24 Nov A Complete Guide to Aluminium Sandwich Sheet Specifications and Performance

Table of Contents

Imagine you need something strong and light for your project. Aluminium sandwich sheets are good because they have two aluminium layers and a special core. This makes them tough and helps stop rust. They also look nice. The right core keeps heat in and helps stop fires. Building rules say you must use safe materials. You should think about these things when you pick aluminium for walls, roofs, or facades.

Advantage

Description

Aluminum sandwich panels are simple to move and put in place, which helps with building jobs.

Impressive Durability

They last a long time and can handle different weather.

Corrosion Resistance

The aluminum layers do not rust easily, so you do not need to fix them often and they last longer.

Aesthetic Appeal

They come in many colors and styles, so you can use them for lots of building designs.

Key Takeaways

Aluminium sandwich sheets are light and simple to put in. This makes them great for many building jobs. These panels are strong and do not rust easily. They last a long time and need little care. Picking the right core material is important. Flame-retardant cores help stop fires and follow building rules. Aluminium sandwich sheets keep heat in or out very well. This saves energy and keeps rooms comfy. Cleaning and checking the panels often is important. This keeps them working well and helps them last longer.

What Is an Aluminium Sandwich Sheet?

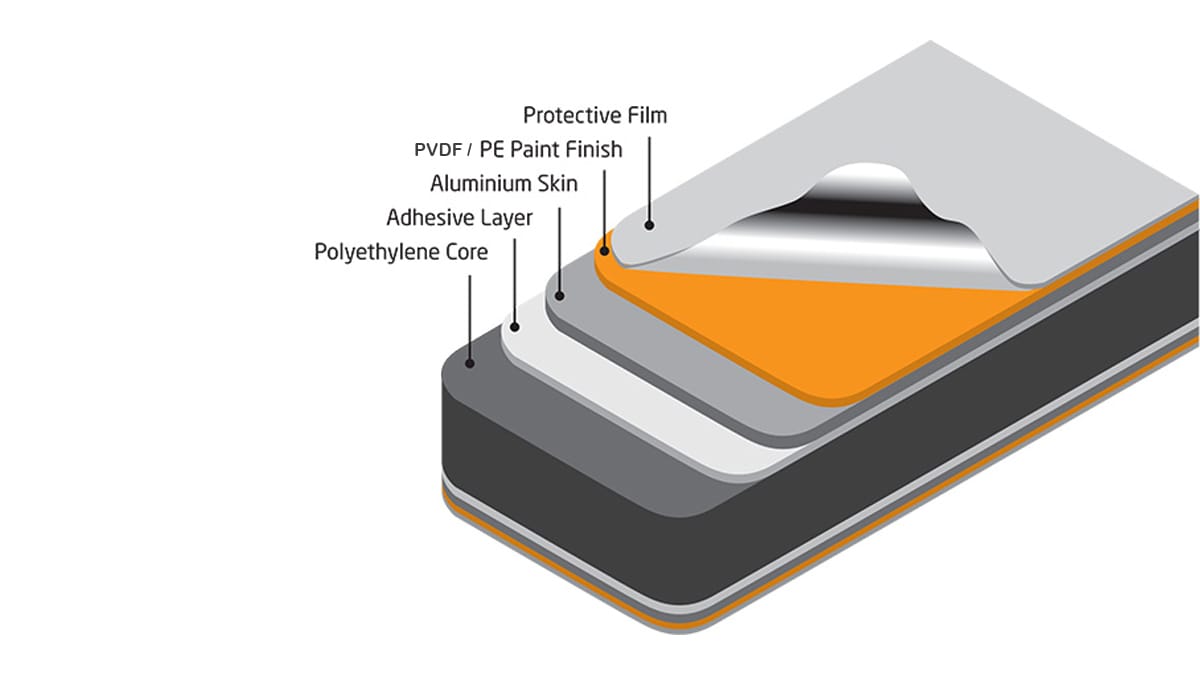

Structure and Layers

Structure and Layers

An aluminium sandwich sheet has three main layers. The outside layers are aluminium sheets. They are about 0.5 mm thick. These sheets keep out rain, sun, and wind. They also make the panel look smooth and modern. The core sits between the aluminium sheets. The core makes the panel strong. It helps with fire safety too. Glue sticks the aluminium sheets to the core. This glue holds everything together. The panel stays strong even in tough weather.

