03 Nov What Is The Typical Lifespan Of Aluminum Composite Panels In 2025

Table of Contents

You can expect aluminium composite panel durability to ensure they last between 10 to 30 years by 2025. With proper care, some panels may even last up to 40 years. Understanding how long these panels last allows you to make better choices for your building.

The longevity of these panels influences your repair costs and impacts the safety of your building.

The lifespan of the panels also plays a crucial role in energy savings and the overall appearance of your building. This can affect your property’s value and the comfort of those inside.

Good aluminium composite panel durability means you receive more value as time progresses.

Key Takeaways

Aluminum composite panels can last 10 to 30 years. Good care can help them last up to 40 years.

Checking panels often and fixing problems can stop damage. This helps panels last longer and saves money on fixing them.

Picking strong materials and coatings, like PVDF, makes panels tougher. These protect panels from bad weather and pollution.

Fire-retardant cores make panels safer and last longer. They are very important for buildings where fires can happen.

Always look at warranties from makers. This helps you know what is covered and keeps your investment safe.

Lifespan of Aluminum Composite Panels

Average Lifespan in 2025

Aluminum composite panels can last 10 to 30 years in 2025. If you take good care of them, some might last up to 40 years. This means your building can use acps for a long time. Many buildings get the longest life when they follow good care and installation steps.

New technology makes aluminum composite panels stronger. Here are some new features you will see in 2025:

Nano-coating helps protect panels from scratches and UV rays. It also keeps panels safe from rust. These coatings help panels look nice and last longer.

Eco-friendly materials and coatings help buildings be greener. These upgrades can make panels last longer too.

Fire-resistant cores make panels safer. They also help panels last longer in tough weather.

Aluminum cladding needs less care than other materials. The table below shows how aluminum cladding compares to other choices:

Material | Maintenance Costs | Durability | Upkeep Requirements |

|---|---|---|---|

Aluminum Composite Panels | Lower | Moderate | Regular inspections |

Solid Aluminum Cladding | Minimal | High | Periodic rinsing |

Wood | Higher | Low | Frequent repairs |

Stone | Higher | High | Less frequent repairs |

Aluminum cladding gives you good value and lasts a long time. You will spend less money and time fixing and cleaning it. This makes it a smart pick for many buildings.

Tip: Check your panels often to find small problems early. This easy step can help your panels last 20–30 years or more.

Warranty and Manufacturer Guarantees

When you buy aluminum composite panels, always look at the warranty. Warranties help you feel safe about your choice. They show that the company trusts their product. Most big brands give warranties that match how long panels should last.

Here is a quick look at some warranty times from top brands in 2025:

Manufacturer | Warranty Period |

|---|---|

ALPOLIC | Not specified in the source |

Praso | 20 years |

SOMMANI ALUCORE | 20 years Coating Warranty |

A warranty covers problems with the panel or coating. Some companies give extra warranties for color or finish. Always read the details so you know what is covered.

Panels can last longer than the warranty if you take care of them. Clean your panels, check for damage, and fix problems fast to help them last.

Note: Warranties do not cover damage from bad installation or poor care. Always hire skilled workers and follow care instructions from the company.

Aluminum cladding is still a top choice in 2025. You get a strong product that lasts a long time and comes with a clear warranty. This helps you feel good about your purchase and plan ahead.

Aluminium Composite Panel Durability Factors

Knowing what affects aluminium composite panel durability helps you choose well. You want your aluminum cladding to last a long time. Three big things matter most: material quality and core type, the environment, and how panels are installed.

Knowing what affects aluminium composite panel durability helps you choose well. You want your aluminum cladding to last a long time. Three big things matter most: material quality and core type, the environment, and how panels are installed.

Material Quality & Core Type

Panels last longer if you pick high-quality materials. Good aluminum makes panels stronger and stops rust. The core inside each panel is important too. Flame-retardant cores make panels safer and last longer. Bad cores can make panels weak and easy to bend or burn.

Most strong acp’s use top PE plastic or flame-retardant cores. These choices help panels last and keep buildings safe. If you pick exterior-grade panels, they work better outside.

Here is how core types are different:

FR core composite panels pass many fire rules. They are good for fire-safe buildings.

PE core panels do not protect as well from fire. Both types can melt in high heat, but FR cores give more time and safety.

Picking the right core helps your aluminum cladding last, especially where fires can happen.

Environmental Exposure

Where you put your aluminum cladding changes how long it lasts. Some places are harder on panels than others. Aluminum cladding lasts longer if it can handle weather, pollution, and temperature changes.

Here are some things in the environment that matter:

Cities get hotter because of the Urban Heat Island effect. This extra heat can hurt your panels.

Humidity, UV rays, and pollution make panels wear out faster.

Salt and chemicals near the coast can cause more rust.

