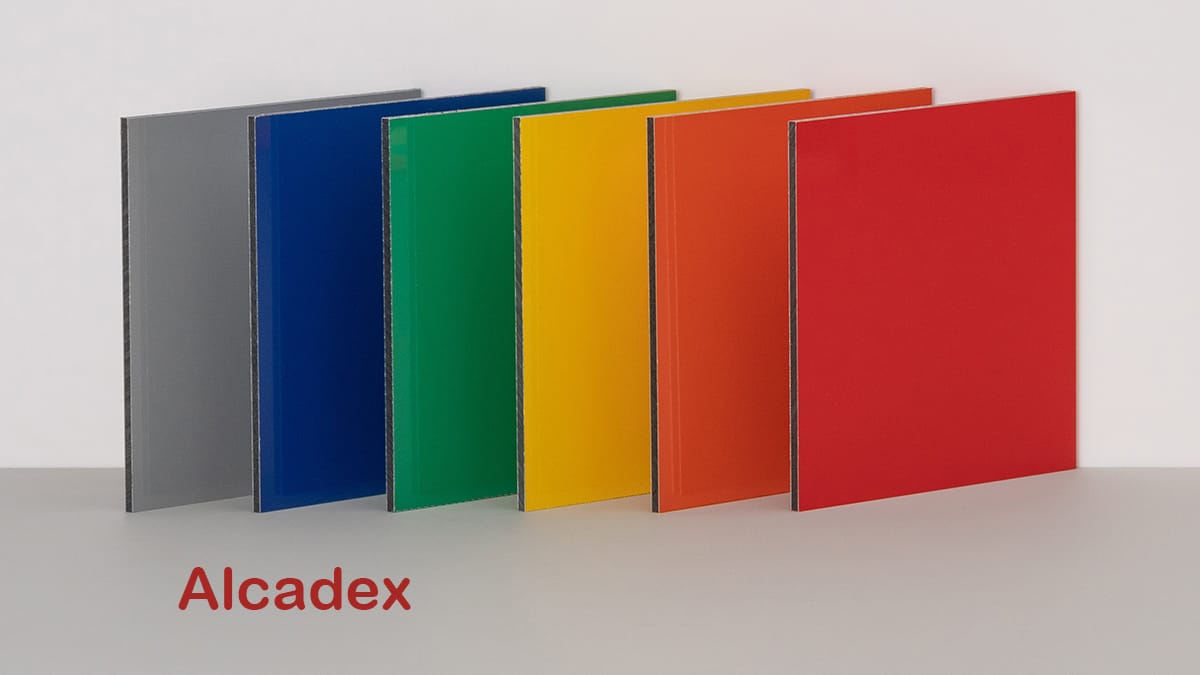

05 Dec Advantages and Disadvantages of Using Aluminium Sandwich Sheets

Table of Contents

If you want a building material that is strong, light, and saves money, aluminium sandwich sheet could be a good choice. Aluminium is tough and does not need much care. It is also easy to put in place and helps keep rooms warm or cool. Many people pick aluminium because it can bend without breaking and does not let in much dust or sand. But, aluminium can get dents, and sometimes you need more waterproofing to stop water from getting in. Here is a quick look at what you might find:

Advantages | Disadvantages |

|---|---|

Cost efficiency | Potential denting |

Ease of installation | Need for additional insulation |

Durability |

|

Low maintenance |

|

Aluminium sandwich sheets are now more popular because more people in North America use aluminium. Builders and homeowners want materials that are light, strong, and save energy. If you want something that is not too expensive and works well, aluminium could be right for your project. But you should think about the bad points before you choose.

Key Takeaways

Aluminium sandwich sheets do not weigh much. They are simple to put in place. This makes them useful for many building jobs.

These panels last a long time. They do not need much care. This helps you save time and money over time.

Aluminium sandwich sheets keep heat in very well. They help lower the cost of heating and cooling.

Think about how these sheets can get dents. You also need to make sure they stay dry. This is important when you pick aluminium sandwich sheets for your project.

Look at the different finishes you can choose. Pick one that fits your style. Remember, there are some limits to how they look.

