01 Jan What Are the Main Types of Aluminum Sandwich Panels

Table of Contents

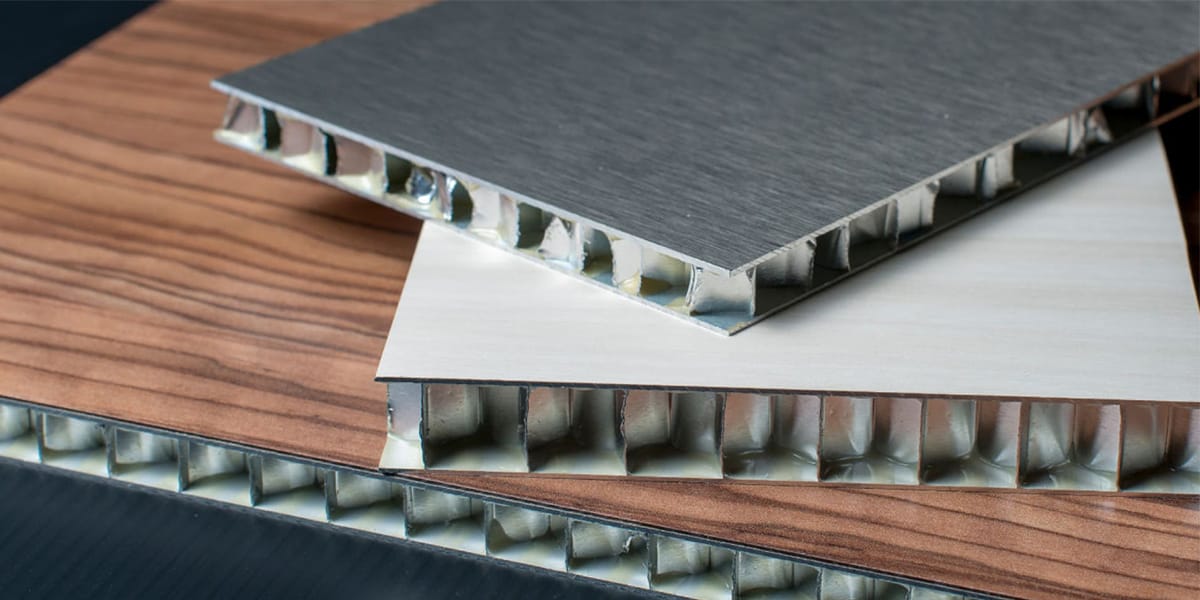

You can find different aluminum sandwich panels types by their core materials. The most common types are foam core, honeycomb core, EPS, PIR, XFLAM, and PE core panels. These panels use materials like expanded polystyrene, glass wool, and polyurethane. They provide insulation and strength for aerospace, construction, transportation, and industrial applications. When you choose an aluminum sandwich panel, be sure to check the structure, features, and best uses for your specific needs.

Key Takeaways

Aluminum sandwich panels have different types. The types depend on the core materials. These include foam, honeycomb, EPS, PIR, XFLAM, and PE. Each type has special features. Each type is used for different things.

Foam core panels are light. They give great thermal and sound insulation. You can use them inside or outside buildings.

Honeycomb core panels are strong and light. They work well for heavy loads. They are used in aviation and transportation.

PIR core panels give better insulation. They also help with fire safety. They are good for cold storage and industrial buildings.

Always think about what your project needs. You should look at insulation, fire safety, and how much weight the panel can hold. This helps you pick the best aluminum sandwich panel.

Aluminum Sandwich Panels Types by Core Material

Foam Core Sandwich Aluminum Panels

Foam core sandwich aluminum panels have a light foam in the middle. You will often see XPS, PET, PVC, or PU foam boards inside. The foam is between two thin aluminum sheets. This makes the panel strong and easy to move.

