22 Feb What Materials Are Used in ACP Panels and Their Properties

Table of Contents

You find three main materials in ACP panels based on material. These are aluminium skins, core materials, and adhesives. Aluminium skins make ACP panels strong and give them a smooth look. Core materials include PE, LDPE, fire-retardant, and mineral-filled types. These core materials change how well ACP resists fire and affect the weight of the ACP. Adhesives stick the aluminium layers to the core, helping to keep the panel stable. The table below shows why each material matters:

Material Type | Key Properties |

|---|---|

Aluminium Skins | Durable, lightweight, strong |

PE Core | Flexible, light, combustible |

LDPE Core | Flame retardant, flexible |

Mineral-Filled Core | Non-combustible, safe |

Adhesives | Bond strength, stability |

You choose these materials for ACP panels based on material for good reasons. You want panels that are light, safe, and durable. PVDF ACP Panel coatings protect aluminium skins from the elements, ensuring the panels remain safe from bad weather. You often see aluminium composite panels on building walls, showcasing how well these materials work together.

Key Takeaways

ACP panels are made of three main materials. These are aluminium skins, core materials, and adhesives. Each material is important for the panel’s strength, safety, and look.

Picking the right core material is very important for fire safety. Mineral-filled cores are best for stopping fires. They are good for places with high fire risk.

Thicker aluminium skins make the panels stronger and stop rust. Use strong coatings like PVDF in tough weather. This helps the panels last longer.

Taking care of ACP panels is easy. Clean them with mild soap and water. This keeps them looking nice and stops damage.

Good ACP panels can help you save time and money. They are light, simple to put up, and give great insulation and weather protection.

ACP Panels Based on Material

ACP panels have three main layers. Each layer helps the panel work well and stay safe. You should know how these layers work together. This helps you pick the best panel for your project.

Aluminum Skins in ACP

Aluminium skins cover both sides of every ACP panel. These skins make the panel strong and smooth. You can pick different thicknesses and alloys. The table below shows common thicknesses and alloy types:

Panel Thickness (mm) | Aluminium Skin Thickness (mm) | Aluminium Alloy |

|---|---|---|

3, 4, 5, 6 | 0.1, 0.12, 0.15, 0.2, 0.3, 0.4, 0.5 | 1100, 3003, 5005 |

Thicker aluminium skins give more strength and stop rust. Good bonding methods help the panel stay flat and tough. Coatings like PVDF, FEVE, or polyester paint protect the aluminium from rain and sun. These coatings keep your panel looking new. Each aluminium alloy has its own mix of strength and rust resistance. You can choose the right alloy for your project.

Tip: Use thicker aluminium skins and strong coatings in places with bad weather or lots of use. This makes your panel last longer.

Core Materials: PE, LDPE, FR, Mineral-Filled

The core is the center of ACP panels. You can choose from different core types. Each type has its own chemicals and fire safety. The table below compares the main core materials:

Core Type | Chemical Composition |

|---|---|

LDPE | Low-Density Polyethylene (LDPE) |

Fire-resistant (FR) | Fire-resistant mineral core with magnesium hydroxide |

Mineral-filled | 70% calcium hydroxide, magnesium hydroxide, and other inorganic materials, 30% polymer |

Fire safety is important when picking a core. The next table shows how each core does in fire tests and where to use them:

Core Type | Fire Resistance Rating | Suitability for High-Risk Environments |

|---|---|---|

PE (Polyethylene) | Lower (flammable) | Less suitable |

FR (Fire-Retardant) | Higher (fire-resistant) | More suitable |

Mineral-Filled | Enhanced fire safety | Highly suitable |

ACP panels are light. Their density is 3.5–5.5 lb/ft² (17–27 kg/m²). This is lighter than solid aluminium. The sandwich shape keeps the panel stiff and flat. The core takes hits, and the aluminium spreads the force. This makes the panel strong. You can use these panels in windy or shaky places. A 4mm thick panel can bend up to 100MPa. It can handle wind speeds up to 90m/s. You can also cut and shape the panels easily.

Heat reflection: White panels bounce back up to 85% of sunlight. This keeps buildings cooler.

Temperature adaptability: ACP panels work from -50℃ to +80℃.

Low temperature performance: You can bend the panel at -50℃ and it will not crack.

Thermal deformation control: The panel grows less than solid aluminium, so it does not warp.

