04 Nov What Is The Structure Of Aluminium Composite Panels

Table of Contents

- 1 Key Takeaways

- 2 Aluminium Composite Panel Structure

- 3 Key Features of Aluminium Composite Panels

- 4 Applications of Aluminium Composite Panels

- 5 FAQ

- 5.1 What makes aluminium composite panels safe in a fire?

- 5.2 How do aluminium composite panels meet fire safety standards?

- 5.3 Can aluminium composite panels catch fire easily?

- 5.4 What should you do if a fire starts near aluminium composite panels?

- 5.5 Why do architects care about fire ratings for aluminium composite panels?

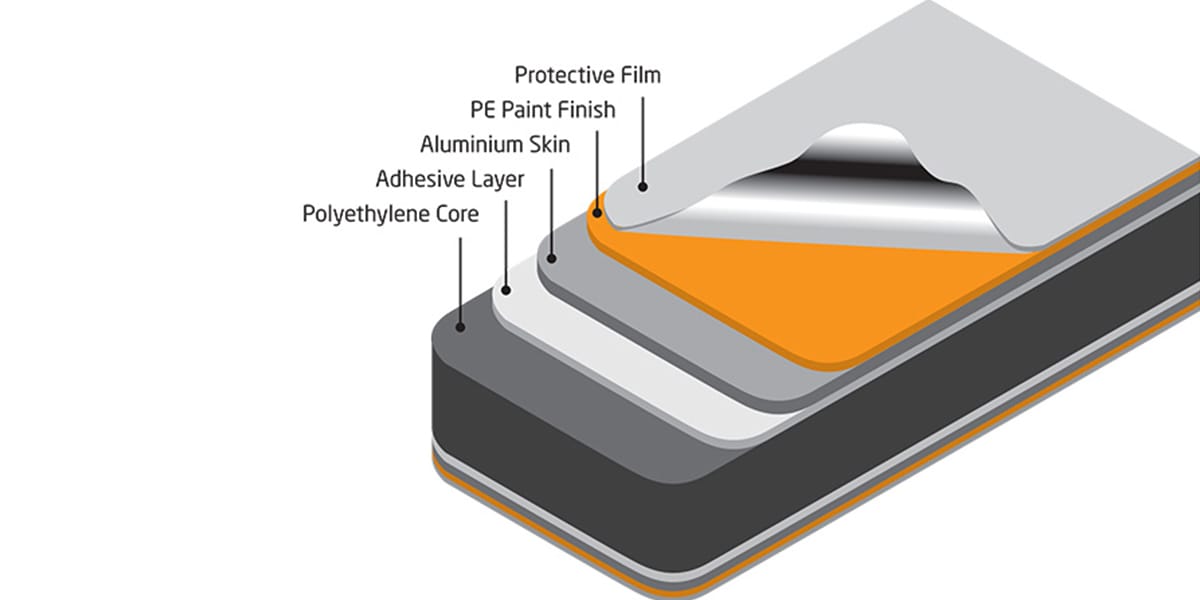

You can spot the aluminium composite panel structure by its special sandwich shape. It has two thin aluminum sheets on the outside. There is a core material in the middle. The core is often made of polyethylene to keep it light. Sometimes, the core uses a fire-retardant material for safety. Glue sticks all the layers together, which makes the panel strong.

The outside aluminum layers are usually 0.2mm to 0.5mm thick. The whole aluminium composite panel structure is often 3mm to 6mm thick. The thickness depends on where you use the panel.

Key Takeaways

Aluminium composite panels have a special sandwich structure. They have two aluminum sheets and a core material. This makes them strong but also light.

The panels give great insulation. They help keep buildings warm or cool. They also block heat and noise. This makes buildings more comfortable and saves energy.

Regular cleaning and checks help the panels last longer. This keeps them strong and looking nice.

These panels can be used in many ways. People use them for building facades, inside designs, and signs. They look good and work well.

Picking the right core material and glue is very important. It helps with fire safety and how well the panels work. Always check fire ratings before you put them in.

