05 Sep Understanding ACP in Aluminum for Modern Construction

Table of Contents

Aluminum Composite Panel, or ACP, is important in modern building. ACP has two thin aluminum sheets stuck to a core that is not aluminum. This makes it light and strong. The design helps people install it easily. It also lets them use many styles. ACP panels are used to fix old buildings. They are used for energy-saving walls and outside wall covers. People use them for inside walls, special wall designs, fake ceilings, signs, kitchen units, and custom furniture. ACP is popular because it can be used in many ways. It does not rust easily. Knowing about ACP helps builders and owners pick the best material.

Key Takeaways

ACP panels are light. They are strong and simple to put up. This makes them great for many building jobs. The sandwich design uses aluminum sheets and a core. This gives ACP panels strength and helps them stand up to weather. There are different core types and coatings. These give choices for fire safety, saving energy, and style. ACP panels are good for outside walls, inside designs, and signs. They help save time and money. Cleaning them often and taking care of them is important. This helps ACP panels last 20 to 30 years and keeps them looking new.

What Is ACP?

ACP Definition

ACP Definition

ACP means Aluminum Composite Panel. People use ACP panels in lots of building jobs. These panels are popular because they are light and strong. Builders and designers pick ACP panels for walls, ceilings, and signs. ACP panels help make buildings look modern and nice.

Industry rules help explain what ACP panels are. These rules make sure ACP panels are safe and good quality. The table below lists some important rules for ACP panels:

Aspect | Details |

|---|---|

National Standards | China: GB/T 17748-2008 (Aluminum-plastic composite panel for building curtain wall), GB/T 22412-2008 (Ordinary decorative aluminum-plastic composite board) |

American Standards | AAMA, ASTM |

European Standards | EN, ISO, BS, QUALICOAT |

International Standard | SGS (testing and certification body) |

Aluminum Material | Use of 3333 or 5333 series aluminum alloys with corrosion resistance and mechanical properties meeting GB/T 3880.2 |

Coating Material | Fluorocarbon resin or equivalent materials with excellent weatherability |

Testing Requirements | Includes appearance quality, thickness, coating hardness, gloss, flexibility, adhesion, impact resistance, chemical resistance, bending strength, peel strength |

These rules help builders trust ACP panels. They also help makers use the right aluminum and coatings. ACP panels must pass tests for strength, weather, and how they look.

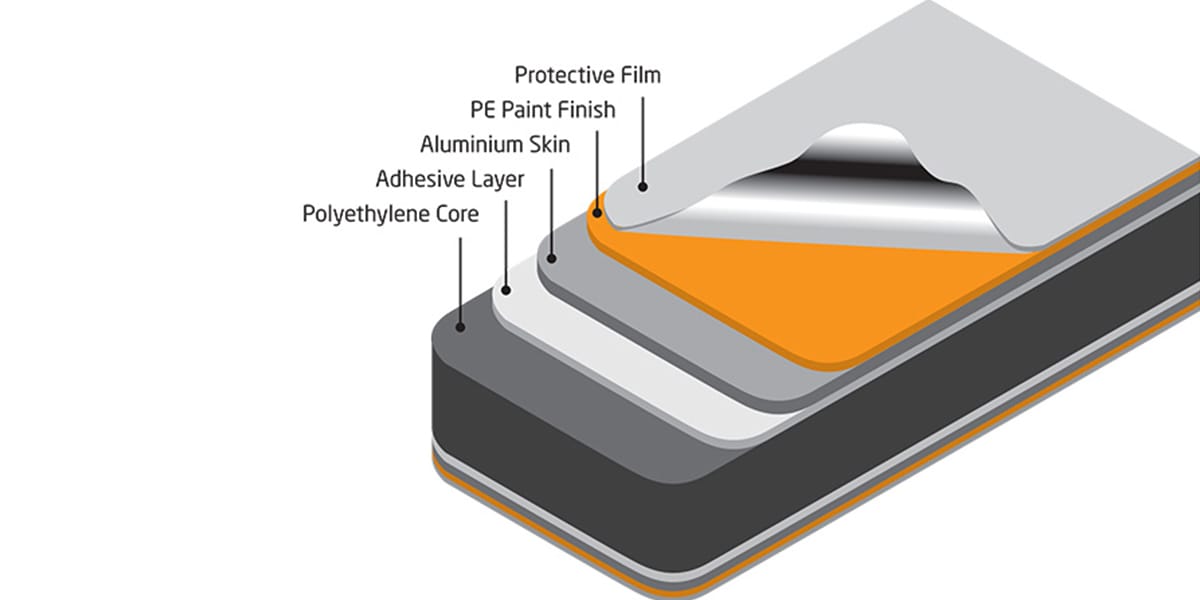

Aluminium Composite Panel Structure

Aluminium composite panels have a special build. Each panel has two thin aluminium sheets. These sheets stick to a core that is not metal. Most cores use polyethylene. This design makes ACP panels strong and light.

