01 Sep Comparing Polyethylene and Mineral Cores for ACP Curtain Walls

Table of Contents

- 1 Key Takeaways

- 2 Which Core for Curtain Walls?

- 3 ACP Core Materials Overview

- 4 Fire Performance

- 5 Structural and Visual Differences

- 6 Cost and Availability

- 7 Fabrication and Installation

- 8 Choosing ACP Core Materials

- 9 FAQ

- 9.1 What is the main difference between polyethylene and mineral core ACP panels?

- 9.2 Can mineral core ACP panels be used for curved designs?

- 9.3 Are polyethylene core panels allowed in high-rise buildings?

- 9.4 How does the cost of mineral core ACP panels compare to polyethylene core panels?

- 9.5 What certifications should ACP panels have for commercial use?

Choosing the right ACP core materials is very important for building safety and how well it works. Studies show that cores that can burn make fire dangers worse. This has led to stricter rules for business buildings. New ideas in core makeup and coatings have made them better at stopping fires. This is very helpful for tall buildings and places where fire is a big risk. Tests also show that the materials in the core and coatings change how heat moves and how fire spreads. So, picking the right core material is very important for fire safety and following the rules.

Key Takeaways

Mineral core ACP panels are much safer in fires than polyethylene cores. They follow strict rules for tall or risky buildings.

Polyethylene core panels weigh less and cost less. But they catch fire easily. Many tall or business buildings do not allow them.

You must pick the right core for your building. Think about how tall it is, fire danger, and local rules. Mineral cores work best for tall buildings. Polyethylene cores are good for short buildings.

Both core types are simple to use. They let you make many designs. But mineral cores make curtain walls stronger and last longer.

You should plan for higher costs with mineral core panels. Their safety is worth the extra money.

Which Core for Curtain Walls?

Fire Safety First

Fire safety is the most important thing when picking a core for curtain walls. Many countries have changed their building rules because of the dangers from flammable ACP core materials. Aluminum composite panels in curtain walls have a sandwich shape. Two aluminum sheets are stuck to a middle core. This core can be filled with minerals or made from plastic. The thickness and what is inside the core decide how it acts in a fire.

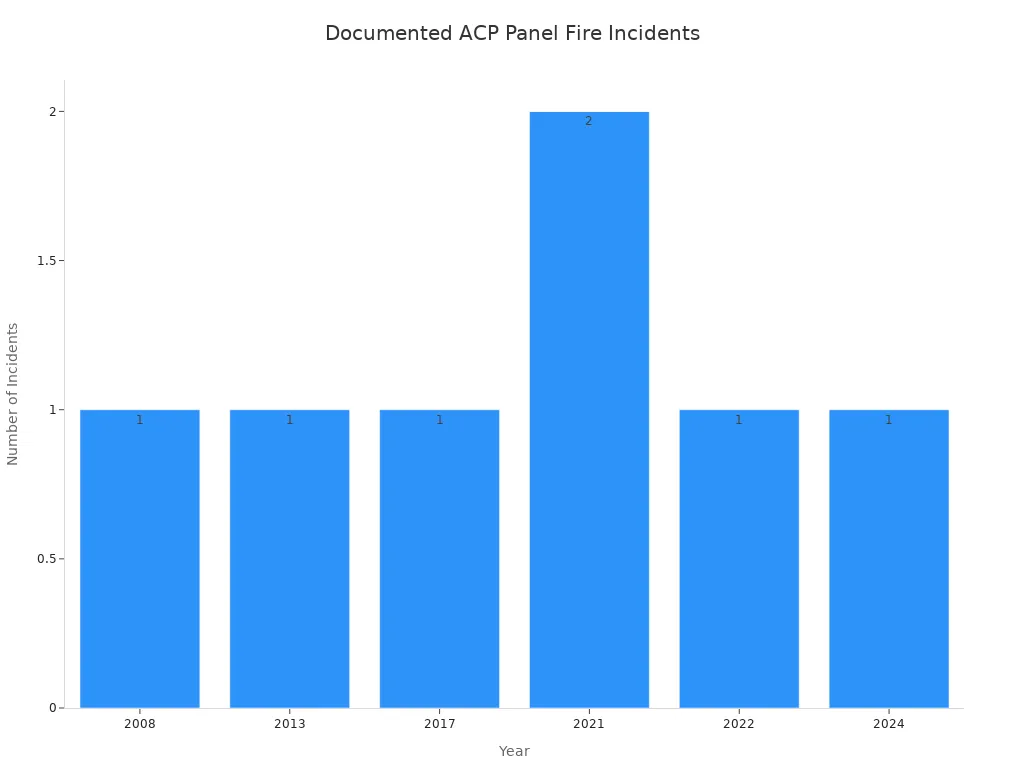

Looking at recent fires shows the dangers of using polyethylene (PE) core panels. These panels have caused many big fires in different countries. The table below shows some of the most well-known cases:

Incident Name | Location | Year | Key Details |

|---|---|---|---|

Grenfell Tower | London, UK | 2017 | Fire spread quickly because of polyethylene core ACM cladding; 72 people died; evacuation plan failed. |

Residential Complex | Valencia, Spain | 2024 | 6,000 m² polyethylene cladding was like 18,000 liters of gasoline; fire spread fast because of ACM panels. |

Torre dei Moro | Milan, Italy | 2021 | Melting polyethylene helped fire move to lower floors; lots of toxic smoke; everyone got out safely. |

Telecom Tower | Changsha, China | 2022 | Fire burned ACM polyethylene cladding and made the fire move up the outside. |

Marina Diamond | Dubai, UAE | 2021 | Fire burned ACM panels with polyethylene core; there was toxic smoke. |

Olympus Tower | Grozny, Russia | 2013 | Fire burned ACM polyethylene cladding; toxic smoke and fire spread happened. |

Monte Carlo Casino | Las Vegas, USA | 2008 | Fire burned ACM panels with polyethylene core; this made the fire worse. |

🔥 Note: Fire tests show that polyethylene core panels catch fire fast, keep burning after the flame is gone, and make toxic smoke and burning drops. These drops can help fire move down the outside of a building. Many countries do not allow PE core panels in tall buildings because of these risks.

Mineral core panels, like A2 and A1 types, are much better at stopping fire. Tests at very high heat, up to 1500°C, show mineral cores do not burn, do not make toxic gas, and do not drip burning stuff. These panels slow or stop fire and help buildings pass tough fire safety tests like NFPA 285 and ASTM E84. The table below shows how well each core type stops fire:

Core Type | Core Material | Fire Resistance Level | Typical Applications | Regulatory Compliance |

|---|---|---|---|---|

Polyethylene (PE) | Plastic (PE) | Low; burns easily | Inside use, short buildings | Often does not pass strict rules |

Fire-Resistant (FR) | Mineral-filled | Medium to high; stops fire better | Taller or riskier buildings | Passes tougher fire safety rules |

A2 Core | Mineral-based | High; does not burn | Big projects needing high safety | Passes strict standards |

A1 Core | Mineral-based | Highest; does not burn | Large, important projects | Best fire safety compliance |

Building owners and designers should always check local fire rules before picking ACP core materials. For tall or risky buildings, mineral core panels give the best safety and help meet the law.

