22 Oct Anodized Aluminium Composite Panel Weather And UV Resistance

Table of Contents

You often see anodized aluminium composite panel on buildings. They are used outside because they can handle bad weather and strong sun. These panels keep their color and shape for many years. Rain, humidity, and UV rays do not damage them easily. Anodized aluminium composite panel has a strong metal layer and a solid center. It also has a special finish on top. This helps stop rust and fading. Many architects pick anodized aluminium composite panel for these reasons:

A shiny, metal look that stays bright

Can be used for many building designs

Lasts a long time, even 40–50 years if cared for

You need weather and UV resistance for anything outside. Anodized aluminium composite panel gives you both. This makes it a good choice for beauty and protection that lasts.

Key Takeaways

Anodized aluminium composite panels can handle weather and UV rays. This makes them great for use outside. These panels can last 40 to 50 years if you take care of them. This helps you save money because you do not need to replace them often. Clean the panels often with warm soapy water. This keeps them looking new and shiny. Pick panels with high dye ratings for better color. This helps the color stay bright and not fade. It is very important to install the panels the right way. Always follow the manufacturer’s instructions to stop damage.

Anodized aluminium composite panel Basics

Structure and Layers

Aluminum composite panels are not just flat sheets. They have many layers, and each layer does something important. These layers make the panels strong and help them last outside.

Here is a table that lists the main parts of anodized aluminium composite panels:

Layer/Component | Description |

|---|---|

Protection Film | A thin layer that keeps the surface safe during transport and installation. |

PVDF/Polyester Resin Based Coating | This coating adds color and protects against scratches and fading. |

Primer Coating | Helps the top coating stick better to the aluminum. |

Aluminium Coil | The strong outer skin made from aluminum. |

Adhesive Film (Polyolefin) | Binds the aluminum to the core. |

Polyethylene Core (LDPE) | The center layer that gives the panel its shape and strength. |

Service Coating (Anti-corrosive) | Adds extra protection against rust and chemicals. |

There are two thin aluminum layers on the outside. The middle part is not made of aluminum. The anodized finish on top makes the panel look shiny and new. This finish also helps protect it from rain and sun. All these layers together make the panel strong but not heavy.

Tip: The layers help stop the panel from bending or breaking in bad weather.

Anodizing Process

Anodizing changes the top of the aluminum. It makes a hard oxide layer that covers the surface. This layer works like a shield. It keeps away rust, scratches, and bad weather. Anodizing also helps paint and glue stick better, so the panel stays strong for a long time.

Here are some ways anodizing helps:

It makes a hard surface that does not get damaged easily.

It keeps the color bright, even after many years.

It makes cleaning easier because dirt does not stick much.

It helps the panel stay strong when it is cold.

Panels with an anodized finish last a long time. You can count on them to look good and stay strong, even outside.

Weather Resistance Features

Protection from Rain and Humidity

You want your building to stay dry, even in wet weather. Composite aluminum panels help keep out rain and humidity. The panels have a surface that water cannot go through. This means water does not get inside the panels. You do not need to worry about swelling or water soaking in. The aluminum layer stops rust, and special coatings keep the panels safe in damp places.

Manufacturers check these panels to make sure they work in tough weather. Here is a table that shows how well composite aluminum panels do in humidity tests:

Test Type | Manufacturer | Result Description | Hours Tested | Blister Rating |

|---|---|---|---|---|

Humidity Test | Alcotex | No blisters after 4000 hours at 100% humidity and 100°F | 4000 | 0 |

Humidity Test | Alpolic | Blister rating of 8 (10 being no creepage at all) | N/A | 8 |

These panels do not get blisters or break down, even after being wet for a long time. The sealed core inside the panel gives more protection. It keeps water out and helps the panel stay strong. Rainscreen cladding systems also help protect buildings. They keep out rain, wind, and snow. The air gap lets air move and stops water from building up. Inside, weather barriers stop water from getting into the building.

Tip: Using composite aluminum panels with rainscreen systems gives your building even better protection from weather and rust.

