp panel gives you many good things. Here are some important physical features that make acp panels popular:

ACP panels are light but strong. You can use them for outside walls and signs.

They stand up to weather. The colors stay bright in sunlight.

ACP panels help block heat and sound.

Many types do not burn easily and are safe for outside walls.

The sandwich shape uses aluminum sheets and a polyethylene core. Surface coatings like PVDF give more protection.

ACP panels do not rust. Aluminum makes a shield in air.

You can cut or bend these panels easily. This makes putting them in place simple.

ACP panels need little cleaning. They do not get very dirty and stay shiny with basic care.

You can choose from many colors and finishes. Some look like wood or marble.

ACP panels cost less than many other materials and are easy to buy.

Tip: You can pick different acp panel types for your project. Some types are made for fire safety. Others have special looks or extra strength.

Aluminium composite panels give you choices, style, and good performance. You can use them for many building jobs. Their many types and finishes mean you can always find the right panel for your design.

Aluminium Composite Panel Composition

Materials Used

Materials Used

Aluminium composite panels have a clever design. Each panel has three layers. Two thin aluminum sheets are on the outside. These sheets make the panel strong. They also protect it from damage. The middle layer is a core made of polymer. Most cores use thermoplastic polythene. This keeps the panel light and strong. It is easy to carry and put in place.

The aluminum sheets can have a special foil on them. This foil helps the panel fight bad weather. It also keeps the colors bright. The core is very important. If you use a normal polyethylene core, the panel stays light and bends easily. But this kind of core can catch fire fast. Some panels use a mineral-filled core instead. This makes the panel safer if there is a fire. Always check the core type before you pick a panel.

Note: The core in aluminium composite panels decides how well it stops fire. Polyethylene cores burn fast. Mineral-filled cores slow fire and keep the panel safer.

Structure and Thickness

The way aluminium composite panels are built gives them special benefits. You get a “sandwich” with two aluminum sheets and a polymer core. The thickness of each layer changes how the panel works. Aluminum sheets are usually 0.04mm to 0.5mm thick. Good panels use at least 0.21mm thick aluminum. Thicker sheets make the panel stronger. They help it stand up to wind and hits.

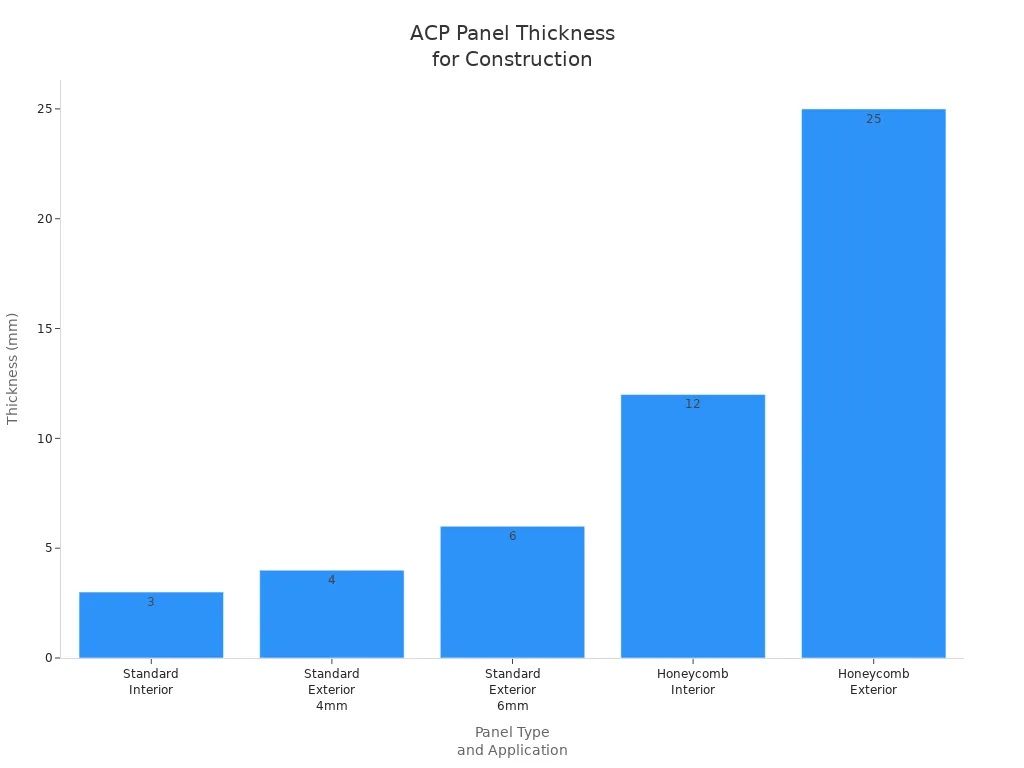

The total thickness of aluminium composite panels matters too. For inside jobs, you use 3mm thick panels. These are light and easy to shape. For outside walls, you need more strength. Panels for outside are usually 4mm or 6mm thick. Thicker panels are better for big buildings or windy places. Some special panels, like honeycomb types, can be up to 25mm thick. These give even more strength and insulation.

