23 Jun A Complete Guide to Aluminum Composite Panel Signage Applications

Table of Contents

Aluminium composite panel signage gives you a modern way to display information or promote your brand. You see more acp signs in cities every year because businesses want materials that last and look sharp. The global market for aluminum composite panel reached $6.9 billion in 2023 and could grow to $11.7 billion by 2033. This rise shows how much people trust acp for strong, eye-catching displays.

Metric | Value | Explanation |

|---|---|---|

Market size (2023) | USD 6.9 billion | Valuation of the global ACP market at the start of the period. |

Projected market size (2033) | USD 11.7 billion | Expected market size after 10 years, indicating strong growth. |

CAGR (2024-2033) | 5.5% | Compound annual growth rate of the ACP market over the forecast period. |

With acp, you get panels that handle weather, offer many colors, and keep their shape over time. Aluminium composite panel signage makes your message stand out and lasts longer than many other options.

Key Takeaways

Aluminum composite panels offer a lightweight, strong, and weather-resistant option for durable signage that lasts longer than traditional materials.

ACP panels come in various thicknesses and finishes, allowing you to customize signs for indoor or outdoor use with vibrant colors and smooth surfaces.

Choosing fire-retardant ACP panels enhances safety, making them ideal for public spaces like schools, hospitals, and malls.

Installation is easy with multiple mounting methods, and simple cleaning with mild soap keeps your signs looking fresh and new.

Using ACP signage saves money over time by reducing maintenance, lowering transport costs, and providing versatile design options.

What Is Aluminum Composite Panel Signage

Aluminium composite panel signage gives you a modern and reliable way to display information, advertise, or decorate spaces. You see these signs in many places because they combine strength, light weight, and a smooth surface for printing. When you choose aluminium composite panels, you get a product that stands out from other materials like wood, PVC, or steel. ACP panels use advanced technology to meet the needs of today’s businesses and public spaces.

ACP Structure

You find that aluminium composite panels have a unique layered design. Each panel has two thin sheets of aluminum bonded to a solid core, usually made from polyethylene or a fire-retardant mineral. This structure gives the panel its strength and keeps it lightweight. Most panels for signage come in thicknesses of 3 mm or 4 mm, which makes them easy to handle and install.

Thickness (inches) | Typical Use Cases | Surface & Edge Characteristics | Weight (lbs/sq.ft.) |

|---|---|---|---|

0.038″ | Counters, tables, wall panels, murals; requires bonding to backer; sanded back for adhesion | Sanded back; edges not specified | 0.43 |

0.090″ | Interpretive and wayfinding graphics; National Parks standard; must be framed or mechanically fastened | Edges black; back surface white | 0.7 |

0.10″ (1/10″) | Double-sided or enclosed in frame; interpretive and wayfinding | Edges black; back surface white | 0.75 |

0.125″ (1/8″) | Double-sided flip books, interpretive and wayfinding; must be framed or fastened | Edges black; back surface white | 0.9 |

0.25″ (1/4″) | Double-sided flip books with binder rings or hinges; aesthetic depth; must be framed or fastened | Edges black; back surface white | 1.8 |

0.5″ (1/2″) | Most popular for outdoor signage; self-supporting; no frame needed; can be profiled and drilled | Edges black; back surface typically black | 3.6 |

0.75″ (3/4″) | Table tops, free-standing elements; self-supporting; profiled and drilled | Edges black; back surface typically white | 5.4 |

1.0″ (1″) | Table tops, free-standing; extra strength; profiled and drilled | Edges black; back surface typically white | 7.2 |

You can see that the most common thickness for aluminium composite panel signage is 3 mm or 4 mm. These sizes work well for both indoor and outdoor signs. The aluminum sheets are usually about 0.15 mm thick, and the core gives the panel its shape and stability. Standard panel sizes include 4′ x 8′, 4′ x 10′, and 5′ x 10′. This makes it easy for you to choose the right size for your project.

