27 Oct Modern Architecture Essentials with Anodized Aluminum Composite Panels

Table of Contents

- 1 Key Takeaways

- 2 Essential Role in Modern Architecture

- 3 What Is an Aluminum Composite Panel

- 4 Benefits of Anodized Aluminum Composite Panels

- 5 Applications in Modern Architecture

- 6 Installation and Maintenance

- 7 Safety and Sustainability

- 8 Material Comparison

- 9 FAQ

- 9.1 What makes anodized aluminum composite panels different from regular panels?

- 9.2 Can you install anodized aluminum composite panels by yourself?

- 9.3 How do you clean anodized aluminum composite panels?

- 9.4 Are anodized aluminum composite panels safe for indoor use?

- 9.5 What design options do you have with anodized aluminum composite panels?

You see how modern architecture changes with anodized aluminium composite panels. These panels transform the appearance of buildings and contribute to hard sustainability goals. Many architects choose anodized aluminium composite panels because they are made from recycled materials and support green building regulations. You see more projects utilizing these materials, as they provide style and are environmentally friendly. Manufacturers are now focusing on recyclable and non-toxic designs, making anodized aluminium composite panels a great choice for today’s buildings.

Key Takeaways

Anodized aluminum composite panels last a long time. They do not rust. This makes them good for modern buildings.

These panels are light. They are simple to put up. This helps save time. It also lowers work costs for building jobs.

Anodized aluminum composite panels help the environment. They use recycled materials. You can recycle them when they are old.

The panels come in many colors and textures. This lets people make creative designs. You can use them inside or outside buildings.

Using anodized aluminum composite panels helps save energy in buildings. They help lower heating and cooling bills.

Essential Role in Modern Architecture

Why Choose Anodized Aluminium Composite Panel

You want your building to last and look nice. Anodized aluminium composite panels help you do both. Many architects pick these panels because they work well in buildings. Here are some reasons you might use them:

They are good for cladding and façades. They stay strong and keep looking nice for a long time.

These panels can handle bad weather and help save energy.

Aluminum is fully recyclable, so it is good for the environment.

Anodized aluminum gets a special treatment. This makes it stronger and stops rust.

The panels give buildings a shiny, modern look that stands out.

You can use them to make cool and different designs.

You also get helpful features:

They last a long time and can take daily use.

The panels are light, so they are easy and quick to put up. This saves time and money.

You do not need to do much to keep them looking new.

There are many colors and textures to choose from for your design.

These panels help keep buildings warm and quiet inside.

Meeting Contemporary Design Needs

Modern buildings need materials that look good and work well. Aluminum composite panels do both jobs. You can use them for bold building fronts or for signs. They are flexible, so you can shape them in many ways. This helps you solve design problems in cities.

Metal composite wall panels make buildings look high-tech. You can use them in big or small projects. They are easy to use for many types of buildings. Their flexibility helps you keep up with new building styles. Anodized aluminium composite panels let you be creative and build for the future.