Advantages of Aluminium Sandwich Sheets

Lightweight and Flexible

Aluminium sandwich sheet is much lighter than other materials. You can move and lift it easily. It is simple to install. You do not need big machines or a large team. Steel is much heavier than aluminum. Aluminum weighs less but is still strong. You can bend or cut aluminium cladding. It fits many shapes and designs.

Material | Density (g/cm³) | |

|---|---|---|

Carbon Steel | 500 | 7.85 |

Aluminum Alloy 6061 | 310 | 2.70 |

High Durability

Aluminium sandwich panels last a long time. They do not rust or get damaged by water. These panels do not crack or bend like wood. They work well in tough weather. You can see how they do in tests:

Metric | Description |

|---|---|

Makes panels last longer and need less fixing. | |

Thermal Performance | Helps save energy and lowers bills. |

Moisture Resistance | Good for wet places and cold storage. |

Aluminium sandwich sheet keeps its shape for years. It does not break in rain, snow, or sun.

Heat Resistance

Aluminum composite panel can handle heat well. It protects against fire and high temperatures. The inside core helps stop heat and flames. Mineral wool cores slow down heat and keep fire from spreading. This makes buildings safer.

Aluminum is strong and light.

It moves heat quickly, which helps in many ways.

Mineral wool cores help with fire safety. They meet strict rules in Europe.

Aluminium cladding is good for places where fire safety is important.

Thermal Insulation

Aluminium sandwich sheet helps keep buildings warm or cool. The panels have a high R-value. This means they stop heat from coming in or going out.

Characteristic | Description | Impact on Performance |

|---|---|---|

λ-value (W/mK) | Lower numbers mean better insulation. | Makes buildings use less energy. |

U-value (W/mK) | Lower numbers mean less heat escapes. | Shows how much heat leaves the building. |

R-value (per inch) | High R-value of 9 per inch for panels. | Lowers heating and cooling needs. |

You pay less for heating and cooling. Aluminium cladding helps save money on energy.

Cost-Efficiency

Aluminum sandwich sheet gives you good value for your money. The panels cost less than many other choices. Here is a look at prices:

Material | Cost per square meter (approx.) |

|---|---|

Aluminium siding | $59.00 to $113.00 |

Fiber cement | $50.60 to $91.50 |

Vinyl siding | $26.90 to $115.50 |

Panel Type | Cost per square meter (approx.) |

|---|---|

Solid aluminum panels | |

Aluminum corrugated | $25 – $50 |

Aluminum perforated | $30 – $70 |

Aluminum honeycomb | $50 – $120 |

Aluminum composite panel does not need much fixing. You do not have to paint or repair it often. Here is how upkeep costs compare:

Material Type | Long-term Maintenance Costs | Maintenance Requirements |

|---|---|---|

Aluminium Sandwich Sheets | Usually lower | Clean, check for damage, look at joints |

Wood | Higher | Needs more care, depends on treatment |

Unprotected Metal | Higher | Needs regular fixing to stop rust and damage |

You spend less over time because it lasts long and needs little care.

Impervious to Dust and Sand

Aluminium cladding keeps dust and sand out. Dirt cannot get inside your building. This helps if you live in a windy or sandy place. The panels fit together tightly. Nothing gets through the cracks. You get a cleaner space and do not need to clean as much.

Tip: If you want a building that stays clean and is easy to care for, aluminum composite panel is a smart pick.

Many people choose aluminium sandwich sheet for their projects. The good points make it popular with builders, homeowners, and architects.

Disadvantages of Aluminium Sandwich Sheets

Susceptibility to Dents

Susceptibility to Dents

Aluminium sandwich sheet can get dents more easily than solid metal. If you hit or drop something heavy, it might leave a mark. The inside core is softer than solid aluminium. This makes it easier to dent. You can look at how different panels handle dents:

Feature | Solid Aluminum Sheets | Aluminum Composite Panels |

|---|---|---|

Construction | One solid layer of aluminum | Two thin aluminum sheets with a soft core |

Dent Resistance | Very strong and hard to dent | Not as strong because of the soft core |

Weight | Heavier because it is solid | Lighter because of the core |

Fire Safety | Very good at stopping fire | Depends on what the core is made of |

Longevity | Can last over 50 years if cared for | Usually does not last as long as solid aluminum |

Maintenance | Needs little care | Easy to clean with soap and water |

Tip: If you think your panels will get hit a lot, pick a thicker panel or add extra protection.