The table below shows how these things affect your panels:

Environmental Factor | Effect on ACPs |

|---|---|

UV Radiation | Makes color fade and panels bend |

Humidity | Can cause mold and rust |

Pollution | Makes panels break down faster, mostly near the sea |

Temperature Changes | Can cause rust or fading without good coatings |

Sunlight Exposure | Needs good coatings to stop damage |

Aluminum cladding fights many of these problems. Its smooth surface keeps water out, so mold does not grow. Special coatings help stop rust and fading. With good care, aluminium composite panel durability can last 20–30 years or more, even in tough places.

Installation Quality

How you put up your aluminum cladding is very important. Good installation keeps panels strong and looking nice. Bad installation can make panels fail early and cost more to fix.

Here are ways installation changes aluminium composite panel durability:

Good sealing and barriers keep water out. This stops rust and keeps glue strong.

Panels need space to move when it gets hot or cold. If you leave space and use flexible parts, panels do not bend or crack.

Strong fasteners keep panels safe in strong winds. Loose panels can shake, fall, or break.

Take off films at the right time and handle panels gently to keep them looking good.

Fire safety means following rules, especially with fire-rated panels on tall buildings.

Tip: Always use skilled workers who know how to install aluminum cladding. This helps your panels last as long as possible.

If you pay attention to these things, your aluminum composite panels last longer. You save money on repairs and your building looks good for many years.

Coatings & Lifespan

PVDF and Protective Coatings

PVDF and Protective Coatings

You want your panels to last a long time. The coating you pick really matters. PVDF coatings help protect aluminum composite panels from bad weather, sunlight, and pollution. These coatings make a strong layer that keeps panels looking new for years.

PVDF coatings help panels stand up to all kinds of weather. They keep panels safe from heat, cold, wind, rain, and UV rays.

Nano PVDF panels can clean themselves and do not get dirty easily. This is helpful in busy places.

Metallic PVDF panels look shiny and are good for stores or offices.

Marble or granite PVDF panels are nice for decoration inside or outside.

PVDF coatings give you many good things:

UV Protection: Stops the sun from hurting the panel’s surface.

Chemical Resistance: Keeps out acids, salts, and fumes.

Water & Humidity Protection: Stops rust in wet places.

Abrasion Resistance: Helps stop scratches from wind or cleaning. 5. Color Stability: Makes the color stay bright for over 20 years.

Note: PVDF coatings help outside aluminum composite panels last longer, even in rough places.

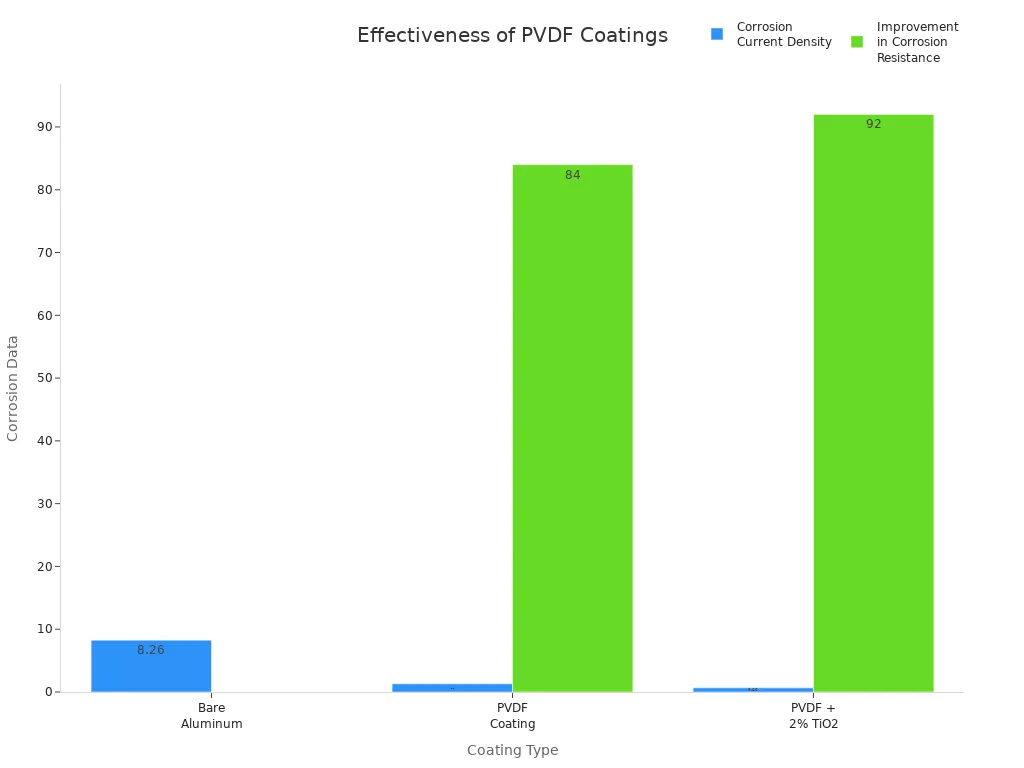

Lab tests show how well PVDF coatings work. The table below shows how different coatings fight rust:

Coating Type | Corrosion Current Density (µA/cm²) | Improvement in Corrosion Resistance (%) |

|---|---|---|

Bare Aluminum | 8.26 | N/A |

PVDF Coating | 1.3 | 84% |

PVDF + 2% TiO2 Coating | 0.66 | 92% |

Outdoor tests, like the Sherwin-Williams “test-fence,” show PVDF coatings keep panels strong and colorful after years in the sun and rain.