You also get a PE-coated surface on most acp panels. This coating protects the sign from weather, UV rays, and scratches. Some panels use special coatings like PVDF for even better durability. You can find panels with anti-bacterial or anti-viral coatings, which are great for hospitals, schools, and public spaces.

Tip: Always store your aluminum composite panels flat in a dry place. This helps prevent warping and keeps your signage looking sharp.

Key Features

When you use aluminium composite panel signage, you enjoy several important features:

- Lightweight and Strong: ACP panels weigh much less than solid metal or glass, but they stay rigid and strong. This makes installation easier and reduces the load on walls or frames.

- Weather Resistance: You can trust aluminium composite panels to handle rain, sun, wind, and temperature changes. The PE or PVDF coating keeps the surface looking new for years.

- Fire Safety: Many acp panels come with fire-retardant cores. These panels meet strict safety standards, such as Class A or B1 fire ratings. Fire-rated panels use mineral cores with up to 90% flame-retardant materials.

- Smooth Surface for Printing: The flat, even surface of acp panels is perfect for digital printing, vinyl graphics, or painting. You get sharp images and vibrant colors every time.

- Customizable Finishes: You can choose from many colors, textures, and finishes. Options include brushed metal, mirror, matte, gloss, and even wood grain. This lets you match your signage to your brand or building style.

- Easy Fabrication: You can cut, drill, and shape acp panels with standard tools. This makes it simple to create custom shapes or fit panels into unique spaces.

- Eco-Friendly: Most aluminum composite panels use recyclable materials. Some new products even use bio-based cores for better sustainability.

Feature | Details / Metrics |

|---|---|

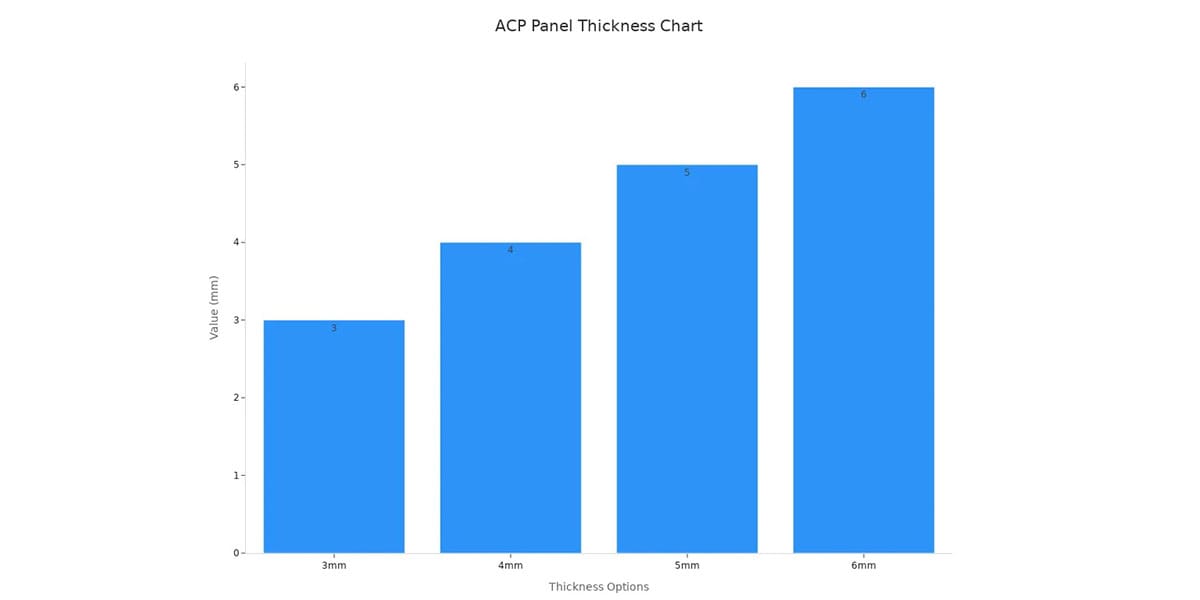

Typical Thickness | 3 mm, 4 mm, 5 mm, 6 mm; thicker panels provide greater strength and durability |