Adhesive Layers in Aluminum Composite Panel

Adhesive layers sit between the aluminium skins and the core. These adhesives hold the layers together. They keep the panel stable. You can pick from different types:

MMA adhesives: Cure fast, need little prep.

Acrylic adhesives: Strong and useful for many jobs.

Epoxy adhesives: Resist heat and chemicals, very strong.

Cyanoacrylate adhesives: Bond fast, but not as tough.

Strong adhesive bonding is important for ACP panels. You want the panel to act as one piece. Weak adhesives can make the layers come apart. This is called delamination. The table below explains why good adhesives matter:

Key Point | Explanation |

|---|---|

Adhesive Bonding | Strong adhesive bonding keeps the panel stable and stops delamination. |

Peel Stresses | Bad joints can cause peel stresses and make layers separate. |

Mixed Adhesive Joints | Using mixed adhesives can lower peel stresses and help stop delamination. |

Adhesive strength helps the panel carry weight.

Water and heat can make adhesives weaker.

Epoxy adhesives are strong but may not work well in wet or hot places.

Good bonding helps your ACP panels last longer and cost less to fix.

Note: Always check the adhesive type and bonding method before you pick an ACP panel. This helps you get the best safety and performance.

Properties of Aluminum Composite Panel Materials

Durability and Weather Resistance

Durability and Weather Resistance

You want your building to last a long time. ACP panels help because they are tough and resist bad weather. The aluminum skins protect the panel from rain and sun. The core materials make the panel strong but light. You can trust ACP panels in many places.

ACP panels go through hard tests in labs. These tests show how strong the panels are:

Test Method | Description |

|---|---|

ASTM B 117 | |

Corrosion creepage | Rust spreads less than 1/16 inch (1.6 mm) from the scratch. |

Blister rating | The panel gets a blister rating of at least 8. |

ACP panels do not rust or blister easily. The anodized finish does not peel off. The surface stays strong against water and dirty air. Anodized aluminum works well in busy and rough places because it is hard and lasts long.

ACP panels also handle wind, rain, and hail. Gas gun tests show ACP panels do not dent or break easily. The sandwich design helps the panels resist hits. You can use these panels in places with storms or strong winds.

Different places can change how long ACP panels last. The table below shows how climate and pollution affect the panels:

Climate type | Main risk factor | Typical lifespan impact |

|---|---|---|

Hot and dry | UV radiation | Coating fades faster |

Coastal | Salt corrosion | Edge damage risk |

Cold | Freeze cycles | Bond fatigue |

Industrial | Acid pollution | Surface degradation |

UV rays can break down paint and make it fade. Humidity can cause mold and rust, especially near the sea. Dirty air makes the surface break down faster. You should pick the right coating and core for your climate to get the best results.