Tip: The three-layer design makes the panel light and strong. You get good insulation and better fire safety than single-layer panels.

Here is a simple look at the layers:

Layer | Description |

|---|---|

Aluminium Sheets | These are the outside layers. They protect from weather and add style. |

Core Material | This is in the middle. It makes the panel strong and helps with fire resistance. |

Adhesive Layer | This glue sticks the core and aluminium sheets together. It keeps the panel from falling apart. |

Common Core Materials

There are different core materials you can pick. Polyethylene (PE) is used a lot. It is light and easy to shape. Some panels have fire-retardant (FR) cores. These can be mineral or honeycomb types. FR cores slow down fire and make buildings safer. Honeycomb cores make the panel stronger and stiffer. If you need the panel to handle hard hits, honeycomb is a good choice. The right core helps you follow safety rules and get the performance you need.

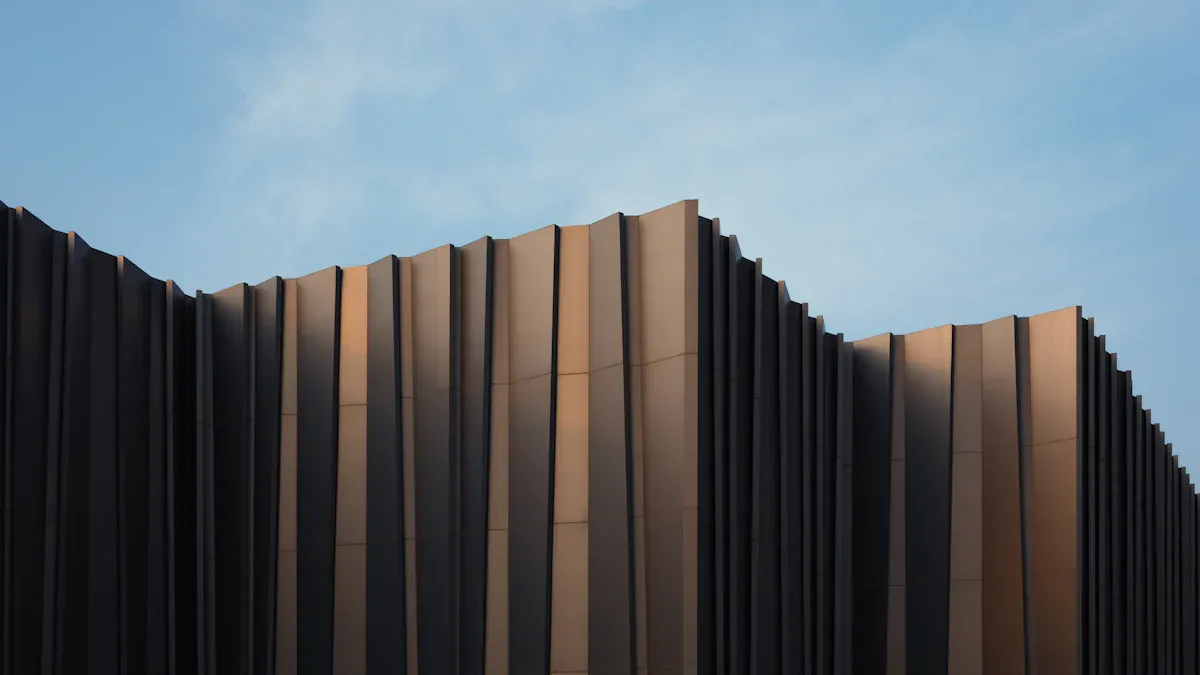

Typical Applications

You may ask, where do people use sandwich panels? Aluminium sandwich sheets are used in many places. In homes, they go on walls, ceilings, and room dividers. Sign makers use them for billboards and signs. They last long and look bright. Stores use them for display stands and cabinets. Factories and labs use aluminium sandwich sheets to protect walls and equipment. You get a strong, light, and nice-looking panel for almost any job.