What Is an Aluminum Composite Panel

Structure and Composition

Structure and Composition

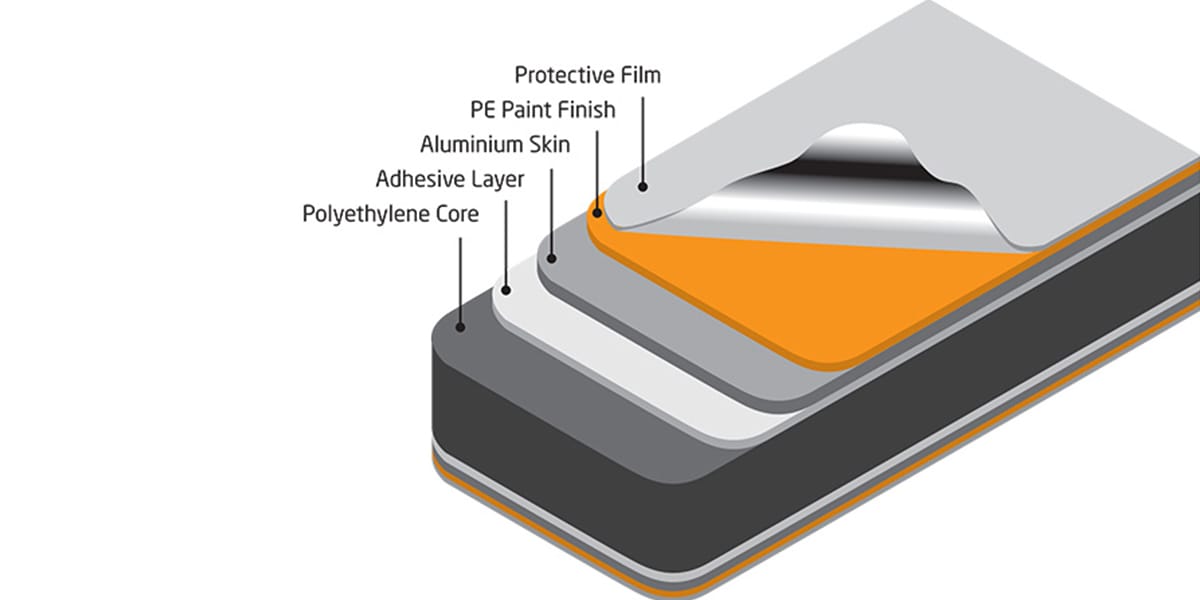

You may ask why an aluminum composite panel is special. This panel has layers that make it strong and bendy. Look at the table below to see its main parts:

Component | Description |

|---|---|

Aluminium Sheets | These are usually 0.5 mm thick. They have a coating that protects them from weather, like PVDF or polyester. |

Core Material | The core is light polyethylene or a mineral-filled material that does not burn easily. |

Adhesive Layer | A tough glue holds the aluminum sheets to the core. This makes the panel strong and sturdy. |

This design keeps the panel light but also strong. It is a good material for many building jobs.

The Anodizing Process

Anodizing makes the outside of aluminum tougher. It uses electricity to add a special oxide layer on the metal. This layer protects the panel from rust and harm. Here is how it works:

Aspect | Description |

|---|---|

Process | Anodizing uses electricity to make a hard oxide layer on the aluminum. |

Benefits | The oxide layer helps stop rust and makes the panel last longer. |

Influencing Factors | The kind of liquid and the settings change the final result. |

Oxide Layer Characteristics | The layer can be thin and smooth or thick and rough, depending on how you anodize it. |

Tip: Anodized panels are used in places like airplanes and cars because they do not wear out fast.

Unique Properties

There are many good things about anodized aluminum composite panels. The oxide layer gives the panel special features:

The panel does not rust or get wet easily, so it lasts longer outside.

The surface is harder, so it does not scratch or dent easily.

You can choose from many colors and finishes for your project.

The panel keeps its shape, even in hot or cold weather.

The material is safe for nature and does not use bad chemicals.

Paint and glue stick well to the surface, so it is easy to install.

These features make aluminum composite panels a smart pick for new buildings. You get something that looks nice, works well, and lasts a long time.

Benefits of Anodized Aluminum Composite Panels

Durability and Corrosion Resistance

Durability and Corrosion Resistance

You want your building to last a long time. Anodized aluminum composite panel protects against weather and damage. The oxide layer from anodizing keeps the surface safe from rust. acp cladding stays in good shape even in tough places. Tests show these panels resist corrosion and wear. You see results like low corrosion and high resistance after water tests. The panels also keep a steady friction level, so they do not wear out fast.

These panels do not bend, crack, or break as time passes.

acp cladding stands up to rain, sun, and dirty air.

You get self-cleaning features, so dirt does not stick much.

The panels pass scratch tests and work in different pH levels.

Test Description | Result |

|---|---|

Corrosion current density after 28 days immersion | 4.846 × 10−8 A·cm−2 |

Corrosion current density of modified film | 7.627 × 10−10 A·cm−2 |

| Z |

Contact angle | 158.1° |

Sliding angle | 3.6° |

Friction coefficient | 0.25 (stable) |

You see acp cladding in many buildings because it is strong and lasts. You do not need to worry about the panels losing shape or color. Studies show acp panels stay strong under stress, unlike wood or canvas. You get value for a long time and do not need many repairs.

Design Flexibility and Aesthetics

You want your building to look special and modern. Anodized aluminum composite panel gives you many choices for color and texture. You can pick matte, brushed, mirror, or colored looks. acp cladding lets you make bold designs for walls, signs, and decorations. You can bend or shape the panels to fit your ideas. Many architects use acp cladding in big projects because it helps them be creative.

