10 Aug What Are the Different Types of Aluminum Composite Materials and Their Key Characteristics

Table of Contents

- 1 Key Takeaways

- 2 Aluminum Composite Materials

- 3 Aluminum Composite Material Types

- 4 Key Characteristics of Different Types

- 5 Choosing the Right Aluminium Composite Panel

- 6 FAQ

- 6.1 What is the main difference between PE core and fire-rated aluminum composite panels?

- 6.2 Can aluminum composite panels be used outdoors?

- 6.3 How do you clean and maintain aluminum composite panels?

- 6.4 Are aluminum composite panels environmentally friendly?

- 6.5 What finishes are available for aluminum composite panels?

Fire-Resistant Core panels

Mirror finish panels

Brushed finish panels

Nano panels

Honeycomb panels

Aluminum matrix composites

Metal composite materials

Architects and builders encounter various aluminum composite material types, each offering unique features. Understanding these aluminum composite material types is essential for adhering to safety regulations, achieving design objectives, and ensuring proper installation. Polyethylene Core panels are the most widely used aluminum composite material type globally due to their flexibility and affordability. Fire-Resistant Core panels are gaining popularity as safety standards become more stringent. Additionally, some aluminum composite material types are designed for specialized purposes, such as preventing germs or graffiti. Selecting the appropriate aluminum composite material type enhances building durability, weather resistance, and overall performance.

Key Takeaways

Aluminum composite panels have different core types. These cores change how strong, safe, and bendy the panels are. – Fire-rated panels have mineral cores. They protect tall buildings better. They are good for places with strict fire rules. – Nano and honeycomb panels are very strong. They help save energy in tough places. – You should pick the right panel for your project. Think about safety, design, and how much money you have. – Picking and installing the right panels is important. This helps buildings last long, stay safe, and look nice.

Aluminum Composite Materials

Structure and Core Materials

Aluminum composite materials have three layers. Two aluminum sheets cover a core in the middle. This makes the panel strong but not heavy. The core is very important for how the panel works. Most panels use a polyethylene core. This core helps the panel keep its shape and is easy to work with. Some brands, like DIBOND®, use a solid PE core that meets fire rules. Other panels, such as Alumanate Signage, use a PE blend core for better printing and cutting. C-TEK® panels are made for good shape and shiny looks.

Some panels are made to resist fire. These use special flame retardants and tiny additives in the core. This helps the panel fight fire and stay strong. Fire-rated panels meet rules like the B1 fire grade. Honeycomb and aluminum matrix composite cores make panels even stronger. The core you pick changes how safe, strong, and useful the panel is.

Note: The core material affects fire safety, strength, and how you work with the panel.

Key Properties

Aluminum composite materials have special features. They are light, so you can move and install them easily. They do not break easily if hit. The surface does not stain and can handle bad weather. These panels also block UV rays and do not rust much. Tests show the color stays the same after years in the sun. They also do not rust after salt spray tests.

Here is a table that shows different core materials:

Core Material Type | Advantages | Disadvantages |

|---|---|---|

Aluminum Core | Light, strong, resists fire | Costs more |

Aluminum Honeycomb Core | Very strong, supports weight | Harder to make, costs more |

Polymer (Non-Aluminum) | Cheap, easy to use, many looks | Can burn if not fire-resistant, not as strong |

Unbreakable Core | Very tough, does not break easily | Not used much, costs more |

New ideas in aluminum composite materials use recycled cores and green coatings. Nano-coatings make them last longer and save energy. You can pick many finishes and print designs on them. These panels are now important for green buildings and new construction.

Aluminum Composite Material Types

Aluminum composite material types give many choices for building and design. Each type has its own core, finish, and how it works. Knowing about these types helps people pick the right one for each job.

give many choices for building and design. Each type has its own core, finish, and how it works. Knowing about these types helps people pick the right one for each job.

Standard (PE Core) Panels

Standard panels have a polyethylene core between two thin aluminum sheets. This makes them strong but not heavy. They weigh about 2.5 pounds per square foot. These panels are much lighter than solid metal. The PE core lets you cut, bend, and shape them easily.

Some main features are:

Many colors and finishes to choose from

Stand up to weather, UV, and rust

Easy to clean and take care of

Good for outside walls, inside walls, signs, and displays

Note: Standard PE core panels work best for buildings up to two stories because they have basic fire safety.

