26 Aug ACP Panels Make High-Rise Living Safer For All

Table of Contents

Fire-rated ACP panels help keep people safe in tall buildings. When put in the right way, they protect people from fire. These panels are important for following building rules. They help keep everyone safe from fire. Not every ACP panel keeps people safe in the same way. Only fire-retardant panels meet tough safety rules. Building owners can trust these panels for more safety. They make the building safer for everyone who lives there.

Key Takeaways

Fire-rated ACP panels with mineral cores slow down fire. They protect people in tall buildings better than plastic-core panels. These panels are light, strong, and resist bad weather. They help save energy by keeping buildings warm or cool. Using certified fire-rated panels is important. Trained workers should install them the right way for safety and strength. Regular checks and care keep ACP panels in good shape. This helps stop fire risks and damage. Following building codes and safety rules is important. Using fire-rated panels saves lives and keeps buildings safe from fire.

ACP Panels Overview

What Are ACP Panels

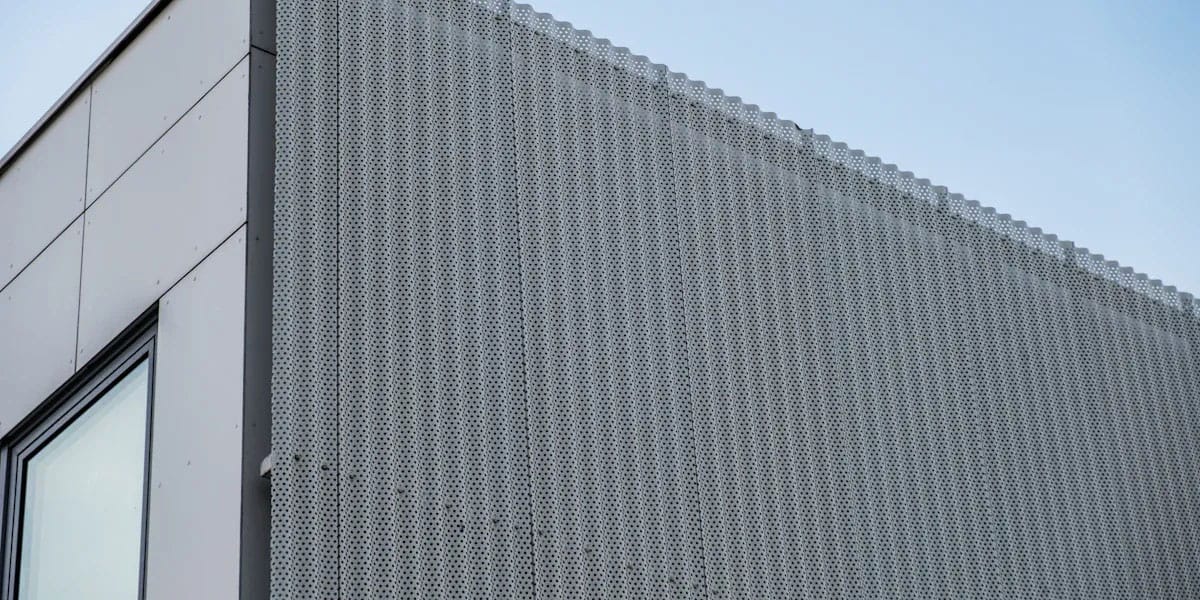

ACP panels are used in many buildings today. They can be put on the outside or inside of buildings. Each panel has three layers. There are two thin aluminum sheets. These sheets cover a middle core. The aluminum is coated to stop rust and scratches. The core can be made from different things. Some cores use PE plastic. Others use fire-rated minerals. The core type changes how safe the panel is in a fire.

Making these panels takes many steps:

The aluminum sheets get cleaned.

A special layer is added to stop rust and help paint stick.

The core is made from plastic or minerals.

Glue films are put on both sides of the core.

The aluminum gets a strong finish like PVDF.

All the layers are pressed together with heat.

Note: Panels with fire-rated mineral cores, like A2 or A1, are safer in fires than panels with PE cores.

These panels are light but strong. They feel smooth to the touch. People use them for building fronts, walls, and signs. The surface can have many colors and textures. This helps architects make cool designs.

How ACP Panels Work

ACP panels protect buildings and make them look nice. Their layers give them many good features:

Details | |

|---|---|

Aesthetic Flexibility | Many colors and finishes let people design modern buildings. |

Weather and Durability | Panels do not rust, fade, or break easily. Fire-rated cores follow safety rules. |

Energy Efficiency | The panels help keep buildings warm or cool. This saves energy. |

Installation and Upkeep | The panels are light, so they are easy to put up. They do not need much care. |

Additional Protection | They block noise, stop bugs and rot, and help keep people safe and comfy. |

New changes include better fire-retardant cores and smart panel tech. Factories now make panels in ways that are better for the planet. These updates make ACP panels safer and more useful for tall buildings.

