29 Aug How to Figure Out ACP Curtain Wall Installation Costs per Square Meter

Table of Contents

You can expect the cost of installing an ACP curtain wall to range from $45 to $150 per square meter. The price can vary depending on the system you choose, the quality of materials, and labor rates. The complexity of the project can also affect the cost of installing the curtain wall. When creating your budget, always consider local prices and material options to get the most accurate estimate.

Key Takeaways

ACP curtain wall installation costs can be $45 to $150 for each square meter. The price changes because of materials, labor, and how hard the project is. – Panels that are better quality and special systems cost more money. But they last longer, are safer in fires, and save energy. – Labor costs go up if the design is hard, the building is tall, or workers need special skills. Simple designs and panels that are already made can help lower the cost. – Always check if the price includes materials, labor, shipping, and extra fees. This helps you avoid surprise costs and keeps your budget safe. – Plan early, ask for clear quotes, and think about buying lots of materials at once or using modular systems. This can help you save money and finish the work faster.

Cost of Installing ACP Curtain Walls

Price Range per Square Meter

The cost to install ACP curtain walls can be very different. Most jobs cost between $45 and $150 for each square meter. If you want to know the price for each square foot, it is usually $25 to $45 for ACP systems. Buying panels in bulk is cheaper, but this does not pay for labor or other costs.

The price to install ACP curtain walls depends on the system you pick. Here is how the price can change:

Standard ACP systems use basic polyethylene (PE) core panels. These panels are simple to put in and cost less money. You will find these systems at the lower end of the price range.

Premium ACP systems have extra features. These can be fire-retardant cores, thicker panels, or special coatings. These upgrades make the panels safer and last longer, but they also make the cost higher.

The price also changes if the system is hard to install, if workers are very skilled, or if your site is tricky.

Tip: Always ask your supplier if the price covers both materials and labor. Some prices only include the panels, not the full cost to install the curtain wall.

What’s Included in the Cost

When you get a price for ACP curtain wall installation, you should know what is included. Most prices cover these main things:

Materials: This means the ACP panels, framing, and basic fasteners.

Labor: The pay for workers who put in the panels and framing.

Design and Engineering: Some suppliers add basic design and engineering in the price.

Standard Accessories: Things like sealants, gaskets, and brackets may be included.

But some important things might not be in the first price:

Usually Included | Sometimes Extra |

|---|---|

ACP panels | Shipping and delivery |

Framing and fasteners | Site preparation |

Labor | Scaffolding or lifts |

Basic design/engineering | Special accessories |

You should always check your price to see if it covers shipping, site work, or special accessories. These extra things can make the total cost of your ACP curtain wall much higher.

Note: Premium systems with advanced features cost more because they need special materials and more skilled workers.

Cost Factors

Material and Panel Quality

The quality of ACP panels changes the cost a lot. Good panels use better materials and special coatings. These things make the price go up. You get better weather protection and longer life. You also need to fix them less often. Cheap panels cost less at first. But you might pay more later for repairs. Some makers use thin aluminum or skip coatings. This makes panels cheaper but not as strong.

Premium panels give:

Fire resistance

Energy savings

Less noise

Keep water out

Easy to shape

Lower quality panels:

Cost less at first

Need more fixing

Can rust or break fast

The brand and finish change the price too. Famous brands and special coatings cost more. They last longer and look nicer. Check if panels meet standards. For example, two layers of 0.5 mm aluminum with fluorocarbon coating.

Here is a table that shows material grades and how they change cost:

Material Grade | Features | Typical Use | Cost Impact |

|---|---|---|---|

Ordinary (LDPE core) | Basic strength, low fire resistance | Indoor, signs | Lowest |

Unidirectional (GFRP) | Higher strength, better fire resistance | Exterior, high-rise | Moderate |

Bidirectional (GFRP woven) | Top strength, best fire resistance | High safety, exterior cladding | Highest |

Labor and Complexity

Labor costs go up if your project is hard. Tall buildings need more workers and tools. If your wall has curves or special shapes, you pay more. Skilled workers cost more money. Stick-built systems take longer to put up. This makes labor cost higher. Unitized systems are faster but need careful work in the factory.

Hard designs need more time and skill.

Custom shapes need extra planning.

Safety rules for wind or fire add work.

Tip: Simple designs and ready-made panels can lower labor costs.

