18 Jan Aluminium Composite Panel Types Explained Simply for Everyone

Table of Contents

Aluminium Composite Panel Types are different kinds of panels. These panels have layers of aluminum and other stuff. You can find these panels on buildings, signs, and vehicles. The market for these panels was $6.46 billion in 2024. It might grow to $9.65 billion by 2030. This shows that these panels are getting more popular.

The market could grow by 7.0% every year from 2025 to 2030.

Industry rules say there are three main types:

PE Core: 100% Polyethylene Core

FR/Plus Core: About 30% Polyethylene & 70% Mineral Filler

A2 Core: About 10% Polyethylene & 90% Mineral Filler

You can learn how to tell these types apart. It is important to pick the right type for your project.

Key Takeaways

Aluminum composite panels have three main types: PE Core, FR/Plus Core, and A2 Core. Each type has special features for different projects.

Picking the right panel type is very important for your project. Think about design, weather, cost, and safety rules to choose well.

Aluminum composite panels are light and strong. They come in many colors and finishes. You can use them inside or outside buildings.

Fire resistance is a key feature. Always look at the fire ratings of panels. This is extra important for buildings where safety matters most.

Good installation and care help panels last longer. Always follow the maker’s instructions to avoid mistakes.

What Is Aluminum Composite Material?

Basic Definition

Basic Definition

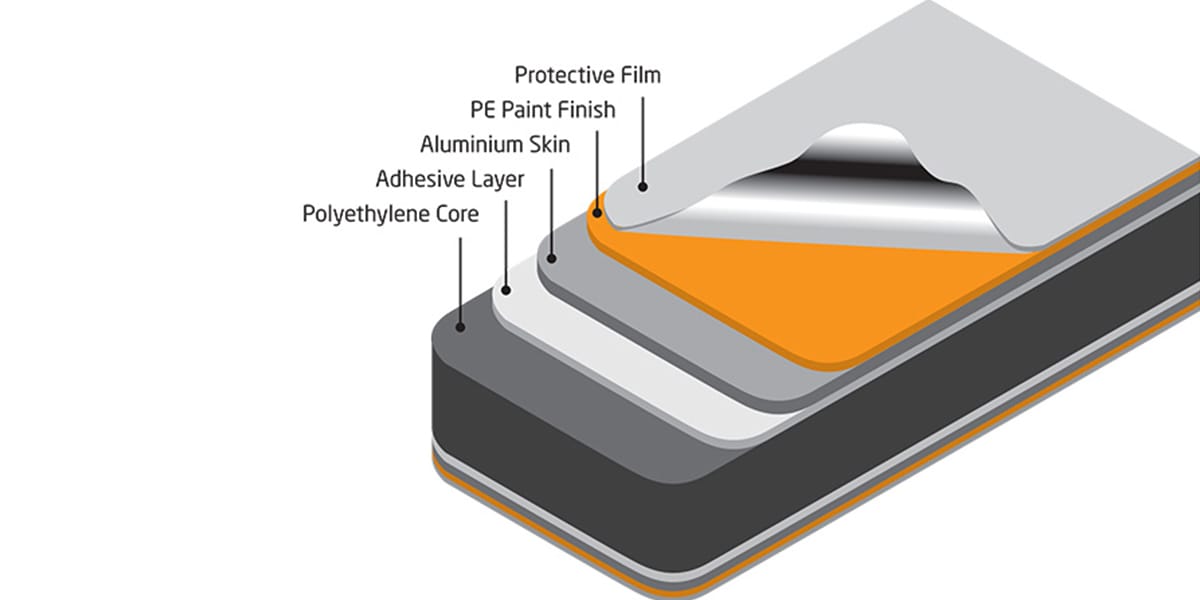

You can spot aluminum composite material on lots of buildings and signs. This material is a flat panel. It has two thin aluminum sheets on the outside. There is a core inside made from something else. People like aluminum composite material because it is strong and light. It is also easy to shape into different forms. You can get it in many colors and finishes. That is why people use it for indoor and outdoor projects.