ACP Panels Safety Benefits

Fire Resistance

Fire Resistance

Fire safety is the most important benefit of ACP panels. Fire-rated panels have mineral cores that do not catch fire easily. These cores slow down flames and keep fires from spreading fast. The panels get top fire safety ratings like FR A1. This rating means the panels do not burn or make smoke. They also do not release harmful gases. Builders use these panels in tall buildings, airports, and hospitals.

Fire-retardant ACP panels have special cores and thicker aluminum sheets. These features help stop heat and flames from moving through the panel.

Panels with B1 and A2 ratings are hard to set on fire. They stop burning quickly when the fire is gone.

Non-fire-rated panels have plastic cores. These can catch fire fast and drip burning stuff. This makes fires spread faster.

Tip: Always look for EN 13501-1 or similar fire safety labels when picking panels for tall buildings.

Weather Protection

ACP panels keep buildings safe from bad weather. Their design blocks rain, wind, and hail. The panels last a long time, often 30 to 60 years. A special coating on the aluminum stops rust and water damage. Extra coatings protect the panels from sun and heat.

Feature | Description |

|---|---|

Lifespan | 30 to 60+ years, showing strong durability |

Corrosion Resistance | Special coatings block rain, snow, and wet air |

Weather Resistance | Panels stand up to strong wind, heavy rain, and hot sun |

Waterproofing | Keeps water out of the building |

Maintenance | Needs only simple cleaning once a year |

Good installation with waterproof barriers and strong mounts is important. High-quality panels with fire-resistant cores protect better and last longer than cheap ones.

Structural Strength

ACP panels make tall buildings stronger without adding much weight. Each panel has two aluminum sheets stuck to a core. This makes the panel light but strong. The design puts less stress on the building’s frame. Workers can move and install these panels more easily than heavy stone or concrete.

ACP panels are light, so they do not weigh down tall buildings.

The panels stand up to weather, hits, and sunlight. They keep their shape and look good for years.

Builders can use these panels in many shapes and colors. This lets them make cool designs without losing strength.

In ventilated facades, the panels help with insulation and block noise.

Fire-retardant cores follow strict safety rules and add more protection.

Note: ACP panels are great for fixing old buildings. They can go over old walls without big changes.

Insulation

ACP panels help keep buildings warm or cool inside. The layers in each panel block heat, cold, and noise. This means people use less energy for heating and cooling. People inside feel more comfortable, and owners save money on energy bills.

The core material slows down heat, keeping rooms at a steady temperature.

With ventilated facades, ACP panels make insulation and sound blocking even better.

Good insulation means less noise from outside and a quieter place to live.

These benefits make ACP panels a smart choice for tall buildings where safety, comfort, and saving energy are important.

Safety Concerns

Non-Fire-Rated Panels

Non-Fire-Rated Panels

Some ACP panels do not protect well against fire. Non-fire-rated panels have a core made from plastic like polyethylene. This kind of plastic catches fire very fast and burns easily. When it burns, it can drip hot, burning pieces. These pieces can start fires in other parts of the building. The smoke from burning plastic is very dangerous. It has gases that can hurt people’s health. These gases make it hard for people to get out. Firefighters also have a harder time doing their jobs.

Fire-rated panels have cores with minerals or magnesium hydroxide. These cores do not burn easily and slow down fire.

Non-fire-rated panels with plastic cores catch fire fast and keep burning after the flame is gone.

Fire-rated panels can last up to two hours in a fire. This gives people more time to leave the building.

Non-fire-rated panels do not have these safety features. They are not safe for tall buildings.

⚠️ Using non-fire-rated ACP panels in tall buildings is very risky. Only fire-rated panels should be used to follow safety rules.

Regulatory Standards

Many countries have strong rules about which panels builders can use. After some big fires, governments banned non-fire-rated ACP panels with plastic cores in tall buildings. For example, England changed its rules in 2018. Now, new buildings or big repairs over 18 meters tall cannot use panels that burn. This rule came after a survey found many buildings with unsafe panels. Other countries in Europe, like France, Germany, Spain, and Sweden, also have bans. Dubai and Australia made similar rules after fires in tall buildings.

The United States uses the International Building Code (IBC) 2021. This code says ACP panels must pass fire tests like NFPA 285 and ASTM E84. The National Fire Protection Association (NFPA) makes strict fire rules. Panels must have fire-retardant cores to pass these rules. The American Architectural Manufacturers Association (AAMA) 2605 standard checks if the panel’s coating can resist sun and chemicals. These rules help keep people safe in tall buildings.

Installation Issues

Even the best fire-rated panels will not work if installed wrong. There are two main ways to put up panels: direct stick and cassette.