Temperature and Abrasion Resistance

You need panels that can handle hot and cold weather. Composite aluminum panels do not crack or bend when the temperature changes. The panels stay strong and keep their shape, even if the weather changes fast. PVDF coatings give extra protection from the weather. These coatings help the panels last longer and keep their color bright, even after years outside.

Here are some ways PVDF and PE coatings help with weathering:

PVDF coatings give strong protection. Your panels can face UV rays and bad weather without fading or breaking.

PE coatings give some protection. They do not last as long as PVDF, but they still help the panels stay strong.

The panels also do not scratch or wear down easily. The anodized layer makes the surface hard and tough. You do not have to worry about dents or marks from wind or daily use. The panels keep looking nice, even in busy places.

Some systems use gasketed rain screens. These panels fit into tracks, and any water that gets in drains out through small holes. The rest of the water dries up, so the wall does not trap water. This design helps the panels last longer and keeps your building safe.

Aspect | Anodized Aluminum Composite Panels | Traditional Aluminum Panels |

|---|---|---|

Weather Resistance | Good, but depends on the core; anodizing adds a protective layer | Excellent, solid aluminum sheets are very strong and resist weather |

Rust Resistance | Anodized layer stops rust | Does not rust, good for wet places |

Longevity | Can last over 50 years with care | Lasts over 50 years if cared for |

Composite aluminum panels give strong protection from weather and rust. They last for many years and keep your building looking new. You can trust these panels to protect your building from rain, humidity, temperature changes, and scratches.

UV Resistance and Color Stability

UV Protection Mechanisms

When you pick a facade, you want it to look nice for years. Anodized aluminium composite panels protect well from uv rays. The anodizing process makes a hard oxide layer on top. This layer works like a shield. It blocks bad uv rays and keeps the panel strong.

Many groups test and set rules for uv protection. These rules help you know your panels will last outside. Here is a table with some important standards for anodized aluminum:

Standard/Specification | Description |

|---|---|

AAMA 611 | Testing and quality rules for anodized aluminum in the US. |

EN 12373 | European standards for anodized aluminum in buildings. |

QUALANOD | International certification for quality anodizing. |

MIL-A-8625 | Military rules for corrosion and wear resistance. |

ISO 7599 | Global standards for anodized aluminum quality. |

Anodized panels resist uv rays better than non-anodized ones. The oxide layer makes the surface harder and stronger. It also helps stop scratches and rust. Non-anodized panels can fade and break down faster in the sun. If you want your aluminum facade to last, pick anodized panels for outdoor use, even in places with lots of humidity or pollution.

Note: The anodized finish does not peel or chip. You do not need to worry about the color fading from sun or rain.

Long-Term Appearance

You want your facade to keep its color and shine for years. Anodized finishes help stop color fading. The dye goes deep into the oxide layer, so the color stays bright. The seal on the panel is very important. A good seal keeps the dye safe from uv rays and water.