Aluminium Composite Panel Structure

Sandwich Design

Sandwich Design

Aluminium composite panels have a sandwich design. There are two thin aluminum sheets on the outside. The middle part is called the core material. This design makes the panel strong and light. The sandwich shape is different from a solid aluminum sheet. You can see the differences in the table below:

Feature | Aluminum Composite Panel (ACP) | Solid Aluminum Sheet |

|---|---|---|

Structure | Multi-layered (aluminum + plastic core + coating) | Single, solid aluminum layer |

Strength & Rigidity | Good stiffness and strength-to-weight ratio | Stronger but less rigid unless thick |

Flexibility | Can be bent with proper equipment but not suitable for welding | Can be bent, rolled, and welded easily |

Durability | Weather-resistant and corrosion-resistant due to coating | Highly durable, especially when anodized or coated |

The sandwich design keeps the panel strong and light. It also helps with insulation and saves energy. The panel can resist fire because of this design. These features make aluminium composite panels good for cladding and other uses.

Aluminum Sheets

The outside layers are made from strong aluminum alloys. These sheets protect the core inside. They also give the panel a smooth look. The thickness of these sheets can change. It depends on how you use the panel. Here is a table with common thicknesses and alloy grades:

Panel Thickness (mm) | Aluminium Skin Thickness (mm) | Aluminium Alloy |

|---|---|---|

3, 4, 5, 6 | 0.1, 0.12, 0.15, 0.2, 0.3, 0.4, 0.5 | 1100, 3003, 5005 |

Surface treatments help protect the aluminum sheets. Anodising makes a strong layer that stops rust. Powder coating gives a hard and colorful finish. Wet painting makes the panel look smooth. These treatments help the panel last longer and look nice.

Core Materials

The core is between the two aluminum sheets. Different core materials are used for different needs. The table below shows common core materials and their fire ratings:

Core Material | Fire Rating |

|---|---|

Low-density ordinary polyethylene | B1 |

Non-combustible core materials | A |

Polyethylene is light and insulates well. Polyurethane helps block sound and heat. Polyvinyl chloride and mineral wool make the panel safer in a fire. The core’s density changes the panel’s weight. PE cores are light. Mineral-filled cores are heavier but safer. Pick the core based on where you will use the panel, especially for tall buildings.

Adhesive Bonding

Adhesive bonding sticks all the layers together. Special adhesives make strong bonds that last. These adhesives can handle stress and weather. The table below shows some adhesive compounds and their strength:

Adhesive Compound | Shear Strength (MPa) | Type of Joint |

|---|---|---|

Epidian 53/PAC/100:80 | 14.14 | Aramid composite |

Epidian 53/IDA/100:50 | 2.74 | Aramid composite and aluminum alloy |

Manufacturers test the bonds to make sure they are strong. The wedge test checks if the adhesive can handle cracks and stress. You can trust the adhesive bonding to keep the panel safe and strong, even in bad weather.

Tip: Using the right adhesive and bonding process helps your aluminium composite panel last for many years, even outside on buildings.

When you know about each part of the aluminium composite panel, you see why people use them so much. The sandwich design, strong aluminum sheets, smart core materials, and tough adhesive bonding all work together. These features make the panels great for cladding and building.

Key Features of Aluminium Composite Panels

Durability and Strength

Durability and Strength

Aluminium composite panels are tough and last a long time. The sandwich structure makes them strong and keeps them safe. These panels can handle daily use without breaking. Tests show how well they work:

Panels with polyurea coating do best in impact tests. One side coated stops things from going through, but it may bulge. If both sides are coated, things can go through, but damage is less than with no coating.

You need to check and care for aluminium composite panels more than solid aluminum cladding. The core inside can get hurt after some time. Solid aluminum cladding lasts longer and needs less care. Still, aluminium composite panels are strong and do not need much work for many jobs.

Checking your panels often helps you find problems early and keeps them looking nice.

Lightness and Flexibility

Aluminium composite panels are light and strong. You can move and put them up easily. A 3.0mm thick panel weighs about 8 kg for each square meter. Because they are light, you do not need big machines to install them. Makers shape the panels before sending them, so you do not have to cut them at the building site.

You can bend, curve, or fold these panels and they stay strong. This lets you make cool shapes for walls and new designs.

Architects use these panels for curved walls and fun building fronts. The panels work for big and small projects.

Because they are light and bendy, aluminium composite panels are great for creative buildings.

Insulation Properties

Aluminium composite panels help keep heat and noise out. The core inside gives better insulation than solid aluminum sheets.

R-values are usually from R-1 to R-6 for each inch thick. This means the panels slow down heat and help keep buildings comfy.

Some panels, like ALPOLIC/fr LT, block sound very well. Tests show they keep out noise, so they are good for busy places.