Aluminium Sandwich Sheet Specifications

Thickness and Dimensions

You need to know the thickness and size before you choose an aluminium sandwich sheet. Thickness affects how strong the panel is and how well it works for your project. If you pick thicker aluminium sheets, you get more strength. For example, tests show that 2 mm thick aluminium sheets can handle much higher force and impact than 1 mm sheets. Thicker aluminium sheet metal also helps the panel last longer in tough jobs like car parts or airplane panels.

You can find many sizes in the market. Here is a table to help you see the common options:

Dimension Type | Standard Sizes |

|---|---|

Width | 1000 mm, 950 mm, 1150 mm, 1200 mm |

Length | 2000 mm to 12000 mm (common: 6000 mm, 10000 mm) |

Thickness (Insulation) | 50 mm to 200 mm (common: 100 mm, 150 mm) |

Thickness (Structural) | 150 mm to 250 mm |

If you need a panel for a wall, you might pick a thinner aluminium sandwich sheet. If you want to use it for a roof or a heavy-duty job, you should look for thicker aluminium sheets. Always check the thickness and size to make sure the panel fits your needs.

Core Material Options (PE, FR, etc.)

The core sits between the aluminium sheets. You can choose from different core materials. Polyethylene (PE) is light and easy to shape. It works well for signs and indoor walls. Flame-retardant (FR) cores give you better fire protection. These cores help you meet strict safety rules in buildings.

Here is a table to show the main differences:

Core Material Type | Fire Resistance | Regulatory Compliance |

|---|---|---|

Polyethylene (PE) | Non-toxic, lower fire resistance | EN 13501-1, ASTM E84 |

Flame-Retardant (FR) | Superior fire protection | Designed to meet stricter fire safety requirements |

If you need panels for places where fire safety matters, you should pick FR cores. If you want panels for simple jobs, PE cores may be enough. Always check the rules for your building before you choose.

Tip: FR cores help you follow fire safety codes. PE cores work for basic jobs but do not protect as well against fire.

Surface Finishes

You can pick from many surface finishes for aluminium sandwich sheets. Some panels have a smooth finish. Others have a brushed or textured look. You can find panels in many colors. Some finishes help the panel resist scratches and stains. If you want a shiny look, you can choose a gloss finish. If you want less glare, you can pick a matte finish.

Surface finishes do more than look good. They help protect the aluminium sheets from weather and dirt. Some finishes make cleaning easier. If you use panels outside, pick a finish that stands up to rain and sun. If you use panels inside, you can focus on style.

Gloss finish: Shiny and bright

Matte finish: Soft and smooth

Brushed finish: Modern and textured

Painted finish: Many color choices

Standard Sizes and Weight

You can find aluminium sandwich sheets in many standard sizes. Most panels come in widths like 1000 mm or 1200 mm. Lengths range from 2000 mm up to 12000 mm. Common lengths are 6000 mm and 10000 mm. The weight depends on the thickness of the aluminium sheets and the core material. Thicker aluminium sheet metal makes the panel heavier and stronger.

If you need light panels, pick thinner aluminium sheets and a light core. If you need strong panels, pick thicker aluminium sheets and a heavy-duty core. Always check the weight before you order. This helps you plan for transport and installation.

Note: Standard sizes make it easy to order and install panels. Custom sizes are also possible if you need something special.

Aluminium Sandwich Sheet Performance

Strength and Load Capacity

Strength and Load Capacity

You want building materials that are strong but not heavy. Aluminium sandwich sheets give you both things. They have two aluminium sheets with a core in the middle. This design makes the panel stiff and hard to bend. The panels can hold heavy things without being heavy themselves. The top and bottom aluminium sheets make the panel tough. People use these panels in boats, cars, and planes. These jobs need materials that are strong but light.

