21 Dec Exploring the Different Types of Composite Panel Cladding

Table of Contents

You can see many types of composite panel cladding in buildings today. The most popular types are aluminum composite panels, insulated metal panels, fiber-reinforced polymer panels, high-pressure laminate panels, honeycomb panels, zinc composite panels, and copper composite panels.

Composite panel cladding gives a modern way to cover buildings. It mixes classic looks with strong materials and easy care. These panels help buildings work better and fit many styles. If you know about the different types, you can pick the best one. You can choose what works for your weather, building style, and green goals.

Key Takeaways

Composite panel cladding is a new way to cover buildings. It looks nice and lasts a long time. It does not need much care.

There are different kinds of composite panels. Some are aluminum, insulated metal, or fiber-reinforced polymer. Each type works best in certain places and for certain uses.

Picking the right composite panel depends on a few things. You should think about saving energy, standing up to weather, and how you want it to look.

There are different ways to put up the panels. Rainscreen and bonded cladding help keep out water and keep heat in.

Cleaning and taking care of composite panels is important. This helps them last longer and look good. It also makes sure they are worth the money you spend.

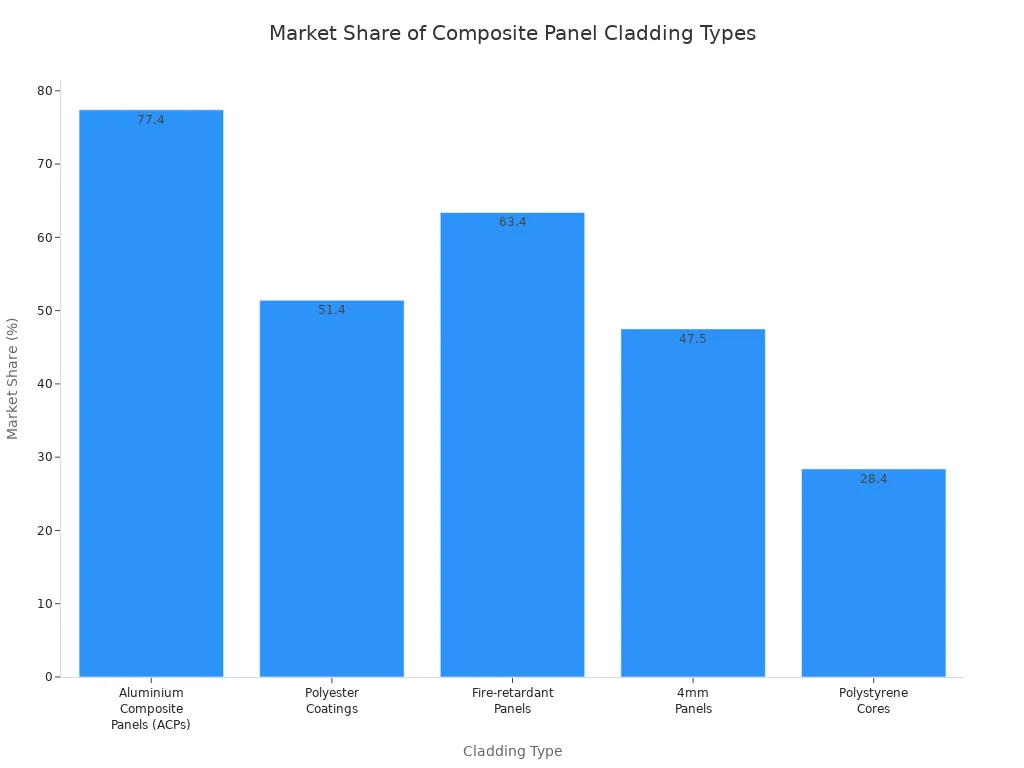

Composite Panel Cladding Types

There are many composite panel cladding types used today. These panels are grouped by what they are made of and how you put them on buildings. You can sort panels by their core, their outer layer, or what they are used for. The table below lists the main types and what makes each one special:

Category | Description |

|---|---|

Lightweight panels made of aluminum sheets with a core, known for design versatility and weather resistance. | |