Here is a table that lists the main features of foam core sandwich aluminum panels:

Specification/Advantage | Description |

|---|---|

Cladding material | |

Core material | XPS/PET/PVC/PU Foam Board |

Max length | 12m |

Max width | 2.4m |

Total Thickness | 10~80mm (customizable) |

Fire rating | B1 |

Insulation | Provides thermal insulation, reducing energy consumption. |

Soundproofing | Absorbs sound waves, suitable for acoustic control applications. |

Lightweight | Easier to handle and install compared to solid materials. |

Structural Support | Contributes to strength and rigidity, allowing for larger panel sizes. |

Versatility | Used for exterior and interior applications, including wall cladding and roofing. |

Weather Resistance | Designed to withstand various weather conditions. |

Common Applications | Building facades, interior walls, signage, transportation, furniture, ceilings, and roofing. |

These panels give great thermal and sound insulation. They are not expensive and you can change their size or shape. Foam core sandwich aluminum panels work for inside and outside jobs. You can use them for walls, ceilings, and furniture. They do not rust, so they are good near salt water. But, they burn faster than some other types, so they are not best for places with high fire risk.

Tip: If you want soundproofing or insulation, foam core sandwich aluminum panels are a good choice.

Honeycomb Core Sandwich Aluminum Panels

Honeycomb core sandwich aluminum panels have a core shaped like a honeycomb. Thin aluminum layers form hexagons inside. This makes the panel very light and very strong.

Honeycomb core sandwich aluminum panels have a core shaped like a honeycomb. Thin aluminum layers form hexagons inside. This makes the panel very light and very strong.

These panels are much stronger than some solid materials.

The honeycomb shape keeps the panel stiff and stops bending.

You can use them where heavy loads need support.

They resist impacts and keep their shape for a long time.

You will see honeycomb core sandwich aluminum panels in these places:

Marine and naval industry (boats and ships)

Aviation (aircraft interiors and floors)

Transport (trucks, buses, and trains)

Honeycomb core sandwich aluminum panels are stiffer and hold more weight than foam core panels. They are about 28% better for load and at least 19% stiffer. They do not insulate as well as foam core panels. But, they are safer in fires because they burn at a higher temperature (about 600°C).

Note: Pick honeycomb core sandwich aluminum panels when you need strong and light panels, like in vehicles or planes.

EPS (Polystyrene) Core Panels

EPS (expanded polystyrene) core panels have a white, foam-like core. They give good insulation and cost less, but are not as strong or fire-safe as other types.

Thermal insulation values are from 0.033 to 0.038 W/mk.

EPS panels are lighter and cheaper than many other sandwich aluminum panels.

They do not hold heavy loads as well as PIR or honeycomb panels.

Fire resistance is lower, so some countries do not allow them in tall buildings.

Here is a table that shows where you can use EPS core panels and their limits:

Applications | Limitations |

|---|---|

Residential Construction | Fire Resistance: EPS is combustible. |

Commercial Buildings | Structural Load Limitations: May not support heavy loads. |

Cold Storage Facilities |

|

Industrial Applications |

|

Temporary Structures |

|

EPS core sandwich aluminum panels are good for homes, cold storage, and temporary buildings. Do not use them in tall buildings or places with strict fire rules.

PIR (Polyisocyanurate) Core Panels

PIR core sandwich aluminum panels use polyisocyanurate foam in the middle. This core gives better insulation and fire safety than EPS.

PIR panels help keep heat out, so you save energy.

They give great sound and heat insulation.

PIR panels resist chemicals and water, so they work in tough places.

They have a Class B fire rating and can handle high heat (up to 600 kW/m²).

PIR panels burn slower than EPS, so they are safer in a fire.

PIR core sandwich aluminum panels have a thermal conductivity below 0.023 W/(m·K), so they insulate very well. They are light, so you can install them easily.

Here is a table of common uses for PIR core sandwich aluminum panels:

Industry | Application Description |

|---|---|

Cold Storage and Refrigeration | Used in cold storage warehouses, refrigerated trucks, and walk-in freezers for insulation. |

Industrial Buildings and Warehouses | Employed for walls and roofs, providing energy-efficient insulation and structural support. |

Commercial Buildings | Applied in shopping malls, office buildings, and supermarkets for thermal efficiency. |

Clean Room Construction | Utilized in pharmaceutical facilities, laboratories, and food processing units. |

Residential Construction | Used in home construction for energy efficiency in walls and roofs. |

Refineries and Chemical Plants | Widely used for thermal insulation in various industrial applications. |

Food Factories | Employed in food processing environments for insulation and hygiene. |

Modular Buildings | Used in the construction of modular structures for efficient insulation. |

Tip: If you want high insulation and fire safety, PIR core sandwich aluminum panels are a great pick.