Accessories and Framing

Accessories and framing are key parts of the system. You need brackets, sealants, gaskets, and fasteners. The kind and quality of these change the price. Strong frames like stainless steel or copper cost more. They last longer. Most jobs use light, fire-safe metal frames. These are cheaper and easy to put in.

Aluminum frames are common and save money.

Special accessories or custom brackets add to the price.

Regional Differences

Where you build changes the cost. Labor costs are higher in big cities. Materials cost more if you ship them far. Local rules may need special panels. These cost more. Some places have more skilled workers. This can make work faster and cheaper.

Note: Always check local prices and rules before you start. This helps you keep your budget safe.

Cost Calculation

Calculation Steps

You can estimate the cost of installing ACP curtain walls by following a few easy steps. Start by measuring the total area you want to cover. Next, choose the type of ACP system and panel quality. Ask your supplier for the price per square meter, including labor and materials. Add the cost for accessories and framing. Check if you need to pay extra for shipping or site preparation.

Here is a simple formula you can use:

Total Cost = (Area in sq. meters) × (Price per sq. meter) + Extra Costs

Tip: Always ask for a detailed quote. This helps you see what is included and what you need to add.

Calculation Example

Suppose you want to install ACP curtain walls on a building with 100 square meters of surface. The supplier gives you a price of $80 per square meter. You also need to pay $1,500 for shipping and $2,000 for site preparation.

Let’s calculate:

Area: 100 sq. meters

Price per sq. meter: $80

Extra costs: $1,500 (shipping) + $2,000 (site prep) = $3,500

Total Cost = (100 × $80) + $3,500 = $8,000 + $3,500 = $11,500

So, the cost of installing ACP curtain walls for this project is $11,500.

Extra Costs

You may face extra costs that are not in the first quote. These can include:

Shipping and delivery fees

Site preparation (cleaning, scaffolding, safety setup)

Special accessories (custom brackets, advanced sealants)

Permit fees or inspection charges

Waste removal after installation

Extra Cost Type | Typical Range |

|---|---|

Shipping | $500 – $2,000 |

Site Preparation | $1,000 – $5,000 |

Accessories | $200 – $1,000 |

Permits/Inspection | $100 – $500 |

Note: Always check for hidden costs before you start your project. This helps you avoid surprises and keeps your budget safe.

Price Reference

Sample Price Table

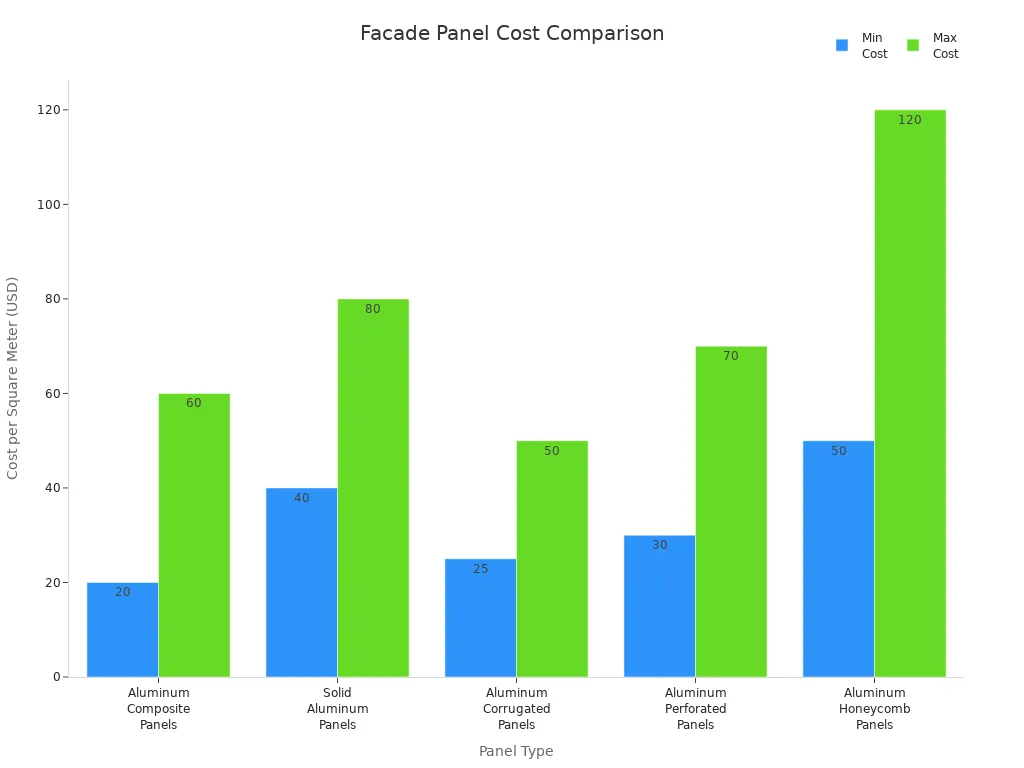

You may want to know how ACP curtain wall prices compare to other facade systems. The table below shows different panel types, their prices, and what they are used for.