Insulated Metal Panels (IMPs) | Panels with metal faces and foam insulation, ideal for energy efficiency and structural stability. |

Fiber-Reinforced Polymer (FRP) | Lightweight, corrosion-resistant panels used in various industries, offering high strength-to-weight ratios. |

High-Pressure Laminate (HPL) | Durable panels made from resin-impregnated paper, known for impact and scratch resistance. |

Honeycomb Panels | Panels with a honeycomb core for high strength and low weight, often used in transport and architecture. |

Zinc Composite Panels | Panels with zinc facing, valued for durability and self-healing patina. |

Copper Composite Panels | Panels with copper facing, known for longevity and unique appearance. |

You can also group composite panels by what is inside, like polyurethane, polyethylene, rock fiber, or wood. The outside layer can be metals such as aluminum, zinc, or copper. People pick panels for different jobs, like fireproofing, stopping germs, or keeping heat in.

Aluminum Composite Panels

Aluminum composite panels are very common in buildings. They are light and simple to put up. The middle part is usually polyethylene or a fire-safe material, with aluminum on both sides. These panels have many good points:

Characteristic | Description |

|---|---|

Lightweight | Easier to handle and install, reducing structural stress. |

Durability | Resistant to corrosion and harsh weather conditions. |

Aesthetic Versatility | Available in various colors and textures, allowing for creative designs. |

Thermal and Sound Insulation | Improves energy efficiency and occupant comfort. |

More affordable than traditional materials like bricks or glass. | |

UV and Chemical Resistance | Stands up to environmental factors, ensuring longevity. |

Environment Friendliness | Made from recyclable materials, promoting sustainability. |

Termite and Fungal Resistance | Resistant to pests and decay, enhancing durability. |

You can use aluminium composite panels for outside walls, inside walls, ceilings, signs, and furniture. These panels help make smooth and modern spaces. They are easy to clean and do not need much care.

Tip: If you want a panel that bends easily and stands up to bad weather, aluminium composite panels are a good pick.

Insulated Metal Panels

Insulated metal panels are another main type of composite panel. You see these in schools, stores, power plants, and other places that need to save energy. These panels have metal on the outside and foam in the middle, which helps keep heat in and gives support.

Feature/Use | Description |

|---|---|

Energy Efficiency | Unique energy-efficient insulation that benefits various building types. |

Lightweight Construction | IMPs are lightweight, making them easier to handle and install. |

Durability | High durability suitable for commercial and industrial buildings. |

Cost-effective Installation | Timely installation as a single component reduces labor costs. |

Climate Considerations | Designed to handle temperature, humidity, airborne particles, and air movement. |

You can get insulated metal panels in different shapes, sizes, colors, and looks. These panels work well with windows and shades, making a full cover for your building.

Fiber-Reinforced Polymer Panels

Fiber-reinforced polymer panels are light but strong. They have a high strength compared to their weight, so they are used in many fields. These panels do not rust and need little care. You can use them for cladding where you want to keep heat in and have many design choices.

Fiber-reinforced polymer panels are light but strong. They have a high strength compared to their weight, so they are used in many fields. These panels do not rust and need little care. You can use them for cladding where you want to keep heat in and have many design choices.

Advantages | Limitations |

|---|---|

High strength-to-weight ratio | Lower compressive strength compared to steel |

Corrosion resistance | Potential wear and degradation under repetitive stress |

Low maintenance | Challenges with fastener retention |

Thermal efficiency |

|

Design versatility |

|

You should know fiber-reinforced polymer panels are not always as strong as steel. Sometimes, it is hard to keep fasteners in place.

High-Pressure Laminate Panels

High-pressure laminate panels are tough and do not scratch or dent easily. You see them in kitchens, offices, wall panels, and hospitals. These panels are made by pressing paper with resin under high pressure.

Unique Properties | Typical Applications |

|---|---|

Residential kitchens and cabinetry | |

Fire resistance | Office furniture and wall panels |

Design versatility | Healthcare settings for hygiene |

Environmental friendliness | Retail spaces for display fixtures |

You can pick high-pressure laminate panels for places that need to stay clean and are easy to wipe down. These panels also come in many styles.