The aluminium sheets make the panel strong and protect it from weather. The core keeps the panel stiff and light. ACP panels often have a special coating. This coating uses things like PVDF or polyester. The coating helps the panel last longer and look smooth.

Aluminium composite panels use a sandwich build. The two aluminium layers cover the core. This build gives the panel high impact strength and keeps it stable. ACP panels stay flat and do not bend much. Builders like ACP panels because they are easy to cut and shape.

People pick aluminium composite panels for many reasons. The panels do not rust and keep their color for a long time. The smooth surface is easy to clean. ACP panels work well for inside and outside walls. They also fit many styles.

Tip: ACP panels are strong, stylish, and easy to put in. Builders can use them for many kinds of projects.

ACP Composition

Aluminium Sheets

Aluminium composite panels have two thin aluminium sheets outside. These sheets make the panel strong and protect the inside core. The aluminium layers help the panel stay flat and not bend. Most panels are between 3mm and 6mm thick. Thicker panels are stronger and last longer. Builders often use 4mm panels for outside walls. These panels stay flat and can handle wind. The aluminium skin is usually 0.1mm to 0.4mm thick. Thinner skins work well inside buildings. Thicker skins are better for outside because they protect more.

The aluminium sheets do not rust. They keep their color and shine for many years. These sheets make the panel easy to cut and shape. Aluminium composite panels fit many building styles. The smooth surface is easy to clean and keeps the panel looking new.

Core Materials

The core sits between the two aluminium sheets. This core is not made of metal. Most panels use a core made from polyethylene. Some panels have a fire-resistant core. These fireproof cores mix polyethylene with special flame retardants. Flame retardants help the panel meet fire safety rules. Fire-resistant cores reach a B1 fire rating. This means they slow down fire and make buildings safer.

Other core materials include foam types like PET, PU, PVC, and XPS. Foam cores give extra benefits. They help with keeping heat in and blocking sound. The foam core keeps the panel light but strong. It helps the panel not bend or break. Panels with foam cores work well inside and outside. The core makes the panel easy to carry and install. It helps the panel last longer and keep its shape.

Note: Fire-resistant ACP panels are important for places where safety matters most. These panels protect people and property by slowing down fire.

Coatings and Finishes

Coatings on aluminium composite panels help them last longer and look good. Factories put coatings like PVDF and polyester on the aluminium sheets. These coatings protect the panel from sun, rain, and scratches. PVDF coatings give strong UV protection and keep colors bright for years. Polyester coatings also protect against fading and weather. They cost less than PVDF coatings.

Different coatings give different benefits. The table below shows how each coating helps with strength and looks:

Coating Type | Durability Benefits | Appearance Benefits |

|---|---|---|

PVDF Coating | Strong weather resistance, UV protection, color stays bright | Many colors, long-lasting finish |

Polyester Coating | Good protection from weather and fading | Lower cost, good color choices |

HPL Coating | Extra tough, adds years to panel life | Many colors, patterns, and textures |

Anodized Coating | Hard, resists corrosion, good for tough places | Shiny metallic look, great for coastal areas |

Wood Grain Coating | Adds warmth and style, looks like real wood | Classic and elegant appearance |

Coatings do more than just make panels look nice. They make cleaning easy and lower the need for repairs. The finish comes ready from the factory. Builders do not need to paint or prime the panels. Coatings help the panel resist fire and protect the environment. They last longer and need fewer replacements.

Tip: Picking the right coating helps aluminium composite panels stay strong and beautiful, even in tough weather.

Types of Aluminium Composite Panels

Aluminium composite panels come in different types for building needs. The main types are PE core panels, fire-resistant panels, and honeycomb panels. Each type has special features for certain projects.

come in different types for building needs. The main types are PE core panels, fire-resistant panels, and honeycomb panels. Each type has special features for certain projects.