Project Requirements

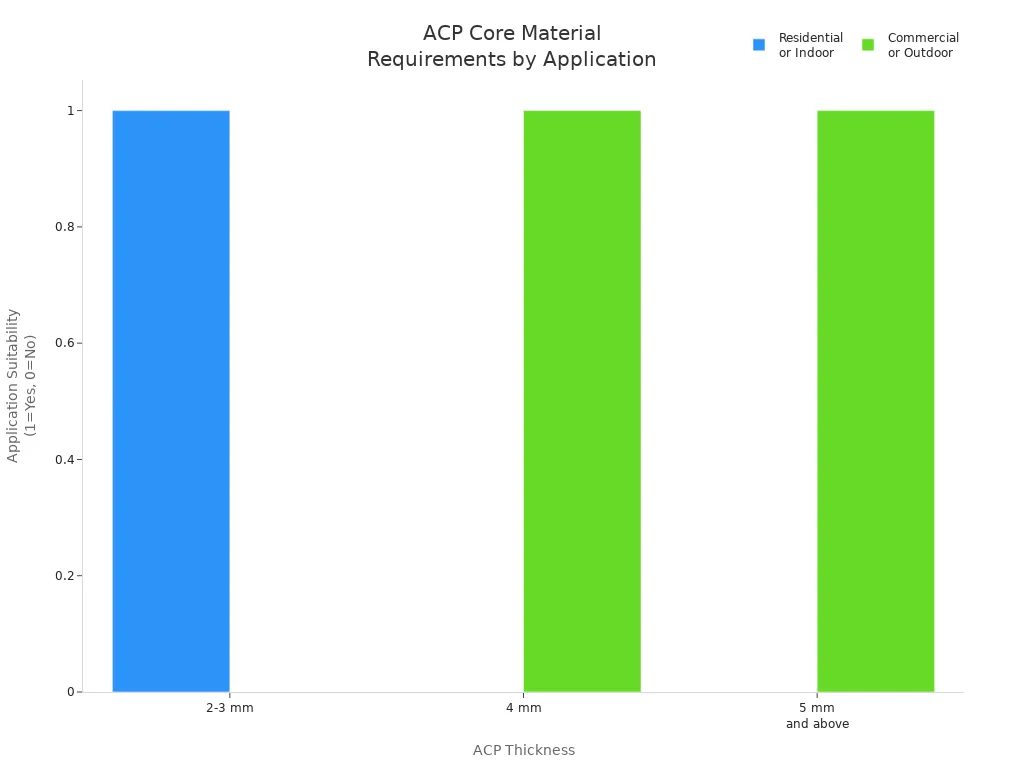

Project needs are also important when picking the right core. Curtain wall jobs are different for homes and businesses. Each kind needs its own panel thickness, core material, and fire rating.

Residential buildings often use thinner panels (2-3 mm) with regular, non-fire-resistant cores. These jobs do not need as much fire safety or strength.

Commercial buildings, especially tall ones, need thicker panels (5 mm or more) with fire-resistant or mineral-filled cores. These panels must handle strong wind and meet tough fire safety rules.

The chart below shows how ACP thickness and core needs change for different jobs:

🏢 Tip: Commercial curtain walls need to be stronger and safer from fire. Picking the right core helps the building follow safety rules and last longer.

ACP Core Materials Overview

Polyethylene Core

Polyethylene cores are used a lot in ACP core materials. Makers use low-density polyethylene or polyurethane for these cores. These polymers make panels light and easy to bend. They also help panels fight rust, which is good in wet or harsh places.

Polyethylene cores sit between two thin aluminum sheets.

These cores are simple to cut and bend. They work well for tricky shapes.

Regular polyethylene cores can catch fire unless treated.

Panels with these cores fit low buildings or places with little fire danger.