Waterproofing Requirements

Aluminium sandwich sheet needs good waterproofing to stay strong. If water gets inside, it can cause big problems. You might see stains or even mold. Water can hurt the core and make the panel weak. Here are some things that can happen if water gets in:

Water can leave wet stains.

Rust can happen over time.

The middle part can break down.

Mold or mildew can grow and make people sick.

You may have to pay more to fix water damage.

Steel inside can rust and push on concrete. This can make cracks and break pieces off. The building may not be as safe if this happens.

Note: Always check the waterproofing before you put up aluminium cladding. Good sealing helps your panels last longer.

Aesthetic Limitations

You might want your building to look a certain way. Aluminium panels come in many colors and finishes. Some people think they look too modern or plain. Dents or scratches can show up and not look nice. Here are some choices you have:

Material Type | Finishes and Color Options |

|---|---|

Aluminum Composite (ACM) | Many finishes like wood-look, matte, shiny, and custom colors. |

100% Aluminum Panels | Also many choices, like wood tones and modern looks. |

ACM panels have lots of finishes and textures.

100% aluminum panels also give you many style choices.

Both let you be creative with design.

Designers like aluminium for its style options. You can get wood or shiny metal looks. Some people like stone, brick, or real wood better. If you want a classic look, aluminium may not be right for you.

Problems like denting, needing waterproofing, and style limits are common with aluminium cladding. Think about these before you pick aluminium sandwich sheet for your project.

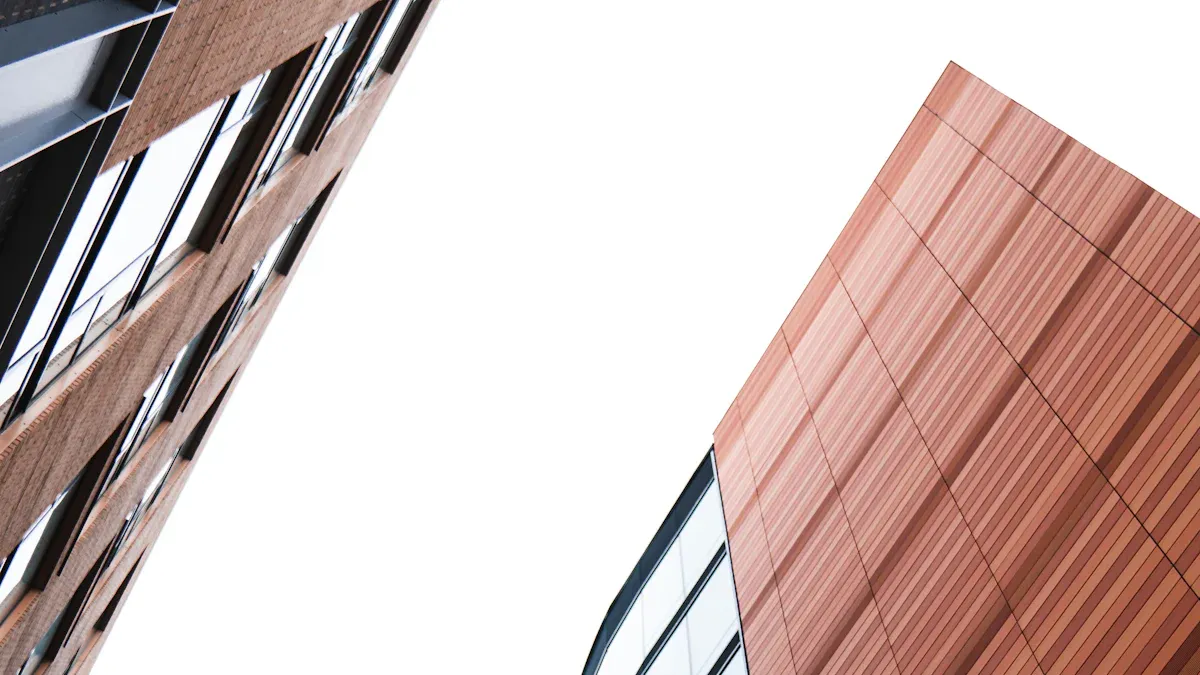

Aluminium Cladding Applications

Building and Construction

Building and Construction

Aluminium cladding is used a lot in new buildings. Builders put it on walls, roofs, and floors. It is light but also strong. Aluminium cladding helps keep heat out in summer. It keeps heat inside during winter. The construction industry uses aluminium cladding more than others. If you want a green building, aluminium cladding is a good choice.