PE Core Panels

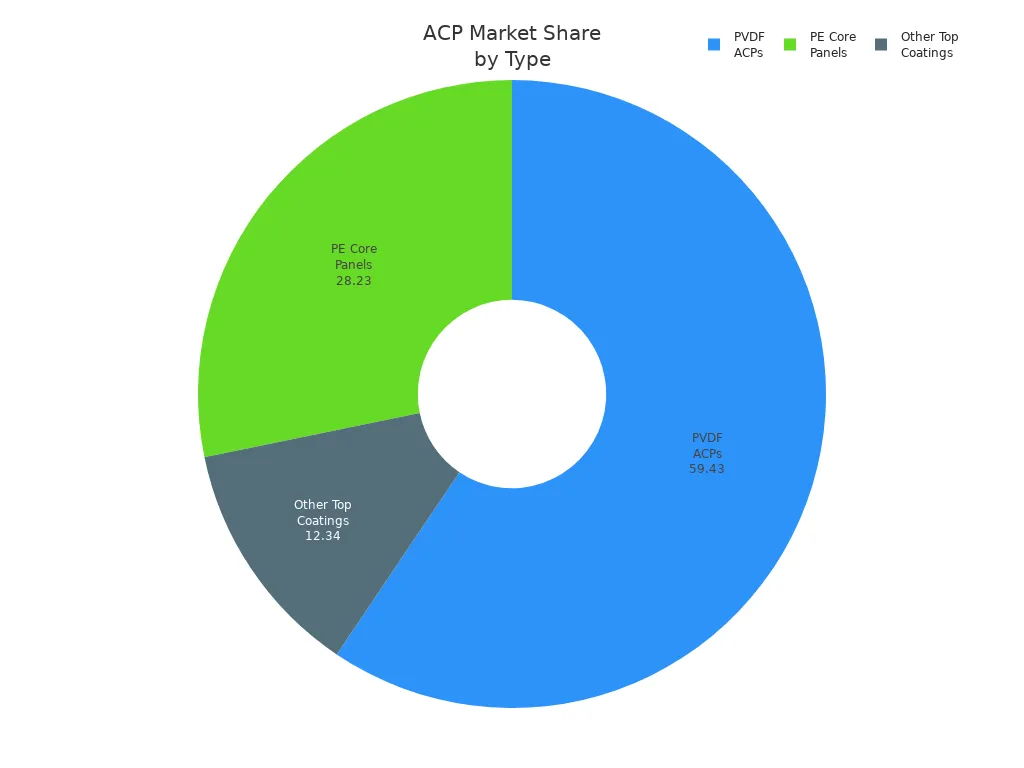

PE core panels have a polyethylene core between two aluminum sheets. These panels cost less than other types. Builders use them for inside walls, ceilings, and signs. PE core panels are popular around the world. The table below shows how they compare to other types:

ACP Type | Market Share (%) | Market Size (Million USD) |

|---|---|---|

PE Core Panels | 28.23% | 2104.58 |

PVDF ACPs | 59.43% | 4430.85 |

Other Top Coatings | 12.34% | 919.70 |

In 2024, the market for PE coated aluminium composite panels was $1.5 billion. Experts think it will grow to $2.8 billion by 2033. Asia Pacific uses the most, with about 45% of sales in 2023. Builders like PE core panels because they are strong, cheap, and easy to use.

Fire-Resistant Panels

Fire-resistant panels have a special core that slows down fire. These panels use mineral-filled or changed polyethylene cores. In China, fire-resistant aluminium composite panels must follow strict rules like GB8624. They usually get B1 or A2 grades for fire safety. These grades follow the ‘Code for Fire Protection of Building Design.’ Fire-resistant panels help keep people and buildings safe. They are good for schools, hospitals, and tall buildings. These panels stop fire from spreading fast.

Note: Fire-resistant panels help buildings follow safety rules and protect people.

Honeycomb Panels

Honeycomb panels have a core shaped like a honeycomb between two aluminum sheets. This shape gives them special benefits:

Honeycomb panels are lighter than other aluminium composite panels, so they are easy to move and put in place.

The honeycomb core makes the panels strong and stiff, so they can hold heavy things.

Air pockets in the core help keep heat and sound out, making buildings quieter and saving energy.

These panels can take hits and soak up energy, which helps protect buildings.

Builders can cut and shape honeycomb panels for special looks and finishes.

Honeycomb panels are good for the environment because they use less material and can be recycled.

Many people use honeycomb panels in planes and trains, showing they are strong and safe.

Honeycomb panels cost more at first, but they save money later because they lower energy bills and need less fixing.

ACP Benefits

Lightweight and Flexible

ACP panels are light, so they are easy to move. They weigh about half as much as solid aluminum. Workers can lift them without much effort. This helps lower shipping costs and saves time. Builders do not need many workers or big machines. The panels can be cut with normal tools. They fit many building shapes. Their flexibility lets architects make curved or special walls. This shows how useful acp is in new buildings.