Honeycomb Panels

Honeycomb panels are special because they are strong but not heavy. They have two thin sheets on the outside and a honeycomb shape in the middle. You can change the inside and outside materials to get what you need.

Honeycomb panels are good when you want strength but not extra weight.

You see these panels in cars, trucks, and buildings.

Note: Honeycomb panels are strong for their weight, so they are great for big areas and light structures.

Zinc Composite Panels

Zinc composite panels last a long time and can fix small scratches by themselves. They bend well and have a flat surface. These panels do not need much care and keep heat steady.

Features | Applications |

|---|---|

Long lasting and durable | Exterior Elements |

Superior bending strength | Facades – Metal Wall Cladding Systems |

Excellent surface flatness | Roofs – Metal Roofing Systems |

Thermal stability | Soffits |

Virtually maintenance free | Rain Screens |

Effective vibration and damping | Awnings |

“Self-healing” patina |

|

Exceptionally cost-effective |

|

You can use zinc composite panels for outside walls, roofs, soffits, rain screens, and awnings. These panels help make buildings look modern and last longer.

Copper Composite Panels

Copper composite panels are very strong and look different from other panels. They are good for the environment and do not need much care. These panels keep heat in and are safe from fire.

Benefits | Drawbacks |

|---|---|

Exceptional durability | Higher initial costs |

Aesthetic appeal |

|

Environmental sustainability |

|

Low maintenance requirements |

|

Excellent thermal performance |

|

Fire resistance |

|

Cost efficiency |

|

You can use copper composite panels for building fronts if you want them to stand out and last a long time. They cost more at first, but you get many good things over time.

Tip: If you want a building front that looks special and lasts for years, copper composite panels are a smart choice.

You can see that each type of composite panel has its own uses. You should look at what each one does best before you pick the right composite panel cladding for your building.

Key Features and Benefits of Types of Composite Panels

Lightweight and Durability

Lightweight and Durability

It is important to use building materials that are easy to move. You also want them to last a long time. Composite panels give you both of these things. There are many types of composite panels. The core can be LDPE, mineral, or aluminum. These cores make the panels light but strong. Honeycomb panels have a special core. This core keeps the panel light and adds strength. Metal composite panels, like ACP and ACM, can last more than 30 years if you take care of them. The table below shows how the core changes what the panel can do and where you use it:

Core Type | Key Properties | Applications |

|---|---|---|

LDPE Core | Lightweight, flexible, recyclable | Green building, complex designs |

Mineral Core | Fire retardant, thermal insulation | High fire safety, thermal insulation |

Aluminum Core | High strength-to-weight, corrosion resistance | Harsh environments, high durability |

You can pick the best panel for your project. Look at the core and the facing material before you choose.

Thermal and Acoustic Performance

Composite panels help keep buildings warm or cool. They also help keep them quiet. Many metal composite panels have a fire retardant core. This makes them safer and better at keeping heat in. Some panels have a high Noise Reduction Coefficient, or NRC. If a panel has an NRC of 0.80 or more, it absorbs most sound. This is good for places like offices or restaurants. Insulated metal composite panels and honeycomb panels help control temperature and noise. High-pressure laminate panels are good when you need both sound and heat control.

Tip: For a quiet and energy-saving space, pick composite panels with a fire retardant core and a high NRC.

Corrosion and Weather Resistance

You want cladding that can handle sun, rain, and wind. Metal composite panels with PVDF coatings block UV rays. These coatings help the panels keep their color for a long time. Honeycomb panels and other composite panels do not warp or crack when the weather changes. Many panels pass tough tests for UV and salt spray. Fire retardant cores make them even safer. Sealed surfaces keep water out. This stops problems like blistering or delamination. You can use these panels in places near the ocean or in tough weather.

Fire retardant cores make panels safer.

Sealed surfaces keep out water.

Aesthetic Options and Finishes

Composite panels let you make your building look how you want. You can choose from many colors, metallics, wood, or stone looks. You can also pick glossy or matte finishes. The facing material can be aluminum, zinc, or copper. This helps you match your design ideas. Wood-plastic composite panels look like real wood but need less care. Some finishes, like anti-graffiti coatings, add extra benefits. You can use these panels for modern, classic, or special styles.