Fire Resistance and Safety

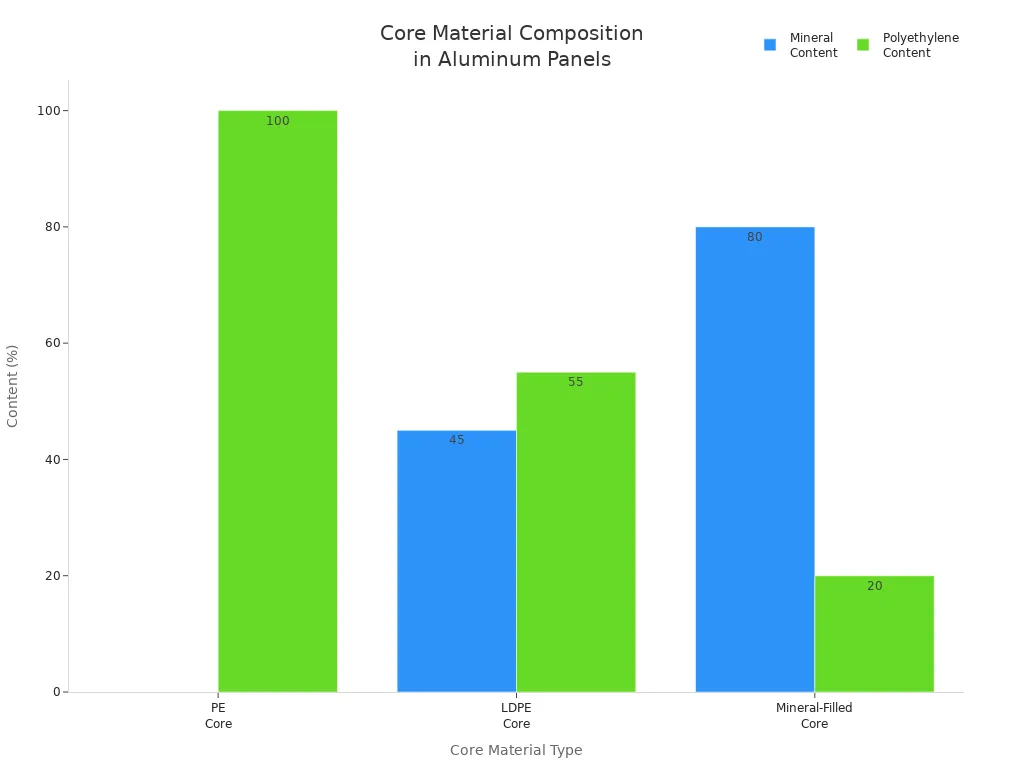

Fire resistance is very important for ACP panels. You need to know how the core material changes fire safety. The core can be made from polyethylene, fire-retardant stuff, or mineral-filled compounds. The amount of polymer in the core changes how the panel acts in fire.

Normal ACP panels have a core made of LDPE or HDPE. These panels can resist fire for up to 5 minutes. Fire-proof panels have a core with 70% inorganic materials and 30% polymer. These panels can resist fire for up to 2 hours. You get much better fire resistance with a mineral-filled core.

Here is a table that shows fire ratings and standards for different core materials:

Core Material Type | Fire Rating | Compliance Standard |

|---|---|---|

Polyethylene (PE) | Non-fire-rated | N/A |

Fire-retardant Core | Fire-rated | NFPA 285, UL 723 |

You should always check the fire rating before you pick an ACP panel. Fire-retardant and mineral-filled cores meet strict safety rules. These panels are safe for tall buildings and public places. The right core material keeps people safe.

Tip: Always ask for the fire rating and safety papers when you buy ACP panels. This helps you follow building rules and keeps your project safe.

Insulation and Lightweight Benefits

ACP panels give good insulation and are light. The sandwich shape helps block heat and noise. The core keeps rooms cool in summer and warm in winter.

ACP panels are light and strong. This makes them easy to put up and move. You do not need heavy supports. The light weight means you can use them on tall buildings without adding too much weight.

Here are some reasons why ACP panels are a smart choice:

ACP panels are light and can fit many building shapes.

Solid aluminum is heavier and costs more, but it resists fire well.

Fiber cement panels are tough but heavy and can crack when wet.

You get a mix of strength, insulation, and lightness with ACP panels. They do not rust or fade like some other materials. You can trust ACP panels to last and look good for years.

Note: Pick ACP panels if you want a light, strong, and energy-saving choice for your building.

Core Types Comparison in ACP

PE vs. FR vs. Mineral-Filled Cores

PE vs. FR vs. Mineral-Filled Cores

It is important to know how each core type affects fire safety, cost, and strength. The table below helps you see the main differences:

Core Type | Fire Safety | Cost | Mechanical Performance |

|---|---|---|---|

PE (Polyethylene Core) | Lower fire resistance; not for high-rise use | Cost-effective | Excellent formability, smooth surface |

FR (Fire-Retardant) | Meets strict fire safety standards | Higher | Slightly heavier, still strong |

Mineral-Filled | Non-combustible mineral-filled core, best for fire safety | Most expensive | Limited color choices, high strength and rigidity |

PE cores are easy to shape and look smooth. FR cores make panels safer from fire. Mineral-filled cores are safest and work best where fire rules are strict.

Fire Safety and Compliance in ACP

Fire safety is very important when picking acp panels. Many places now have rules for fire safety. The table below shows how each core does in fire tests:

Core Type | Application Areas | EN 13501-1 Rating | Notes |

|---|---|---|---|

Fire-Retardant PE | Malls, offices, schools, mid-rise facades | B1 | Improved fire resistance |

Mineral/A2 | High-rise, hospitals, airports, public venues | A2 | Non-combustible, best for critical facades |

Fires in buildings have caused new safety rules. Now, more panels use mineral-filled cores to stop fire from spreading. These panels help keep people safe inside. Always check if your acp meets local fire rules before buying.

Tip: Grade A2 panels have mineral cores and do not burn. Grade B1 panels use flame-retardant polyethylene and slow down fire but can still burn.

