23 Jan Technical Specifications and Performance Analysis of Aluminum PVDF Coatings

Table of Contents

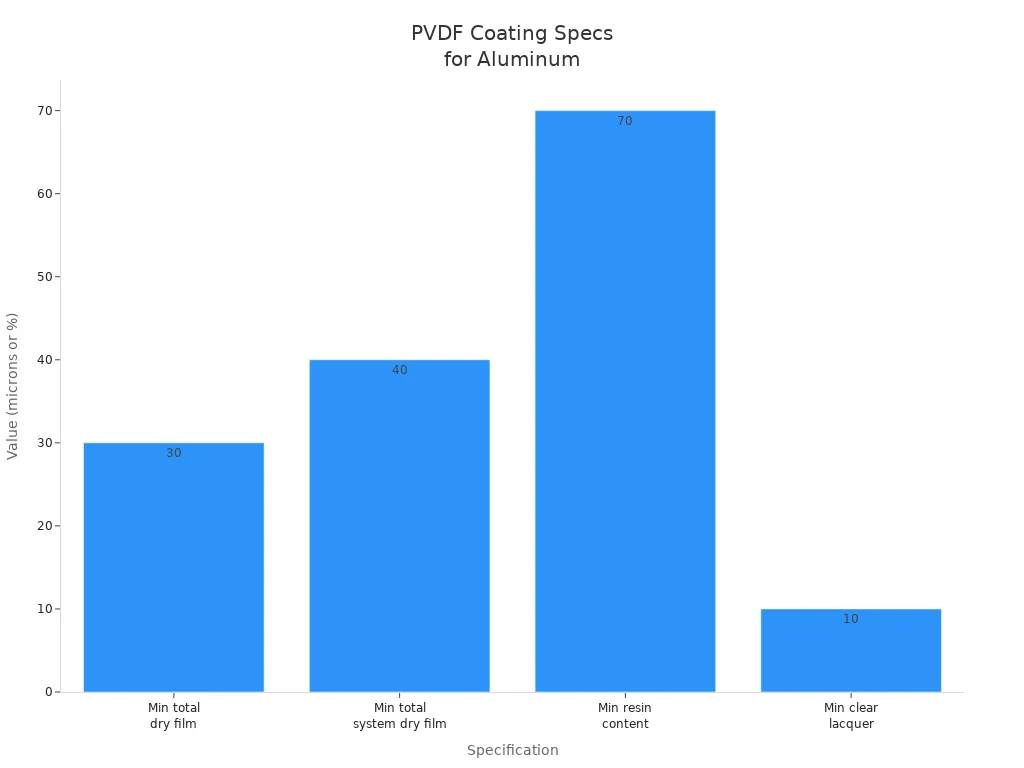

PVDF coatings play a crucial role in protecting aluminum surfaces. They are formulated with a blend of 70% fluoropolymer resin and 30% acrylic, making the aluminium pvdf coating exceptionally durable. This robust formulation allows it to withstand harsh weather conditions, chemicals, and fading. Engineers and architects favor these coatings because they maintain their color and shine for an extended period. Additionally, they provide protection against challenging environments. The table below outlines key technical specifications for PVDF Coating:

Specification | Value |

|---|---|

Minimum total dry film thickness | 30 microns (1.2 mils) |

Minimum total system dry film thickness | 40 microns (1.6 mils) |

Minimum resin content | 70% Kynar500 or Hylar5000 |

Coating system | 2-coat or 3-coat system |

Minimum clear lacquer thickness | 10 microns minimum |

PVDF coatings enable aluminum to last over 30 years, performing effectively even in challenging locations.

These coatings also prevent corrosion and damage.

Key Takeaways

PVDF coatings keep aluminum safe for more than 30 years. This makes them great for tough places. These coatings stop corrosion, UV rays, and fading. They help the color and shine last a long time. Putting on PVDF coatings needs many steps. This makes them strong and safe for the environment. You do not need much upkeep. You only need to wash them sometimes to keep them working well. Picking PVDF coatings gives you better value over time. They help you save money on fixing and replacing things.

