01 Aug How to Cut Aluminum Composite Panels Safely and Precisely

Table of Contents

To ensure safe and accurate cutting aluminium composite panels, it’s important to choose the right tools. Always wear safety gear and protect the panel’s surface during the process. These panels are widely used in various projects, including building facades, retail stores, upscale homes, and signage. They are popular because they are durable and have a clean appearance. When cutting aluminium, be sure to leave the protective film on the finished side to prevent scratches or damage.

Key Takeaways

Pick the best tool for your cut. Use a circular saw for straight lines. Use a jigsaw for curves. This helps you get clean and exact cuts.

Always wear safety gear like gloves, goggles, and a dust mask. This keeps you safe from sharp edges, dust, and loud sounds.

Leave the protective film on the finished side while cutting. This stops scratches and damage from happening.

Hold the panel tight with clamps on a steady surface. This keeps it from moving and helps you cut safely and correctly.

Make the edges smooth after cutting with files and sandpaper. This makes your work look nice and helps the panels last longer.

Cutting Aluminium: Tools and Methods

When you cut aluminium composite panels, you can pick from many tools. Each tool is good for certain cuts. Some tools are safer or more exact than others. The table below shows a quick guide:

Tool Type | Best For | Precision | Safety Tips |

|---|---|---|---|

Circular Saw | Straight cuts | High | Use fine-toothed blade, wear eye protection |

Jigsaw | Curves, angles | Moderate | Clamp panel, use metal-cutting blade |

Router/CNC | Complex shapes, edges | Very High | Secure panel, use dust extraction |

Utility Knife | Thin panels, scoring | Moderate | Score gently, avoid too much pressure |

Panel Saw/Shear | Fast straight cuts | High (panel saw), Moderate (shear) | Use guards, clamp panel, check blade type |

Tip: Keep the protective film on the finished side. This stops scratches when cutting aluminium.

Circular Saw

A circular saw is fast and makes straight cuts. Use a carbide-tipped blade with 60–80 teeth for smooth cuts. Hold the panel tight before cutting aluminium so it does not move. Keep your hands away from the blade. Wear safety glasses. After you cut, file the edges to make them smooth.

Advantages: Fast, exact, works well for thick panels.

Disadvantages: Needs careful use and the right blade. Wrong use can make rough edges or bend the panel.

Jigsaw

A jigsaw is good for curves and small shapes. Pick a fine-toothed, bi-metal blade with at least 24 teeth per inch. Clamp the panel tight to stop shaking. Cut slowly and follow your line for best results.

Best for: Curved cuts and small shapes.

Tip: Put masking tape on the cut line to protect the surface.

Router & CNC Router

Routers and CNC routers help you cut complex shapes and get clean edges. CNC routers use computers for very exact and repeat cuts. Use solid carbide spiral bits or V-groove bits for different looks. Always hold the panel tight and use dust removal.

Handheld routers: Good for small jobs and more control.

CNC routers: Best for big projects and detailed work.

Utility Knife & Scoring

For thin panels, you can score and snap with a utility knife. Use gentle, repeated cuts instead of pushing hard. This works best for straight cuts on panels less than 4mm thick. Be careful—too much force can crack or break the edge.

Panel Saw & Shear

Panel saws and shears make fast, straight cuts. Panel saws give smoother edges. Shears are quick but may leave rough edges. Always use the right blade and clamp the panel near the cut.

Safety: Use guards and wear PPE to keep safe from flying pieces.

Picking the right tool and blade helps you get clean, exact cuts when cutting aluminium composite panels.

Preparation and Safety

Workspace Setup

Set up your workspace before you start. Choose a clean, dry area with good lighting. Remove any clutter from your workbench and floor. Keep your tools organized and within easy reach. Make sure you have a fire extinguisher nearby and clear exits in case of emergency. Place your panel on a stable, flat surface. Use clamps to hold the panel steady while you work. This helps prevent slips and keeps your hands safe.

Tip: Always check that your tools are in good condition before you begin. Dull blades or loose parts can cause accidents.

Personal Protective Equipment

Wear the right personal protective equipment every time you work with aluminum composite panels. This keeps you safe from sharp edges and flying debris. You should use:

Safety goggles to shield your eyes from dust and small pieces

A dust mask to keep you from breathing in fine particles

If you use power tools, consider wearing ear protection and fire-resistant clothing. These extra steps help protect you from loud noise and sparks.

Panel Handling

Handle panels with care to avoid damage and injury. Clean and dry the surface before you start. Plan your cuts and measure carefully to reduce mistakes and waste. Always use the right tool for the job, such as a circular saw or jigsaw with a fine-tooth blade. Cut slowly and follow your marked lines to avoid chipping the edges.

Keep the protective film on the finished side of the panel. This film helps prevent scratches during cutting. For extra surface protection, place the finished side face down when possible. Use rubber mallets if you need to move the panel, which helps prevent dents or marks. Always follow the manufacturer’s instructions for best results.

Step-by-Step Cutting Guide

Marking and Measuring

Marking and Measuring

Getting your marks and measurements right is very important. This helps your panels look neat and fit well. Here are some steps to follow:

Make sure the wall or surface is straight and even. This stops your panels from being crooked.

Use a plumb line or laser to draw straight up-and-down lines where panels meet.

Draw a base line for where you want to start. This keeps your panels even and straight.

Begin at a key spot, like a corner. Put your first panel a little past the plumb line at the lowest spot. This gives you a good starting point.

Keep adding panels along your lines. Check the gaps often.

Put shims between panels to keep the spaces the same.

Leave the protective film on while you mark and measure. This keeps the panels from getting scratched or changing color.

Take off the film only after you finish each part.