More than half of last year’s market money came from walls and floors with aluminium cladding.

Insulated aluminium cladding panels help lower your heating and cooling bills.

The core inside aluminium cladding keeps heat from leaving, so your building stays cozy.

Tip: Aluminium cladding is smart if you want a building that lasts and saves money.

Transportation

Aluminium cladding changes how cars, trains, and planes are made. It makes vehicles lighter but still strong. Lighter vehicles use less fuel and can carry more things. Aluminium cladding also helps keep people safe in crashes.

Aluminium cladding can make vehicles up to 30% lighter.

This means better gas mileage and lower carbon costs.

In planes, aluminium cladding saves fuel and lets them carry more.

It also cuts down on shaking and stands up to heat.

Industrial Uses

Factories and warehouses need strong cladding. Aluminium cladding lasts a long time in tough places. You see it in cold storage, food plants, and solar projects. Aluminium cladding keeps temperatures steady and goes up fast.

Industrial Application | Benefit of Aluminium Cladding |

|---|---|

Cold Storage | Keeps things cold |

Food Processing | Easy to clean and tough |

Solar Panel Enclosures | Protects and keeps heat in |

Industrial Walls | Stands up to damage and weather |

Note: Aluminium cladding is quick to install and can be made to fit any factory need.

Residential Projects

People like aluminium cladding for homes because it looks nice and is easy to care for. You can use it for walls, ceilings, and soundproofing. Aluminium cladding makes furniture light and modern. Outside, it protects your house from wind, rain, and sun.

Aluminium cladding panels make smooth walls and ceilings.

You get strong, weatherproof signs for inside and outside.

Aluminium cladding furniture is light and easy to clean.

Homeowners say it helps them get the look they want.

If you want a modern home with less work, aluminium cladding is a good pick. It also meets energy rules, so it is good for the planet. Just remember, fire safety is important with some core materials.

Aluminium sandwich sheet is strong and light. It helps you save money. It lasts a long time and does not break easily. It can handle heat and is simple to take care of. But it can get dents. You need to make sure it stays dry. Some people do not like how it looks. Think about what your project needs before you choose aluminium. Here is a simple guide to help you:

Criteria | Aluminium Sheets | Aluminium Plates |

|---|---|---|

Application Requirements | Good for light and pretty parts | Best for heavy and strong jobs |

Mechanical Properties | Easier to change and bend | Stronger and harder to bend |

Fabrication and Processing | Simple to cut and shape | Needs special tools to weld |

Cost Considerations | Costs less for most jobs | Costs more for each piece |

Weight Considerations | Great when you want things light | Needed for big and tough jobs |

Surface Finish and Aesthetics | Easy to make look nice | Can be painted or made shiny |

Aluminium works well for many things. It is a good choice if you want something that lasts.

FAQ

What makes aluminum sandwich sheets different from regular metal panels?

You get two thin aluminum layers with a lightweight core in the middle. This design gives you strength, insulation, and less weight than solid metal panels.

Can you paint or decorate aluminum sandwich sheets?

Yes, you can paint them or add finishes. Many panels come in different colors and textures. You can match your style or project needs.

How do you clean aluminum sandwich sheets?

Just use mild soap and water. Wipe with a soft cloth. You do not need special cleaners. Avoid harsh chemicals to keep the finish looking good.

Are aluminum sandwich sheets safe for outdoor use?

You can use them outside. They resist rust and weather. Make sure you seal the joints well to keep water out. Good waterproofing helps them last longer.

Susceptibility to Dents

Susceptibility to Dents Building and Construction

Building and Construction