17 Dec Aluminium Sandwich Sheet vs Other Composite Panels: What Sets Them Apart in 2025

Table of Contents

You want the best panel for your project. Aluminium sandwich sheet is special in 2025. Top companies use it because it is strong. It is easy to install and stands up to bad weather. You save money and get better safety. This makes it a smart choice. The market is growing fast for aluminium sandwich sheet and composite panels.

The global composite panel market will be USD 77.24 billion in 2025.

Aluminium composite panels will grow at a CAGR of 7.0% from 2025.

Reason | Description |

|---|---|

Durability | Aluminium sandwich sheet lasts long and is lightweight. |

Quick Installation | You save time and work with fast installation. |

Weather Resistance | Aluminium sandwich sheet keeps out rain and frost. |

Cost-effectiveness | You spend less but still get good quality and safety. |

You should compare cost, strength, installation, safety, sustainability, and how you use it. Picking aluminium sandwich sheet helps you follow safety rules. It also helps your project last longer.

Key Takeaways

Aluminium sandwich sheets are light and strong. They are easy to put in place. They work well for many types of projects. These panels stand up well to bad weather. They help keep buildings warm or cool. This saves energy. Picking aluminium sandwich sheets can help you save money over time. They last a long time and do not need much care. More people want aluminium composite panels now. This shows that many builders use them in new buildings and designs. Aluminium sandwich sheets can be recycled. This makes them good for the environment and green building rules.

Key Comparisons: Structure and Materials

Aluminium Sandwich Sheet Construction

You want a panel that is strong and light. Aluminium sandwich sheets give you both. These panels have two thin aluminum sheets on the outside. The middle part is called the core. The core can be XPS foam, honeycomb, or mineral-filled. This design makes the panel strong but not heavy. You get good thermal insulation and weather protection. The foam or honeycomb core helps absorb impacts and keeps the panel light. You can cut and shape these panels easily at the job site. This makes them quick and easy to install for any project.

When you pick aluminium sandwich sheets, you get more than just a panel. You get something that stands up to tough weather and stops rust. It also keeps your building safe. The core you choose is important. XPS foam gives great insulation. Honeycomb cores are best for strength and low weight. Mineral-filled cores help stop fires. You can pick the core that fits your needs.

Types of Aluminum Composite Panels

There are many kinds of aluminum composite panels. The most common type has a thermoplastic core, usually polyethylene. This core sits between two thin aluminum sheets. Some panels have fire-resistant mineral cores. These are good for tall buildings and places where safety is important. Some panels use honeycomb cores for extra strength and less weight. Others use foam for better insulation.

Here is a simple comparison of the main types:

Feature | Aluminum Composite Panels (ACP) | |

|---|---|---|

Structure | Two thin aluminum alloys with a thermoplastic core | Honeycomb core layer |

Weight | Heavier due to plastic core | Lighter due to honeycomb core |

Form Retention | Less formable | Better formability and shape retention |

Applications | Wall cladding, signage, furniture | Aviation, aerospace, construction, military |

You can see that aluminum honeycomb panels are best for projects that need high strength and low weight. Regular aluminum composite panels work well for cladding, signs, and furniture.

Material Properties Overview

It is important to know how these panels work. Aluminum sandwich sheets and aluminum composite panels both have special benefits. Here is a side-by-side look:

Property | Aluminum Sandwich Sheets | Aluminum Composite Panels |

|---|---|---|

Strength | Strong due to aluminum sheets | |

Weight | Lightweight due to XPS foam core | Lightweight due to lower density |

Thermal Conductivity | Excellent thermal insulation from XPS foam | Good thermal insulation (0.15 – 0.1 W/m/K) |

Corrosion Resistance | Excellent, suitable for humid environments | Generally durable |

Workability | Easy to cut and shape | Easy to install due to lightweight nature |

Weather Resistance | Good, maintains performance outdoors | Generally durable |

Both options give you strong and light panels. Aluminum sandwich sheets give better insulation and stop rust. Aluminum composite panels are easy to install and last a long time.