XFLAM and Fire-Resistant Core Panels

XFLAM and other fire-resistant core panels use special materials to stop fire from spreading. These panels meet strict fire safety rules like CAN/ULC-S134, NFPA 285, and ASTM E119. You can use them in buildings where fire safety is very important.

Standard | What It Measures | Typical Threshold |

|---|---|---|

CAN/ULC-S134 | Full-scale wall test (Canada) | Flame height below roof line & limited heat flux |

NFPA 285 | Multi-storey fire propagation (USA) | No vertical or lateral spread beyond prescribed limits |

ASTM E119 | Hourly fire resistance | 1- to 2-hour ratings for critical walls |

XFLAM panels have top fire resistance (Group 1-S) and can save up to 30% in system costs. They are also more cost-effective than other sandwich aluminum panels. You will find these panels in hospitals, schools, and tall buildings where fire safety matters most.

Note: Use XFLAM or other fire-resistant core panels if you need to follow strict fire codes or want extra safety.

PE (Polyethylene) Core Panels

PE (polyethylene) core panels have a plastic core between two aluminum sheets. These panels are light and easy to shape. But, PE cores catch fire easily and can help fire spread fast.

Many countries do not allow PE core sandwich aluminum panels in tall or commercial buildings.

The International Building Code (IBC) and NFPA 285 require strict fire tests for these panels.

After big fires like the Grenfell Tower tragedy, many places now require fire-resistant cores for buildings over 75 feet.

Regulation | Description |

|---|---|

International Building Code (IBC) | Imposes strict regulations on the use of PE core panels, especially in tall buildings. |

NFPA 285 | Requires panels to pass fire tests before use on tall buildings. |

Fire Safety Regulations | Many jurisdictions require fire-resistant (FR) core panels for buildings above certain heights, typically over 75 feet. |

You may still see PE core sandwich aluminum panels in small signs, displays, or short buildings. Always check your local building codes before picking this type.

⚠️ Warning: Do not use PE core panels in tall or public buildings because of fire risks.

Now you know the main aluminum sandwich panels types by core material. Each type has its own good points and limits. When you choose sandwich aluminum panels, always match the panel type to your project’s needs for safety, strength, and performance.

Key Characteristics of Sandwich Aluminum Panels

Strength and Weight

Strength and Weight

The strength of aluminum sandwich panels depends on a few things. The core material, skin thickness, and how well the layers stick together all matter. Panels are sorted by these features. If the skins are thicker and the core is denser, the panel is stronger. This means it can hold more weight. Engineers use bending tests to see how much weight a panel can take.

Here is a table that lists important strength facts:

Metric | Description |

|---|---|

Changes how stiff and strong the panel is | |

Skin Thickness | Thicker skins make the panel bend less |

Bonding Quality | Good bonds make the panel stronger |

Testing Methods | Bending tests show how much weight it can hold |

If the core is thicker and denser, the panel can hold more weight. Denser cores mean the panel can take more before breaking.

Thermal and Acoustic Insulation

Aluminum sandwich panels keep heat out very well. The type of core inside changes how well it blocks heat. Foam or honeycomb cores work best for keeping heat out. These panels help save energy and keep rooms comfortable.

The core stops heat from moving through the panel.

Buildings with these panels use less energy.

The core also helps block noise.

Low-density foam absorbs sound at lower sounds. High-density foam works better for higher sounds. You get both heat and sound protection in one panel.

Fire Resistance

Fire resistance is very important for aluminum sandwich panels. Always check the fire rating before picking a panel. Panels with mineral wool or fire-resistant PIR cores are best for stopping fire.

Here is a table that shows fire resistance:

Core Material | Fire Resistance Properties |

|---|---|

High-density mineral wool | Stops flames from spreading |

Fire-resistant PIR | Needs special stuff to resist fire |

Panels with A2 fire behavior, S1 smoke, and D0 flaming drops are very safe. These panels are good for places like offices and stores.