The core in these panels stops heat and sound from moving through. Solid aluminum sheets do not block heat or sound as well because they let it pass through.

If you want a quiet building that saves energy, aluminium composite panels are a good pick.

Applications of Aluminium Composite Panels

Aluminium composite panels are used in many places. Their special structure and features make them popular. You can see them on new buildings, inside rooms, and in factories. The sandwich design keeps them light and strong. This is why people use them for many jobs.

Aluminium composite panels are used in many places. Their special structure and features make them popular. You can see them on new buildings, inside rooms, and in factories. The sandwich design keeps them light and strong. This is why people use them for many jobs.

Building Facades

Many buildings use aluminium composite panels on the outside. These panels make buildings look modern and protect them from bad weather. They do not rust, fade, or get damaged by the sun. You can pick from lots of colors, textures, and finishes to match your style. The table below shows why architects like aluminium composite for outside walls:

Benefit Type | Description |

|---|---|

Aesthetic Versatility | Gives many colors, textures, and finishes for cool designs. |

Sustainability | Light, eco-friendly, and can be recycled for green buildings. |

Durability | Stays strong against weather, rust, and fading for a long time. |

You can use these panels for new buildings or when fixing old ones. They help save energy and keep the building safe.

Interior Design

Aluminium composite panels are great for inside rooms, too. You can use them for cool walls, ceilings, cabinets, and even furniture. They come in finishes like wood, stone, metal, and 3D patterns. This helps you make any look you want. Here are some ways to use aluminium composite at home or work:

Pick a bright color or texture for a fun wall.

Mix shiny and dull finishes for a cool effect.

Use panels for ceilings, cabinets, or the front of furniture.

Room Type | |

|---|---|

Bedroom | Stone, Fluted, Wood, Metal, or 3D wall panels |

Living Room | Stone, Fluted, Wood, Metal, or 3D wall panels |

Partitions | Solid colors and many styles for a smooth look |

Your space will look nice and be easy to clean.

Signage and Industrial Uses

You also see aluminium composite panels in signs and factories. They are light and strong, so you can shape and put them up easily. They work for machine covers, equipment boxes, and safety barriers. The panels do not break easily and can handle chemicals and water. This keeps your signs and machines safe and looking good.

Property | Description |

|---|---|

Lightweight | Easy to move and install without much weight. |

Durable and robust | Works well in tough factory places. |

Corrosion resistance | Lasts long even in wet or chemical areas. |

Impact resistance | Stops damage from bumps and hits. |

You can use aluminium composite panels inside or outside. They give you choices, safety, and style everywhere.

The sandwich structure of aluminium composite panels gives you lots of benefits. The two aluminum sheets and the core work as a team. This makes the panels light, strong, and tough. These benefits help you use them for buildings, signs, and transport. If you know how they are made, you can pick panels that fit your needs and style. Cleaning and checking for damage keeps the panels looking nice and lasting longer. You get even more benefits if you follow expert tips for picking and caring for them.

The benefits are weather resistance, insulation, and easy design choices.

Knowing the structure helps you choose panels with the best benefits for your project.

Taking care of your panels gives you more benefits and helps them last longer.

FAQ

What makes aluminium composite panels safe in a fire?

The core material can help stop fire from spreading. Manufacturers test the panels to make sure they are safe. The aluminum sheets also slow down the fire. Always check the fire rating before picking a panel for your building.

How do aluminium composite panels meet fire safety standards?

Panels must pass tough fire tests to be used. The core material is tested to make sure it is safe. You can find labels that show the fire rating. Ask for certificates to be sure your panels are safe.

Can aluminium composite panels catch fire easily?

Panels with a polyethylene core can burn faster than those with a mineral-filled core. Pick panels with a high fire rating for places with more fire risk. The aluminum sheets help slow down the fire.

What should you do if a fire starts near aluminium composite panels?

Follow fire safety rules and use a fire extinguisher. Leave the area right away. Call emergency services for help. Check your panel’s fire rating to know how it will react.

Why do architects care about fire ratings for aluminium composite panels?

Architects pick panels with good fire ratings to keep buildings safe. Fire safety rules help them choose the right panels. Ask about fire ratings when you plan your project. Good fire protection keeps people and buildings safe.

Tip: Always check the fire rating and fire safety rules before you put up aluminium composite panels. This helps you stay safe and follow building codes.

Sandwich Design

Sandwich Design Durability and Strength

Durability and Strength