31 Aug Essential ACP Curtain Wall Installation Guidelines for Modern Buildings

Table of Contents

You should follow clear installation guidelines when you install ACP curtain walls. Paying close attention to each step helps you create a safe and strong building. Good installation saves energy and ensures the building remains durable for a long time. Remember, even small mistakes can cause leaks or damage. Always use the best methods and check your work at every step.

Key Takeaways

Always follow the rules when you install ACP curtain walls. This helps make them strong, safe, and keeps water out.

Measure everything the right way. Use good materials and fasten things correctly. This stops leaks and damage from happening.

Seal every joint with good sealants. This keeps water and air out. It also helps save energy.

Check and test the wall often. This helps you find problems early. It also makes the wall last longer.

Clean and take care of the panels a lot. This keeps them looking nice and helps them last longer.

ACP Curtain Wall Installation Guidelines

Key Requirements

You have to follow strict rules when you install ACP curtain walls. These rules help you build a wall that is safe and strong for a long time. There are some important things you must remember:

Structural Support: The curtain wall needs enough support on every floor. Movement joints help the wall deal with wind, temperature, and building movement. You must check that anchors, brackets, and fasteners are up to engineering standards.

Water Resistance: All joints and edges should be sealed with strong silicone. This keeps water out and stops leaks and rust.

Air Infiltration Control: Use air barriers and layers of sealing. These steps stop air from leaking in and help save energy.

Accommodation of Building Movement: Add expansion joints and flexible anchors. These let the wall move safely when the building shifts or grows.

Tip: Always check the wall for flatness, straight lines, and correct seam width. Small mistakes can cause big problems like leaks or wasted energy.

Here is a table that lists the most important ACP curtain wall installation rules and limits:

Installation Aspect | Key Guidelines and Tolerances |

|---|---|

Column Installation | Elevation deviation ≤ 3 mm; front-to-rear deviation ≤ 2 mm; left-right deviation ≤ 3 mm; distance between columns ≤ 2 mm |

Beam Installation | Connectors and rubber pads firmly installed; horizontal elevation deviation between adjacent beams ≤ 1 mm; max elevation deviation of same beam ≤ 5 mm |

Curtain Wall Flatness | Flatness deviation ≤ 3 mm; vertical slit deviation ≤ 10 mm; seam width deviation ≤ 2 mm; cross seam straightness ≤ 3 mm |

Keel Installation | Components inspected and calibrated before installation; three-person team for positioning; connectors and rubber pads installed at predetermined positions and quality checked |

Sealing | Weather-resistant silicone sealant thickness > 3.5 mm; sealant density ≥ 8 mm; polyethylene foam used at bottom of sealing notch; sealant applied on two opposite sides only |

Installation Process | Pre-installation checks of keel, column, lightning protection; installation from top to bottom; use of wood board module to control seam width; temporary fixing and adjustment by pulling wire |

Post-installation | Cleaning of surface dirt; comprehensive inspection by quality inspectors; removal of protective tape and glue marks promptly |

You should always use these rules to stop common problems. Bad waterproofing, missing expansion joints, and crooked walls can cause leaks, rust, and even damage the building. You can stop these problems by using thermal breaks, keeping different metals apart, and checking your work at every step.

Safety and Compliance

You must follow all safety rules and codes when you put in ACP curtain walls. These codes keep you, the building, and everyone inside safe. You need to use approved shop drawings and structural plans. Skilled workers and the right tools are needed for every step.

Building Codes: Check local codes, especially if there are hurricanes or strong winds. The wall must stand up to wind, dead loads, and live loads.

Manufacturer Specifications: Follow the manufacturer’s instructions for cutting, sealing, and fastening. Length, hole size, and bends must stay within strict limits.

Quality Control: Check every part for scratches, correct sealant, and good gasket installation. Do not use parts that do not meet the rules.

Material Selection: Use high-quality aluminum alloys and composite panels. Surface treatments like powder coating and anodizing make them last longer and look better.

Note: If you skip steps or ignore the rules, you might get leaks, lose energy, or pay for repairs. Always use the right sealants, anchors, and fasteners. Make sure every part fits and works as it should.

You need to work with engineers and architects to match the building’s movement and enclosure needs. Think about thermal expansion, live load changes, and long-term bending. These steps help your ACP curtain wall stay safe and strong for many years.

ACP Curtain Wall Basics

Image Source: pexels

Image Source: pexels

What Is ACP?