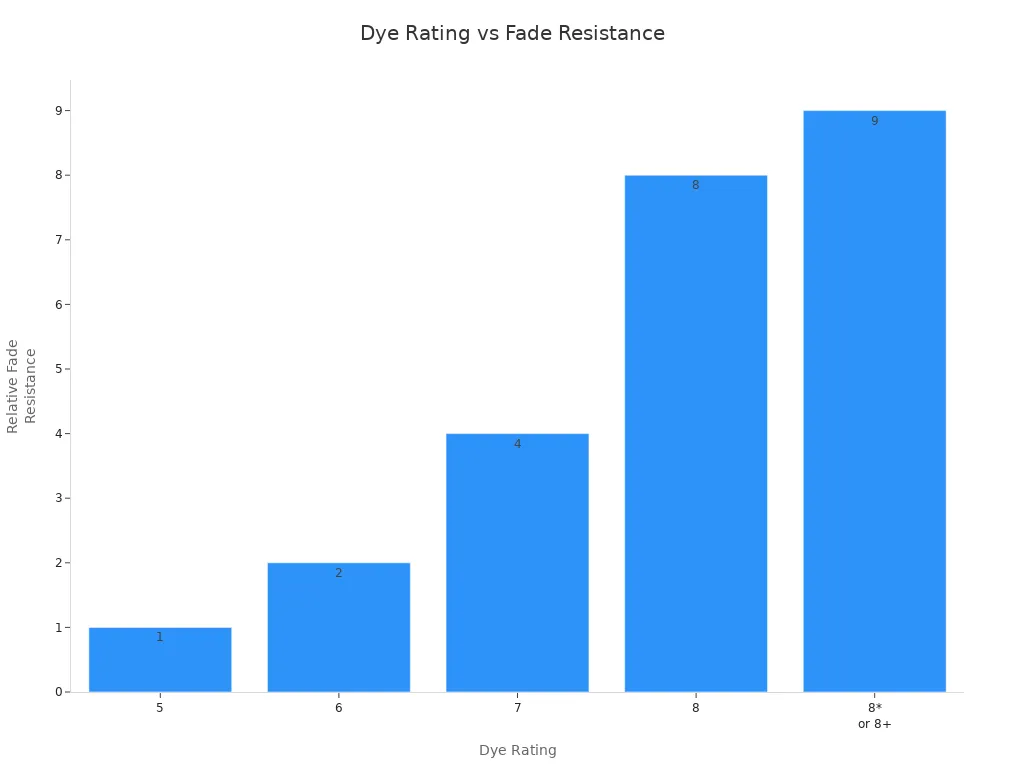

Fade resistance is measured by dye ratings. Higher numbers mean better protection. Here is a table that explains these ratings:

Dye Rating | Description |

|---|---|

5 | Baseline fade resistance |

6 | Twice as fade-resistant as 5 |

7 | Twice as fade-resistant as 6 |

8 | Twice as fade-resistant as 7 |

8* or 8+ | Best fade resistance |

You can see how fade resistance gets better with higher dye ratings in this chart:

To get the best color, look for panels with high dye ratings. Here are some tips to help you choose:

Pick colors with deeper shades. These fade less than light colors.

Choose panels with high dye saturation. More dye means more protection.

Type II coatings give the best dye saturation and fade resistance.

A good seal is key. Nickel seals work well because they bond with the dye and add extra protection from uv rays. The seal keeps out water and dirt, so your panels stay clean and bright.

If you follow these steps, your facade will look fresh for many years. You will not see much fading, even after years of strong sun. Anodized panels give your building a modern look that lasts. You can trust them to keep your building looking new and nice.

Tip: Always check for certifications like QUALANOD or ISO 7599. These show your panels meet strict rules for uv protection and color stability.

Corrosion and Chemical Defense

Corrosion Resistance

You want your building to last a long time. Rain, salt, and pollution can cause damage. Anodized aluminium composite panels help stop this damage. The anodized layer works like a shield. It keeps rust away and helps the panels look new. Makers test these panels using tough rules from around the world. One test is called ASTM B 117. It sprays salt on the panels for 4,000 hours. The test shows that rust does not spread far from the scratch line. The panels get a blister rating of at least 8. This means the panels are strong against rust and damage.

Test Method | Description |

|---|---|

ASTM B 117 | Panels are sprayed with salty water for 4000 hours. |

Corrosion creepage | Rust spreads less than 1/16 inch (1.6 mm) from the scratch. |

Blister rating | The panel gets a blister rating of at least 8. |

The anodized finish does not peel or come off. The surface stays strong against water and dirty air. This makes anodized aluminium composite panels good for cities and places near the sea.

Performance in Harsh Environments

Some places have tough weather or lots of chemicals. Anodized aluminium composite panels work well in these places. Class I anodize coatings are very strong. These panels are tested with salt spray for 3,000 hours. You should clean the panels often to remove salt, dirt, and pollution. This helps the panels stay strong against rust.

Evidence | Description |

|---|---|

Sets a high standard for aluminum used in buildings, tested with 3,000 hours of salt spray. | |

Maintenance Requirement | Clean panels often to get rid of salt, dirt, and pollution so they do not rust. |

Durability | Anodized aluminum is great for busy places and tough weather because it is hard and lasts a long time. |

In cities, panels can touch strong chemicals. Some examples are:

Very rough materials

Alkaline chemicals

Acidic chemicals

Mortar

Labs test panels to see if they can handle chemicals. One test uses muriatic acid to check if the panel stays strong. The HCl bubble test looks for bubbles to see if the coating fails. These tests show that anodized aluminium composite panels can handle harsh chemicals and still fight rust.