Here is a table to show common thicknesses and uses for aluminium composite panels:

Panel Type | Thickness Range | Typical Application | Notes on Usage |

|---|---|---|---|

Standard ACP Sheets | 3mm – 6mm | 3mm for interior | 3mm sheets are light and easy to use inside. |

|

| 4mm and 6mm for exterior | 4mm is easy to install; 6mm is for heavy-duty jobs. |

Honeycomb Panels | 12mm – 25mm | 12mm for interior | Honeycomb panels are strong and keep heat out. |

|

| 25mm for exterior | 25mm is used for extra strength and insulation outside. |

The thickness of the aluminum sheets and the core both matter. If you want a panel that lasts longer, pick one with thicker aluminum. This gives better protection from hits and weather.

You should also think about fire safety. The core is the key part. Standard panels with polyethylene cores do not stop fire well. If you want more safety, choose panels with mineral-filled cores. These can meet strict fire rules like B1 or A2. They help keep your building safe.

Aluminium composite panels are special because of their smart build. They are light, strong, and easy to use. You can pick from many thicknesses and core types. This lets you choose the right panel for your needs, whether you care about looks, strength, or fire safety.

ACP Panel Features

Durability and Strength

When you pick dibond panels, you get strong and tough panels. These panels can handle daily bumps and scratches. The sandwich design uses two aluminum sheets and a hard core. This makes the panel both strong and bendy. Dibond panels do not dent or break easily. They are good for buildings because they last long and stand up to bad weather.

Here is a table that shows how strong ACP panels are:

Property | Test Standard | Average Value / Requirement |

|---|---|---|

Tensile Strength | ASTM C 297 | 7.4 N/mm² (flatwise tensile strength) |

Impact Resistance | ASTM D 2794 | 1.5 in-lb reverse impact per mil substrate thickness |

These panels meet tough rules for strength. They last longer than many other building materials because they do not get damaged by weather.

Lightweight and Rigid

Dibond panels are light but also very stiff. A 4mm ACP panel weighs about 7.8 pounds for each square meter. This makes it easy to carry and put on tall buildings. The panels stay flat and do not bend or twist much. You can use them on high buildings because they are strong against wind and rain. Some types are fire-safe and follow strict safety rules.

Dibond panels have a sandwich design that makes them stiff.

They are strong and last long on tall buildings.

Light panels are quick and simple to install.

Fire-safe types help keep your building safe.

Dibond panels cost less and bend better than PVC. They are stronger and last longer, so you save money.

Aesthetic Options

You can pick from many looks with dibond panels. They come in shiny, dull, brushed, metal, or printed styles. Some look like wood, stone, or metal. This means you can match any style you want. Special coatings keep the colors bright and the surface smooth. You can print pictures or patterns for a special look.

Many looks help you make cool building fronts.

Panels work for homes and businesses.

You can pick from lots of styles and finishes.

Dibond panels save money, last long, and look great. You can trust them for any project because they are flexible and cost less.

ACP Cladding and Applications

Exterior Cladding

Exterior Cladding

You can see acp cladding on many building outsides. This cladding covers walls, pillars, and even ceilings. When you use dibond for outside cladding, it is light and simple to put up. You do not need heavy supports like with stone or brick. Dibond panels stand up to weather, sun, and rust. This helps your building look new for a long time.

Here is a table that shows how cladding choices compare:

Advantage Category | ACP Panels (Dibond) | Stone/Brick |

|---|---|---|

Weight & Installation | Lightweight, quick to install | Heavy, slow to install |

Cost & Maintenance | Lower cost, easy upkeep | Higher cost, more upkeep |

Durability | Resists weather and corrosion | Can crack or stain |

Aesthetics | Many finishes, consistent look | Natural, unique look |

Environmental Impact | Uses less material, recyclable | Quarrying impacts nature |

You can use acp cladding for outside walls or building fronts. These panels come in many colors and textures. You can match any style you want. Dibond makes buildings look modern and saves energy.

Interior Uses

Dibond panels are good for inside buildings too. You can use them for walls, room dividers, and ceilings. Many offices and malls use dibond for a clean look. You can also find dibond in tables, cabinets, and chairs. These panels are light, so you can bend them into shapes or patterns.

Wall cladding: Covers walls for a smooth look.

Partition walls: Splits rooms but stays light.

Ceiling panels: Adds style and hides wires.

Furniture: Makes strong and stylish tables and cabinets.

Dibond lets you be creative with design. You can bend or fold it and it stays strong. You can pick from almost 40 colors and finishes. Some look like wood or metal. Dibond helps keep rooms warm and quiet. It is easy to clean and lasts a long time, so you save money.

Tip: Use dibond inside and outside to keep your style the same and save money.

Other Applications

Dibond is used for more than just cladding. You see it in signs, billboards, and display boards. The panels are light and last long outside. Many companies use dibond for logos because it looks good and stays bright.

Dibond is also used in buses and trucks. Makers use it for vehicle bodies because it is strong and light. In hotels and homes, dibond furniture is liked for its modern look and easy care.