Application Suitability Based on Core Material

Pick the right acp core for your project. Here are some tips:

Use PE core acp for signs or small jobs where fire is not a big risk.

Pick fire-resistant acps with FR cores for schools, hospitals, and offices.

Choose acp with mineral-filled core for tall buildings, airports, and public places.

The US, EU, and Australia now need non-combustible acp for tall buildings. You must follow these rules to keep people safe and pass checks. The right acp core keeps your building safe and protects your money.

Real-World Performance of ACP Panels

Durability in Harsh Environments

You want your acp facade to last a long time. ACP panels use strong materials. These materials help the panels handle heat, rain, salt, and dirty air. The aluminum surface and special coatings protect the panels from sun, water, and chemicals. This keeps your acp facade looking new for many years. You can see how acp works in real buildings:

Case Study | Location | Key Challenges | Performance Characteristics |

|---|---|---|---|

Saudi Arabia | High heat, fire risk | Weather resistance: ΔE=0.8, thermal stability: 0.15% change, B1 fire rating | |

High-end resort hotel | Phuket, Thailand | Mold, rain, salt spray | Mildew resistance: level 0, salt spray: <5% corrosion, wind resistance: level 5 |

The coating on acp panels stops acid, salt, and sun from hurting the panels. You can use acp facades in cities by the sea, deserts, or places with lots of pollution. The panels keep their color and shape, even when the weather changes a lot.

Maintenance and Longevity

You do not need to spend much time taking care of your acp facade. Good coatings protect the panels from rust and color loss. You only need mild soap and water to clean your acp. Check your panels often to find any damage early. Keep your acp facade away from water to stop bending.

ACP panels usually last 30 to 50 years. They last this long because of strong aluminum and good coatings. Many acp panels have warranties for up to five years. Some brands, like Maxmetal, give even better warranties. You can trust your acp facade to last for many years if you take care of it.

Aesthetic and Finish Options

You can pick many styles for your acp facade. The finish you choose helps your panels fight sun and keep their color. Here is a simple guide:

Coating Type | UV Resistance and Color Retention |

|---|---|

PVDF (Polyvinylidene Fluoride) | Keeps over 80% gloss and color after 10 years; best for outdoor facades |

Polyester Coatings | Good for inside or shaded facades; may fade after 3–5 years in strong sun |

Coatings like PVDF and FEVE protect your acp facade from scratches, dirt, and weather. You can choose bright colors, shiny metal, or stone looks. The finish stays shiny and is easy to clean. Your acp facade will look nice and new for a long time.

Tip: Pick PVDF-coated acp for outdoor facades that get lots of sun or bad weather.

You need to understand acp panel materials to make smart choices for your project. The right acp materials improve safety, energy savings, and building strength. You can see the main factors in the table below:

Factor | Why It Matters |

|---|---|

Material Quality | High-grade acp materials last longer and perform better. |

Panel Thickness | Thicker acp panels resist impacts and work well outdoors. |

Surface Coating | Good coatings protect acp from weather and keep colors bright. |

Fire Resistance | Certified acp panels with mineral cores keep buildings safe. |

Manufacturer Reputation | Trusted acp brands give you reliable results. |

When you pick acp, always check fire ratings and match the panel to your building’s needs. You should choose acp with the right thickness, finish, and core for your project. You can save time and money by using acp that is easy to install and maintain. New acp technology also gives you more color and texture choices. You help the environment by choosing acp with recycled content. You get a safe, strong, and good-looking building when you select the best acp for your needs.

FAQ

What is the main advantage of using acp panels?

You get lightweight panels that are easy to install. acp panels resist weather and last for years. You can use them for many building styles and shapes.

Can you use acp panels for indoor walls?

Yes, you can use acp panels inside buildings. They work well for wall cladding, ceilings, and partitions. You get a smooth finish and many color choices.

How do acp panels help with fire safety?

You improve fire safety by choosing acp panels with mineral-filled or fire-retardant cores. These panels slow down fire spread and meet strict safety standards.

Are acp panels easy to clean and maintain?

You clean acp panels with mild soap and water. The surface resists stains and dust. You spend less time on maintenance, and your panels keep their color.

What finishes can you choose for acp panels?

You pick from glossy, matte, metallic, or stone finishes. acp panels offer many colors and textures. You match your building style and keep the facade looking fresh.

Durability and Weather Resistance

Durability and Weather Resistance PE vs. FR vs. Mineral-Filled Cores

PE vs. FR vs. Mineral-Filled Cores