ACP means Aluminum Composite Panel. You can find ACP panels on many new buildings. These panels have a special build. There are two thin aluminum sheets on the outside. The middle part is not aluminum. It is usually made of polyethylene or a fire-safe mineral. The aluminum layers help the panel stand up to bad weather. They also stop rust and come in many colors. The core helps the panel stay strong and light. It also makes the panel safer from fire and hard to break.

This design makes ACP panels easy to use. You can cut, bend, or shape them for different looks. The panels do not peel or get damaged by rain or sun. They last a long time and do not need much care.

Tip: ACP panels mix the good things from metal and non-metal. You get strong, safe, and flexible panels in one product.

Benefits for Modern Buildings

There are many good things about using ACP curtain walls. They help keep heat in or out, so you save money. The panels can handle bad weather and do not burn easily. They are light, so workers can put them up fast. The surface does not break or wear out quickly. This means you do not fix them often. You can pick from many colors to match your building. The way they are made is better for the planet.

You should also think about the price. ACP curtain walls cost more than some other walls. But they work better and last longer. Here is a table to compare:

Aspect | ACP Curtain Wall (Unitized) | Window Wall (Double Glazed) |

|---|---|---|

Approximate Cost per Sq. Ft. | $104.9 | $54.6 |

Installation Complexity | High | Lower |

Structural Engineering | Required | Not required |

Installation Time | Longer | Shorter |

Performance Advantages | Superior thermal, water, and air control | Good thermal, better compartmentalization |

Typical Usage | Commercial buildings | Residential buildings |

ACP curtain walls cost more at first. But you save energy and get more safety. You can also choose many designs. This makes them a smart pick for new office buildings.

Pre-Installation Steps

Site Measurement

You need to start with accurate site measurement before you install ACP curtain walls. Good measurements help you avoid problems later. If you make mistakes in measuring, you can face big issues. The panels may not fit right, and the wall can lose strength. This can make the building unsafe and cause leaks or gaps. Always use the right tools, like tape measures and levels, to check every part of the wall area.

Tip: Double-check your measurements against the shop drawings. This step helps you catch errors early and keeps your work on track.

You should also look at the site conditions. Clean the area and make sure nothing blocks your work. If the surface is uneven, fix it before you start. A smooth and clean base helps the panels stay strong and last longer.

Cutting and Planning

You need a clear cutting plan for ACP panels. This plan helps you use each panel the right way and reduces waste. Follow these steps to make sure your cutting and planning go well:

1. Use precise measuring and marking tools, such as tape measures, levels, and chalk lines, to mark the layout on the substrate. 2. Clean the substrate to remove dirt, debris, or grease. 3. Level the surface if it is uneven. 4. Apply primer to the substrate to help the panels stick better. 5. Mark the layout of the ACP panels clearly using chalk lines. 6. Cut the panels with tools made for ACP materials. 7. Wear safety gear like safety glasses, gloves, and ear protection. 8. Fix the panels to the substrate using fasteners or adhesive as needed. 9. Seal the joints between panels with the right sealant to stop water and air from getting in.

You should always check your layout and dimensions against the shop drawings. This step makes sure you follow the installation guidelines and helps you avoid mistakes. Careful planning and cutting keep the wall strong and looking good.

Frame and Bracket Installation

Mullions and Transoms

You have to put in mullions and transoms carefully. Mullions go up and down. Transoms go side to side. These parts make the main frame for your ACP curtain wall. Check each piece to see if it is straight and strong. Use a spirit level to keep the frame even. Mullions need to match the building’s structure. Transoms connect to mullions and help hold panels.

Here are steps for a strong frame:

Mark where mullions and transoms will go on the wall.

Put in mullions first. Use anchors that can hold the weight.

Attach transoms to the mullions. Make sure each joint is tight.

Check if everything lines up after each step. Use a tape measure and level.

Look for gaps or loose parts. Fix any problems before you keep going.

Tip: Always use materials that do not rust for frames. This helps your curtain wall last longer and look nice.

Bracket Fixing

You need to pick the right way to fix brackets for your job. Brackets hold the frame to the building. They help carry weight and keep the wall steady. Different ways work better for different buildings and places.

