28 Oct What Is Anodized Aluminum Composite Panel Technology

Table of Contents

You find anodizing aluminium composite panels when you need strong and light building materials. These panels consist of layers of aluminum and a core. The anodizing aluminium surface is special. The anodizing process creates a hard oxide layer that is much stronger than paint. You can see how long each finish lasts:

Finish Type | Lifespan (Years) |

|---|---|

Anodized | 10 – 25 |

Polyester Paint | 5 – 10 |

Fluoropolymer Paint | 20 – 30 |

Anodized aluminum does not scratch or rust easily. This makes anodizing aluminium composite panels a great choice for architects and builders. It is also ideal for anyone who wants strong and aesthetically pleasing materials. You benefit from the advantages of anodized aluminum in every aluminium composite panel project.

Key Takeaways

Anodized aluminum composite panels are light and tough. They work well for many building uses. The anodizing process makes a strong oxide layer. This layer stops scratches, rust, and fading. It helps the panels last a long time. These panels come in many colors and finishes. You can use them for creative designs. Using anodized aluminum composite panels can save energy. They help with green building because they can be recycled. They also use resources well. It is easy to take care of these panels. Just clean them with soap and water. This keeps the panels looking new for many years.

Anodized Aluminum Composite Panels Overview

Panel Structure

Anodized aluminum composite panels have a clever design. They are strong but not heavy. The outside has two thin sheets of anodized aluminum. In the middle, there is a solid core. This core uses mineral fillers and a thermoplastic binder. The core helps keep the panel light and tough. The aluminum sheets are about 0.50 mm thick. These panels are easy to move and put in place. They can handle bad weather and daily use.

The outer layers are two sheets of anodized aluminum.

The inside core has mineral fillers and a thermoplastic binder.

This design makes the panel light and strong.

You can use these panels for outside walls, soffits, or inside walls.

This design mixes the good parts of metal and plastic. The anodized surface keeps the panels safe from scratches and rust. You also get a smooth, modern look that stays nice for a long time.

Composite vs. Solid Aluminum

If you compare anodized aluminum composite panels to solid aluminum sheets, you see some clear differences. Solid aluminum uses more metal. This makes it heavier and costs more money. Anodized aluminum composite panels use less aluminum. They are cheaper and easier to use. You still get strong panels, but you do not pay extra for heavy metal.

Panel Type | Cost Implication |

|---|---|

Aluminum Composite Panels | |

Solid Aluminum Sheets | Cost more because they use more aluminum. |

Anodized aluminum composite panels give you more choices for design. The anodized finish comes in many colors and textures. You can pick panels that fit your style. The light weight makes them quick and safe to install. You save time and money. You also get panels that last and look good.

Tip: If you want panels that are light, strong, and look nice, anodized aluminum composite panels are a smart pick for any building job.

Anodizing Aluminium Composite Panel Process

What Is Anodizing

You may wonder how these panels get their strong finish. The answer is the anodizing process. This uses electricity and acid to change the surface. The new layer is much harder than normal aluminum. Here is how the process goes:

Cleaning – First, you wash the panels to get rid of dirt.

Etching – Next, you smooth out tiny marks on the surface.

Anodizing – Then, you put the panels in an acid bath and use electricity. This step makes a thick, tough oxide layer on the anodized aluminium.

Dye (optional) – If you want color, you add dye now.

Sealing – Last, you seal the surface to keep in the color and make it stronger.

A chemical reaction happens during anodizing. The process uses an acid solution, often sulfuric acid. Electricity flows through the solution. The aluminum is the anode. Oxygen forms at the surface and builds the oxide layer. You can see the main reactions in this table:

Step/Reaction | Description |

|---|---|

Electrolysis | Electricity moves through acid and forms aluminum oxide on the panel. |

Hydrogen Release | Hydrogen gas forms at the cathode. |

Oxygen Release | Oxygen forms at the anode and builds the oxide layer. |

Benefits of the Oxide Layer

The oxide layer gives many benefits to these panels. At first, the layer is thick and has tiny holes, so it can take in dye for color. After sealing, it gets very hard and smooth. The panels resist rust, fire, scratches, and fading. The oxide layer also stops pitting and weather damage.