Installation Method | Description | Fire Safety Impact |

|---|---|---|

Direct Stick | Workers use tape to stick panels to metal channels. Joints are closed with Styrofoam strips. | Panel edges can touch flames. Styrofoam can help fire spread. Tape might fail, so panels can fall and fire can move faster. |

Cassette | Workers bend the panel edges and use brackets and screws. Joints are closed with mastic. | This way is stronger, but empty spaces behind panels can let fire move. Fire stopping is needed to block fire from spreading. |

If workers make mistakes, like not sealing joints or missing fire stops, fire can move fast through the building. These mistakes make it harder for people to escape. Firefighters also have more trouble stopping the fire. Fires in tall buildings around the world show that bad installation makes fires worse.

Past Incidents

Some big fires have shown what happens when the wrong panels are used or installed badly. In 2016, a fire in Singapore’s Toh Guan Road killed one person. The building had ACP panels that did not pass fire tests. Checks found over 50 buildings in Singapore with unsafe panels, even though they had certificates. The Grenfell Tower fire in London in 2017 killed at least 30 people. The fire spread fast because workers put flammable ACP panels on the building during repairs. After these fires, many countries changed their rules and told people to remove unsafe panels.

Incident Location | Year/Date | Description | Consequences/Fatalities | Cause/Issue Identified |

|---|---|---|---|---|

Grenfell Tower, London | 2017 | Fire spread fast because less fire-resistant ACP panels were used during repairs | At least 30 deaths | Use of unsafe, flammable ACP panels |

Toh Guan Road, Singapore | 2016 | Deadly fire caused by ACP panels that did not pass fire tests; over 50 buildings had unsafe panels | 1 death | Use of panels that failed fire safety tests |

Jalan Bukit Bintang, Malaysia | Early 1990s | Fire in a low building with poor quality ACP panels | Not specified | Use of poor quality ACP panels |

Note: These fires show why we need strong rules, good installation, and regular checks. Only fire-rated ACP panels should be used in tall buildings to keep everyone safe.

ACP Panels vs. Other Cladding

Fire Safety Comparison

Fire safety is very important for people who own or design buildings. Different cladding types protect against fire in different ways. The table below shows how some common cladding types compare:

Fire Classification | Description | Examples | Fire Safety Performance |

|---|---|---|---|

A1 | Non-combustible, no flame spread, no smoke or flaming droplets | Stone, concrete, metal, certain glass | Highest fire safety, preferred for high-rise and critical buildings |

A2 | Limited combustibility, minimal smoke and flaming droplets | Some metal composite panels, treated wood, high-density fiberboards | Good fire resistance, better than combustible materials but less than A1 |

B | Moderate fire performance, higher ignition and flame spread risk | Untreated wood, expanded polystyrene foam, low-density fiberboards | Suitable for low-rise or non-critical areas, less fire safe than A1/A2 |

Fire-rated ACP panels have mineral-filled cores. These cores slow down fire and make less smoke. These panels must pass hard tests like NFPA 285 and EN 13501-1. They are safer than regular panels with plastic cores. But they are not as safe as stone or metal, which do not burn at all. Smoke and bad gases are also a big problem during fires. The chart below shows how safe A1, A2, and B cladding types are in a fire.

Feature | ACM (Fire-rated) | |

|---|---|---|

Core Material | Polyethylene (flammable) | Mineral-filled (fire-resistant) |

Fire Resistance | Lower, more flammable | Higher, meets strict fire codes |

Typical Use | Interiors, low-rise buildings | High-rises, hospitals, schools (high fire safety needs) |

Tip: Always look for fire safety labels before picking cladding for tall buildings.

Performance Differences

Cladding types are different in weight, strength, how easy they are to put up, and cost. The table below shows these differences:

Performance Aspect | Alternative Cladding Systems | |

|---|---|---|

Weight | Lightweight, reduces structural load | Heavier (e.g., stone, fiber cement) requiring stronger support |

Fire Resistance | Available in fire-resistant variants | Fiber cement superior fire resistance; wood less fire resistant |

Durability | Good weather resistance; less durable than solid aluminum under extreme conditions | Solid aluminum more durable; wood prone to warping and pests; stone very durable |

Installation Ease | Easy to handle and install due to light weight and flexibility | Stone and wood require skilled labor and longer installation times |

Cost | More cost-effective than solid aluminum and stone | Stone and wood generally higher cost due to material and labor |

Maintenance | Low maintenance, resistant to weather and pests | Wood requires high maintenance; stone low maintenance but costly |

Aesthetic Flexibility | High; wide range of colors, textures, and shapes including woodgrain and metallic finishes | Wood and stone limited in customization and finishes |

Environmental Impact | Recyclable, energy efficient, but higher carbon footprint in production than fiber cement | Fiber cement lower carbon footprint; wood sustainability varies |

Fire-rated panels cost more because they use better materials and need skilled workers. They last longer, stand up to weather, and need less care. Cheaper panels may save money at first, but can cost more later and are less safe. For tall buildings, fire-rated panels meet safety rules and help lower insurance costs.