You find panels in basic colors, metallics, and matte shades.

You can order special colors for your brand or design.

acp cladding works inside and outside buildings.

You see smooth color changes from inside to outside.

Feature | Description |

|---|---|

Durability | High impact resistance and non-combustibility. |

Design Flexibility | Can be curved, rolled, and fabricated into custom shapes. |

Aesthetic Appeal | Available in various colors and finishes, enhancing architectural vision. |

Applications | Suitable for exterior facades, decorative panels, and more. |

Feature | Description |

|---|---|

Flatness | Provides a seamless transition of color from indoor to outdoor spaces. |

Formability | Exceptional performance in exterior cladding applications. |

Color Options | Offers 91 colors and finishes for diverse design possibilities. |

You can use acp cladding to make your building stand out. Car and tech companies use these panels for branding and decoration. You get flexibility for any building project.

Energy Efficiency and Sustainability

You want your building to save energy and help the planet. Anodized aluminum composite panel helps keep indoor temperatures steady. You pay less for heating and cooling because acp cladding saves energy. Insulated aluminum composite panels use more insulation, which helps meet energy rules. Studies show panels with tight air seals cut heat loss by up to 54% in winter.

You get better thermal performance for energy-saving buildings.

acp cladding supports green goals by using recycled materials.

You can recycle the panels when you are done with them.

Making the panels uses less energy, so it is better for nature.

Feature | Contribution to Green Certifications |

|---|---|

Use of recycled materials | Supports resource conservation |

Recyclability at end of life | Promotes circular economy |

Energy-efficient production | Reduces overall environmental impact |

Improved thermal performance | Enhances energy efficiency in buildings |

You help your building earn green awards like LEED or BREEAM. acp cladding makes your project more eco-friendly.

Cost Advantages

You want to save money on your building project. acp cladding gives you cost savings from start to finish. The panels are light, so you spend less on shipping and putting them up. You do not need much care, which saves money over time. acp panels last longer than many old materials, so you do not pay for lots of repairs.

You get good value because the panels stay strong.

acp cladding helps you finish jobs faster, saving on work costs.

You can pick from many options to fit your budget and style.

You see acp cladding in many buildings because it works well and saves money. You make smart choices for your building’s future.

Tip: When you use anodized aluminum composite panel, you get strength, design choices, energy savings, and long-term value. Your building looks good and works well for many years.

Applications in Modern Architecture

Anodized aluminum composite panels have changed how buildings look today. You see these panels used inside and outside many buildings. They help make spaces strong, nice to look at, and save energy. Let’s see how you can use acp for different building needs.

Anodized aluminum composite panels have changed how buildings look today. You see these panels used inside and outside many buildings. They help make spaces strong, nice to look at, and save energy. Let’s see how you can use acp for different building needs.

Cladding and Facades

You often find acp on the outside of stores, houses, and schools. These panels protect buildings from rain, wind, and sun. They make buildings stronger and help them last longer. You can pick finishes like smooth, rough, shiny, wood, or stone. This lets you match any style you want.

The panels are light and simple to put up.

They do not catch fire easily, so buildings are safer.

Special coatings can stop graffiti or reflect sunlight.

You can print logos, patterns, or pictures for branding.

These panels work for new buildings or fixing old ones.

acp cladding gives buildings a modern look. You can use it on the outside or as a main design feature. Many architects like acp for facades because it is tough and easy to use.

Ventilated Rainscreen Systems

You can use acp in ventilated rainscreen systems to keep buildings dry. These systems let air move behind the panels. This helps get rid of water and stops mold from growing. You protect the building and save energy.

The panels block water and wind from getting in.

You lose less heat and keep rooms comfortable.

The system helps buildings meet green rules.

You can use acp on tall towers or small offices.

Ventilated rainscreen systems with acp help buildings last longer. You also spend less on repairs and energy bills.

Soffits and Building Fascias

You can use acp for soffits and fascias to finish roof and wall edges. These panels give buildings a neat and modern look. You can choose from many colors and textures.

acp panels keep their color and shine for years.

They do not rust, even in wet places.

The panels do not bend or crack in hot or cold weather.

Some panels have a 25-year guarantee, and some last 50 years.

You do not need to do much to keep them nice. acp cladding stays strong and pretty, so it is a smart pick for outside details.