Durability and Corrosion Resistance

You want panels that last a long time. Aluminum sandwich panels are very tough. The type of aluminum alloy changes how well the panel fights rust. Unlike wood or vinyl, aluminum does not bend, crack, or lose color. You only need to clean them a little to keep them nice.

Good aluminum alloys fight bad weather.

Panels stay strong even in rough places.

They need little care and last a long time.

Aluminum sandwich panels give you strength, heat protection, fire safety, and last a long time. You can pick the right kind for your project.

Types of Sandwich Panels: Applications

Building Facades and Cladding

Building Facades and Cladding

Aluminum sandwich panels are used on the outside of buildings. They protect the building and make it look new and stylish. You can use them for outside walls, signs, insulation, and even inside walls or ceilings. The table below shows where these panels are often used:

Type of Panel | Common Applications |

|---|---|

Outside walls, building fronts, insulation, signs, inside walls, fake ceilings, machine covers, container building |

These panels are strong and light. They also stand up to bad weather.

Cleanrooms and Laboratories

Cleanrooms and labs need special panels to stay clean and safe. These panels have smooth surfaces that do not collect dust. They are easy to wipe and keep clean. The core is often rock wool or polyurethane for extra safety. These panels must not wear out fast or build up static. Here are some things they need:

Light weight

Very strong

Good in earthquakes

Do not burn easily

Do not rust

Component | Requirements |

|---|---|

Surface Material | Smooth, no dust, easy to clean, tough, no static |

Core Material | Rock wool, polyurethane, glass magnesium, and more |

Connection Material | Aluminum profiles, screws, expansion tubes, and more |

You can trust these panels in places where being clean and safe is very important.

Cold Storage and Refrigeration

Cold storage rooms and fridges need panels that keep cold air in. PU and PIR core panels are best for this job. They help save energy and keep food cold. PIR panels are even safer in fires and keep heat out better than PU panels. You see these panels in food storage and cold trucks.

PU and PIR panels keep cold in and cost less.

PIR panels are safer in fires and block heat better.

These panels help keep food fresh and lower your bills.

Transportation and Industrial Uses

Aluminum sandwich panels are used in trucks, trains, ships, and factories. They last a long time and do not get damaged by bad weather. They also keep heat out and help save energy. The table below lists some good things about these panels:

Advantage | Description |

|---|---|

Durability | |

Thermal Insulation | The core keeps heat out and saves energy. |

Fire Resistance | Can meet fire safety rules for risky jobs. |

Lightweight Nature | Easy to move and put in, so you save time and money. |

You can move and set up these panels fast because they are light. They also help you follow fire safety rules and keep rooms at the right temperature.

Tip: Pick the right panel for your job to get the best strength, safety, and energy savings.

Aluminum Sandwich Panel Comparison Table

It is important to pick the right aluminum sandwich panel for your project. Each sandwich panel type has its own good points. The core material changes how the panel works and where you use it. The table below lets you compare the main sandwich panel types. You can see what each one does best and where it is used.

Core Material | Key Features & Advantages | Typical Applications |

|---|---|---|

Polyethylene (PE) | Lightweight, cost-effective, good insulation, easy to shape, moderate weather resistance | Signage, interior walls, ceilings |

Polyurethane (PU) | Excellent thermal insulation, strong sound absorption, high energy savings, good weather resistance | Cold storage, industrial buildings, residential construction |

Polyvinyl Chloride (PVC) | Good thermal insulation, fire resistance, strong weather resistance, easy to clean | Hospitals, schools, commercial buildings |

Mineral Wool | High fire resistance, acoustic insulation, strong weather resistance, durable | Theaters, industrial plants, high-rise buildings |

Honeycomb Structure | Exceptional strength-to-weight ratio, high structural stability, good weather resistance | Aerospace, high-performance transport, marine |

EPS (Polystyrene) | Good insulation, lightweight, cost-effective, moderate weather resistance | Temporary structures, cold storage, residential walls |

PIR (Polyisocyanurate) | Superior thermal insulation, high fire resistance, energy savings, strong weather resistance | Cold storage, cleanrooms, food factories, modular buildings |

🏆 Tip: If you need high fire resistance, mineral wool and PIR sandwich panels are the best. For strong and light panels, honeycomb aluminum composite panels are great for planes and vehicles.