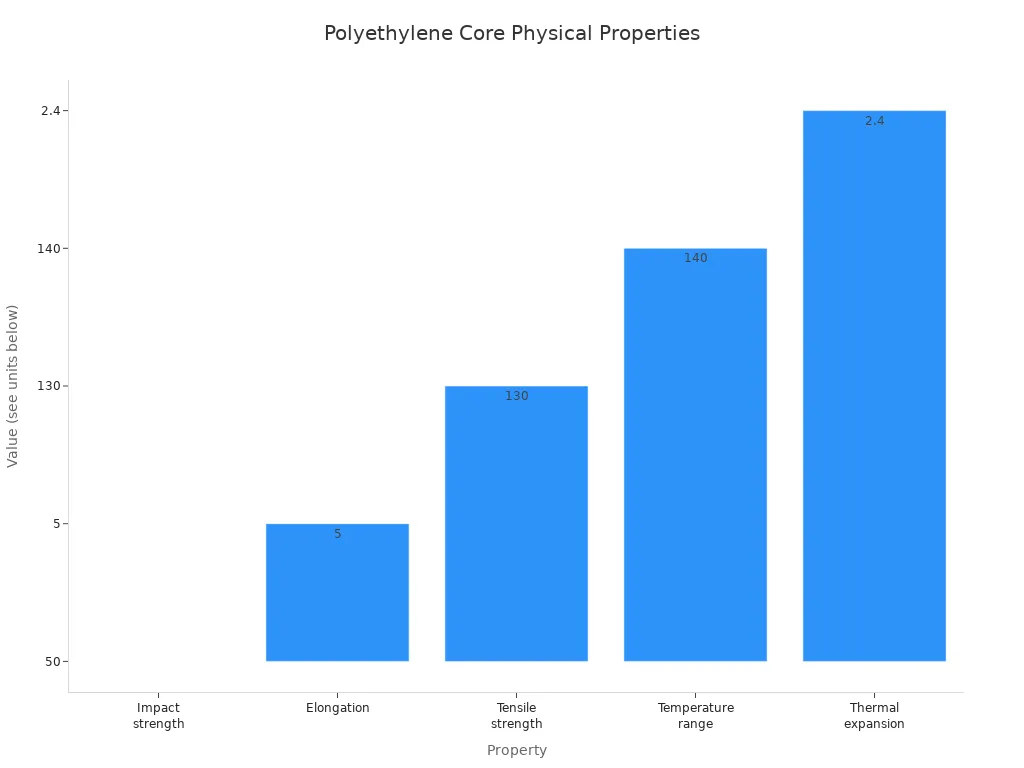

The table below lists key facts about polyethylene cores:

Property | Description/Value |

|---|---|

Core Material | Polyethylene (PE), lightweight, corrosion-resistant, recyclable |

Chemical Resistance | Resistant to acids, alkalis, oils, solvents |

Physical Properties | Impact strength: 50 kg/cm², elongation: 5%, tensile strength: 130 MPa |

Temperature Resistance | -50°C to +90°C |

Processing | Easy to cut, groove, punch, drill, bend, roll |

⚠️ Note: Polyethylene cores in ACP core materials burn fast. Many building rules say not to use them in tall or risky buildings.

Mineral Core

Mineral cores are safer for ACP core materials. They are best for buildings where fire safety matters most. These cores have lots of minerals like magnesium hydroxide and aluminum hydroxide. A little polymer is mixed in too. The mineral part can be up to 95% in the best panels.

Mineral cores slow heat and let out water vapor when hot. This helps stop fire from spreading.

They make a barrier that blocks flames and smoke.

Panels with mineral cores meet hard fire safety rules. They are needed for tall or public buildings.

These panels are good for the planet. They use minerals and aluminum that can be recycled.

The table below shows what is inside different mineral core grades:

Aspect | Grade A2 Mineral Core Composition | Grade B1 Mineral Core Composition |

|---|---|---|

80-95% | 50-70% | |

Key Components | Aluminum hydroxide, Magnesium hydroxide, Modified silicate, Nano-grade clay, Zinc borate complex | Aluminum hydroxide, Magnesium hydroxide, Organic phosphorus flame retardant, Calcium carbonate filler, Other additives |

Organic Flame Retardants | None | Present |

Fire Resistance Performance | Excellent | Lower compared to A2 grade |

🛡️ Tip: Mineral core ACP core materials give top fire safety. They help buildings pass tough safety checks.

Fire Performance

Polyethylene Core Risks

Polyethylene core panels can be very dangerous in fires. These panels have a plastic core that burns fast and gets very hot. In big fire tests, ACP panels with polyethylene cores made flames taller than 25 feet. They also gave off a lot of heat, more than 6 MW. The table below shows how different panels act in fires:

Panel Type | Core Material | Flame Height in Large-Scale Fire Tests | Peak Heat Release Rate | Fire Safety Compliance and Usage |

|---|---|---|---|---|

Fire-Rated ACP Panel | Mineral core (e.g., alumina trihydrate, magnesium hydroxide) | Under 10 feet | Below 1 MW | Meets strict fire safety codes; used in high-rise buildings, hospitals, schools |

Standard ACP Panel | Polyethylene core | Over 25 feet | Above 6 MW | Combustible; involved in severe fire incidents; less safe for critical applications |

A fire in a tall apartment building in Australia showed how quickly flames can move with polyethylene core panels. The fire went up 13 floors in only 15 minutes. Lab tests by CSIRO had to stop after just 90 seconds because the fire and smoke got too strong. After this, officials told people to take out these panels and use safer ones.

⚠️ Alert: Polyethylene core panels can come apart in a fire. This lets more fuel show and makes the fire worse. Many countries do not allow these panels in ventilated façades or risky buildings now.

Mineral Core Benefits

Mineral core panels use materials that do not burn, like calcium silicate or magnesium hydroxide. These minerals help block flames and heat. The aluminum layers on both sides also fight fire, since they melt at about 660°C. This mix helps keep fires from moving across the outside of buildings.

Studies show mineral-rich cores do not burn easily and make less heat. Special tests prove mineral core panels lose less mass and give off less heat when there is a fire. This helps buildings stay strong even when it is very hot.