Core Material Comparison

Core Material Type | Composition | Performance Characteristics |

|---|---|---|

Polyethylene (PE) | Lightweight plastic | Provides flexibility and reduces weight |

Fire-Resistant (FR) Cores | Mineral-filled materials | Enhances fire resistance, suitable for high-rise buildings |

You can pick a core that fits your project. Polyethylene cores keep panels light and flexible. Fire-resistant cores are best for tall buildings.

Aluminum Cladding vs. Composite Panels

Aspect | Aluminum Cladding | Aluminum Composite Panels |

|---|---|---|

Core Material | Solid aluminum sheets | Aluminum sheets with various cores (plastic, mineral, foam, honeycomb) |

Fire Resistance | Non-combustible | Varies: plastic core burns, mineral core resists fire |

Durability | High | Good, depends on core quality |

Weight | Heavier | Very lightweight |

Solid aluminum cladding gives the best fire resistance and lasts the longest. Aluminum composite panels are lighter and give you more choices for the core.

Market Trends and Panel Innovations

You want the newest technology for your project. In 2025, the market for aluminum composite panels and composite facade panels is growing fast. Builders now like materials that are light and strong. More projects use aluminum facade panels for cladding, signs, and inside design. The transportation industry, like cars and planes, also uses these panels for their strength and low weight.

Tip: Pick fire-resistant, antibacterial, or antistatic panels for hospitals, schools, and tall buildings. These new features help keep places safer and cleaner.

Here are the top trends in the market:

Companies now use recycled aluminum and bio-based cores in aluminum composite panels.

Builders are choosing materials that are better for the environment.

More projects use aluminum facade panels for noise control and decoration.

Trend Description | Details |

|---|---|

Market Growth | The market for fire-resistant, antibacterial, and antistatic composite panels is growing a lot in 2025. |

Key Drivers | More demand in building, especially for tall and energy-saving buildings. |

Innovations | Better fire resistance and antibacterial features are changing the market. |

Leading Region | Asia-Pacific, especially China and India, is leading because of fast city growth and new buildings. |

Market Value | Projected Growth |

|---|---|

Aluminum Composite Panels Market | Worth $6.63 billion in 2025, expected to grow at a CAGR of 8.8% from 2025 to 2033. |

Fire-Retardant Panels | Will stay popular because of more building projects and focus on safety. |

You want to be ready for the future. Pick aluminum sandwich sheets or aluminum composite panels that fit your project. You get the best value, safety, and performance by choosing the right panel.

Durability and Performance

When you pick a panel, you want it to last. You also want it to work well. Aluminum sandwich sheets are strong in 2025. They last a long time and protect your building in any weather. Let’s see how these panels do in real life.

When you pick a panel, you want it to last. You also want it to work well. Aluminum sandwich sheets are strong in 2025. They last a long time and protect your building in any weather. Let’s see how these panels do in real life.

Impact and Wear Resistance

You need panels that can take hits and bumps. Aluminum sandwich sheets are great at stopping dents. Tests show foam or honeycomb cores help absorb energy. These panels do better than most other composite panels.

Aluminum foam sandwich panels with stainless steel sheets are tough and soak up energy.

These panels can take hard hits and keep your building safe.

Tests show aluminum foam sandwich panels bend less than steel plates when hit.

Panels with Al6061 sheets can take bigger hits and soak up more energy than other materials.

The thickness of the aluminum sheets and foam core changes how much force the panel can handle.

You get panels that stay strong and keep their shape. They work well in busy places or rough weather. This means you fix them less and worry less about damage.

Lifespan and Maintenance

You want panels that last many years. You also want them to be easy to care for. Aluminum sandwich sheets give you both. Aluminum does not rust, even in wet or salty places. Cleaning is easy and fast.