Fire Retardancy | Classified by GB8624 standard: Class A (non-combustible), B1 (flame retardant), B2 (combustible), B3 (flammable) |

Fire Resistance | Fireproof ACPs resist fire up to 2 hours; mineral cores contain ~70% inorganic materials and 30% polymer |

Core Material | Normal ACP: LDPE/HDPE polymer cores; Fire-rated ACP: mineral cores with halogen-free flame retardants |

Coating | Fluorocarbon (PVDF) coatings provide surface protection and weather resistance |

Environmental | Panels made from 100% recyclable materials (minerals, aluminum, polymer) supporting green building standards |

You notice that aluminium composite panels offer more than just good looks. They give you flexibility, durability, and safety. You can use them for many types of signage, from shopfronts to wayfinding signs in parks. ACP panels also support digital printing and smart surface technologies, so you can create signs with high-resolution images and custom branding.

Aluminum composite panel signage stands out because it combines all these features in one product. You get a lightweight, strong, and versatile material that works for almost any signage need. When you compare acp to other materials, you see that it offers better performance, easier handling, and more design options.

Benefits of ACP Panels

Durability

Durability

When you choose acp for your signage, you get a material that stands up to tough conditions. Aluminium composite panels resist rain, wind, and sunlight. The special coatings on acp panels protect your signs from fading and scratches. You do not have to worry about rust or corrosion, even if you install your signs outdoors. Reports from Japan and the USA show that acp panels work well in harsh marine environments, such as ships and oil platforms. These panels keep their shape and strength, even after years of use. You can trust acp to deliver long-lasting results for your signage applications.

Note: ACP panels with fire-retardant cores add extra safety for public spaces and buildings.

Lightweight

You will notice that acp panels feel much lighter than other materials like steel or stone. Aluminum alloys have a density of only 2.73 g/cm³, while steel is almost three times heavier. This lightweight property makes acp easy to carry, lift, and install. In one study, engineers used aluminium composite panels to build portable shelters with strong, rigid walls. The panels provided both strength and easy handling. When you use acp, you save time and effort during installation. You also reduce transportation costs because you can move more panels at once.

Versatility

Aluminium composite panels give you many options for your signage projects. You can cut, bend, or shape acp panels to fit any design. The smooth surface works well for digital printing, vinyl graphics, or painting. You can choose from a wide range of colors, textures, and finishes. Some panels look like brushed metal, wood, or even mirror glass. This aesthetic versatility helps you match your signs to your brand or building style. ACP panels work for many applications, such as shopfronts, wayfinding signs, and decorative displays. You can use high-performance acp panels for both indoor and outdoor projects.

- Design flexibility: Create custom shapes and sizes.

- Color and finish options: Match your brand or theme.

- Easy installation: Save time and labor.

Cost-Effectiveness

You want your signage to look great and last long without breaking the bank. ACP panels offer a smart solution. Research shows that aluminium composite panels can lower total lifecycle costs by 20-30% compared to traditional materials. You spend less on maintenance because acp does not need regular painting or sealing. The lightweight design also cuts down on labor and transport costs. The table below compares acp with other common signage materials:

Feature | Wood | Stone | Concrete | ACP (Aluminum Composite Panel) |

|---|---|---|---|---|

Initial Cost | Moderate | High | Moderate | Moderate |

Long-Term Cost | High (due to maintenance and replacement) | High (maintenance) | Moderate | Low (minimal maintenance) |

Low | High | High | High | |

Weight | Low | High | High | Low |

Installation Cost | Moderate | High | High | Moderate |

Maintenance | High (regular painting, sealing) | Low (minimal) | Low (periodic cleaning) | Low (minimal cleaning) |

You see that acp panels offer high durability and low maintenance. This means you save money over time. ACP also uses less energy during production and installation, making it an energy-efficient choice. You get strong, attractive signage that fits your budget and lasts for years.

Tip: ACP panels with weather and corrosion resistance help you avoid costly repairs and replacements.