Wall panels can be used inside or outside. These panels last a long time and look nice. Roofing panels help save energy and keep out rain. Facade panels make buildings look new and modern. Aluminum composite panels are easy to put in and stand up to bad weather.

When you look at sandwich panels, think about saving energy, fire safety, and how strong they are. You want panels that last and help you save power. Sandwich panels with continuous bonding are strong all over. Discontinuous bonding uses less material in some spots.

Your aluminum sandwich panel choice depends on what you need. You get things like saving energy, weather protection, and easy setup. Pick the sandwich panels that fit your project for the best results.

How to Choose the Right Aluminum Sandwich Panel

Assessing Project Needs

Assessing Project Needs

Start by thinking about what your project needs. Every building is different. Think about where you will use the panel. Is it for outside, inside, or a cold room? Decide if you need more strength, better insulation, or fire resistance. Some projects need panels that hold heavy things. Others need panels that can be shaped or colored in many ways.

Here are some things to check before you pick a panel:

The insulation core material (PUR, PIR, Rock Wool, EPS)

Panel thickness and thermal transmittance value (U-Value)

Quality and thickness of the outer cladding sheet

Fire resistance class

Load-bearing capacity and mechanical strength

Ease of installation and detail profiles

Manufacturer warranty and certification

Tip: Write down your main goals for the project. This helps you focus on the most important features.

Matching Panel Type to Application

Pick a panel type that fits your project. If you want high insulation, choose PIR or PU cores. For fire safety, pick rock wool or fire-resistant cores. If you need light panels for transport, honeycomb cores are best. Some projects need panels that bend or have special colors. You can find panels for almost any shape or style.

Application Area | Best Panel Type | Why Choose It? |

|---|---|---|

Cold Storage | PIR, PU Core | High insulation |

High-Rise Buildings | Fire-Resistant, Rock Wool Core | Fire safety |

Transport | Honeycomb Core | Lightweight, strong |

Creative Designs | Flexible Core, ACP | More design flexibility |

Always check if the panel type fits your design needs. Some panels bend or shape more easily. This helps you make special looks.

Budget and Compliance Considerations

Think about your budget and local building rules. Some panels cost more because they are safer or look better. You may pay extra for panels that meet strict safety rules. Always ask for the manufacturer’s warranty and check for certifications. This helps you avoid problems later.

Note: Saving money now may cost more later if you do not follow the rules.

Talk to suppliers about your budget and design needs. They can help you find the best panel that meets all safety and style rules.

You now know about the main types of aluminum sandwich panels. Each type is different and has its own features. When you compare panels, think about these things:

How long the panel will last

If you can use it in many designs

How well it keeps heat or cold out

What is on the outside surface

Pick a panel that matches what your project needs. If you are not sure, ask a supplier or an expert for help. They can help you choose the best panel for your building.

FAQ

What is the best aluminum sandwich panel for fire safety?

Pick panels with PIR or mineral wool cores. These materials help stop fire. They follow strict safety rules. Always look at the fire rating before buying.

Can you use aluminum sandwich panels outdoors?

Yes, you can use these panels outside. They stand up to weather and do not rust. Builders use them for walls, roofs, and building fronts.

How do you clean aluminum sandwich panels?

Clean panels with mild soap and water. Use a soft cloth or sponge. Do not use strong chemicals. This keeps the surface looking nice.

Are aluminum sandwich panels good for sound insulation?

Foam or mineral wool cores block noise well. These panels help make rooms quiet. They are good for sound insulation.

How long do aluminum sandwich panels last?

Panels last more than 20 years. They do not rust or break easily. Clean them often to help them last longer.

Strength and Weight

Strength and Weight Building Facades and Cladding

Building Facades and Cladding Assessing Project Needs

Assessing Project Needs