Interior Uses and Signage

You can use acp inside buildings for many creative ideas. These panels help you make modern spaces that stand out. Here are some common ways to use them:

Application Type | Description |

|---|---|

Feature Walls | acp makes walls look fancy in homes and offices. |

Ceilings | You can design cool ceilings that make rooms brighter. |

Partitions | The panels are strong and easy to clean, good for dividing rooms. |

Corporate Signage | acp keeps signs and logos looking bright and colorful. |

You can also use acp for custom signs and branding. The panels let you print images or names, making your space special.

Renovations and Retrofits

You can use acp to make old buildings look new again. The panels are light, so you can add them to walls without heavy work. This saves time and money when fixing buildings.

acp cladding covers old walls and hides damage.

You make buildings warmer and save energy.

The panels give buildings a fresh, modern look.

You can pick finishes to match old styles or try something new.

Many architects use acp for renovations because it is flexible and easy to put up. You can change schools, offices, or homes with these panels.

Tip: When you use acp in your building, you get strong protection, a modern look, and value that lasts. You can pick from many ways to use aluminum composite panels for your needs.

You see acp in lots of building projects today. These panels help you make safer, better, and nicer spaces. Whether you build new or fix old places, acp helps you create designs that last.

Installation and Maintenance

Preparation and Planning

Preparation and Planning

You need to plan carefully before you install acp on your building. Good preparation helps you get the best results for all applications, whether you use acp for cladding, soffits, or other parts. Follow these steps to make sure your project goes smoothly:

Clean the wall surface and check that it is strong.

Install the framing to match the size of each acp panel.

Measure and cut each acp panel with care.

Attach the panels to the framing using the right fasteners.

Use sealants and flashing to keep water out.

Inspect the finished cladding and clean the panels.

Set up a regular maintenance plan to keep your acp looking new.

Tip: Careful planning at the start helps you avoid problems later and keeps your cladding strong for years.

Mounting Methods

You have several ways to mount acp for cladding and other uses. The right method keeps your panels safe and helps them last. Here are some best practices:

Anchor each acp panel based on engineering plans and shop drawings. This gives strong support and lets the panels move as temperatures change.

Make sure the attachment system allows the panels to move up, down, and sideways. This stops buckling and keeps joints tight, even when the weather changes from very cold to very hot.

Prevent stress on fasteners and sealants by letting the acp move as needed. This keeps your cladding safe and looking good.

You can use these mounting methods for both exterior and interior cladding. They help you avoid common problems and keep your acp in top shape.

Cleaning and Upkeep

You want your acp to look great and last a long time. Regular cleaning and care are important for all cladding projects. Follow these best practices:

Clean your acp soon after installation to remove dust and dirt.

Use mild soap and clean water with a soft cloth or sponge.

Pick cleaning agents with a neutral pH to protect the anodized layer.

Plan seasonal cleaning, like more often in dusty summers.

Have professionals inspect your cladding to catch problems early.

Protect your acp from harsh weather when possible.

Fix small scratches with touch-up paint and call experts for big repairs.

Keep records of all cleaning and repairs.

Train your staff on how to care for anodized surfaces.

Store extra panels safely to prevent damage.

Although acp resists corrosion and wear, harsh chemicals or neglect can harm its natural beauty. Always use gentle cleaning methods to keep your cladding looking its best.

You can keep your acp panel installations looking new with simple care. This helps your cladding last longer and keeps your building looking modern.

Safety and Sustainability

Fire Resistance

You want your building to be safe from fire. Anodized aluminum composite panels help you follow strict safety rules. Some panels have special fire-resistant cores. These panels pass many fire safety tests around the world. The fire rating changes with the core type and how thick the panel is.

FR grade panels meet fire safety rules in many countries.

The core and thickness make a difference in fire resistance.

You can use these panels in schools, hospitals, and offices for more safety.

Tip: Always check the fire rating before you choose panels. This helps keep people and buildings safe.

Environmental Impact

You want to help the planet when you build. Anodized aluminum composite panels help lower your building’s impact on nature. You can recycle both the aluminum skins and the core. This makes your project greener. Many panels, like ALUCOBOND, help you get LEED points. You also see better results in life cycle checks, which look at energy use and waste over time.