You get better fire and scratch resistance because the oxide layer is harder than paint.

The panels last longer in both wet and dry places.

The sealed surface keeps the color bright and the panel looking new.

The thickness of the oxide layer is important. Thicker layers protect better against rust and damage. For example, a layer between 1.6 and 6.0 micrometers can protect panels for over 1,000 hours in tough conditions.

When you pick anodized aluminum composite panels, you get strong panels, color choices, and easy care. The anodized aluminium finish helps your aluminium composite panel project last longer and look great.

Key Features of Anodized Aluminium Composite Panels

Corrosion and Scratch Resistance

Corrosion and Scratch Resistance

You want building materials that last a long time. Anodized aluminum composite panels protect well against rust and scratches. The anodized layer makes a tough shield on the outside. This shield does not peel or break off. The panels can handle rain, wet air, and dirty city air. The thick oxide film on anodized aluminium is stronger than on regular panels. Coatings stick better to this surface, giving extra protection.

The anodized layer has two parts. One part is thick and has tiny holes. The other part is thin and blocks water and chemicals. These two parts work together to keep out moisture and chemicals.

The surface stays smooth and does not scratch easily.

You see less rust and fewer marks, even in rough places.

When you pick anodized aluminum composite panels, you spend less on repairs. You also avoid problems like color fading and small holes. These panels are a good choice for buildings near the sea or in busy cities.

Durability and Low Maintenance

You want panels that last many years with little work. Anodized aluminum composite panels are strong for a long time. The anodized finish keeps the surface safe from weather and sun. This means the panels do not lose color or break down fast. Most panels last about 10 years outside. If you choose panels with good PVDF coatings, they can last 15 to 20 years or more.

The panels keep their color and strength for a long time.

You do not need to paint or fix them often.

Cleaning is easy. You just need soap and water.

The panels are light, so you can move and install them easily. This saves time and money when building. The panels also resist fire and hard hits, making your building safer.

Tip: If you want something light and strong, anodized aluminum composite panels are great for new buildings or fixing old ones.

Aesthetic Versatility

You can make cool designs with anodized aluminum composite panels. These panels come in many colors and finishes. You can pick shiny metal looks, wood styles, or bright modern colors. The anodized aluminium keeps its color well and does not fade fast. The natural oxide layer helps the color stay bright, even after years outside.

Color Series | Available Colors |

|---|---|

PVDF/Kynar 500® | Bone White, Ascot White, Sandstone, Almond, Bright Silver (Metallic), Dove Grey, Champagne (Metallic), Battleship Grey, Charcoal Grey, Black, Sunset Red (SMP Finish), and more. |

Natural Series | Clear Matte, Extra Dark Bronze |

Designer Series | Weathered Wood, Warm Cherry, Honey Oak, Dark Walnut, Copper Brown |

Matte Series | Matte Ash Grey, Matte Black |

Polyester | Polar White, Antique White, Silver Metallic, Raven Black, and more. |

You can also get clear anodized, dark bronze anodized, and black anodized finishes. Some finishes may take longer to get, but you have more choices for your project. The panels keep their color longer than painted panels. Anodized aluminum composite panels fade less, so your building looks new for years.

Panel Type | Color Retention Characteristics | Lifespan in Color Consistency |

|---|---|---|

Anodized Aluminum | Noted for durability and resistance to fading. | Longer lifespan |

Painted Panels | May have a shorter lifespan in color consistency. | Shorter lifespan |

You can use these panels for modern outside walls, creative rooms, or signs that stand out. The design options help you make your ideas real.

Eco-Friendliness

You care about the earth. Anodized aluminum composite panels help you build green. The panels use less aluminum than solid sheets, so they save resources. The anodizing process does not add bad chemicals to the surface. The panels can be recycled when you are done with them.