Technical Specs of Aluminium PVDF Coating

Chemical Composition and Structure

Aluminium pvdf coating uses a careful mix of materials. The main parts are fluorocarbon resin and acrylic resin. Usually, there is 70% fluorocarbon resin and 30% acrylic resin. This mix makes the coating strong and bendable. Special pigments help the coating stand up to bad weather.

Component | Percentage | Effect on Performance |

|---|---|---|

Fluorocarbon resin | 70% | Makes the coating tough and weatherproof |

Acrylic resin | 30% | Helps the coating stay flexible |

Special pigments | N/A | Adds extra protection from weather |

The way pvdf molecules are built is important. PVDF is a polymer with some crystals inside. It has about 50% crystals. The chain has CH2 and CF2 groups that switch places. These groups give pvdf special electrical powers. PVDF does not dissolve in most chemicals. The carbon-fluorine bonds are very strong. This makes pvdf resist chemicals well. The structure lets pvdf have piezoelectricity and ferroelectricity. These features help aluminium pvdf coating work in tough places.

Coating Thickness and Application Process

Aluminium pvdf coating needs to be at least 25 microns thick. This thickness helps the coating fight bad weather, chemicals, and sunlight. Putting pvdf coating on aluminum takes several steps:

First, clean and remove grease from the aluminum. Then, use a chrome-based coating.

Next, put on a primer to protect the metal. The primer also helps the top layer stick.

After that, add the pvdf top layer with color. Bake the coating so it sets.

Last, put on a clear pvdf layer for more protection. Bake this layer too.

Tip: The way aluminium pvdf coating is put on is better for the environment than dip coatings. It keeps colors even and stops fading.

These rules help the coating last many years with little care. Using two or three coats and baking twice makes the coating work better. Aluminum products look nice and stay strong.

Color, Finish, and Aesthetic Options

Aluminium pvdf coating comes in many colors and finishes. These coatings keep their color and shine for a long time. They work well for homes and businesses. PVDF finishes are tough and look good for years.

Aluminium pvdf coating comes in many colors and finishes. These coatings keep their color and shine for a long time. They work well for homes and businesses. PVDF finishes are tough and look good for years.

Finish Type | Description |

|---|---|

Flat | Looks dull and does not reflect light |

Half-shiny | Shines a little |

Very shiny | Has a bright, glossy look |

Mirror-like | Looks like a mirror |

Custom colors | Special colors and textures you can pick |

PVDF coatings have bright colors and lots of shine. Even after years outside, buildings still look nice. The color and finish rules help aluminum products look new for a long time.

PVDF coatings keep their color and shine for years.

They work for homes and businesses.

PVDF finishes last long and look good.

Industry Standards and Compliance

Industry standards help make sure aluminium pvdf coating is high quality. The most important rule is AAMA 2605. Many companies make coatings that meet or beat these rules. Some coatings use 70% pvdf fluoropolymer liquid or FEVE-based powder. Top coatings like Tnemec’s Fluoronar do even better than the AAMA 2605 rules.

AAMA 2605 is a key rule for aluminum pvdf coatings.

Many companies offer coatings that follow AAMA 2605, like 70% pvdf fluoropolymer liquid and FEVE-based powder.

Top coatings such as Tnemec’s Fluoronar do better than AAMA 2605.

Following these rules means the coating works well in hard places. The rules check for weather resistance, color staying power, and UV protection. These things help aluminum products last and look good.

Aspect | Evidence |

|---|---|

Weathering Resistance | PVDF coatings stand up to weather, sunlight, chalking, and fading, so they last a long time. |

Color Retention | PVDF paints keep their color for years, so architects like them. |

Erosion Rate | PVDF coatings wear away slowly, so colors and designs last. |

UV Resistance | PVDF coatings block UV rays, helping them stay strong and work well over time. |

Note: If you follow AAMA 2605, aluminium pvdf coating will protect and make aluminum look good for many years.

PVDF Coatings for Aluminum: Performance

Weather and UV Resistance

PVDF coatings help aluminum stand up to bad weather. They keep rain, sun, and wind from hurting the metal. The pvdf structure blocks strong sunlight and UV rays. This stops the coating from breaking down fast. Buildings with pvdf coatings look good for many years. They stay nice even in places with tough weather.