Dibond panels give you many choices for cladding, furniture, and signs. You can trust them for almost any job that needs a strong and easy material.

Safety and Environmental Impact

Fire Safety

It is important to think about fire safety with ACP panels. Many panels have a core made of polyethylene. This material can burn fast if it gets very hot. Some panels use a mineral-filled core instead. These slow down fire and help keep buildings safe. Always check the fire rating before you buy panels. Pick panels that follow strict fire rules. This keeps people and buildings safer.

If you want more fire safety, choose ACP panels with a mineral-filled core. These panels help stop fire from spreading.

Compliance

You need to follow rules when you use ACP panels. Building codes tell you what is safe and what is not. Check local laws before you start building. Many places want ACP panels to pass fire tests. Look for panels with certificates that show they meet these rules. Some panels have labels like B1 or A2. These labels mean the panels are good at stopping fire. Make sure workers follow safety steps when they put in panels. Good compliance helps you avoid trouble and keeps everyone safe.

Here is a table to show what common labels mean:

Compliance Label | Fire Resistance Level | Typical Use |

|---|---|---|

B1 | Hard to catch fire | Commercial buildings |

A2 | Does not burn | Tall buildings |

None | No rating | Not a good choice |

Environmental Concerns

You should think about the planet when you pick building materials. ACP panels use aluminum and polymers. Most of these materials can be recycled. New recycling methods save more than 90% of the panel’s weight. This helps cut down on waste and saves resources. You can throw away panels safely if they pass safety checks. Panels do not let out bad chemicals if handled right. The main thing is to make sure panels are safe and recycle as much as you can. You help the earth when you pick panels that support recycling.

Tip: Ask your supplier about recycling ACP panels. This helps you handle waste and care for the planet.

ACP Panel Maintenance

Cleaning

Cleaning

You need to clean ACP panels regularly to keep them looking new and strong. Start by removing loose dirt with a soft brush or broom. Use pure water first to wash away dust. If you see stains, dip a soft cloth in a mild soap and water solution. Gently scrub the panels in circular motions from top to bottom. For tough spots, use an isopropyl solution or a non-abrasive metal surface cleaner. Always rinse the panels with clean water to remove any soap or cleaner. Dry the panels with a soft cloth or let them air dry. Never use harsh chemicals, stiff brushes, or abrasive materials like steel wool. These can scratch or damage the surface.

Tip: Always collect all cleaning materials before you start. Check the panels after drying to make sure no dust or streaks remain.

How often you clean ACP panels depends on where your building stands. In busy city areas, clean every 2-4 weeks to stop pollution buildup. In quieter places, clean every 2-3 months. Before monsoon or hot seasons, do a deep clean to prevent moisture damage. Regular cleaning keeps panels bright and helps them last longer.

Area Type | Cleaning Frequency |

|---|---|

Urban/Traffic | Every 2-4 weeks |

Low Pollution | Every 2-3 months |

Seasonal (before monsoon/heat) | Deep clean |

Lifespan

ACP panels can last a long time if you care for them well. Quality panels with good coatings, like PVDF, often last 20-30 years on building exteriors. The type of coating matters. PVDF coatings protect better than polyester, especially against sun and rain. The core material and how the panels are made also affect how long they last. If you install panels correctly and follow manufacturer advice, you get the best results.

Environmental factors play a big role. Sunlight, salt air near the coast, freezing and thawing in mountains, and big temperature changes can wear panels down. Regular cleaning with mild soap and water helps keep panels strong and looking good. If you choose panels with ISO certification and strong coatings, you increase their lifespan.

ACP panels give you years of service when you clean them often and pick the right type for your building’s needs.

Now you know ACP panels are strong and light. They also look nice on many buildings. These panels are easy to put up. You can pick from lots of colors and styles. When picking panels, think about fire safety rules. You should also check building codes and insurance needs. Some panels are risky because of their core. Safer panels, like all-aluminium ones, follow strict rules. They help lower your risk. Always make sure the panels you use are safe and approved.

Fire safety and following rules are very important.

There are safer panel choices for your project.

Think about the good and bad points before choosing.

FAQ

What is the main use of ACP panels?

You use ACP panels mostly for building exteriors and interiors. They cover walls, ceilings, and pillars. You also see them in signs and furniture. ACP panels make buildings look modern and protect them from weather.

Are ACP panels waterproof?

Yes, ACP panels resist water. The aluminum sheets and coatings keep out rain and moisture. You can use them outside without worry. Always check for proper sealing at the joints for best results.

Can you paint or print on ACP panels?

You can paint or print on ACP panels. Many companies use them for colorful signs and displays. The smooth surface holds paint and graphics well. You get bright, long-lasting colors.

How do you cut ACP panels?

You can cut ACP panels with simple tools like a circular saw or a jigsaw. Always use a sharp blade. Wear safety gear to protect your hands and eyes. Cut slowly for a clean edge.

Materials Used

Materials Used Exterior Cladding

Exterior Cladding Cleaning

Cleaning