07 Aug What Are ACM Metal Panels and Their Main Features

Table of Contents

You can see ACM metal panels on many new buildings. Each panel has three layers. There are two aluminium sheets and a core that is not aluminium. This makes ACM panels strong, light, and easy to shape. Builders pick aluminium composite panel systems because they last long and look nice. The ACM panel market was about $8.5 billion in 2023. Many people want them in Asia-Pacific, North America, and Europe. In the last ten years, aluminium composite materials got more popular. They save energy, cost less, and come in many styles. You can find aluminium composite solutions on tall buildings and cool interiors.

Key Takeaways

ACM metal panels are tough and light. They are simple to shape. This makes them good for outside walls, inside spaces, and signs.

These panels have three layers. There are two thin aluminum sheets. The middle layer changes the weight, price, and fire safety.

ACM panels can handle bad weather. They do not rust or fade. They last a long time and do not need much care.

You can pick from many colors, finishes, and textures. This helps match any style or brand.

Fire safety is very important. Always choose panels with the right core and safety labels. This keeps buildings safe.

ACM Metal Panel Basics

What Is an ACM Panel

You can spot an acm metal panel on new buildings. This panel is called a sandwich panel. It has two thin aluminium sheets on the outside. There is a core in the middle. The panel is strong and light. It is also flat and works for many things. Builders and designers like acm panels. They are simple to cut and bend. You can shape them easily. These panels work for both outside and inside jobs.

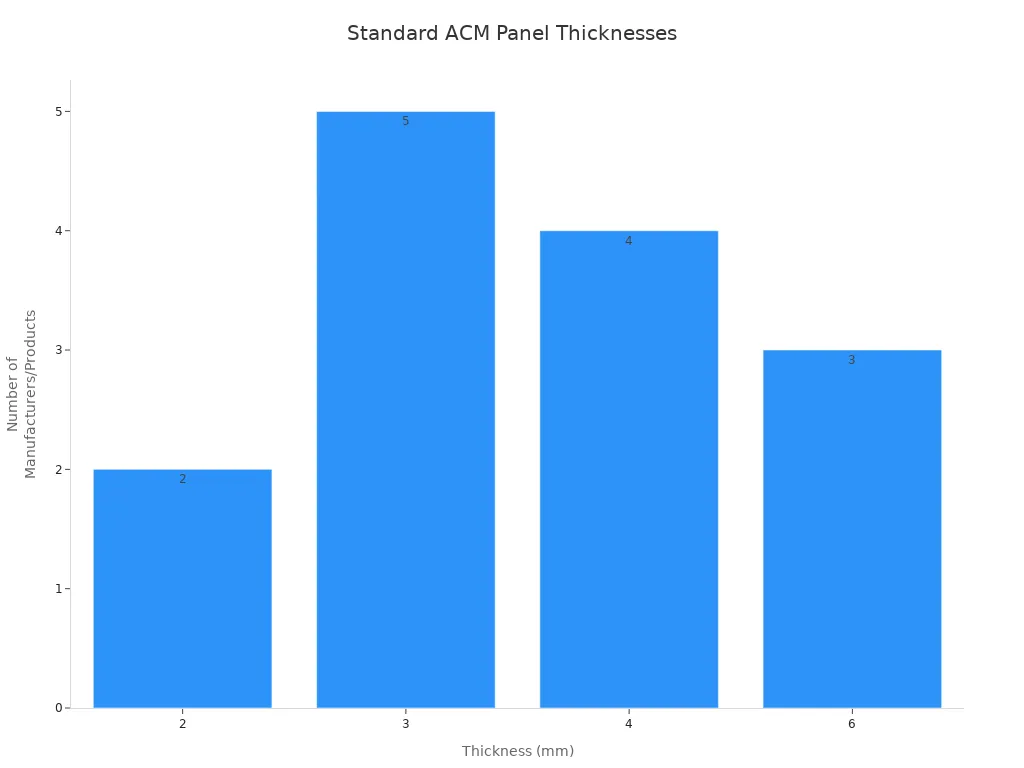

Aluminum composite panels come in many sizes and thicknesses. Most acm panels are between 2mm and 6mm thick. The most used thicknesses are 3mm, 4mm, and 6mm. Standard sheet sizes are 4 feet by 8 feet and 4 feet by 10 feet. Some companies make bigger panels for special needs. Here is a table that lists some common sizes and thicknesses:

Product/Manufacturer | Thickness Range (mm) | Size Range (inches) |

|---|---|---|

Alucobond | 3 to 6 | 50 x 98 to 62 x 196 |

Dibond | 2 to 4 | 48 x 96 to 60 x 120 |

CMG Metals | 3, 4 (6 limited) | 62 x 196 |

~3 | 48, 60 x 96, 144 | |

3 | 48 x 120 | |

Farco Plastics | 3, 4, 6 | 48 x 96, 120 |

You can also check this chart to see which thickness is used most:

Tip: If you need a special size or thickness, many suppliers can make custom acm panels for your project.

Aluminum Composite Materials Structure

The way aluminum composite material panels are built gives them special features. Each panel has three main layers:

Aluminium Sheets:

There are two thin aluminium sheets on the outside. These sheets are usually between 0.12mm and 0.50mm thick. The aluminium makes the panel strong. It also protects it from weather and gives a smooth look.Core Material:

The core sits between the aluminium sheets. You can pick from different core types. The most common is polyethylene (PE). It is light and easy to use. Some panels have a fire-retardant (FR) core with minerals. This type helps stop fires and meets safety rules. Some panels use aluminum honeycomb cores. These make the panel even stronger and stiffer.Coating Layer:

The outer aluminium sheets often have a special coating. This layer keeps the panel safe from UV rays, rain, and dirt. Common coatings are PVDF and PE paint.

Here is a table that shows the usual structure of aluminum composite materials:

Layer Component | Description / Typical Thickness |

|---|---|

Aluminum Sheets | Two outer layers, 0.12mm to 0.50mm thick |

Core Material | Polyethylene (PE), Fire-Retardant (FR), or Aluminum honeycomb |

Coating Layer | PVDF or PE coating for weather resistance |

Overall Panel Thickness | Usually 3mm, 4mm, or 6mm |

The core material changes how acm panels act. If you pick a PE core, the panel is light and cheap. But PE cores can catch fire fast. You should use them only in safe places, like short buildings or inside rooms. If you want better fire safety, pick a fire-retardant core. These cores have minerals that slow down fire. They help the panel meet safety rules like ASTM E119 and NFPA 285. Aluminum honeycomb cores make the panel very strong and stiff. This is good for big or special projects.

Polyethylene (PE) cores are light and cheap but burn fast.

Fire-retardant (FR) cores have minerals that stop fire from spreading.

Aluminum honeycomb cores give extra strength and stiffness.

The core you pick changes the weight, cost, and safety of the panel.

The Grenfell Tower fire in London showed why fire safety is important. Panels with PE cores helped the fire spread quickly. Now, many builders use fire-retardant cores for tall and business buildings.

Note: Always check local building codes before you pick a core type for your aluminium composite panel project.

How acm panels are built changes what they can do. You get a panel that is light, strong, and easy to put up. The aluminium sheets protect from weather and look modern. The core changes the weight, cost, and fire safety. The coating keeps the panel looking new for a long time. When you pick aluminum composite material panels, you get many choices for design and use.