Here is a table with common bracket fixing ways and what they do:

Bracket Fixing Method | Description & Advantages | Key Features & Applications |

|---|---|---|

Cast-in Anchor Channels | TCRS, hot-rolled, and cold-rolled profiles; ETA certified; good for seismic, static, fire loads | Tested for corners, thin slabs; approved for dynamic loads |

Mechanical Anchors | Stud anchors give flexibility when anchor channels cannot be used | Versatile; proven for facades |

Chemical Anchors | Fast-curing adhesive with HIT-Z rods; works in cracked and non-cracked concrete | Torque-controlled; works even if holes are not cleaned |

Screw Fastening on Steel | Needs knowledge of steel properties and thickness | Choose based on material characteristics |

Direct Fastening on Steel or Concrete | Uses powder actuated tools; stainless steel recommended for durability | High fastening rate; pre-drilling guides nails; high load capacity; minimal drilling depth (23 mm) |

Pick the bracket fixing that fits your building’s needs. Cast-in anchor channels are good for heavy loads and earthquakes. Mechanical anchors help if plans change. Chemical anchors work fast and in hard spots. Screw fastening and direct fastening are for steel or concrete frames.

Remember: Always check the bracket type with the engineering plan. This keeps your curtain wall safe and strong.

Panel Mounting

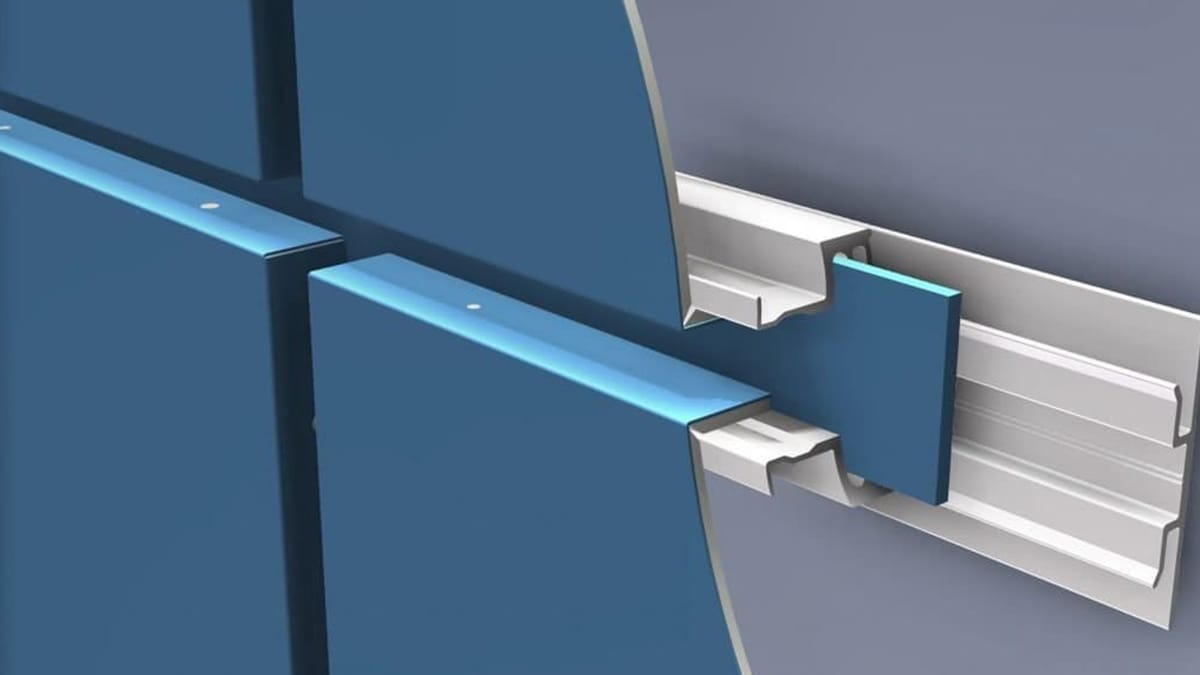

Cassette System

Cassette System

You will often use the cassette system when you mount ACP panels. This system lets you hang panels on a frame, much like sliding a book onto a shelf. The cassette or rainscreen method creates a small gap behind the panels. This gap lets air move and water drain away. You help protect the building from leaks and keep the panels dry. The cassette system also makes it easy to remove or replace panels if you need to fix something later.

Tip: Always check that the frame is strong and straight before you hang the panels. This step helps the panels fit well and last longer.

Uniform Gaps

You must keep uniform gaps between each ACP panel. The best practice is to leave a gap of 10-15 mm. These gaps let the panels expand and contract when the temperature changes. If you skip this step, the panels can bend or crack. Use spacers and guide marks to keep the gaps even. You should also fill the gaps with a silicone-based sealant or a dry gasket. This keeps out water and dirt while letting the panels move safely.

Panel Gap Size | Purpose | How to Maintain |

|---|---|---|

10-15 mm | Allows movement, stops buckling | Use spacers, check with tape measure |

Uniform gaps help your wall look neat and work well in all weather.