Applications of Aluminium Composite Panels

Aluminum composite panels give you many options for modern signage and design. You can use acp in a wide range of applications because of its strength, light weight, and easy customization. Let’s look at some of the most common applications for acp panels.

Outdoor Signage

You often see acp used for outdoor signage. These panels handle weather changes, sunlight, and rain without losing their color or shape. Many businesses choose acp for shopfronts, retail signs, and large advertising boards. For example, Adidas used acp panels for a huge FIFA World Cup display near Munich airport. Construction companies use acp for hoarding around building sites. You can print high-quality graphics on acp, making your advertising stand out in busy streets or event spaces.

- Shopfronts and retail signs

- Construction hoarding

- Event and festival signage

ACP panels help your outdoor signage last longer and look professional, even in tough environments.

Indoor Signage

Inside buildings, acp panels offer clean lines and a smooth surface for graphics. You can use them for wayfinding signs, corporate branding, or lobby displays. JetBlue’s JFK Terminal 5 features acp in its interior signage, blending style with function. Schools and offices use acp for wall graphics and directories. You can cut acp into custom shapes, so your signage fits any space.

- Wayfinding and directories

- Corporate branding

- School and hospital signs

Decorative Uses

Acp also works well for decorative applications. You can use it for architectural cladding, interior decoration, and artistic displays. The Mount Gambier Library in Australia used acp panels for a unique exterior screen. Trade shows often feature custom acp displays because you can print, cut, and shape the panels easily. Companies like AstraZeneca use acp for bespoke interior signage and wall art. These panels let you create eye-catching designs for both advertising and decoration.

- Architectural cladding

- Trade show exhibits

- Artistic and branded wall features

You can see that acp fits many common applications, from advertising to interior design. Its versatility makes it a top choice for both functional and creative projects.

Choosing ACP for Signage

When you plan your next project, you need to know how to choose the right acp panel. Picking the best option helps your signage last longer and look better. Let’s break down the main things you should consider.

When you plan your next project, you need to know how to choose the right acp panel. Picking the best option helps your signage last longer and look better. Let’s break down the main things you should consider.

Thickness Options

You find acp panels in several thicknesses, usually from 3mm to 6mm. Thicker panels give you more strength and stability. For most outdoor signs, 4mm or 6mm works well. Thinner panels, like 3mm, fit indoor displays or smaller signs. The aluminum skin also comes in different thicknesses, from 0.1mm up to 0.5mm. Thicker skins add durability, especially in busy areas.

Parameter | Thickness Options / Values | Notes / Range |

|---|---|---|

Panel Thickness | +/- 0.2mm tolerance | |

Aluminum Skin Thickness | 0.1mm, 0.12mm, 0.15mm, 0.2mm, 0.3mm, 0.4mm, 0.5mm | +/- 0.02mm tolerance |

Core Types

You can choose between two main core types for acp: standard polyethylene (PE) and fire-retardant (FR). PE cores work well for most indoor uses and low-rise buildings. If you need extra safety, especially in public spaces or tall buildings, pick an FR core. These cores use mineral fillers like alumina trihydrate. FR acp panels meet strict fire codes, such as NFPA 285, and help protect people and property.

Surface Finishes

Acp panels come with many surface finishes. You can pick from matte, gloss, brushed metal, or even wood grain. Most panels use a PVDF or FEVE coating for weather resistance. These coatings keep your acp looking new, even after years outside. You can match your brand colors or create a unique look for your signage.

Coating Type | Features |

|---|---|

PVDF | Best for outdoor durability |

FEVE | High gloss and color retention |

PE | Good for indoor applications |

Anodized | Metallic finish, scratch resistant |

Certifications

You want to make sure your acp meets safety and quality standards. Look for certifications like ASTM E84, BS 476, and DIN 4102 for fire resistance. Panels should pass weather resistance tests, such as 5,000 hours of QUV exposure. Reliable acp brands follow ISO 9001:2008 for quality control. Many offer a 10-year warranty, so you know your signage will last.