Many things change how much weight a panel can hold. You should know about face yielding and core shearing. Indentation and face wrinkling can also happen. Sometimes the skin and core can come apart. These problems show why the design is important. Aluminium has the best strength-to-weight ratio for sandwich panels. This makes it great for jobs that need strong and light materials. That is why car and plane makers use aluminium sandwich sheets.

Stiffer aluminium sheets make the panel stronger.

The core helps stop some problems.

High strength-to-weight ratio makes panels easy to use.

Used in boats, cars, and planes for strong, light parts.

Insulation and Fire Safety

Good insulation keeps buildings comfy and saves energy. Aluminium sandwich sheets can have different insulation values. The core material changes how well the panel insulates. Here is a table to show how cores work:

Core Material | Insulation Value (R-value) | Notes |

|---|---|---|

Polystyrene | High-density polystyrene | Makes buildings use less energy. It is also cheap. |

Polyisocyanurate | Highest rated per inch | Has no CFCs and works well if you need thin panels. |

Micore | About half of polystyrene | Class A fire-rated, used for buildings that must not burn. |

You also want your building to be safe from fire. The core material changes how fire-safe the panel is. You should check fire safety rules and see how cores do:

Fire Safety Standard | Core Material | Fire Performance Impact |

|---|---|---|

EN 13501-1 | Mineral Wool | Very good fire resistance |

| PIR | Medium fire resistance |

| EPS | Not as good fire resistance |

Mineral wool is best for places with lots of fire danger. PIR is okay for most jobs with some fire risk. EPS is only for places with little fire risk. Fire-safe panels help you follow safety rules and keep people safe.

Mineral wool is best for high fire danger.

PIR is good for medium fire risk.

EPS is for low fire risk.

Tip: Always check your local fire rules before you pick a core. Fire-safe panels help keep everyone safe.

Durability and Weather Resistance

You want panels that last a long time. Aluminium sandwich sheets are tough and do not rust. Tests show these panels can handle sunlight. PVDF coatings keep the color and protect the surface for up to 20 years. The aluminium sheets do not rust, even near the ocean. Good coatings give even more protection. The design stops the panels from bending or breaking in bad weather.

You can expect aluminium sandwich sheets to last about 50 years or more. How long they last depends on where you use them and how you care for them. Aluminium is strong and does not rust, so it stays good for a long time.

Panels last about 50 years or more.

Aluminium sheets do not rust or corrode.

PVDF coatings protect from sun and rain.

Panels keep their shape in tough weather.

Note: Clean and check your panels often to help them last longer.

Installation Efficiency

You want to finish your building fast. Aluminium sandwich sheets help you save time. These panels are made in a factory before they get to you. This means you spend less time working at the building site. The panels fit together easily. You can put up metal cladding faster than old ways.

Factory-made panels mean less work at the site.

Easy design makes installation quick.

Metal cladding goes up faster than old materials.

🛠️ Fast installation saves you money and helps you finish your project on time.

Choosing the Right Aluminium Sandwich Sheet

Assessing Project Needs

Assessing Project Needs

Before you pick an aluminium sandwich sheet, think about your project. Where will you use the sandwich panel? If you need strong walls or roofs, check the thickness. Thicker panels are stronger and keep heat in better. They also help protect against fire. For high insulation or fire safety, mineral wool or polyurethane cores work best. For simple jobs, polystyrene cores are fine. The core material changes how well the panel works.