Key Features of ACM Panels

Lightweight and Strength

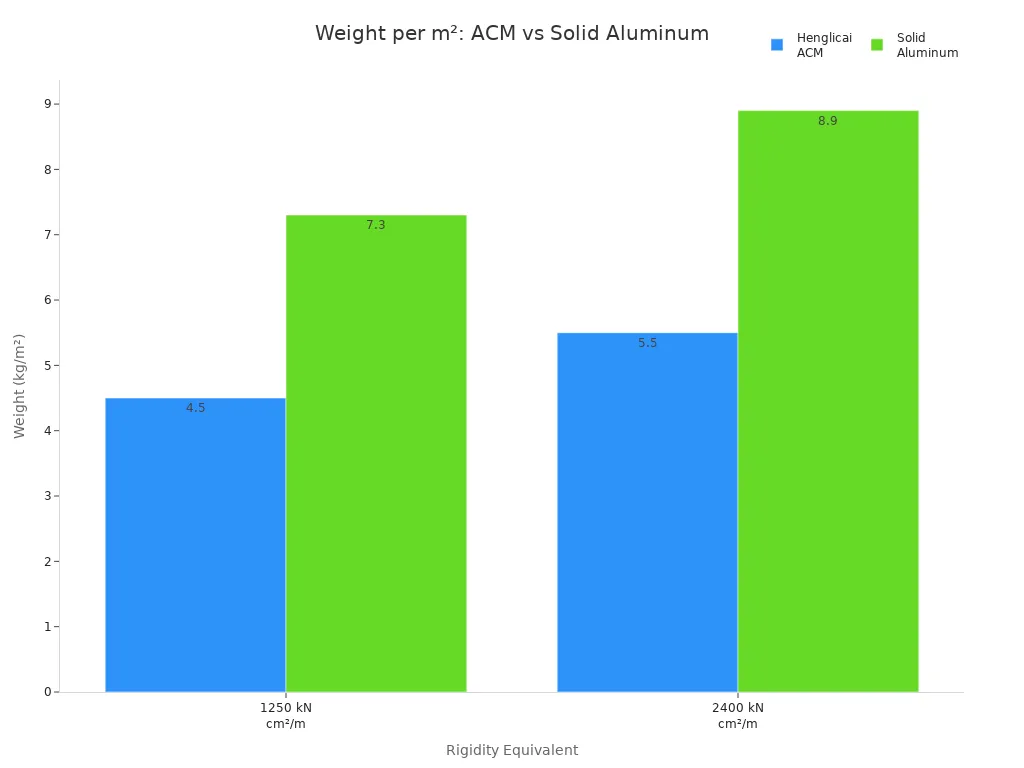

ACM panels are light but also very strong. They use two thin aluminium sheets and a core. This makes them much lighter than solid metal sheets. Most ACM panels weigh between 3 and 8 kilograms per square meter. Solid aluminum panels with the same strength weigh more. You can see this in the table below:

Panel Type | Thickness (mm) | Weight (kg/m²) | Rigidity Equivalent |

|---|---|---|---|

Henglicai ACM | 3 | 4.5 | 1250 kN cm²/m |

Solid Aluminum | 2.7 | 7.3 | 1250 kN cm²/m |

Henglicai ACM | 4 | 5.5 | 2400 kN cm²/m |

Solid Aluminum | 3.3 | 8.9 | 2400 kN cm²/m |

You can lift, move, and put up these panels easily. This saves time and money on your job. The panels are light and strong, so you do not need heavy supports. They have a high strength-to-weight ratio. This is better than many other wall materials. ACM panels work well for new buildings and fixing old ones.

Tip: If you want to make your building lighter and install panels faster, choose ACM panels for your outside walls.

Durability and Weather Resistance

ACM panels last a long time and stand up to bad weather. The aluminium layers protect the panel from rain, wind, and sun. These panels do not rust, even in tough places like near the sea or in cities. Here are some reasons why ACM panels last:

Aluminium forms a layer that stops rust.

Panels keep their color and shape after years outside.

You can use them where there is salty air, lots of rain, or strong wind.

If you live by the ocean or in a city with pollution, ACM panels keep your building looking nice. They also stand up to hail, flying things, or bumps. This means you fix them less and save money.

Clean your panels often and use the right screws to help them last longer.