Tip: Light acp panels help finish jobs faster and save money.

Key advantages of lightweight ACP panels:

Easier to move and carry

Lower costs for work and setup

Fast to shape with simple tools

Durability and Weather Resistance

ACP panels are strong and last a long time. They can last 20 to 30 years or more. Special coatings like PVDF protect the surface from sun and rain. The panels keep their color and shine in bad weather. Good setup and cleaning help acp panels last longer. Builders use acp for outside walls because it does not rust or fade. The panels also resist damage from acid or alkali. Their strength means fewer fixes and less need to replace them.

Feature | Benefit |

|---|---|

PVDF Coating | UV protection, lasts long |

FEVE Coating | Shiny, keeps color |

Aluminum Layers | Stops rust |

Aesthetic Options

ACP panels give many choices for colors and looks. The smooth surface can be painted or printed on. Builders can pick shiny, flat, or bright finishes. Custom designs and textures are easy to make. This helps acp panels fit any style or brand. These choices make buildings look special and get noticed. The many finishes also help acp panels stay nice in tough weather. Architects use acp for both new and old styles. This shows it is a good and smart choice.

Note: ACP panels mix style and strength, so they are great for creative and useful building projects.

ACP Applications

Exterior Cladding

Builders use acp panels to cover outside walls. This is called exterior cladding. The panels protect buildings from rain and wind. They also block sunlight. ACP panels help keep buildings warm or cool. The panels make buildings look smooth and modern. Architects like acp because it is light and simple to put up. The panels do not rust or fade. This keeps the outside bright for many years. Many tall buildings, schools, and hospitals use acp panels outside. The panels come in many colors and styles. Designers can pick what fits best.

Using acp panels outside helps buildings last longer and look new.

Interior Uses

People use acp panels inside homes and offices. These panels work for walls, ceilings, furniture, and decorations. The table below shows how people use them and why:

Interior Application | Description | Key Benefits | Typical Use Cases |

|---|---|---|---|

Partitions | Divides rooms in homes and offices | Strong, light, saves money | Home offices, work spaces |

False Ceilings | Covers wires and pipes above | Stops moisture, slows fire | Kitchens, bathrooms, stores |

Furniture | Used in cabinets and closets | Looks nice, strong, resists water | Living rooms, bedrooms, shops |

Interior Cladding | Covers walls for decoration | Strong, many finishes | Stores, salons, hotels |

Signage | Indoor signs and nameplates | Looks good, lasts long | Business signs, house names |

ACP panels make rooms look new and stylish. The panels do not soak up water or stains. This makes cleaning easy. Furniture made with acp stays strong and looks good for years. Ceilings with acp hide wires and lights. This makes rooms safer and better looking.

Signage

Businesses use acp panels for signs because they last long. ACP panels do not get damaged by weather or sun. Signs made with acp stay bright and do not break. The panels are light, so putting them up is cheap. The table below shows how acp compares to other sign materials:

Material | Durability | Maintenance & Cost | Additional Notes |

|---|---|---|---|

Aluminum Composite Panels (ACP) | Very strong; does not fade or crack | Needs little care; saves money | Light, easy to put up |

Acrylic | Not as strong outside; needs cleaning often | Costs more to keep up | Sun can damage it |

PVC | Not very strong; few design choices | Cheap but not green | May need new signs soon |

Wood | Can bend or rot | Costs a lot to care for | Heavy, hard to install |

ACP panels are better than other sign materials. They last longer and need less work. Businesses pick acp for signs inside and outside. This saves money and keeps signs looking new.

ACP panels are used for outside walls, inside rooms, and signs. These uses show why acp panels are a top choice in building today.

Selecting ACP Panels

Factors to Consider

Picking the right aluminium composite panel takes careful thought. Builders and owners check many things before they choose.

Building Codes and Regulations: Every project must follow local safety rules. These rules keep people and buildings safe.

Material Quality: Good aluminium and certified cores help panels last longer. They also protect against bad weather.

Panel Thickness: Thick panels like 4mm or more are best for outside walls. Thin panels work well inside buildings.

Surface Coating: PVDF coatings protect from the sun and keep colors bright. Good coatings help panels look new for a long time.

Fire Resistance: Panels with mineral-filled cores slow fire and meet safety rules.

Manufacturer Reputation: Trusted makers give good aluminium composite panels. They help avoid problems with weak materials.

Professional Installation: Skilled workers put panels in the right way. Good installation keeps buildings safe and strong.