Feature | Details |

|---|---|

Core Material | Polyethylene (PE) |

Weight | Light (about 2.5 lbs per square foot) |

Flexibility | Very flexible; many shapes and colors |

Durability | Stands up to weather, stains, and rust |

Applications | Walls, signs, inside spaces, displays |

Fire-Rated (Mineral Core) Panels

Fire-rated panels use a mineral core instead of PE. The core has magnesium hydroxide and aluminum trihydroxide. These do not burn and have no halogen. These panels meet tough fire rules like ASTM E84 and NFPA 285. They are good for tall buildings, hospitals, and schools.

The mineral core stops toxic smoke and melted drops in a fire.

Fire-rated panels slow down fire for up to 120 minutes.

New ways of making them keep panel gaps small, so fire cannot spread fast.

Tip: Pick fire-rated panels when fire safety rules are strict.

Mirror Finish Panels

Mirror finish panels get their shiny look from anodic oxidation. This gives a modern style to buildings. These panels are strong, flat, and resist weather and rust.

The mirror surface bounces back what is around it, making spaces look bigger and brighter.

These panels are light, easy to use, and clean themselves.

People use them for inside walls, signs, and decorations.

Brushed Finish Panels

Brushed finish panels go through special steps:

The aluminum gets cleaned and treated.

The PE core is pressed between aluminum sheets with heat and pressure.

Coatings make them shiny, tough, and stop rust.

These steps make panels that look nice and do not scratch or stain easily. They also block UV rays and bad weather. Brushed finish panels work inside and outside and give a modern feel.

Nano Panels

Nano panels have two aluminum sheets and a nano PVDF coating. This coating makes them last longer, block UV, and clean themselves. Nano panels stay clean, keep their color, and last longer than regular panels.

Nano panels are good for the planet because you can recycle them.

Their shiny surface helps keep buildings cool and saves energy.

They work well in tough places like big buildings and factories.

Honeycomb Panels

Honeycomb panels have a core shaped like a honeycomb. This makes them stiff but still light.

The honeycomb shape gives them lots of strength for their weight.

These panels can replace heavier things like plywood.

Honeycomb panels are great for big walls, ceilings, and places where weight matters.

Note: The honeycomb core helps stop bending and takes in energy, so these panels are good for hard jobs.

Aluminum Matrix Composites (AMCs)

Aluminum matrix composites have an aluminum base with ceramic bits like silicon carbide. These panels are strong, stiff, and carry heat and electricity well.

AMCs do not rust or wear out fast, so they are used in planes, cars, ships, and the army.

Using them in cars and planes saves fuel and cuts pollution.

AMCs are used for both building and special parts in engineering.

Metal Composite Materials (MCMs)

Metal composite materials are not the same as regular aluminum panels. MCMs use special resins like PVDF and FEVE for a strong, even finish.

MCMs have lots of recycled stuff and a fire-safe core, so they pass fire tests.

These panels block UV, keep their color, and do not scratch, with long warranties.

MCMs can be made in many shapes, textures, and finishes for cool building designs.

Panel Type | Core Composition | Strength & Durability | Fire Resistance | Intended Use / Applications |

|---|---|---|---|---|

Standard ACP | PE core | Strong | Basic | Walls, signs, inside spaces |

Fire-Rated ACP | Mineral-filled core | Strong | Very good | Tall buildings, hospitals, schools |

Mirror ACP | Shiny finish | Medium | Basic | Inside walls, signs |

Honeycomb Panel | Honeycomb core | Very strong | Good | Big walls, ceilings |

Metal Composite | Bonded metals | Very strong | Good | Hard jobs, building fronts |

The main differences between aluminum composite panels are in their cores, coatings, and how they are built. These things change how safe, strong, and useful the panels are. Picking the right type makes sure your project is safe, works well, and looks good.

Key Characteristics of Different Types

Durability and Weather Resistance

Durability and Weather Resistance

Aluminum composite panels last a long time in many places. Their coatings, like PVDF or polyester, stop colors from fading in the sun. In hot areas, these coatings keep panels from bending. In cold places, the aluminum does not crack or change shape under snow. These panels do not soak up water, so they do not rust in rain or wet air. Near the ocean, special coatings protect them from salt and wetness. In windy spots, strong installation keeps panels from moving. These features make aluminum composite panels great for tough weather. They are a smart pick for cladding in hard climates. Their strength and weather resistance help them last for years.