Mineral filled polymer cores with fire retardants work well against fire.

Mineral filled non-combustible cores have less energy and are safer in fires.

New rules after big fires say many new buildings must use mineral core panels.

🛡️ Tip: Mineral core panels follow strict fire safety rules. They are now used in tall buildings, hospitals, and schools. Using them makes it much less likely for fire to spread on building walls.

Structural and Visual Differences

Rigidity and Strength

Polyethylene core panels are light and easy to bend. These panels can curve when builders put them in place. Builders like them for projects with curved or shaped walls. But, being flexible means they are not as strong. Strong winds or hits can dent or bend these panels. Polyethylene core panels are best for short buildings with less wind.

Mineral core panels are much stiffer than polyethylene ones. The minerals inside make the panel hard to bend. These panels keep their shape even when pushed or pressed. Engineers pick mineral core panels for tall buildings. Their extra strength helps curtain walls stay safe in strong winds. The table below shows how the two core types compare:

Property | Polyethylene Core | Mineral Core |

|---|---|---|

Flexibility | High | Low |

Rigidity | Moderate | High |

Impact Resistance | Moderate | High |

Wind Load Support | Low to Moderate | High |

🏗️ Tip: If a building is tall or in a windy place, mineral core panels are stronger and safer.

Color and Identification

Companies use colors and marks to tell panel types apart. Polyethylene core panels usually have a blue or black center. Mineral core panels look gray, white, or green. Some brands print words or put colored lines on the edge. These marks help workers pick the right panel during building.

Polyethylene core: Blue or black center, sometimes no mark.

Mineral core: Gray, white, or green center, often with “A2” or “FR” printed.

Inspectors look at these colors and marks before saying a project is safe. Picking the right panel keeps the building safe and passes checks. Using the wrong panel can cause safety risks and failed checks.

🔍 Note: Always look at the core color and label before putting in panels. This easy check can stop mistakes and make the building safer.

Cost and Availability

Price Comparison

Price Comparison

How much a project costs can change with the ACP panel type. Polyethylene core panels are usually cheaper than mineral core panels. The table below shows what each type costs in big markets:

ACP Panel Type | Price Range (USD per sq ft) | Converted Price Range (USD per sq m) |

|---|---|---|

Polyethylene (PE) Core | $15 – $25 | $161 – $269 |

Mineral Core (Fire-Resistant) | $20 – $35 | $215 – $376 |

Mineral core panels cost more because they use better, fire-resistant materials. The higher price is because these panels must meet strict fire safety rules. Project managers should watch out for price changes. The cost of raw materials, like aluminum, has gone up a lot in the last few years. For example, aluminum went from $1,750 per ton in 2020 to $2,701 per ton in 2022. Big world events, like the Russia-Ukraine war, made EU energy prices jump by 31%. New rules for the environment, like EPA VOC limits, made glue prices go up by 9%. All these things make ACP panel prices hard to guess.

💡 Tip: When planning your budget, add extra money for price changes because of world supply chain problems.

Lead Times

How long it takes to get ACP panels depends on the core type, how busy the supplier is, and if you want special designs. Top makers answer questions in four hours. If you want a special color or texture, it takes 7 to 14 days to make a sample. The best suppliers deliver most orders on time, so projects stay on track. New factories with robots, like one in Guangdong, China, make panels 31% faster. This means both polyethylene and mineral core panels can arrive sooner. Mineral core panels are newer, so wait times can change, but new tech is helping them catch up.

🚚 Note: Talk to suppliers early and give clear project details to avoid delays and get your panels on time.

Fabrication and Installation

Workability

Fabricators like ACP panels because they are easy to use. Polyethylene core panels are simple to cut and bend. Workers can punch holes or glue them with normal tools. These panels are easy to drill too. Teams can make curves or columns without special machines. Mineral core panels, like HUABOND A2 fireproof ACP, are just as easy to work with. Workers say mineral core panels cut and glue like polyethylene ones. No extra steps are needed for these panels. Both types let workers pick and change panels fast on busy sites.

🛠️ Tip: Teams can use regular tools for both mineral and polyethylene core panels. This keeps projects moving and means less training is needed.