Fastening Methods

You need to use the right fastening methods to keep ACP panels safe and secure. Use stainless steel or aluminum screws or rivets with pre-drilled holes. Do not overtighten the fasteners. This step lets the panels move when the temperature changes. Combine mechanical fasteners with adhesives for extra strength. Always use corrosion-resistant fasteners and weatherproof coatings to stop rust.

Use the hanging method to let panels move without stressing the fasteners.

Fix vertical and horizontal frames first, then attach panels with screws or rivets.

Leave a 10-15 mm gap between panels and fill it with sealant or a gasket.

Check that all fasteners can handle wind loads and building movement.

You must also think about reinforcement. The size and height of each panel, along with local wind pressure, decide how much stiffening you need. Use building codes and wind data to choose the right reinforcement. Add stiffeners to large panels or those in high-wind areas. Make sure the frame does not bend more than allowed. This keeps the panels flat and safe.

Regularly inspect your fasteners and sealants. This helps your curtain wall stay strong against wind and weather for many years.

Sealing and Finishing

Joint Sealing

You need to seal every joint in your ACP curtain wall to keep water and air out. Good joint sealing protects your building from leaks and mold. High-performance silicone sealants work best for this job. Products like UltraPruf™ II SCS2900, SilPruf™ SCS2000, SCS1200 Construction Sealant, SilPruf™ SCS6000 ACP Weather Proofing Sealant, and TOSSEAL™ 381 give you strong adhesion and flexibility. These sealants stay soft and stretch with the wall, so cracks do not form. You also get mildew resistance and a waterproof seal that lasts for years.

Before you apply sealant, clean the joint area. Use primers such as SS Construction Primers (Weatherseal) to help the sealant stick better. Weatherstrips like UltraSpan™ US1100 fill tough spots and keep the seal tight. For extra protection, use UltraSpan™ UST2200 Transition Sheets. These sheets block water and air from getting inside. Always check the seal after installation. Look for gaps or bubbles and fix them right away.

Tip: Use a caulking gun for smooth application. Press the sealant deep into the joint for a strong bond.

Surface Protection

You want your ACP panels to last a long time, even in harsh weather. Protective finishes on the aluminum layers help resist corrosion, UV rays, and moisture. These finishes keep the panels looking new and stop fading from sunlight. Some panels have a wooden finish for extra weather resistance and style.

Here are steps you can follow to protect your ACP panels:

Use protective coatings and sealants to block rain, sun, and pollution.

Pick high-quality ACP panels from trusted brands.

Hire professional installers for correct placement.

Inspect panels often for damage or wear.

Repair any problems quickly to stop further damage.

Feature | Benefit |

|---|---|

Corrosion resistance | Stops rust and extends life |

UV stability | Prevents fading and warping |

Impact resistance | Protects against dents |

Fire-resistant core | Adds safety and durability |

Regular care and the right protection help your ACP curtain wall stay strong and beautiful for many years.

Inspection and Quality Control

Alignment Checks

Alignment Checks

You need to check the alignment of every ACP panel and frame. Good alignment keeps your curtain wall strong and looking sharp. Use a spirit level and a laser line to check if panels sit straight. You should look at both vertical and horizontal lines. If you see gaps or uneven seams, fix them right away.

Here is a simple checklist for alignment checks:

Place a spirit level on each panel edge.

Check the top and bottom of every panel.

Look at the seams between panels. The gap should stay the same size.

Use a measuring tape to check the distance between panels.

Stand back and look at the wall from different angles.

Tip: If you find a panel out of line, loosen the fasteners and adjust it. Tighten the fasteners again after you fix the position.

A well-aligned wall looks better and works better. You stop leaks and keep the wall strong against wind and rain.

Structural Testing

You must test the strength of your ACP curtain wall. Structural testing helps you find weak spots before problems start. You can use simple tools or call in experts for bigger jobs.

Common structural tests include:

Test Type | What It Checks | How You Do It |

|---|---|---|

Pull-out Test | Fastener strength | Use a pull gauge on anchors |

Water Penetration | Leak resistance | Spray water on joints |

Wind Load Test | Panel and frame strength | Use fans or wind machines |

You should record the results of every test. If a panel or fastener fails, replace it before you finish the job.

Note: Always follow the test methods in the building code or the manufacturer’s guide. This keeps your wall safe and up to standard.

Regular inspection and testing help you catch mistakes early. You save time and money by fixing problems before they grow. Your ACP curtain wall will last longer and protect your building better.

Best Practices and Mistakes

Efficient Installation

You can save time and money with smart installation. Modular installation uses parts made in a factory. These parts come ready to use, so you do not need to change them much on-site. This way, the quality is better because the factory checks everything. You also make fewer mistakes and waste less material.