Core Material | Properties |

|---|---|

Polyethylene (PE) | Lightweight, cheap, good at keeping heat in. |

Polyurethane (PU) | Great for keeping heat in, absorbs sound. |

Polyvinyl Chloride (PVC) | Good at keeping heat in, helps stop fires. |

Mineral Wool | Stops fires, blocks sound, keeps heat in. |

Matching Specifications to Use

Pick the best sandwich panel for your job. Look at the thickness and type of aluminium sheets. Thicker panels are stronger and keep heat in better. But they cost more and weigh more. Match the panel to what you need. If you want to save energy, pick thicker aluminium sheets. If you want to spend less, thinner panels may work. The glue between the aluminium sheets and the core keeps the panel strong. Strong glue makes sure your panel stays safe and stiff.

Thicker panels keep heat in and are stronger.

Thicker panels can weigh more and cost more.

Pick the right thickness for your project needs.

Environmental and Budget Factors

You want your building to be safe and good for the planet. Aluminium sandwich panels help you build green. Aluminium sheets can be recycled over and over. You do not lose quality when you recycle them. Many sandwich panels have EPDs. These show how they affect the environment. If you want to follow green rules, look for LEED certification. This helps you build in a way that is better for the earth.

LEED certification helps you build in a green way.

ACM panels can be recycled again and again.

Think about how much the panels cost too. Here is a table to help you compare:

Panel Type | Description | |

|---|---|---|

Solid Aluminum Panels | $40 – $80 | Made from one sheet, strong and lasts long. |

Aluminum Honeycomb Panels | $50 – $120 | Two sheets with a honeycomb core, strong and keeps heat in. |

Aluminum Composite Panels | Usually cost more | Many layers, very strong and keeps heat in well. |

Aluminum Corrugated Panels | Cheaper | Not as strong or good at keeping heat in. |

Color Coated Aluminum Sheets | Cheaper | Not as strong or good at keeping heat in. |

📝 Tip: Always talk to your supplier about what you need. They can help you pick the best panel and make sure you follow the rules.

Sandwich Panel vs. Alternatives

Solid Aluminium Sheets

Solid Aluminium Sheets

You might want to know how solid aluminium sheets are different from sandwich panels. Solid aluminium sheets have just one layer of metal. This makes them heavier than sandwich panels. You can bend, roll, or weld these sheets without much trouble. They are good for roofs, machines, and vehicles. Solid aluminium sheets last a long time, especially with a coating. They do not catch fire, so they are safe in hot places. But they cost more for each square meter, especially if you need thick sheets. They are not as stiff unless you use a thick sheet.

Feature | Aluminum Sandwich Sheets | Solid Aluminum Sheets |

|---|---|---|

Structure | Multi-layered | |

Weight | Lighter | Heavier |

Flexibility | Bendable, not weldable | Bendable, weldable |

Durability | Weather-resistant | Very durable |

Fire Safety | Depends on core | Non-combustible |

Cost | Cost-effective | More expensive |

Steel Sandwich Panels

Steel sandwich panels are another option you might see. These panels use steel for the outside layers instead of aluminium. Steel makes the panel heavier but also stronger and stiffer. Steel panels need more care to stop rust from forming. They cost less than aluminium sandwich panels because they are easier to make. If you want a strong panel and do not mind the extra weight, steel sandwich panels are a good choice.

Attribute | Aluminum Sandwich Panels | Color Steel Sandwich Panels |

|---|---|---|

Weight | Heavier | |

Corrosion Resistance | High | Moderate |

Cost | Higher | Lower |

Pros and Cons

When you pick between sandwich panels and other materials, you should look at what is good and bad about each one. Aluminium sandwich panels keep heat out and help with insulation. They are tough against sandstorms. They do not get damaged by UV rays or bad weather, so they last a long time. You can use them in tall buildings because they are light and easy to shape. They meet fire safety rules and look nice in many designs. They do not rust easily, which is good near the ocean.

But there are some things to watch out for. Aluminium sandwich panels can get bigger when they get hot. Some panels may not follow all safety rules if you do not check the core. They cost more at first than some other choices. The surface can get very hot in the sun.