Maintenance Needs | |

|---|---|

Low, non-corrosive aluminum facers | |

Solid Aluminum Panels | Needs maintenance to prevent corrosion |

You save time and money on cleaning. Aluminum composite materials only need simple cleaning to look good. Solid aluminum panels need more care to stop rust. Sandwich sheets with special coatings stay strong and shiny for years.

Tip: Pick aluminum sandwich sheets if you want panels that need little care and stay strong for a long time.

Insulation and Weather Resistance

You want your building to stay comfy and safe in any weather. Aluminum sandwich sheets keep heat and cold out. The foam or honeycomb core helps block heat and cold. This makes your building use less energy. Aluminum composite panels also keep heat out because of their polyethylene core. Panels with thick polyurethane foam (PUF) cores work even better. If you want the best climate control, pick PUF panels.

Rockwool panels are best for blocking noise. They stop sound better than most other panels. But aluminum sandwich sheets still give good thermal and sound protection for most jobs.

Weather matters. If you build where there is wind, rain, or hot and cold days, you need tough panels. Insulated panels with foam or mineral wool cores work in all climates. Rust-proof aluminum composite sheets are great for buildings near the sea or in wet places. You get panels that stand up to bad weather and keep your building dry and safe.

Note: Aluminum sandwich sheets keep water out, so you do not have to worry about leaks or mold.

You get panels that protect your building, save energy, and look good for years. Pick aluminum sandwich sheets for the best mix of strength and performance in any weather.

Cost and Value

Material and Installation Costs

You want to keep your project on budget. Aluminum cladding gives you a smart way to save money. The panels are light, so you spend less on transport and labor. You do not need heavy equipment to lift aluminum cladding. This lowers your installation cost. Many builders choose aluminum sandwich sheets because they are easy to cut and fit. You finish your job faster and pay less for labor.

Aluminum cladding also helps you avoid extra costs. The panels resist rust and water. You do not need to buy special coatings or pay for repairs. When you compare aluminum cladding to other panels, you see that the cost is lower over time. You get strong panels and high quality without breaking your budget.

Tip: Always check cost considerations before you start your project. Aluminum cladding often gives you the best value for your money.

Long-Term ROI

You want your investment to pay off. Aluminum sandwich sheets give you a strong return. The panels last for many years. You save money on energy bills because the foam or honeycomb core keeps your building cool or warm. Decorative PU aluminum cladding may cost more at first, but you save more over time. You spend less on repairs and cleaning.

Aluminum honeycomb panels are very light. You do not need extra support, so you save on building costs. ALUMINA aluminum cladding protects against water and sun. This means your panels look new for longer. You get high quality and a great return on your investment.

Market Trends in 2025

You want to choose a product that will stay popular. The aluminum cladding market keeps growing. In 2025, the aluminum composite panels market will rise from $6.53 billion to $6.87 billion. This shows a strong demand. The aluminum sandwich panel market will grow even faster, from $1.6 billion in 2023 to $3.2 billion by 2032. You see more builders picking aluminum cladding for its low cost and high quality.

Aluminum cladding is now the top choice for many projects.

Builders trust aluminum cladding because it saves money and lasts longer.

The market for aluminum cladding grows every year.

You get the best value when you pick aluminum cladding. You save on cost, get high quality, and invest in a product that will last.

Fire Safety and Regulations

Fire-Resistant Panel Options

Fire-Resistant Panel Options

You want your building to be safe if there is a fire. Picking the right panel is very important. Many aluminum sandwich sheets and composite panels can stop fire from spreading. Some panels have special fire-retardant cores or coatings. These panels help keep schools, hospitals, and tall buildings safe.

Here are some common fire-resistant panel choices:

Class A (ASTM E84) panels are best for schools and hospitals.