When UV light is strong, hollow fiber walls get thinner by half after 384 hours.

More fluorine shows up in the soaking liquid during UV tests, so some damage happens even with weak UV light.

Tests show UV light changes how much the hollow fibers can stretch before breaking.

These facts show pvdf coatings last longer in sunlight than most other coatings. PVDF helps aluminum stay strong outside. This makes pvdf great for buildings in sunny or beach areas.

Corrosion and Abrasion Resistance

Aluminum can get damaged in places near the sea or factories. Salt, chemicals, and dirt can make it rust. PVDF coatings act like a shield. They stop water and chemicals from touching the metal. This makes aluminum less likely to rust.

ZLDH/pvdf coating blocks rust the best.

Tests show ZLDH/pvdf protects better because it has a less negative corrosion number.

ZLDH/pvdf has the lowest rust rate of all tested coatings.

PVDF coatings do not wear out easily.

They need little care and last a long time.

PVDF coatings do not fade in the sun like powder coatings.

These features help aluminum stay strong and look nice, even in busy places. The coating also stops scratches and damage from daily use. PVDF is a smart pick for places where lots of people walk.

Color Retention and Gloss

Color and shine are important for buildings. PVDF coatings keep their color and gloss for many years. This matters to people who want their buildings to look new.

Requirement | Detail |

|---|---|

Specification | AAMA 2605 |

Duration | 10 years exposure |

Location | South Florida |

Properties | Gloss and color retention must be maintained |

Keeping color and shine is a big rule for paints that last.

SLP theory says strong chemical bonds and stretching power help coatings last longer.

PVDF coatings meet tough rules for color and shine. Even after years in the sun, they do not turn white or lose color. This keeps aluminum looking bright and fresh.

Maintenance Needs

PVDF coatings need very little care. Owners do not have to paint them often. The coating stays strong and clean with easy steps.

Maintenance Task | PVDF Coating | Powder Coating |

|---|---|---|

Wash frequency | Every year or more | |

Chalking check | Minimal risk | Needed after 5–10 years |

Re-touch/repaint need | Rare | Common after 12–15 years |

Seal and joint inspection | Regular cycles | Same as PVDF |

Checking the coating every year keeps it working well.

Washing all parts should be done often.

Owners should write down what they do in a report.

These easy steps keep the coating strong. PVDF coatings save time and money for owners. The coating protects aluminum and keeps it looking good with little work.

PVDF Coating Aluminum Extrusion Profiles & Comparisons

PVDF vs. Other Coating Types

PVDF vs. Other Coating Types

Many engineers look at pvdf coating aluminum extrusion profiles and compare them to other finishes like anodized or polyester coatings. PVDF is better at stopping weather and rust. The table below shows how PVDF and anodized finishes are different:

Panel Type | Weather Resistance | Corrosion Resistance | Best Use Areas |

|---|---|---|---|

Anodized | Very Good | Very Good | Urban, busy places, some coastal |

PVDF | Excellent | Excellent | Coastal, factories, tough weather |

PVDF does not react with most chemicals. It lasts longer than anodized coatings in rough places. PVDF gives more color choices and keeps colors even. PVDF does not crack when shaped, unlike anodized sheets. PVDF can last up to 50 years and keeps its color and shine for over 20 years. Powder coatings may lose color or crack after only 7-8 years outside.

Use Cases for Aluminum Extrusions

Architects and builders use pvdf coating aluminum extrusion profiles in many areas. These profiles protect buildings and other structures in hard places. The table below shows common uses:

Sector | Application Example |

|---|---|

Construction | Walls, ceilings, beams |

Infrastructure | Tunnels, bridges, barriers |

Transport | Train and bus panels |

Industry | Chemical plant machines |

PVDF-coated aluminum works well for outside walls. It stands up to sunlight, wet air, and chemicals. This makes it great for buildings near the sea or in dirty cities. PVDF coating aluminum extrusion profiles help lower care costs and keep buildings looking fresh.

Note: PVDF-coated aluminum gives long-lasting value and a smooth look for both building and factory projects.