Fire Resistance

Fire resistance is very important for safety. Standard panels with polyethylene cores give basic fire protection. Fire-rated panels have mineral cores for better safety. Panels with B1 or A2 ratings follow strict fire rules. They stop burning when the flame is gone. Some fire-rated panels can resist fire for over an hour. This makes them good for hospitals, schools, and tall buildings.

ACM Core Type | Fire Resistance Rating (minutes) | Typical Applications |

|---|---|---|

Polyethylene (PE) | Interior, low-risk areas, signage | |

Fire-Retardant (FR) | 30 – 60 | Exterior cladding, mid-rise buildings |

High-Performance FR | Over 60 | High-rise, hospitals, schools, cladding |

Weight and Flexibility

Weight and flexibility matter for building and design. Standard panels with PE cores weigh about 3.5–5.5 kg per square meter. They bend easily for cool shapes. Fire-rated panels are a bit heavier because of their mineral cores. They still bend but not as much. Honeycomb panels weigh about 6 kg per square meter at 10mm thick. They are very strong but do not bend much. Their stiff shape is good for big projects.

Applications

Aluminum composite panels can be used in many ways. Builders use them for cladding, facades, and wall covers. Designers pick them for inside walls, ceilings, and signs. Factories use these panels for frames, mounts, and displays. Their light weight and strength make them good for signs, exhibits, and booths.

Common uses are:

Cladding and building fronts

Signs inside and outside

Wall covers and room dividers

POP displays and booths

Comparison Table

Panel Type | Durability | Fire Resistance | Weight/Flexibility | Common Applications | Key Characteristics |

|---|---|---|---|---|---|

Standard ACP | High | Basic | Light, flexible | Signage, wall linings, displays | Versatile, easy to put up |

Fire-Rated ACP | High | Enhanced | A bit heavier, bends some | Cladding, tall buildings, hospitals | Strong, safe for tough rules |

Honeycomb Panel | Very High | Good | Heavier, stiff | Big cladding, ceilings | Very strong, supports structure |

Mirror/Brushed | Medium | Basic | Light, flexible | Fancy signs, inside spaces | Looks nice, easy to clean |

Nano Panel | Very High | Enhanced | Light, flexible | Facades, hard places | Cleans itself, saves energy |

Tip: Pick the right aluminum composite panel for your project. Think about what you need for cladding, signs, and how long it should last. Always check the main features for each type.

Choosing the Right Aluminium Composite Panel

Application Needs

Picking the right aluminum composite panel means knowing what your project needs. Each job needs panels with certain features. Tall buildings need panels that can handle bad weather and fire. Signs and displays need panels that are light and easy to cut. In cars, buses, or trains, panels must be strong but not heavy. This helps save fuel.

Some important things to think about are:

Material composition: Good aluminum and core make panels last longer.

Thickness: Thicker panels are stiffer for buildings and vehicles.

Surface finish: Coatings protect panels outside.

Color and design: Many choices help make creative signs.

Fire safety: Certified panels are needed for public places.

Installation and maintenance: Easy-to-use panels save time and money.

Budget: You need to balance cost and how well the panel works.

Tip: Always pick panels that fit what you need for buildings, signs, or vehicles.

Safety and Compliance

Safety and rules are very important when picking panels. For public or business buildings, panels must pass tough fire tests. NFPA 285 is a big test for fire safety. Panels with fire-retardant cores help stop fires from spreading. In cars and buses, panels must also be safe if hit and last a long time.

Fire safety: Pick panels with mineral-filled cores for better fire protection.

Building codes: Make sure panels have certificates from trusted groups.

Manufacturer reputation: Buy panels from companies known for good quality.

Environmental standards: Panels should help with green building and recycling.

Note: Using certified panels keeps people and buildings safe in all projects.

Cost Considerations

The price of panels depends on many things. Better aluminum and special cores cost more. Fire-retardant panels are more expensive because they are safer. Thicker panels and special looks, like mirror or brushed, also raise the price. Custom colors and sizes for signs or vehicles add to the cost.

Factor | Impact on Cost |

|---|---|

Aluminum grade | Better grade, higher price |

Core type | Fire-retardant costs more |

Panel thickness | Thicker panels cost more |

Surface finish | Special looks add cost |

Customization | Makes price go up |

Brand reputation | Well-known brands may cost more |

Panels with PVDF coatings last longer and do not rust, so they are a smart buy for buildings and vehicles. Top brands give long warranties, sometimes up to 30 years, which adds value and peace of mind. For signs, picking the right mix of price and quality means your signs will last a long time.