Modular systems need fewer workers and less equipment. This makes your project safer and faster.

Prefabrication and machines help you finish big jobs quickly, even if they cost more at first.

The cassette fixing method uses mobile fasteners. This lets you put up panels faster and helps stop wind and water from getting in.

Rout and Return panels have V-groove cuts and folds. This makes them easy to seal and attach.

Modern facade engineering helps you use materials well and skip extra work.

These smart ways help you follow the rules and finish on time. You also keep the site cleaner and get better results.

Common Errors

You need to watch for common mistakes when you install ACP curtain walls. Many problems start when you do not plan well or skip steps. Here are some mistakes and how to stop them:

Prevention Measures | |

|---|---|

Missing or poorly applied sealants at corners and joints | Use the right sealants and follow instructions; have someone else check the sealing |

Incorrect flashing and trim cover installation | Use clear drawings; work with the contractor; check fit and stickiness |

Misalignment from poor framing or bad measurements | Check shop drawings; measure carefully; use checklists |

Improper sealing of shear blocks and water dams | Seal blocks and dams the right way; do not use too much sealant so holes stay open |

Damage from bad erection techniques | Hire skilled workers; handle panels with care; follow best steps |

Skipping routine maintenance | Follow a plan; check and replace gaskets and sealants every year |

Many mistakes happen when workers are not trained or skip steps. Weak panels, loose edges, or gaps can let water in and hurt your building. Always use skilled workers and check your work at every step. Good rules help you avoid these problems and keep your curtain wall strong for years.

Maintenance Tips

Routine Inspection

You should check your ACP curtain wall often. Regular checks help you find problems early. This keeps your building safe. Look for loose panels or broken sealants. Watch for rust or other damage. Use a checklist so you do not forget anything.

Inspection Item | What to Look For | Action to Take |

|---|---|---|

Panel Alignment | Gaps or seams that look uneven | Adjust or refasten |

Sealant Condition | Cracks, peeling, or missing spots | Replace or repair |

Surface Damage | Scratches, dents, or stains | Clean or touch up |

Fasteners | Screws or rivets that are loose | Tighten or replace |

Signs of Water Entry | Wet spots, mold, or leaks | Seal and dry area |

Tip: Check your wall every six months. Write down what you find and fix. This helps you stop big problems and keeps your wall strong.

Regular care means checking seals and fasteners. Add new sealant or coatings when needed. Get experts to check your wall every five to seven years. This helps your wall stay safe and last longer.

Cleaning and Repairs

You can keep your ACP curtain wall looking nice with cleaning and quick repairs. Follow these easy steps:

Look at panels for dirt or stains.

Rinse panels with clean water first.

Use a soft brush to scrub stains gently.

Rinse again to wash off all soap.

Dry panels with a soft cloth.

For hard stains, use dish soap for grease. Try window cleaner for bird droppings. Mix vinegar and water for water spots. Do not use rough cleaners or strong chemicals. These can hurt the panel’s surface.

Use touch-up paint for small scratches.

Call experts for dents or big damage.

Clean and add coating if you see rust.

Fix loose panels right away.

Replace broken panels with ones that match.

Cleaning often removes salt, dirt, and pollution. This keeps your wall looking good and helps it last longer. Hire cleaning companies for tall buildings to stay safe.

Checking and cleaning your wall stops water, rust, and coating damage. These steps help your building stay safe, save energy, and look great for many years.

You learned the most important installation guidelines for ACP curtain walls. These steps help you build safe and strong walls. Always follow professional standards and best practices. Regular checks and cleaning keep your wall in good shape. If you face complex problems, talk to experts for advice. Careful work and routine care help your building last longer.

FAQ

What is the best way to clean ACP curtain walls?

You should use mild soap and water. Rinse the panels with clean water. Use a soft cloth or sponge. Avoid harsh chemicals or rough brushes. These can damage the surface.

How often should you inspect ACP curtain walls?

You should inspect your ACP curtain wall every six months. Look for loose panels, damaged sealant, or signs of water leaks. Regular checks help you find problems early.

Can you install ACP panels in rainy weather?

You should avoid installing ACP panels during rain. Wet surfaces can stop sealants from sticking. Wait for dry weather to get the best results and a strong bond.

What should you do if you find a loose panel?

You need to tighten or replace the fasteners right away. Check the panel for damage. If you see cracks or dents, replace the panel. Quick repairs keep your wall safe.

Cassette System

Cassette System Alignment Checks

Alignment Checks