Fire-resistant panels can be used for:

Outside walls

Inside walls and room dividers

Ceilings

Furniture

Signs and displays

You can see how panels are different in fire rating and use:

Panel Type | Core Material | Fire Rating | Applications |

|---|---|---|---|

Fire-Resistant Aluminum Composite Panel | Mineral-filled fire-resistant core | Class A (ASTM E84) | High-rise buildings, sensitive areas |

Aluminum Sandwich Panels | Non-Toxic Polyethylene, Flame-Retardant Core | EN 13501-1, ASTM E84 | Wall cladding, signage, and more |

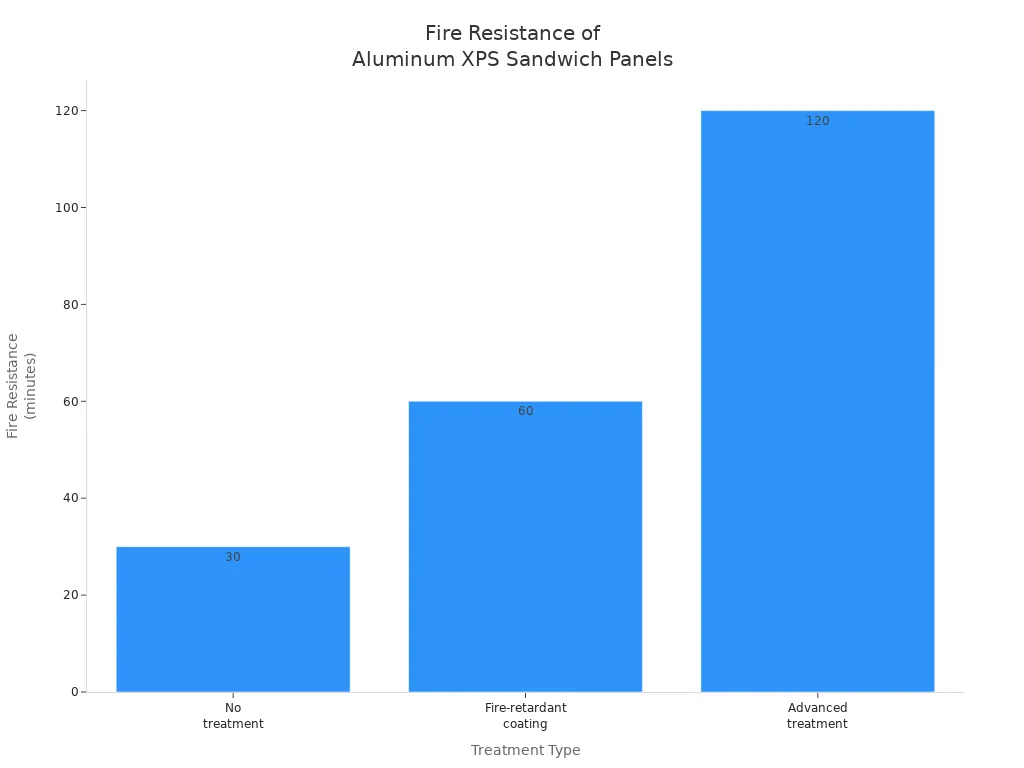

Aluminum XPS sandwich panels give you choices for fire safety. If panels are not treated, they last less than 30 minutes in fire. With fire-retardant coatings, they last up to 1 hour. Special treatments can make them last up to 2 hours. This chart shows how treatments help panels stay safe longer:

Tip: Always pick panels with real fire safety ratings for your project. This keeps people and buildings safe.

Compliance with 2025 Codes

You need panels that follow strict fire safety rules in 2025. Aluminum does not burn, so it helps your building pass checks. XPS foam cores get special chemicals to make them safer in fire. Makers test panels to meet rules like Class A or Class B.

Aspect | Details |

|---|---|

Fire Resistance | Aluminum does not burn; XPS foam core can burn but is treated with fire-retardant chemicals. |

Testing and Certification | Panels are tested carefully to meet or beat fire-safety rules, like Class A or Class B. |

Compliance Standards | Following local and world fire safety rules is very important for selling panels. |

You should pick panels that meet EN 13501-1. This rule checks if panels burn, how fast fire spreads, smoke, and burning drops. Meeting these rules makes your building safer and worth more.

EN 13501-1 is a main rule in the EU.