The light panels use less energy to move and cost less to ship.

You use fewer materials, so you make less pollution.

The panels last longer, so you do not replace them often.

Anodized aluminium stands up to weather and sun, so you throw away fewer broken panels. You help the planet and still get strong, modern materials.

Note: When you pick anodizing aluminium composite panel technology, you get strong, pretty, and earth-friendly panels all in one.

How These Key Features Benefit Your Projects

When you use anodized aluminum composite panels, you get many good things. These include rust resistance, long life, light weight, easy care, earth-friendliness, and lots of design choices. These features make your projects better. You save time and money, make nice spaces, and help the environment. Whether you build an office, a school, or a store, these panels help you reach your goals.

Applications of Aluminum Composite Panels

Aluminum composite panels are used in many buildings today. You see them on tall towers, inside malls, and on signs outside. Anodized aluminum composite panels have special features. These features make them a smart choice for lots of projects. Let’s look at how people use them and why you might pick anodized aluminium.

Aluminum composite panels are used in many buildings today. You see them on tall towers, inside malls, and on signs outside. Anodized aluminum composite panels have special features. These features make them a smart choice for lots of projects. Let’s look at how people use them and why you might pick anodized aluminium.

Architectural Facades

Anodized aluminum composite panels are often used on building outsides. These panels work well for ventilated facades. Ventilated facades help keep buildings cool and quiet. The panels help with heat and sound insulation. This can lower energy use by more than 30%. The anodized layer protects the panels from weather. It also keeps buildings looking new for years.

Application Type | Description |

|---|---|

Ventilated facades | Help with heat and sound insulation, lowering energy use by over 30%. |

Renovations and refurbishments | Good for fixing old buildings, light, and easy to put in without big changes. |