Tip: If you want a panel that looks nice and lasts long, aluminum composite material is a good choice.

Structure and Components

Aluminum composite material has a simple but smart design. It has three main parts you should know:

Top Aluminum Sheet: This layer is on the outside. It usually has a special coating. The coating helps protect it from weather and scratches.

Core Material: The middle part is called the core. It can be made from polyethylene or minerals. The core makes the panel strong and not too heavy.

Bottom Aluminum Sheet: This layer is on the back. It helps support the panel. It also keeps the panel flat and steady.

Here is a quick look at the structure:

Layer | Purpose |

|---|---|

Top Aluminum Sheet | Protection and appearance |

Core Material | Strength and lightness |

Bottom Aluminum Sheet | Support and stability |

You can see why aluminum composite material is helpful. The layers work together to make a panel that is tough and easy to use.

Why Classify Aluminium Composite Panel Types?

Purpose of Classification

You may ask why we sort aluminium composite panels. The reason is easy to understand. Sorting helps you choose the best panel for your job. Each panel type has its own features. Knowing these features helps you make smart choices.

Here are some big reasons to sort these panels:

Diverse Applications: Different panels work for many things, like building fronts, signs, or wall covers.

Safety Considerations: Some panels can stop fires or fight germs. These features help keep people safe and healthy.

Compliance with Standards: You must follow safety and strength rules in building. Sorting panels helps you meet these rules.

Using the right panel type gives you many good things. The table below lists some main uses and benefits:

Purpose/Benefit | Description |

|---|---|

Aesthetic Features | Panels come in many looks and colors. They make buildings look nice. |

Panels are a cheaper choice for walls and building fronts. | |

Eco-Friendliness | Panels help make green buildings and lower heat reflection. |

Maintenance-Free Nature | Panels do not get dirty or stained easily. You spend less time cleaning. |

Ease of Installation | Panels are fast and simple to put up. This saves time on jobs. |

Note: Sorting panels helps your project look good, stay safe, and not cost too much.

Meeting Different Needs

Architects, builders, and users all want different things. Sorting aluminium composite panels helps match the right panel to each need. Some jobs need panels that are light and easy to move. Other jobs need panels that can stop fire or handle bad weather.

The table below shows how panel types fit these needs:

Property/Feature | Description |

|---|---|

Adaptability | You can cut and shape panels for special designs. |

Weight | Panels are lighter than normal aluminum. You can put them up easily. |

Some panels give extra fire safety. | |

Weather Performance | Panels can handle sun, rain, and snow. They last a long time. |

Aesthetic Options | You can pick from many colors and finishes for your design. |

Common Uses | Panels are good for signs, wall covers, and building fronts. |

When you know these differences, you can pick the best panel for your job. You save time, money, and work by choosing the right panel from the start.

Types of Aluminium Composite Panels

There are many ways to sort aluminium composite panel types. You can group them by core material, surface finish, application, fire resistance, and thickness. Each way helps you know which panel is best for your needs.

There are many ways to sort aluminium composite panel types. You can group them by core material, surface finish, application, fire resistance, and thickness. Each way helps you know which panel is best for your needs.

By Core Material

The core material is a main way to sort aluminium composite panel types. The core sits between two aluminum sheets. It gives the panel strength and weight. Here are the most common core materials:

Polyethylene (PE): This is the main core material. It makes panels light and easy to use. You get good protection from rust and a smooth look.

Mineral-Filled Core: Some panels mix minerals with polyethylene. These panels are better at stopping fires and are stiffer.

Fire-Resistant (FR) Core: You see these where safety matters most. They use more minerals and less polyethylene.

Panels with a PE core feel lighter. They work well for signs or indoor walls. Panels with mineral cores are good for places where fire safety is needed.

Tip: Always check the core material before you pick a panel. The core changes how the panel works and where you can use it.