Long-Term Maintenance Plan: Cleaning and checking panels often helps them last longer.

Environmental Considerations: Using safe sources helps save energy and protect nature.

Technological Advancements: New features make panels safer and better at keeping heat in.

Tip: Picking aluminium composite panels carefully helps buildings stay safe, look nice, and last a long time.

Comparing ACP to Solid Aluminium

Builders compare acp panels and solid aluminium panels for big jobs. Both have good points, but their costs and features are not the same.

Aluminium composite panels cost less than solid aluminium panels. They are light, so they do not make buildings heavy. This makes putting them up easier. Solid aluminium panels are stronger but cost more because they are heavy. The price of acp panels changes with quality and fire safety. Good acp panels cost more but are still cheaper than solid aluminium panels.

Aspect | Aluminum Composite Panels (ACP) | Solid Aluminum Panels |

|---|---|---|

Cost | Cheaper for big projects | Costs more, makes building expensive |

Weight | Light, easy to put up | Heavy, makes buildings heavier |

Durability | Depends on quality; good panels last longer | Very strong and lasts longer |

Cost Variability | Changes with quality and safety | Always costs more, does not change much |

Builders pick acp panels for projects that need to save money. The light weight of aluminium composite panels saves time and money. Solid aluminium panels are best for jobs that need extra strength. Each type works for different needs. Knowing these facts helps builders choose the right material.

ACP Maintenance

Cleaning Tips

Cleaning Tips

Cleaning ACP panels often helps them look new and last longer. In cities, dust and pollution can cover panels fast. Clean the panels every three to six months. If the area is busy or dirty, clean every three months. Here are some easy cleaning steps:

Wash the panel with clean water to get rid of dirt.

Mix a gentle soap with warm water.

Use a soft cloth or sponge to wipe the panels gently.

Do not use strong chemicals, bleach, ammonia, rough pads, or metal tools.

Wash the panels again to remove any soap left.

Dry the panels with a soft cloth so no water spots stay.

Never use strong water jets near the edges or seams.

Clean panels when the weather is not too hot or cold. Check the panels two times a year, after winter and summer. Look for damage or loose parts. Fix scratches with paint right away. Change cracked caulking to keep water out.

Tip: Clean ACP panels after winter to get rid of salt. In summer, check if the color faded.

Preventing Damage

Many things can hurt ACP panels, especially outside buildings. Knowing these problems helps you stop expensive fixes.

Sunlight can break sealants, causing dirt and water marks.

Dirt can scratch panels if cleaning does not happen often.

Cleaning the wrong way, like blasting with water, makes more dirt stick.

Panels can get damaged before they are put up if stacked or packed wrong.

The factory coating is thin and cannot be fixed by sanding or painting.

Taking care of panels saves money over time. The table below shows how much it costs to care for different wall materials:

Cladding Material | Maintenance Cost Over Time | Extra Notes on Care and Value |

|---|---|---|

Aluminum Composite Panels | Low | |

Solid Aluminum | Low to Moderate | Lasts long, needs some insulation |

Steel | High | Needs lots of care to stop rust |

Wood | Moderate to High | Needs painting and sealing often |

EIFS | Moderate to High | Needs checks and repairs often |

Fiber Cement | Moderate to High | Needs lots of care, does not save much energy |

Note: ACP panels need less care than most other wall materials. This makes them a smart choice for saving money in the long run.

Aluminum composite panels give lots of good things for new buildings. Builders like that they can be recycled. Recycling them saves energy and helps keep heat in. These panels help buildings use less energy and get green awards. Picking the right panels and taking care of them makes them last a long time. They stay strong and look nice for many years. Builders need to put them in the right way and follow building rules. ACP panels work well for outside and inside jobs because they are flexible.

Picking ACP panels helps make buildings that are green, strong, and look great.

FAQ

What is the lifespan of ACP panels?

Most ACP panels last 20 to 30 years. Good coatings and regular cleaning help them stay strong and bright. Builders often choose ACP for projects that need long-lasting materials.

Are ACP panels safe for fire protection?

Fire-resistant ACP panels use special cores with minerals. These panels slow down fire and meet safety rules. Many schools and hospitals use fire-rated ACP for extra safety.

Can ACP panels be recycled?

Yes, ACP panels can be recycled. Factories can separate the aluminum from the core. Recycling helps save energy and protects the environment.

How do you repair scratches on ACP panels?

Small scratches can be fixed with touch-up paint. For deep damage, workers may replace the panel. Regular checks help spot problems early.

ACP Definition

ACP Definition Cleaning Tips

Cleaning Tips