Tip: Wash your panels with gentle soap and water. Do not use strong acids or bases so the surface stays strong and shiny.

Installation and Maintenance

Proper Installation

Proper Installation

You want your panels to last a long time and look nice. Always follow the instructions from the manufacturer. This helps you avoid mistakes and keeps your building safe. Metal can get bigger or smaller when it gets hot or cold. If you do not leave space, the panels might bend or twist.

Here is a table with the best ways to install anodized aluminium composite panels:

Installation Best Practices for Anodized Aluminium Composite Panels |

|---|

Follow the manufacturer’s instructions and contract documents. |

Leave space for the metal panels to move. |

Make sure subgirts and fasteners are spaced and lined up right. |

Attach panels so they do not bend or twist. |

Put in flashings to stop water from getting in. |

Let the panels move at places where things go through them. |

Use panels that are at least 4 mm thick for outside walls. This thickness helps the panels last longer. Pick the right fasteners and adhesives. If you use the wrong ones, the panels might fall off or bend. Always check your measurements before you cut the panels. Use the right tools so your cuts are smooth.

Tip: It is best to hire people who know how to install these panels. This helps stop mistakes and keeps your panels strong.

Maintenance Tips

You can keep your panels looking new with easy care. Wash them with warm soapy water and a soft cloth or sponge. Rinse them well to get rid of soap. Do not use strong chemicals or rough tools. These can hurt the surface.

Here are some simple ways to take care of your panels:

Clean them often to get rid of dirt and chalk.

Be careful with ladders and tools so you do not scratch or dent the panels.

If you see small scratches, use paint from the manufacturer to fix them.

Check the seals and joints every few months. Look for damage or things that are worn out. Check for water or dirt behind the panels. Test the coating every two or three years. This helps you find problems early.

Here is a table that shows how much it costs to take care of different cladding materials:

Cladding Material | Maintenance Cost Comparison | Maintenance Requirements |

|---|---|---|

Anodized Aluminum Composite Panels (ACM) | Usually lower because they are strong and need little care | Only a little care is needed |

Wood Cladding | Costs more because it needs a lot of care | Needs regular care to stop rot and bugs |

Brick Cladding | Costs more, usually more than ACM | Needs repairs and care sometimes |

Stone Cladding | Costs more, one of the most expensive choices | Needs very little care |

Fiber Cement Siding | Costs more because it needs painting and sealing | Needs care from time to time |

Note: Anodized aluminium composite panels need less care than wood or brick. You save time and money over the years.

You get strong protection from rain, sun, and pollution when you choose anodized aluminium composite panels. These panels keep their color and shape for decades, even in harsh climates like those at the Burj Khalifa. Regular cleaning helps your panels look new. You save money because you do not need to replace or repaint them often.

Finish Type | Warranty Period |

|---|---|

High-quality PVDF | |

PE coating | More than 20 years |

Class I Anodize | 5 years |

Extended Warranty | Up to 10 years |

Panels resist fading and rust.

You spend less on repairs and cleaning.

Your building stays bright and modern for years.

Tip: Pick panels with PVDF coatings for the best long-term results.

FAQ

How long do anodized aluminium composite panels last outdoors?

These panels can last outside for 40 to 50 years. The anodized finish keeps out sun, rain, and pollution. Your building will look bright and last a long time.

Do these panels fade in strong sunlight?

You do not have to worry about fading. The anodized layer blocks UV rays and keeps the color bright. Panels with high dye ratings stay bright the longest.

Are anodized aluminium composite panels hard to clean?

Cleaning these panels is easy. Use warm soapy water and a soft cloth. Do not use strong chemicals or rough tools. Clean them often to keep them looking new.

Can I install these panels myself?

It is best to hire trained people to install the panels. Good installation stops bending, leaks, or damage. Always follow the manufacturer’s instructions to keep the panels safe and strong.

What makes anodized panels better than painted panels?

Anodized panels have a harder and stronger surface. The finish does not peel or chip. They resist scratches, rust, and fading better than most painted panels.

Proper Installation

Proper Installation