Aesthetic Option | Description |

|---|---|

Custom Colors | Match branding or project style |

Textures | Smooth or rough surfaces for more interest |

Metallics | Shiny, modern finishes |

Wood and Stone Finishes | Natural look that lasts |

Glossy/Matte | Bright or soft appearance |

Specialized Finishes | Anti-graffiti, shiny coatings |

Note: Composite panels are easy to care for and stay looking nice for a long time. This makes them a smart pick for many projects.

Installation Systems for Composite Panel Cladding

Rainscreen Cladding Systems

Rainscreen Cladding Systems

Rainscreen cladding systems help protect buildings from water and wind. These systems have panels on the outside and a gap behind them. Air moves in this gap and lets moisture leave. This keeps the inside wall dry and safe. Rainscreen systems lower wind pressure and stop water from getting in. Flashing and sealants are used at the joints. These materials keep water out and make the system strong.

The space behind the rainscreen lets air move all the time. This air flow helps push out any water that gets through the panel joints. It stops water from reaching the inside wall.

The gap between the rainscreen and building adds extra insulation.

Flashing covers the joints and edges.

Sealants block water from getting inside.

Rainscreen cladding systems help buildings last longer. They also give buildings a modern and neat look.

Bonded Cladding Systems (ETICS)

Bonded cladding systems, or ETICS, use glue or fasteners to stick panels to the wall. These systems are easy to put up and cost less than some other ways. Bonded cladding adds insulation, so it helps save energy. You need to check bonded systems often. Weather can change how the joints and panels look over time.

Advantages | Disadvantages |

|---|---|

Weather can change how panels look | |

Low cost to install | May not last as long as other systems |

Easy to put up | Joints can have problems |

Makes buildings more efficient | Panels may look different after some time |

Bonded cladding is good if you want fast results and to spend less money. You need to plan for upkeep to keep the panels looking nice.

Choosing the Right System

You should think about a few things before picking an installation system. The materials used matter for how long it lasts and how much care it needs. The way you fasten panels changes how they look and how hard they are to put up. You can put panels up and down or side to side to match your design. If you want a green building, think about the environment.

Factor | Description |

|---|---|

Material Composition | The core and outside layers affect how long it lasts and upkeep. |

Fastening Systems | Exposed or hidden fasteners change looks and how hard to install. |

Installation Orientation | Up and down or side to side changes design and strength. |

Environmental Impact | Using green materials helps meet eco-friendly rules. |

Interlocking or simple fixing systems save time.

Less upkeep means you spend less money later.

It is important to use green materials in new buildings. Look for panels made from recycled or earth-friendly stuff. Fire resistance and insulation help keep buildings safe and save energy. The right system makes your building work better and last longer.

There are many composite panel cladding types you can pick for buildings. Each type has special benefits for inside and outside use. Some are light and strong. Others save energy or work well for outside walls. When you look at your choices, think about cost, how well they work, and how they look. Taking care of the panels helps them stay nice and last longer. Always choose the type that fits your project’s needs and style for the best results.

FAQ

What is the main advantage of using composite panel cladding?

Composite panels are light and strong. They last for many years. You can pick from lots of designs. It is easy to put them up. Cleaning them does not take much work.

Can you use composite panels for both inside and outside walls?

Yes, you can use composite panels in many places. People use them on the outside of buildings. You can also use them for inside walls, ceilings, or even furniture.

How do you clean and maintain composite panel cladding?

Clean panels with gentle soap and water. Use a soft cloth or sponge. Do not use strong cleaners. If you clean them often, they stay nice and last longer.

Are composite panels safe in a fire?

Many composite panels have fire-retardant cores. Always check the fire rating before you buy. Fire-rated panels help keep your building safer.

Can you recycle composite panel cladding?

Most aluminum and metal composite panels can be recycled. You help the earth when you pick panels made from recycled stuff or panels you can recycle later.

Lightweight and Durability

Lightweight and Durability Rainscreen Cladding Systems

Rainscreen Cladding Systems