Advantages | Disadvantages |

|---|---|

Heat expansion issues | |

Durability against sandstorms | Risk of non-compliant panels |

UV and weather resistance | High initial cost |

Lightweight and flexible for high-rise construction | Surface heating |

Fire safety compliance |

|

Aesthetic versatility |

|

Corrosion resistance in coastal areas |

|

🏗️ Tip: Metal-faced sandwich panels give you strength, insulation, and design choices. Always pick the panel that fits your project best.

Installation and Maintenance

Preparation and Handling

Preparation and Handling

You want your aluminium sandwich sheets to stay in good shape. Store panels flat in a cool, dry spot. Do not put them on the ground. This keeps them safe from water. Cover panels so dust and sunlight do not hurt them. Never put heavy things on top. This can bend or damage the panels. Leave the protective film on until you install them. The film stops scratches and dust. Wear clean gloves when you touch the panels. Gloves keep off fingerprints and stains. Always lift panels by their edges. Do not drag them on rough floors.

Installation Tips

You can put up aluminium sandwich sheets if you follow these steps. First, check if the roof or wall is strong enough. Clear the work area before you start. Make sure you can get materials and tools easily. Try to install panels when the weather is dry and calm. Use self-drilling screws with washers that resist weather. These keep panels tight and stop water leaks. Seal all joints and edges with special compounds. This keeps out water and protects your building.

Maintenance Guidelines

Taking care of your aluminium sandwich sheets helps them last longer. Wash off dirt with clean water. If dirt stays, use a soft cloth and mild soap. For hard stains, use an isopropyl solution. Clean the panels two times each year. Check for scratches, dents, or rust every year. Fix small problems fast so they do not get worse. Here is a table to show what to do and how often:

Maintenance Task | Frequency |

|---|---|

Clean surfaces with mild soap and water | Twice a year |

Inspect for scratches, dents, or corrosion | Annually |

Address minor issues promptly | As needed |

Aluminium panels can have problems like rust, pitting, or layers coming apart. You can stop these by picking good materials and coatings. Check panels often to find problems early. If you see cracks or damage inside, use thicker panels or add protection. Testing for impact and making better designs also help keep panels strong.

🛠️ Tip: Good planning, careful work, and regular cleaning help your aluminium sandwich sheets stay safe and last a long time.

You should know about aluminium sandwich sheet specifications before you choose. The right aluminium panel is strong and lasts a long time. It keeps heat in and gives you many design options. Always check the core material and fire safety. This helps you follow building rules. Look at the table below for important facts:

Details | |

|---|---|

Durability | Aluminium panels are tough and can handle bad weather. |

Insulation | Good cores help save energy in your building. |

Maintenance | Aluminium is easy to care for, but sealing stops leaks. |

Aluminium panels are light, so they are easy to move and cost less. You should ask suppliers or experts before you buy aluminium sheets. They can help you choose the best aluminium and stop you from making mistakes.

FAQ

What is the main benefit of using aluminium sandwich sheets?

You get a strong and lightweight panel. These sheets resist rust and last a long time. You can use them for many building jobs. They also help keep your building warm or cool.

Can you use aluminium sandwich sheets outdoors?

Yes, you can use them outside. The panels resist rain, sun, and wind. Good coatings protect the surface. You should check the finish for extra weather protection.

How do you clean aluminium sandwich sheets?

Use clean water and mild soap. Wipe with a soft cloth. For tough stains, use isopropyl alcohol. Avoid harsh cleaners. Clean panels twice a year for best results.

Are aluminium sandwich sheets fire safe?

Note: Fire safety depends on the core material. If you need better fire protection, choose panels with a fire-retardant core. Always check local building codes before you buy.

Can you recycle aluminium sandwich sheets?

Yes, you can recycle them. Aluminium is 100% recyclable. Many panels use recycled aluminium. Recycling helps the environment and saves resources.

Structure and Layers

Structure and Layers Strength and Load Capacity

Strength and Load Capacity Assessing Project Needs

Assessing Project Needs Solid Aluminium Sheets

Solid Aluminium Sheets Preparation and Handling

Preparation and Handling