Evidence Type | Description |

|---|---|

Recycling & VOC Rating | ALUCOBOND can be recycled, so both the core and aluminum skins get reused. |

LEED Certification | Using recycled materials in ALUCOBOND helps you earn LEED points and lowers harm to the environment. |

Life Cycle Assessments | An LCA checks the building’s impact over its life, showing energy savings and better sustainability. |

Note: Picking panels you can recycle helps you protect nature and use fewer resources.

Health and Indoor Air Quality

You want everyone to have healthy spaces. Anodized aluminum composite panels do not let out bad chemicals into the air. You get clean indoor air because these panels have low VOC ratings. You can use them in places where people spend lots of time, like schools and offices. The smooth surface does not hold dust or mold. You keep your building safe and comfy for all.

You make indoor air better and create a nicer place for people to live and work.

Material Comparison

Versus Traditional Aluminum Panels

You might ask how anodized aluminum composite panels compare to regular aluminum panels. The table below shows the main differences:

Feature | Aluminum Composite Panels (ACPs) | Traditional Aluminum Panels |

|---|---|---|

Weight | Lightweight | Heavier |

Thermal Insulation | Enhanced | Needs extra insulation |

Cost | More budget-friendly | More expensive |

Durability | 40-50 years with maintenance | 40-80 years |

Maintenance Requirements | Low | Higher due to corrosion |

Installation Process | Easier and faster | More labor-intensive |

ACPs are lighter than regular aluminum panels. You can put them up faster and spend less money. They help keep your building warm or cool. You do not have to work hard to keep them nice.

Versus Other Cladding Materials

You can pick from many cladding types, like stone, glass, or fiber cement. ACPs have special advantages. The table below compares ACPs with stone cladding:

Feature | Aluminum Composite Panels | Stone Cladding |

|---|---|---|

Cost | Cheaper; lower labor costs | More expensive; needs special substrate |

Maintenance | Low; scratch and rust-resistant | Durable but can be damaged by cleaners |

Flexibility | Highly flexible; many shapes possible | Less flexible; mostly slabs |

Installation | Lightweight, easy, and quick | Long process; needs skilled labor |

Variety of Textures | Wide range of colors and textures | Limited variety |

You can bend ACPs into different shapes. There are more colors and textures to choose from. ACPs are simple to install and cost less than stone. You do not need to spend much time cleaning them.

Cost and Performance

You want cladding that lasts and saves you money. ACPs have coatings that stop water, dents, and sun from hurting them. They last longer than wood or vinyl. These panels are strong and can handle wind and rain. ACPs pass hard tests for fire and weather safety.

ACPs block water and sun better than many other materials.

You get panels that work well for a long time.

Some systems let you make changes while building, which saves time and money.

ACPs can be tricky to install, but you finish faster with the right tools.

Tip: Pick ACPs if you want cladding that is strong, flexible, and saves money. Your building will look modern and last for years.

You notice anodized aluminum composite panels change how buildings look today. These panels are strong and let you design in many ways. They are also good for the environment. You can use them for lots of building projects. Experts think new things will come soon:

There will be more colors and special designs.

More recycled materials will be used.

Some panels will check the air and surroundings.

Building with panels will be quicker with new systems.

When you pick these panels, you help make buildings better and more modern.

FAQ

What makes anodized aluminum composite panels different from regular panels?

Anodized panels have a strong oxide layer on top. This layer helps stop rust and scratches. You also get more choices for color and finish. Regular panels do not have this extra layer.

Can you install anodized aluminum composite panels by yourself?

You can put up small panels with simple tools. For big jobs, it is better to hire experts. They know how to install the panels safely. This helps your panels last longer.

How do you clean anodized aluminum composite panels?

Use mild soap and water with a soft cloth to clean. Do not use strong chemicals or rough sponges. Clean the panels often to keep them looking nice. For hard stains, use a gentle cleaner made for aluminum.

Are anodized aluminum composite panels safe for indoor use?

Yes, you can use these panels inside buildings. They do not let out harmful chemicals. The smooth surface does not hold dust or mold. This helps keep the air inside clean and safe.

What design options do you have with anodized aluminum composite panels?

You can choose from many colors, textures, and finishes. Some panels look like wood or stone. You can bend or shape them for cool designs. This lets you match your own style.

Structure and Composition

Structure and Composition Durability and Corrosion Resistance

Durability and Corrosion Resistance Preparation and Planning

Preparation and Planning