Fire-Retardant Cores

You also need to think about fire safety. Fire-retardant and non-combustible cores make panels much safer. These cores slow down fire and stop it from spreading fast. Many building rules now say you must use these safer materials.

Core Type | Fire Safety Benefit |

|---|---|

Non-combustible | Meets strict safety rules, reduces fire spread risk |

Mineral-filled | Limits flames, withstands high heat, no harmful smoke |

Flame-retardant | Stops flames and smoke, keeps people and property safer |

Tough building rules mean you must use safer panels in many places.

You feel safer and your building is better protected when you pick panels with fire-retardant cores. These panels also last longer because they can handle heat and fire.

Maintenance Tips for Aluminum Composite Panels

Cleaning & Care

You can keep your aluminum composite panels looking new with the right cleaning habits. Clean your panels at least twice a year. If you live near the coast or in a city with lots of pollution, you may need to clean them more often. Use a soft cloth and mild detergent. Avoid harsh chemicals or rough scrubbers because they can damage the finish.

Practice | Description |

|---|---|

Use a light detergent for washing both inside and outside panels. Pre-test the detergent first. | |

Prevent dirt, dust, and pollutants buildup. Use a soft cloth, mild detergent, and water. | |

Avoid harsh chemicals | Harsh chemicals and abrasive materials can damage the panel’s finish. Stick to mild detergents. |

Use touch-up paint for repairs | For small scratches or chips, use manufacturer-provided touch-up paint for seamless repairs. |

Tip: Clean your panels right away if you see stains or dirt. This stops long-term damage and keeps your building looking sharp.

Preventing Common Issues

You can prevent most problems with simple steps. Make sure you store and install panels in dry, well-ventilated places. Remove the protective film within 45 days after installation. Check the sealants around the edges to keep water out. Avoid installing panels in areas with heavy smoke, dust, or chemicals.

Regular cleaning and inspections help stop corrosion and delamination.

Salt, strong sunlight, and humidity can cause damage. Clean and check panels more often in these conditions.

Keep up with maintenance to avoid costly repairs later.

Inspections & Repairs

Regular inspections help you spot damage early. Look for cracks, loose panels, or faded spots every year. If you find small scratches or dents, you can fix them with touch-up paint or filler. For bigger repairs, follow these steps:

Sand the damaged area gently.

Apply aluminum filler to dents or scratches.

Sand again for a smooth finish.

Use primer and matching paint.

Buff and polish for shine.

Add a sealant for extra protection.

Note: Address minor damage quickly. This can save you thousands in replacement costs and help your panels last for decades.

You can expect aluminum composite panels to last 10 to 30 years. With good care, some panels might last up to 40 years. The table below shows what affects how long your panels last:

Factor | Description |

|---|---|

Material Composition and Quality | Better materials make panels stronger and last longer. |

Surface Finishes and Coatings | Special coatings like PVDF protect panels from weather and keep colors bright. |

Core Material and Fire Resistance | Fire-retardant cores help panels stay safe and last longer. |

If you choose good installation, strong coatings, and regular cleaning, you save money.

Aluminum panels need less fixing and cleaning.

Insulated panels help keep rooms warm or cool, so you pay less for energy.

You save money over time and your building looks nice for many years.

FAQ

How can you tell if your aluminum composite panels need replacement?

Look for fading, warping, or loose panels. If you see cracks or water stains, your panels may need replacement. Regular checks help you spot these problems early.

Do you need special tools to clean aluminum composite panels?

No, you do not need special tools. Use a soft cloth, mild detergent, and water. Avoid harsh chemicals or rough scrubbers.

Tip: Clean panels twice a year for best results.

Can you paint over aluminum composite panels?

Yes, you can paint them. Use paint made for metal surfaces. Clean and dry the panels first.

Use primer for better results.

Follow the paint manufacturer’s instructions.

What is the difference between PE and FR core panels?

Core Type | Fire Safety | Typical Use |

|---|---|---|

PE | Low | Small buildings |

FR | High | High-rise, public |

FR cores give better fire protection. You should use them for safer buildings.

Does warranty cover color fading?

Most warranties cover color fading for a set number of years. Always check your warranty details.

Note: Warranties do not cover damage from poor cleaning or harsh chemicals.

PVDF and Protective Coatings

PVDF and Protective Coatings