By Surface Finish

Surface finish changes how aluminium composite panel types look and last. You see panels with different coatings and textures. These finishes protect the aluminum from weather, scratches, and fading. They also help you match the panel to your design.

Surface coatings stop rust, sun damage, and water. You get panels that stay bright and clean for years. You can pick glossy, matte, brushed, or wood grain finishes. This lets you choose the look for any project.

Note: A good surface finish keeps your panels looking new and strong, even in tough places.

By Application

You use aluminium composite panel types for many jobs. The job helps you pick which panel works best. Here are some common uses:

Exterior Wall Decoration: You see panels on building fronts and signs. These panels need to be tough and handle weather.

Indoor Wall Coverings: You use thinner panels for offices, shops, or homes. They look clean and are easy to put up.

Building Curtain Walls: You find thicker panels here. They hold heavy loads and keep buildings safe.

Signage: You pick light panels for signs. They are easy to cut and shape.

You match the panel type to the job. This helps you get good results and avoid problems later.

By Fire Resistance

Fire resistance is important for aluminium composite panel types. You want panels that meet safety rules, especially for tall buildings or busy places. Panels get tested using strict methods.

Testing Method | Description |

|---|---|

NFPA 285 | Checks fire safety in a full wall setup. Measures how flames spread up and sideways. |

Flame Spread Requirements | Flames must not go more than 10 feet above a window. Flames must not go more than 5 feet from the window center. |

Panels with more minerals in the core stop fire better. Always look for fire ratings when you pick panels for public or tall buildings.

By Thickness

Thickness changes how aluminium composite panel types work. You find panels in different thicknesses. Thicker panels hold more weight and last longer.

Thickness Options (mm) |

|---|

2 mm, 3 mm, 4 mm, 6 mm |

Thicker panels work for curtain walls and building outsides. Thinner panels are good for indoor walls or signs. Here is a quick guide:

Application Type | Total Thickness Requirement | |

|---|---|---|

Exterior Wall Decoration/Advertising Signs | 0.2mm (per sheet) | ≥ 4mm |

Indoor Aluminum Composite Panels | 0.1mm (per sheet) | ~ 3mm |

Building Curtain Wall Panels | 0.5mm (per sheet) | > 4mm |

Aluminum composite panels are made to handle wind, rain, and even earthquakes. The system lets the panels move with heat and uses rust-proof fasteners. You get panels that pass tests for air, water, and strength.

Other Metal Coatings

Metal coatings can also change how you sort aluminium composite panel types. Some panels use steel, zinc, or titanium on the top layer. For example, a zinc composite panel uses titanium zinc for extra strength and a special look. These coatings help the panel stay flat, steady, and let you make cool shapes for special designs.

Tip: If you want a panel with extra strength or style, look for panels with advanced metal coatings.

Now you know how to sort aluminium composite panel types by core material, surface finish, application, fire resistance, thickness, and metal coatings. This helps you pick the right panel for your project every time.

Comparison of Panel Types

Key Differences Table

Key Differences Table

It is important to know how these panels compare. Each type has good and bad points. The table below shows the main differences.

Feature | Aluminum Composite Panels (ACM) | Solid Aluminum Panels |

|---|---|---|

Weight | Lighter and easier to carry | Heavier and harder to lift |

Durability | Strong but less tough against hits | Very strong, resists damage |

Insulation | Better at keeping heat and sound in | Not as good at insulation |

Installation | Fast and simple to put up | Takes more time and work |

Finishes | Many colors and styles | Fewer design choices |

Fire Resistance | Lower, depends on the core | Does not burn, higher safety |

Cost | Cheaper for big projects | Costs more to ship and install |

Maintenance | Easy to clean and care for | Needs more cleaning and fixing |

Aluminum composite panels are light and easy to use. You can pick from many colors and finishes. These panels help keep buildings warm and quiet. They cost less for big jobs and do not need much cleaning.