Panel Type | Cost Range (per sq. meter) | Advantages | Typical Applications |

|---|---|---|---|

Aluminum Composite Panels | $20 – $60 | Lightweight, versatile, cost-effective | High-rise buildings, commercial facades |

Solid Aluminum Panels | $40 – $80 | Strong, durable, customizable | High-impact areas, canopies |

Aluminum Corrugated Panels | $25 – $50 | Affordable, strong, good insulation | Industrial buildings, warehouses |

Aluminum Perforated Panels | $30 – $70 | Allows light and air, customizable | Facades, sunscreens, partitions |

Aluminum Honeycomb Panels | $50 – $120 | Excellent insulation, lightweight | High-performance applications |

📝 Tip: ACP panels usually cost less than solid aluminum or honeycomb panels. ACPs give you a good mix of price and performance.

Quick Comparison

ACP curtain walls have a lower starting price than most other aluminum facade panels. ACPs are flexible for design and easy to put in. This is why many builders pick them for projects.

Here is a simple chart that shows the lowest and highest costs for each panel type:

ACP panels start at only $20 per square meter.

Solid aluminum panels and honeycomb panels cost more but are stronger or insulate better.

Corrugated and perforated panels are priced in the middle.

If you want something affordable that looks modern, ACP curtain walls are a smart choice. Always pick the panel that fits your project and budget.

Cost-Saving Tips

Getting Accurate Quotes

You can save money if you get good quotes for your ACP curtain wall project. First, tell the supplier what you want and what your design looks like. When you talk to suppliers or builders, give them your plans and details. This helps them know what you need.

Give your building drawings, project plans, and what materials you want.

Say which curtain wall system you want, like stick, unitized, or ladder.

Pick workers who know how to work with ACP curtain walls.

Use websites or services that give free and correct price estimates.

Make sure your papers have sizes, materials, how to put it together, and what the system needs.

📝 Tip: If you give more details, your quote will be more exact. Talking clearly helps you stop hidden costs and delays.

Ask for a list of what is in the quote. This helps you compare prices and know the real cost to put in your curtain wall.

Reducing Costs

You can spend less on ACP curtain wall installation by planning smart. Many builders use light aluminum. This means you do not need heavy supports and you pay less to build. Using ready-made and modular systems helps too. They make the job faster and cut labor costs.

Buy lots of materials at once to get lower prices and save on shipping.

Use value engineering to build better without losing quality.

Pick suppliers with good supply chains and machines that make things fast. This can save money and make better products.

Choose strong materials that do not need much fixing later.

💡 Note: Using ready-made parts and modular systems helps you finish faster and waste less.

If you plan early and work with skilled people, you can keep your project on budget and get the most for your money.

ACP curtain wall installation costs about $25 to $45 per square foot. This is what the newest industry numbers show. Your final price can change for many reasons. Material quality, labor, and project size all matter. Use the steps and tips in this guide to guess your own cost. Always get a few quotes from different suppliers. Check what each quote covers. This helps you plan your budget and stops any surprises.

FAQ

How do you know if the quoted price includes labor?

Always ask your supplier for a detailed breakdown. Look for a line that says “labor” or “installation.” If you do not see it, the price may only cover materials.

Can you install ACP curtain walls in cold weather?

You can install ACP curtain walls in cold weather. Workers may need special sealants and extra safety steps. Cold temperatures can slow down the work.

What is the cheapest ACP panel type for curtain walls?

Cost Range (per sq. meter) | |

|---|---|

Standard PE Core | $20 – $35 |

Fire-Retardant | $35 – $60 |

Standard PE core panels cost the least. You can use them for basic projects.

Ask for a full quote with all details.

Check if shipping, site prep, and accessories are listed.

Compare quotes from different suppliers.

Do ACP curtain walls need much maintenance?

ACP curtain walls need little maintenance. You should clean panels once or twice a year. Check for loose fasteners and sealant cracks. This keeps your wall looking good and working well.