It covers all fire safety needs for panels.

Following this rule helps you get more jobs and keeps people safe.

Note: Panels that meet 2025 rules help you feel safe and avoid big problems.

Installation and Handling

Weight and Ease of Installation

You want panels that make work simple and quick. Aluminum sandwich sheets are much lighter than other panels. This low weight lets you move panels without big machines. You save time and money on labor. Here is how some materials compare:

Material | Thickness | Weight (kg/m²) | Weight (lbs/ft²) |

|---|---|---|---|

Geely ACP (Aluminum + Polyethylene core) | 3 mm | 3.55 | 0.73 |

Solid Aluminum Sheet | 3 mm | 8.1 | 1.66 |

Medium-Density Overlay (MDO) | Varies | 5-10 | 1.02 – 2.05 |

Wood Panel | Varies | 6-12 | 1.22 – 2.44 |

Aluminum sandwich sheets weigh less than solid aluminum and wood. This makes putting up panels easier and safer. You finish jobs faster and lower the chance of getting hurt.

When you put up panels, you may face some problems:

Measure each panel before you start. Wrong sizes can cause trouble.

Use the right tools to shape panels. Getting help from experts makes things easier.

Make sure panels keep water out. This stops leaks.

Line up the mounting system and check corners.

Fasten panels with screws and cover spaces for strong results.

Tip: Pick light panels to save time and money. You get good results with less work.

On-Site Adaptability

You want to be able to change things during installation. Aluminum composite panels let you do that. You can cut and shape panels at the job site. Regular tools work well for this job. If plans change, you can fix panels fast. This helps you solve problems and finish on time.

Field-made systems let you make special cuts and changes. You can handle last-minute updates or fit panels in tight spots. Aluminum panels are light, so moving and changing them is easy for everyone.

Note: Choose panels you can change on-site. You stay in charge and make your project better.

Sustainability and Environmental Impact

Recyclability of Aluminium Sandwich Sheets

You want your building to help the planet. Aluminium sandwich sheets make this easy. These panels can be recycled almost completely. When you are done with them, you do not make much waste. You can send old panels to recycling centers. Workers take out the aluminum and use it again for new things.

Aluminum composite panels can be recycled about 95%.

This is much better than other composite panels, which are recycled less.

Choosing aluminium sandwich sheets gives you a big benefit. Facade panels that can be recycled help keep the environment clean. They also cut down on landfill waste. If you care about the planet, these panels are the best choice.

Tip: Pick panels that can be recycled to make your project greener and better for the earth.

Green Building Standards

You want your building to follow green rules. Aluminium sandwich panels help you do this. These panels give great insulation, so your building uses less energy. You save money on heating and cooling. You also help the earth by using less energy.

Aluminium sandwich panels help you get LEED and BREEAM certifications because they insulate well.

Insulated sandwich panels make it easier to get LEED certification by saving energy.

These panels help meet BREEAM standards and make your building better for the environment.

Your project stands out when you use panels that meet green standards. Builders like these panels because they are good for the planet. You show you care about the future by picking materials that protect the earth.

Note: Choose aluminium sandwich sheets if you want your building to meet green standards and help the environment.

Design Flexibility and Applications

Customization and Aesthetics

Customization and Aesthetics

You want your project to look special. Aluminum sandwich sheets help you make cool designs. In 2025, you can pick from many sizes and finishes. You can bend these panels into curves or sharp angles. You can even make tricky shapes. This means you can match your ideas for any building or sign.

You can choose shiny, flat, or rough finishes. You can pick colors that match your brand or style. These panels work well for stores, buildings, and signs. You get panels that look nice and work well. Your building or sign will get noticed and look high quality.

Tip: Use aluminum sandwich sheets to add bright colors and fun shapes to your project. You will impress people with a new and bold look.

Best Use Cases

You want to know where aluminum sandwich sheets work best. These panels do better than other composite panels in many places. You get more value and better results each time.