Aspect | Details |

|---|---|

Fire Resistance Standards | ASTM E 84 / E 119, BS 476 part 6 / 7, DIN 4102 part 1 |

Weather Resistance | Passed SGS 5,000 hours QUV weather resistance testing |

Manufacturing Quality | ISO 9001:2008 certified manufacturing process |

Warranty | 10 years limited warranty |

Tip: Always match the acp features to your project needs. Thicker, fire-rated panels work best for outdoor or high-traffic areas. For indoor signs, lighter panels with simple finishes may be enough.

Installation and Maintenance of ACP Panels

Preparation

You should start by checking your acp panels for any damage before installation. Store the panels flat in a dry area to prevent warping. Gather all your tools, such as drills, saws, and measuring tape. Clean the surface where you will mount the acp. Make sure the area is free from dust and grease. This step helps the panels stick better and last longer.

Mounting Methods

You can install acp panels using several methods. For cladding and facades, use a frame system. Attach the frame to the wall, then fix the acp panels with screws or rivets. Some projects use adhesive tapes for a smooth look. Always follow the manufacturer’s instructions for spacing and fasteners. You can cut acp panels to fit corners or curves. This flexibility makes acp easy to install on many surfaces.

Mounting Method | Best Use Case | Tools Needed |

|---|---|---|

Mechanical Fixing | Exterior facades | Drill, screws, frame |

Adhesive Mounting | Indoor signage | Adhesive tape, level |

Hanging Systems | Temporary displays | Hooks, rails |

Tip: Always wear gloves and safety glasses when handling acp panels.

Cleaning Tips

You can keep your acp signage looking new with simple cleaning steps. Use a soft cloth or sponge with mild soap and water. Avoid harsh chemicals or abrasive pads, as they can scratch the surface. Rinse with clean water and dry with a soft towel. For tough stains, use a diluted alcohol solution. Clean your acp panels every few months, or more often in dusty areas.

- Wipe gently to avoid scratching.

- Test any cleaner on a small area first.

- Remove bird droppings or tree sap quickly to prevent stains.

Troubleshooting

You may notice issues like dents, loose panels, or fading over time. Regular inspections help you catch problems early. Experts recommend checking your acp panels at 1, 3, and 5-year intervals. Use non-destructive inspection tools to spot hidden damage. Some buildings use sensors to monitor strain and detect changes in the panels. If you find defects, measure the depth and check for voids using special equipment. Keep records of repairs and inspections in a digital database. This helps you track trends and plan future maintenance. Always use qualified technicians for repairs to ensure safety and quality.

Note: Scheduled inspections and proper documentation help your acp signage last longer and look its best.

Aluminum composite panel signage gives you a smart choice for many projects. You benefit from a lightweight yet strong material that resists weather, corrosion, and impact. ACP panels offer:

- Easy installation and low maintenance

- Many colors and finishes for custom designs

- Fire-retardant options for safety

- Cost savings over time

You can use ACP for outdoor signs, indoor displays, and even building cladding. If you want signage that lasts and looks great, talk with signage professionals or explore ACP options for your next project.

FAQ

What makes ACP panels better than traditional sign materials?

You get lightweight panels that resist weather and last longer than wood or PVC. ACP panels also offer more color and finish choices. You can install them easily and save money on maintenance.

Tip: ACP panels do not rust or warp like wood or metal.

Can you use ACP panels for both indoor and outdoor signs?

Yes, you can use ACP panels inside buildings and outside. They handle sun, rain, and wind. You can also print bright graphics on them for indoor displays.

How do you clean aluminum composite panel signage?

Use a soft cloth with mild soap and water. Avoid strong chemicals or rough pads. Rinse with clean water and dry with a towel. Clean your signs every few months to keep them looking new.

Are ACP panels safe for public spaces?

You can choose fire-retardant ACP panels for extra safety. These panels meet strict fire codes. Many schools, hospitals, and malls use them for signs and wall coverings.

What finishes and colors can you get with ACP signage?

You can pick from matte, gloss, brushed metal, wood grain, and even mirror finishes. ACP panels come in many colors. You can match your brand or building style easily.

Durability

Durability