Note: Picking the right cladding keeps people safe, saves money, and protects building value.

Best Practices

Certified Products

Certified Products

Choosing certified fire-rated panels is very important for tall buildings. These panels must pass hard fire tests like EN 13501-1, ASTM E84, or GB 8624. Builders should check for certificates from trusted groups like UL, CE, or SGS. Real fire-retardant panels have at least 70% non-combustible core. These certificates show the panel can stop fire, smoke, and burning drops. Good installation also helps keep the panels safe in a fire.

EN 13501-1, ASTM E84, and GB 8624 certificates

NFPA 285 or BS 8414 fire tests for tall buildings

Third-party certificates from UL, CE, SGS

At least 70% non-combustible core inside

Benefit Category | Description |

|---|---|

Certified panels pass tough fire tests and follow building codes for hospitals and tall buildings. | |

Lightweight Construction | Panels are lighter than stone or solid aluminum, so they are easier and faster to put up. |

Maintenance Efficiency | Smooth panels do not get dirty easily; cleaning is easy and coatings last many years. |

Design Flexibility | Panels can be cut and shaped for cool designs. |

Economic Advantages | Lower costs for putting up and taking care of panels over time. |

Sustainability | Panels can be recycled and save energy, which helps the environment. |

Professional Installation

Trained workers must follow the maker’s rules when putting up panels. They use things like wet sealant joints, hanging systems, and dry gasket joints. Installers make sure panels are fixed to strong walls. They use safe materials and follow building codes. Good installation keeps panels safe in a fire and makes them last longer.

Tip: Always use trained workers who know fire safety rules and the right ways to install panels.

Maintenance

Taking care of panels keeps them safe and looking good. Clean panels with soft soap and a cloth. Do not use strong cleaners or rough tools. Check for cracks, loose panels, or peeling early. Fix problems fast so they do not get worse. Keep panels away from very hot or cold weather to stop warping. Getting help from experts for care and repairs keeps panels safe.

Wash panels with gentle soap and water.

Look for damage and fix it right away.

Do not use harsh cleaners or let panels get too hot or cold.

Have experts check panels often.

Code Compliance

Following building codes is needed for safety. Builders must use certified fire-rated panels and follow local fire rules. Emergency plans should have more than one way out, safe stairwells, and working alarms. Sprinklers and smoke alarms help stop fires and warn people. Fire services check things like fire doors, lights, and extinguishers. Teaching people how to leave safely helps during emergencies.

Stairwells with air pressure to keep out smoke

Smoke alarms and sprinklers that work all the time

Emergency systems with fire-safe wires

Regular fire safety checks

Practice drills and safety lessons for everyone

Note: Good emergency plans and regular checks help keep people and buildings safe in tall buildings.

Fire-rated ACP panels help keep tall buildings safe when experts pick and install them. Keeping the panels in good shape and following new safety rules saves lives and protects buildings.

These panels slow down fires, protect hallways and stairs, and keep the building strong.

Checking and certifying the panels often makes sure they follow fire safety rules and lower dangers.

Building owners should always use certified ACP panels and learn about new safety rules to keep everyone safe.

FAQ

What makes fire-rated ACP panels safer than regular panels?

Fire-rated ACP panels have mineral-filled cores. These cores do not catch fire easily. They slow down flames and stop fire from spreading fast. Regular panels use plastic cores. Plastic burns quickly and helps fire move. Fire-rated panels follow strict safety rules. They help keep people safe in tall buildings.

How can building owners check if their ACP panels are certified?

Owners should look for labels like EN 13501-1 or ASTM E84. UL labels also show the panels are tested. Trusted groups give certificates if panels pass fire tests. Builders can ask for test reports. They can also check with the maker for proof.

Do ACP panels need regular maintenance?

Yes, ACP panels need care to stay safe. Cleaning and checking the panels keeps them looking good. Owners should look for cracks or loose panels. Fixing problems early stops bigger issues. Experts can check if panels meet safety rules.

Can ACP panels be recycled after use?

Most ACP panels can be recycled. The aluminum and mineral cores go to recycling centers. Recycling helps cut down on waste. It also supports green building. Owners should call local recycling services to throw panels away the right way.

Are ACP panels suitable for all climates?

ACP panels work in many types of weather. They stand up to rain, wind, and sun. Special coatings stop rust and fading. In very hot or cold places, owners should pick panels with extra weather protection for best results.

Fire Resistance

Fire Resistance Non-Fire-Rated Panels

Non-Fire-Rated Panels Certified Products

Certified Products