Solid aluminum panels are best for strength and fire safety. They last longer and do not break easily. You may pay more and spend more time putting them up. There are fewer design choices, but you get better fire safety.

Tip: Choose aluminum composite panels if you want something light and nice looking. Pick solid aluminum panels if you need strong fire safety and toughness.

Think about what your project needs before you choose. Both panel types are useful in building and design.

Choosing the Right Panel Type

Factors to Consider

You want your project to look good and last long. Picking the right aluminum-plastic composite panel helps you do this. Here are some things you should think about:

Design and Style: Pick a panel that fits your building’s look. Make sure it matches your design plans.

Climate and Environment: Check if the panel can handle your weather. Some panels keep heat in and block rain, sun, or snow.

Budget and Maintenance: Think about how much you want to spend now and later. Some panels are cheaper to clean and fix.

Supplier and Manufacturer: Choose a company you can trust. Good suppliers give you better panels and help if you need it.

Challenges and Limitations: Watch out for problems like panels getting bigger or smaller with heat. Make sure you follow building rules.

Weather is very important when you pick an aluminum-plastic composite panel. You need panels that can handle strong weather and keep heat and sound inside. The panels must also meet safety rules. Strong aluminum panels are good for outside walls because they last in tough weather.

Common Mistakes

Many people make mistakes when they pick or put in aluminum composite panels. You can avoid these problems if you know what to look for:

Common Mistake | Description | Solution |

|---|---|---|

Improper Installation | Fasteners are not put in right or sealing is not enough. The panel may not have room to move with heat. | Follow the maker’s instructions and hire people who know what to do. Check the panels often. |

Water Infiltration | Water gets in through joints and causes rust or mold. | Use sealants that stop water and check the panels often. |

Surface Damage | Panels get scratched or lose color from bad weather. | Use coatings to protect the panels and be careful when putting them in. |

Delamination | The aluminum layers come apart from water or bad glue. | Pick good panels and seal them well when you install them. |

Color Fading | The color fades from too much sun. | Pick panels with coatings that block UV rays and clean them often. |

Fire Safety Concerns | Panels without fire-retardant cores can help fires spread. | Pick panels with fire-retardant cores and make sure they meet safety rules. |

Thermal Movement | Panels get bent from getting bigger or smaller with heat. | Use joints that let the panels move and use flexible sealants. |

You can make a good choice if you check each thing and learn from these mistakes. The right aluminum-plastic composite panel gives your project strength, style, and safety.

You have learned about the main types of aluminum composite panels. Each type works for different jobs. Fire-resistant, UV-resistant, and wooden finish panels are used a lot in building today.

Type of ACP Panel | Features |

|---|---|

Fire-Resistant ACP Panels | Mineral-filled core helps stop fire from spreading. |

UV-Resistant ACP Panels | Special coating keeps the color and finish outside. |

Wooden Finish ACP Panels | Looks like real wood, is light, and easy to put up. |

Knowing about these types helps you pick the right panel for your project. You can save money and plan for the future. Use what you know to choose panels that last long, look nice, and help make green buildings.

FAQ

What is an aluminum plastic composite board?

You see an aluminum plastic composite board as a panel with two aluminum sheets and a plastic core. You use it for signs, walls, and decorations. This board gives you strength and a smooth look.

Can you use these panels for building exterior walls?

Yes, you can use these panels for building exterior walls. They protect your building from rain and sun. You also get many color choices for your design.

Are aluminum composite panels safe for modern construction?

You find aluminum composite panels in modern construction because they are light and strong. Some panels have fire-resistant cores. Always check safety ratings before you choose a panel.

How do you clean and maintain these panels?

You clean these panels with mild soap and water. Use a soft cloth to wipe the surface. Avoid harsh chemicals to keep the finish looking new.

What finishes can you choose for these panels?

You can pick from glossy, matte, brushed, or wood grain finishes. Each finish gives your project a different style. Choose the one that fits your design best.

Basic Definition

Basic Definition Key Differences Table

Key Differences Table