Application Area | Advantage |

|---|---|

You get a modern look and strong protection. Your building stands out and lasts longer. | |

Energy Efficiency | Reflective coatings help keep buildings cool. You save money on air conditioning. |

Sustainability | You support green building. These panels use recycled materials and can be recycled again. |

Lightweight Nature | You upgrade old buildings safely. The panels do not add much weight. |

Fire Safety | Fire-retardant options meet strict safety rules. You protect people and your reputation. |

You can use aluminum sandwich sheets in schools, hospitals, offices, and stores. You can put them on walls, ceilings, and signs. You get panels that fit many jobs and help your project do well.

Note: Pick aluminum sandwich sheets for projects that need style, safety, and smart energy use. You make a good choice for now and the future.

Choosing the Right Panel

When to Choose Aluminium Sandwich Sheets

You want your project to look great and last long. Pick aluminum cladding if you need panels that are light. These panels are easy to move and put up. Aluminum cladding is best when you want to finish fast. You save time and money because you do not need big machines. If you like many styles, aluminum cladding has lots of colors and patterns. You can bend it for curves or make sharp lines. Aluminum cladding keeps your building warm or cool. It does not need much cleaning or fixing. You can use it in schools, offices, hospitals, and stores. Aluminum cladding protects from rain, wind, and sun. If you care about nature, aluminum cladding can be recycled. It helps you follow green building rules.

When to Choose Other Composite Panels

Sometimes you need panels that are even stronger or safer from fire. Pick other composite panels if your project needs more strength. Solid panels are good for busy places or where things might get damaged. If fire safety is most important, choose panels with mineral cores. These panels follow strict safety rules. You may want better sound or heat insulation. Some composite panels block noise better. For special jobs, like tall buildings, pick panels with high fire ratings. These panels give more safety. Some cost more, but they keep people and buildings safer.

Decision Checklist

You want to pick the best panel for your job. Use this checklist to compare aluminum cladding and other panels:

Checklist Item | Description |

|---|---|

Design and Pattern | Pick aluminum cladding if you want more design choices. |

Material or Product Grade | Choose the right grade of aluminum cladding for your needs. |

Delivery Time | Aluminum cladding often arrives faster, so you finish sooner. |

Certificates and Awards | Check for fire safety and quality certificates on aluminum cladding. |

Tip: Always check the grade, style, and certificates before you buy aluminum cladding. This helps you get better results and feel sure about your choice.

You make your project safer, stronger, and nicer when you pick the right aluminum cladding. Take time to think about what you need and match it with the best panel.

You want panels that are strong and safe. Aluminium sandwich sheets are light but tough. They are easy to put up and resist fire well. Other composite panels can be stronger or block sound better. Pick what fits your project best. Think about cost, design, and safety before you decide.

Are you ready to pick? Check your list and ask a good supplier. You get the best results when you choose the right panel for your needs.

FAQ

What makes aluminium sandwich sheets better for fast installation?

Aluminium sandwich sheets are light. You can carry them easily. You do not need big tools. You finish jobs faster. This saves you money on labor.

Are aluminium sandwich sheets safe for tall buildings?

Aluminium sandwich sheets have good fire safety. Many panels pass strict fire rules. Builders use them in tall buildings. They help keep people and things safe.

Tip: Always look at fire ratings before buying panels for tall buildings.

Can I recycle aluminium sandwich sheets after use?

You can recycle almost all aluminium sandwich sheets. Recycling helps the planet. You make less waste. You help green building rules.

Panel Type | Recyclable (%) |

|---|---|

Aluminium Sandwich Sheet | 95% |

Other Composite Panels | 60% |

Where should I use aluminium sandwich sheets for best results?

Aluminium sandwich sheets work well on walls, signs, and ceilings. They are good for schools, hospitals, and offices. You get better safety, style, and save energy.

Pick aluminium sandwich sheets for projects that need to last and look modern.

Fire-Resistant Panel Options

Fire-Resistant Panel Options Customization and Aesthetics

Customization and Aesthetics