Design Flexibility

Architects like ACP panels because they give many design choices. Polyethylene core panels bend into cool shapes and fit tight curves. Designers use them for creative walls and special building parts. Mineral core panels also let designers make flexible shapes. Factories make these panels in lots of colors and textures. Both types work for flat walls, round columns, and angled parts. The table below shows what each panel type can do:

Feature | Polyethylene Core Panels | Mineral Core Panels |

|---|---|---|

Curved Shapes | Yes | Yes |

Custom Colors | Yes | Yes |

Textured Finishes | Yes | Yes |

Column Cladding | Yes | Yes |

🎨 Note: Designers do not have to give up style or cool looks when they pick mineral core panels. Both types help make modern and special buildings.

Choosing ACP Core Materials

High-Rise vs. Low-Rise

Picking ACP core materials depends on how tall the building is and what safety it needs. Tall buildings must follow strict fire safety rules. Codes like ASTM E84 and NFPA 285 say to use mineral-filled fire-resistant cores for these buildings. These cores do not burn or help fire spread. That is why they are best for outside walls where safety matters most. Polyethylene cores are light but do not pass these rules. They can be dangerous in fires in tall buildings.

Short buildings, usually two stories or less, need different things. Polyethylene core panels cost less and are easy to put in. They also keep heat in well. But they do not stop fire as well, so they are only used where fire risk is low. The table below shows how each core type works for different building heights:

Core Material Type | Fire Safety Characteristics | Cost Implications | Typical Use Case for Building Height |

|---|---|---|---|

Polyethylene (PE) Core | Lower fire resistance | Less expensive, lightweight | Suitable for low-rise buildings (up to 2 stories) |

Mineral-Filled FR Core | High fire resistance, meets NFPA 285, ASTM E84 | More costly, required for compliance | Required for high-rise and multi-story buildings |

🏢 Tip: Always check your local rules before picking ACP core materials for curtain walls. Safety rules can be different in each place.

Safety vs. Budget

It is hard to balance fire safety and cost when picking ACP core materials. Building rules care most about stopping fires, especially in tall or public buildings. These rules say you must use panels with fire-resistant cores to keep fire from spreading and keep the building strong. Mineral-filled cores cost more, but they keep people safe and help you follow the law.

Polyethylene cores cost less at first and are easy to put in. But they can catch fire, which can cause problems with rules and make things more risky. The table below shows how cost and safety are different for each core:

Core Material | Cost Aspect | Fire Safety Aspect | Performance Aspect |

|---|---|---|---|

Polyethylene Core | Lower cost | Faces fire risk, regulatory limits | Lightweight, easy to install |

Mineral-Filled FR Core | Higher cost | Meets strict fire codes | Durable, safe for tall buildings |

🔒 Note: Safety should always come first when picking materials for curtain walls. Spending more on fire-resistant ACP core materials keeps people and buildings safe, even if it costs more.

Mineral core panels are safer in fires and block more noise. They follow strict safety rules, so they work well for tall or busy buildings. Polyethylene core panels are cheaper and lighter. But they do not pass hard fire tests. The table below shows the main differences:

Performance Aspect | Mineral Core ACP | Polyethylene Core ACP |

|---|---|---|

Fire Resistance | High | Low |

Compliance | Strong | Limited |

Application | High-risk sites | Low-rise, interior |

Project teams should look at local rules and ask experts before picking panel types.

FAQ

What is the main difference between polyethylene and mineral core ACP panels?

Polyethylene core panels have plastic in the middle. Mineral core panels have minerals that do not burn. Mineral cores are safer in fires and follow stricter rules.

Can mineral core ACP panels be used for curved designs?

Architects use mineral core ACP panels for curved walls. These panels bend well and let them make cool shapes. Builders can use normal tools to put them in.

Are polyethylene core panels allowed in high-rise buildings?

Most rules do not let polyethylene core panels in tall buildings. These panels catch fire fast and make fires worse. Mineral core panels are safe for tall buildings.

How does the cost of mineral core ACP panels compare to polyethylene core panels?

Mineral core ACP panels cost more than polyethylene ones. The higher price is because they are safer in fires and follow more rules. Project leaders should plan for this extra cost.

What certifications should ACP panels have for commercial use?

ACP panels for business buildings should pass tests like ASTM E84 and NFPA 285. Mineral core panels usually pass these tests. Always check your local rules before picking panels.

Price Comparison

Price Comparison