Finishes and Design Options

You can pick from many looks and colors for ACM panels. Companies offer lots of finishes and shades. The most common finishes are PVDF, FEVE, and HDPE. These finishes protect the panels from sun, water, and dirt. PVDF coatings can last 15 to 20 years or more. The best panels can last up to 50 years.

Finish Type | Characteristics | Typical Lifespan |

|---|---|---|

Superior resistance to weathering, UV, and fading | 15 to 20+ years | |

Polyester Coating | Less durable than PVDF, used as protective finish | Less than PVDF |

General ACM Panels | Varies by quality and conditions | 20 to 30 years |

High-Quality PVDF Panels | Enhanced durability under ideal conditions | Up to 50 years |

You can choose from many colors, like metallic, matte, or custom ones. Some panels look like wood, stone, or brushed metal. You can also pick shiny, flat, or rough surfaces. Some finishes help save energy by bouncing sunlight away and keeping buildings cool.

Color Options: Pick standard, metallic, matte, or custom colors for your brand.

Texture Options: Choose smooth, brushed, wood, or stone-like surfaces.

Special Coatings: Get anti-graffiti, shiny, or easy-to-clean finishes.

These choices help you match your project’s style and make cool designs.

Thermal and Fire Performance

ACM panels help save energy in your building. The core acts as a barrier and slows down heat. Standard polyethylene cores have a low R-value, about 0.0057. Some insulated metal panels with foam cores have R-values from 16 to 32 or more. This keeps your building warm in winter and cool in summer. You can save money on energy bills.

Panel Type | Core Material | Typical R-Value |

|---|---|---|

Maxmetal® HD ACM Panel | Polyethylene | 0.0057 (very low) |

Insulated Metal Panels (IMPs) | Foam Core | R-16 to R-32+ (high) |

IMPs (per inch) | Foam Core | Up to R-8.4 per inch |

Fire safety is important too. If you pick ACM panels with fire-resistant cores, you get more protection. These panels have mineral-filled cores that slow fire and make less smoke. They pass tough fire tests like ASTM E119 and NFPA 285. Fire-resistant panels can last 30 to 60 minutes or more in a fire. This makes them safe for tall buildings, schools, and hospitals.

Always check your local building rules to make sure you pick the right core for your project.

You can count on ACM panels for saving energy, standing up to hits, and keeping your building safe. Their design helps you meet today’s rules for comfort and safety.