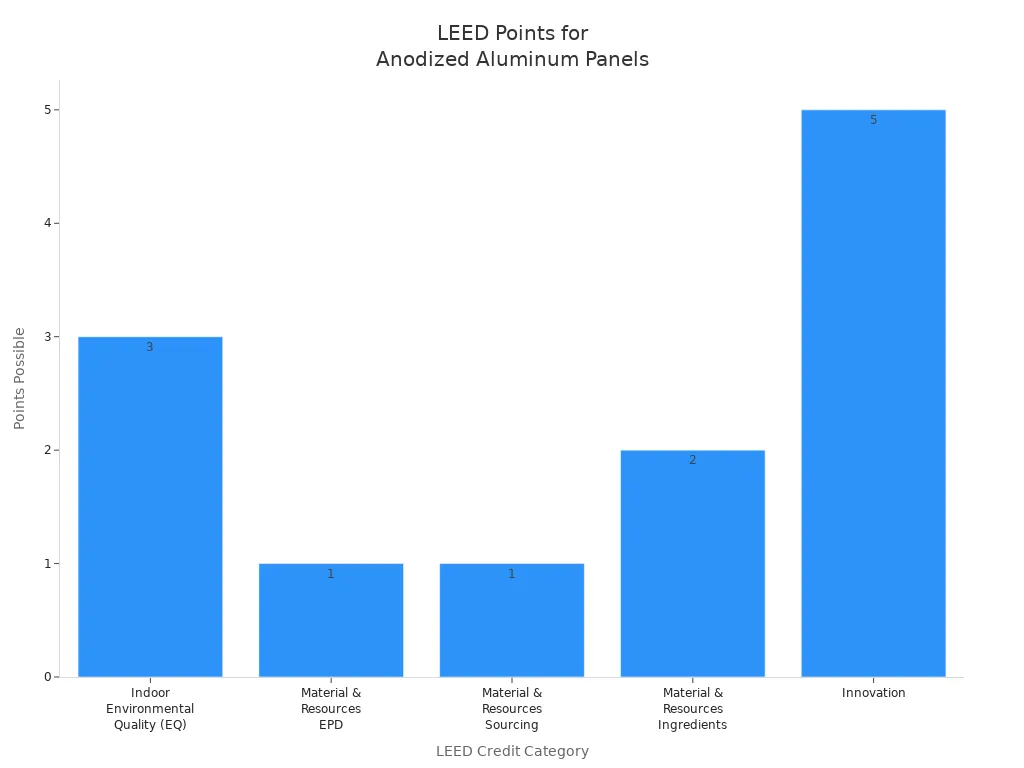

Using anodized aluminium helps the environment. The panels can be recycled. They can help your building get LEED points. The panels do not give off bad chemicals. They also reflect sunlight. This keeps buildings cooler when it is hot outside.

Tip: Using anodized aluminium for facades can lower your energy bills. It also makes your building better for the planet.

Interior Design

You can use aluminum composite panels inside buildings. They work for walls, ceilings, and room dividers. Anodized aluminum composite panels come in many colors and finishes. You can make rooms look modern, bright, or cozy. The panels do not scratch or stain easily. They stay nice with just a little cleaning.

Advantage | Description |

|---|---|

Durability | Hard to scratch or rust, so they last a long time. |

Aesthetic Appeal | Many colors and patterns, making rooms look better. |

Low Maintenance | The anodized layer does not fade and needs little care. |

Versatility | Good for walls, ceilings, and other uses inside. |

Lightweight | Easy to carry and put in, great for new buildings. |

Insulation | Helps keep rooms warm and quiet. |

Fire Resistance | Some panels meet fire safety rules. |

You can design rooms in many ways with anodized aluminium. The panels are light, so you can install them fast. They also help rooms stay comfortable by blocking noise and keeping heat in.

Signage and Branding

Anodized aluminum composite panels are great for signs and logos. You see them on banners, shop signs, and company names. The panels show bright colors that last a long time. They do not get ruined by rain, sun, or dirt. Your signs stay clear and easy to read.

Application Type | Description |

|---|---|

Advertising and signage support | Good for banners and signs because they last and look bright. |

Interior and decorative cladding | Used for walls and ceilings, with lots of choices for looks. |

You can cut and shape the panels for any sign. Using anodized aluminium for signs helps your brand stand out. The panels are easy to recycle. This is good for green businesses.

Note: If you pick anodizing aluminium composite panel technology, you get panels for facades, rooms, and signs. You also save energy and help the earth.

You get lots of good things with anodized aluminum composite panels. New features include nano-sealing, which helps stop stains. Digital printing lets you make cool designs. The panels now have safer cores that slow down fire. Builders like anodized aluminium because it does not scratch easily. It is simple to clean and easy to put in place. These panels help the environment by using recycled stuff and safe coatings. More people want anodized panels now. This shows they are important for new and green buildings.

If you want panels that last, look nice, and need little care, anodized aluminium is a smart pick.

Sustainability Feature | Benefit |

|---|---|

Recycled materials | Less waste, saves resources |

Energy efficiency | Lowers energy use, supports green buildings |

FAQ

What makes anodized aluminum composite panels different from painted panels?

Anodized panels have a tougher surface than painted ones. The anodized layer sticks right to the aluminum. Painted panels have a layer that can peel or chip off. Anodized panels do not scratch or fade as easily.

Can you recycle anodized aluminum composite panels?

Yes, you can recycle these panels. The aluminum and the core come apart easily. Recycling saves resources and cuts down on waste. Many builders pick these panels for green building projects.

How do you clean anodized aluminum composite panels?

You just need mild soap and water to clean them. Use a soft cloth or a sponge. Do not use strong chemicals or rough scrubbers. Cleaning them often keeps the panels looking nice.

Tip: Clean your panels every few months to keep them looking good.

Where can you use anodized aluminum composite panels?

You can use these panels for outside walls, inside walls, ceilings, and signs. They work well both indoors and outdoors. The panels are light and strong, so you can put them in many places.

Corrosion and Scratch Resistance

Corrosion and Scratch Resistance