Limitations and Considerations

PVDF coating aluminum extrusion profiles have many good points, but there are some things to watch out for. In the last ten years, some problems have happened, like rust under the coating, bubbles, or peeling. Getting the surface ready the right way helps the coating stick well. Using non-chrome choices in the process can lower rust protection. Liquid PVDF coatings work best outside because they block sunlight better than powder coatings. Powder coatings may not have all the color choices, so design options can be limited.

Rules for the environment are important too. PVDF coatings must follow strict rules for harmful chemicals called VOCs. Many finishers use systems to catch and destroy VOCs, making PVDF a greener choice.

Selecting the Right PVDF Coating

Environmental and Longevity Factors

Picking the right PVDF coating depends on where you use it. Some places have lots of moisture or chemicals in the air. Coastal cities and factories are examples. These things can make coatings wear out faster. PVDF coatings work well in tough weather. Tests in south Florida show almost no color change after 10 to 15 years. Lab studies also say PVDF panels keep their color and shine.

Key things that affect how long PVDF coatings last include:

UV light can make colors fade slowly.

Moisture can break down the coating over time.

Chemical resistance helps the coating stay strong.

Most companies promise PVDF coatings will last 20 to 30 years. Good materials and careful making help them last longer. PVDF coatings like Kynar Aquatec last over 20 years in hot, wet places. Other paints may only last five years in the same weather. PVDF coatings stand up to strong sun, heat, and humidity. This makes them great for hard places.

Cost-Effectiveness and Value

Price is important when picking a coating. PVDF coatings cost more at first. But they save money because they last longer and need less care. PVDF coatings keep their color, fight bad weather, and stop rust. If you compare PVDF and powder coatings, PVDF gives better value over time. Powder coatings may be cheaper at first.

Coating System Comparison | PVDF Coating | Alternative Coating |

|---|---|---|

Costs more at first but keeps color and lasts long; saves money later | Cheaper at first but fades fast and needs more care or new paint | |

PVDF vs Anodizing | Many colors, finishes, and design choices with strong weather resistance | Looks metallic but has fewer color choices and less design freedom |

Cost vs Performance | Costs more but works better for longer and needs little care | Cheaper at first but costs more later because it does not last as long |

Big projects can get discounts for buying a lot. Suppliers help with storing and shipping, making things easier. PVDF coatings are a smart pick for people who want their building to last and look good.

PVDF coatings help aluminum stay strong and look nice. The special fluorocarbon process makes a tough finish. This finish does not get damaged by weather or chemicals. It also stops fading. Big buildings like Burj Khalifa use PVDF coatings. The Shard uses them too. These buildings stay bright and last long in hard places.

Advantage | Description |

|---|---|

Weather Resistance | Handles rain, sun, and wind for many years. |

UV Radiation Resistance | Keeps colors bright, even with strong sunlight. |

Chemical Resistance | Does not react with most chemicals or pollution. |

Long-term Savings | Needs less care and saves money over time. |

Aesthetic Benefits | Makes aluminum look new and nice. |

Builders and architects should pick PVDF coatings for projects. These coatings work well for places with tough weather. They help buildings last and look good for a long time.

FAQ

What makes PVDF coatings better than regular paint for aluminum?

PVDF coatings use a strong fluoropolymer resin. This resin helps protect aluminum from weather and chemicals. It also stops fading. Regular paint does not last as long. It cannot keep its color as well.

How long does a PVDF coating last on aluminum surfaces?

Most PVDF coatings last more than 20 years. Some can protect aluminum for up to 30 years. The coating stays strong in tough places. It keeps its color for a long time.

Can PVDF coatings be cleaned easily?

Yes. PVDF coatings only need simple washing every year or two. Dirt and stains do not stick much. Owners save time and money on cleaning.

Are PVDF coatings safe for the environment?

PVDF coatings follow strict rules about harmful chemicals. Many makers use systems to control bad emissions. This makes PVDF coatings safer for the environment.

What color and finish options are available with PVDF coatings?

PVDF coatings come in many colors and finishes. Choices include flat, shiny, and mirror-like looks. Custom colors and textures are also possible for special designs.

PVDF vs. Other Coating Types

PVDF vs. Other Coating Types