Applications of Aluminium Composite Panel

Building Facades and Cladding

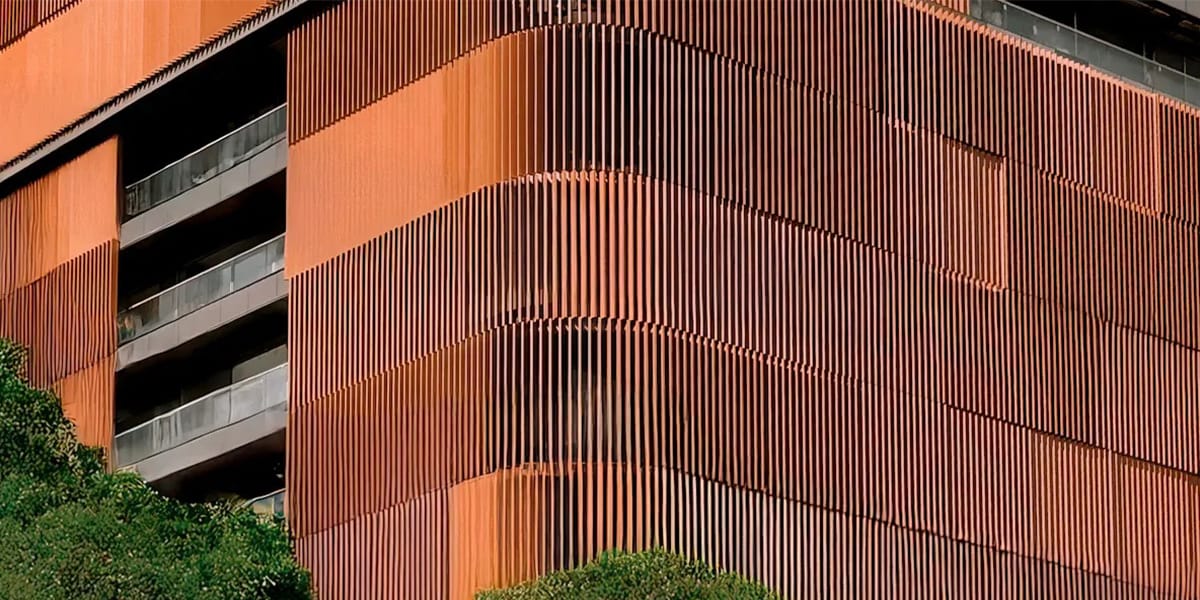

Building Facades and Cladding

You can see acm panels on many new buildings. Architects like acm cladding for lots of reasons. The panels are light, so workers put them up fast. They help slow down fire and heat, which keeps people safer. There are many colors and finishes, like wood or stone looks. This lets you pick any style you want. ACM panels use recycled aluminum and can be recycled again. This is good for the planet. These panels do not get damaged by bad weather, pollution, wind, or hail. Your building will last longer with them.

ACM cladding is good for new buildings and fixing old ones. You can use it to cover big walls or make cool shapes. The panels help block noise and keep heat in or out. This saves energy in your building. With acm cladding, your building is strong, safe, and looks great.

Interior and Decorative Uses

You can use acm panels inside for many fun ideas. Designers use them for ceilings, columns, and kitchen counters. You might see them as doors for cabinets, tables, or shelves. ACM panels are also good for stands at shows or displays.

These panels come in shiny, flat, mirror, or metal looks. You can match any style, from modern to classic. ACM cladding inside gives you smooth walls and bold designs. Some panels look like wood or stone, which adds warmth or style. They help keep rooms quiet and warm or cool.

Tip: ACM panels are simple to clean and last longer than wood or plasterboard.

Signage and Branding

ACM panels are great for signs and branding. You can cut, bend, and print on them easily. Here are some reasons why acm cladding works well for signs:

The panels are light, so signs are easy to hang.

Many colors and finishes help match your brand.

They stand up to sun, rain, and snow, so signs look new.

You can put up signs fast and save money.

ACM panels cost less than steel or glass but look nice.

You can recycle them, which is good for the earth.

People use ACM panels for store signs, billboards, and displays. The panels stay flat and bright for a long time, so your message is easy to see.

Safety and Maintenance

Fire Safety

You need to pay close attention to fire safety when you use ACM panels. Not all panels offer the same level of protection. In major markets, you must look for panels that meet strict fire safety certifications. These include EN13501-1 in Europe and AS 1530.1 in Australia. The highest rating is A1, which means the panel is non-combustible and does not help a fire spread. Panels with a fully ceramic core reach this level. You also find other types, such as PE, FR, and A2. A1 panels are the gold standard, especially for tall or important buildings.

The tragic Grenfell Tower fire in 2017 showed what can happen if you use the wrong panels. Combustible ACM panels and poor fire barriers caused the fire to spread quickly. Many buildings did not have enough fire barriers or used panels that were not tested for fire safety. Building codes now require fire barriers and non-combustible materials. You should always check that your panels pass tests like NFPA 285 and follow local codes. If you want the best safety, choose a fireproof acm panel with an A1 rating.

Note: Always ask your supplier for fire test certificates before you buy ACM panels.

Cleaning and Upkeep

You can keep your ACM panels looking new with regular cleaning. Use a soft, damp cloth with water between 20°C and 30°C and a mild soap. Do not clean panels when they are very hot or freezing. Start by rinsing the panels from top to bottom. Then, use a soft sponge with mild detergent for sticky spots. Clean with gentle, even strokes to avoid streaks. Rinse well and dry with a lint-free cloth or squeegee.