Aluminum composite material panels are strong and last a long time. They can be used in many different projects. Each type has special features. Some are good at stopping fire. Others are easy to keep clean. Picking the right panel keeps people safe and saves money. It also makes sure the building stays strong.

Checklist for choosing the best panel:

Find out what your project needs and what safety rules to follow.

Look at different panel types to see how tough they are and how well they stop fire.

Make sure the panels are simple to put up and take care of.

Pick finishes and colors that match your design.

Check if the supplier is good and offers a warranty.

FAQ

What is the main difference between PE core and fire-rated aluminum composite panels?

PE core panels have a plastic core. This makes them light and easy to bend. Fire-rated panels have a mineral core. This helps them stop fire better. Builders pick fire-rated panels for places with strict fire rules.

Can aluminum composite panels be used outdoors?

Yes, most aluminum composite panels work outside. They stand up to rain, sun, and rust. If you put them up right, they last a long time on buildings, signs, and walls.

How do you clean and maintain aluminum composite panels?

Clean panels with mild soap and water. Use a soft cloth to wipe them. Do not use strong cleaners or rough tools. Cleaning often keeps panels looking nice and stops stains.

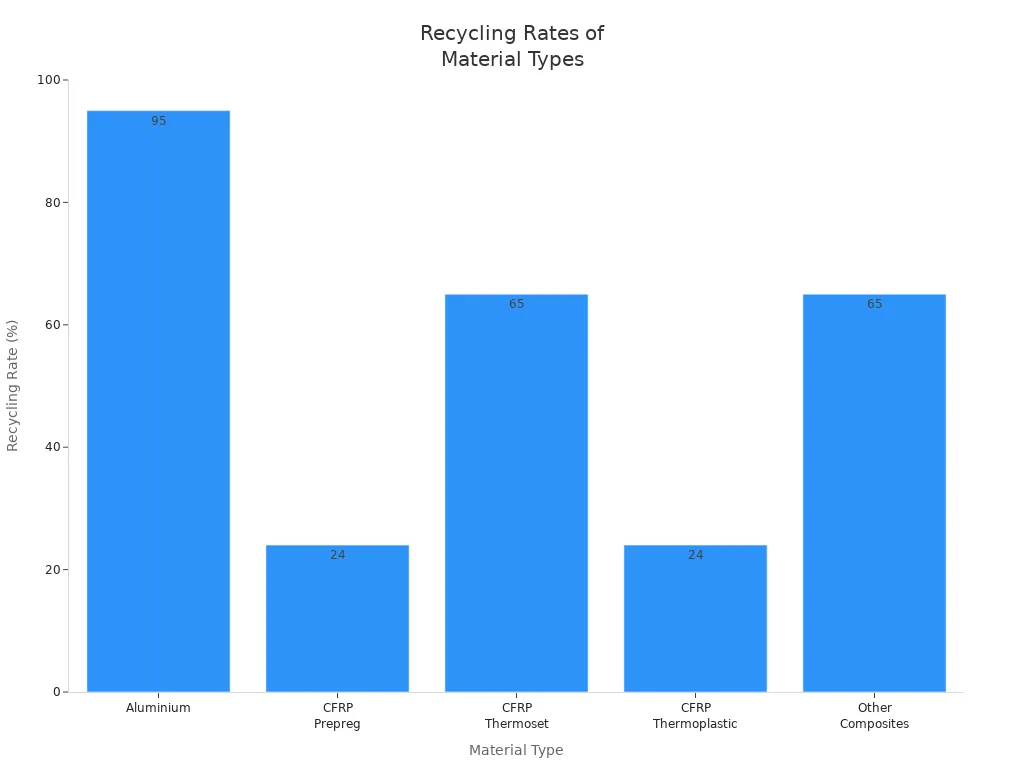

Are aluminum composite panels environmentally friendly?

Many panels use recycled stuff and can be recycled again. Some have coatings that are good for the planet. Picking green panels helps make buildings better for the earth.

What finishes are available for aluminum composite panels?

You can get panels in mirror, brushed, matte, or custom colors. Some have special coatings to stop dirt or graffiti. Designers can find panels to fit almost any style.

Durability and Weather Resistance

Durability and Weather Resistance