Clean your panels as often as you clean your windows. In busy or dirty areas, you may need to clean more often.

Deep clean every six months to a year to remove tough stains.

For tall buildings, hire professionals with the right equipment.

Avoid harsh tools or strong chemicals, as these can damage the surface.

ACM panels need less routine maintenance than stone or brick, but they can get dents or scratches in busy areas. You may need to replace panels more often than with solid aluminum or stone. Regular cleaning helps your panels last longer and keeps your building looking sharp.

Tip: Remove sticky substances like glue right away to prevent stains.

Benefits and Advantages of ACM

Cost-Effectiveness

When you pick ACM panels, you get long-term value. The price for ACM panels is usually $15 to $30 per square meter. Some fancy panels can cost $161 to $376 per square meter. This is more than metal or vinyl siding, which is cheaper. But ACM panels give you more than just a cover. They last for many years and handle bad weather well. You do not have to fix or replace them often. These panels block UV rays and do not rust or fade fast. This saves you money on repairs.

You also save money on work and setup. ACM panels are light, so workers put them up fast. You do not need big machines or special skills. This makes labor cheaper. You can keep panels outside without worry. You can cut and measure them at the job site, which is quick. Over time, the good things about ACM panels make the higher price worth it.

Tip: Just clean your ACM panels simply to keep them looking new. This means you spend less on upkeep.

Design Flexibility

ACM panels let you be creative with your designs. You can cut, bend, or shape them easily. You can make curved walls or cool building shapes. You do not need special tools for tricky forms. The panels come in many looks, like shiny, wood, or mirror. This gives you lots of choices for any project.

You can use ACM panels for outside walls, signs, inside walls, columns, or roofs. The panels fit many ways of putting them up. You can swap or move them if you need to. They last a long time and keep their look. You can match any style or brand. This helps your building look special and nice.

Environmental Impact

Caring for the earth is important today. ACM panels help you build in a greener way. The aluminum in these panels can be recycled. Some brands use up to 85% recycled aluminum. When your building is old, you can recycle the panels. You just take the aluminum out from the core. This means less trash in landfills and helps the planet.

ACM panels also help save energy in your building. They keep heat in or out, so you spend less on heating and cooling. They last a long time, so you do not replace them often. This saves resources. Making and moving ACM panels uses less energy than concrete or steel. By picking ACM panels, you help the earth by using less, making less pollution, and recycling.

Note: Always check if your ACM panels are made from recycled or safe materials. This helps your project be even more green.

You now know that an acm metal panel gives you strength, light weight, and many design choices. You can use an aluminium composite panel for building exteriors, interiors, or signs. These panels last a long time and need little care. You can trust them to keep your project looking modern and fresh. If you want a smart, durable solution, consider ACM panels for your next build.

FAQ

What is the typical lifespan of ACM panels?

You can expect ACM panels to last 20 to 30 years. High-quality panels with PVDF coatings may last up to 50 years. Regular cleaning helps keep them looking new.

Can you paint or customize ACM panels after installation?

You can order ACM panels in many colors and finishes. Most panels come pre-finished. Painting after installation is not recommended because it may not stick well or last long.

How does the acm installation process work?

You start by measuring and cutting the panels to fit your design. Workers attach them to a frame using special clips or screws. The acm installation process is quick and does not need heavy equipment.

Are ACM panels safe for use in schools and hospitals?

You can use ACM panels with fire-retardant or non-combustible cores in schools and hospitals. Always check local building codes to make sure you pick the right type for safety.

Do ACM panels help with energy savings?

Yes, ACM panels add a layer that helps slow down heat transfer. This can keep your building cooler in summer and warmer in winter. You may save money on energy bills.

Building Facades and Cladding

Building Facades and Cladding