Tip: Use good tools like tape measures, levels, and chalk lines. Mark your lines with chalk or a thin marker for best results.

Cutting Process

There are many tools you can use to cut aluminium composite panels. Each tool has its own way to use it and safety steps. The table below shows how to use each tool and what to watch out for:

Cutting Tool | Step-by-Step Procedure | Key Safety Checks and Tips |

|---|---|---|

Jigsaw | – Use a jigsaw with a 24-toothed or higher blade for smooth, precise cuts. | – Check blade sharpness. |

Circular Saw | – Measure and plan cuts before starting. | – Wear safety goggles. |

Shearing Machine | – Adjust blade gap for panel thickness. | – Set correct blade gap. |

Cold Chisels | – Pick a chisel wider than the panel. | – Use proper sharpening angle. |

CNC Router | – Use lubricants for easier cutting. | – Keep workspace clean. |

Laser Cutting | – Use fiber laser for reflective aluminum. | – No residue means high quality. |

Drilling Holes | – Use power tools with HSS bits for clean holes. | – Pick the right drill bit. |

Note: Always wear gloves, goggles, and a dust mask when cutting aluminium composite panels. Clamp your panel tightly so it does not move.

Tips for Chip Removal and Blade Selection

Use sharp blades made from high-speed steel, carbide, or polycrystalline diamond. Sharp blades cut better and leave fewer rough spots.

Change your tool’s speed and how fast you move it. This helps you cut quickly but still get smooth edges.

Use cutting fluids or coolants to keep the panel cool and help chips move away.

Clean away chips often. This stops them from piling up and making rough edges.

For CNC routers, use climb milling or contour milling paths. These paths help make the edges smoother and reduce burrs.

Check your blades and bits before you use them. Replace any that are dull or broken.

Chipbreaker tooling breaks chips into smaller pieces. This makes it easier to clean up and helps your tools last longer.

Finishing Edges

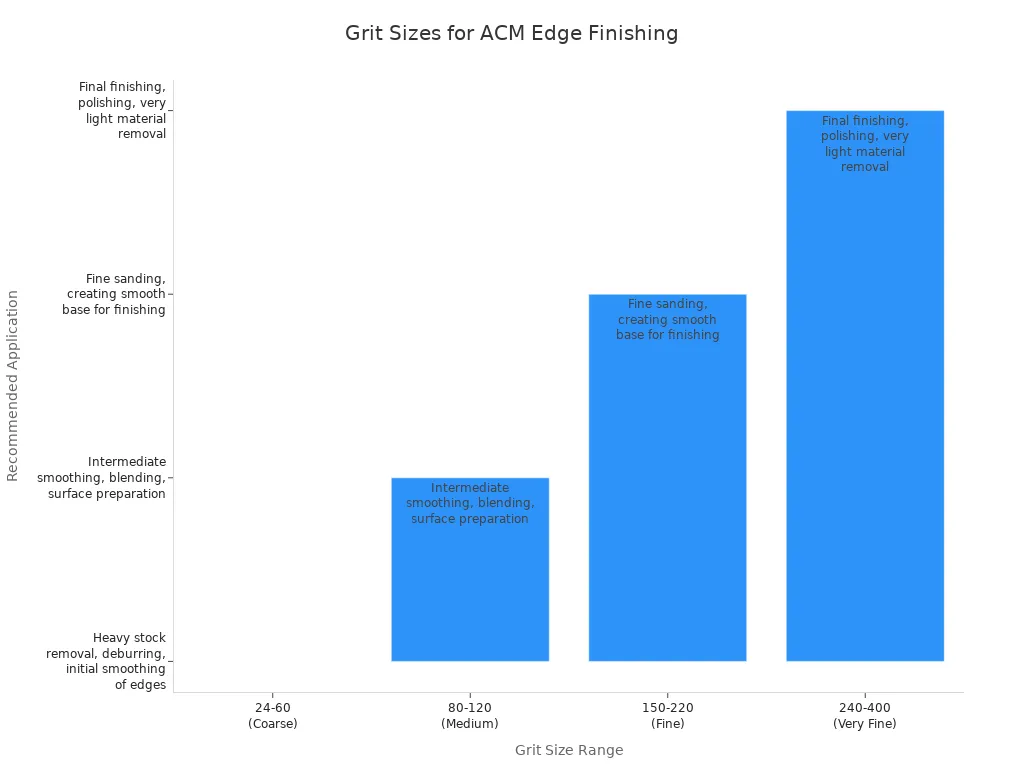

After you cut aluminium composite panels, you need to smooth the edges. This makes your work look neat and finished. Start by trimming rough spots with a file or rounded metal bar. Sand the edges with a sanding block and 120 grit sandpaper. For a smoother edge, use finer sandpaper.

Grit Size Range | Application for Aluminum Composite Panels (ACM) and Metals |

|---|---|

24-60 (Coarse) | Heavy stock removal, deburring, initial smoothing of edges |

80-120 (Medium) | Intermediate smoothing, blending, surface preparation |

150-220 (Fine) | Fine sanding, creating smooth base for finishing |

240-400 (Very Fine) | Final finishing, polishing, very light material removal |

Aluminum oxide abrasives are good for finishing edges. They stay sharp and do not get too hot. Ceramic grit sanding belts also work well for aluminium, especially if you want a cooler cut. For light sanding or sanding around curves, use non-woven surface conditioning belts.

You can also use snap-on trims, aluminum extrusions, or custom pieces to cover and protect the edges. Add edge sealants, paint, or special trims to keep out water and sun damage. These steps help your panels last longer and look nice.

Tip: Use a fine-tooth blade (60-80 teeth) when cutting aluminium composite panels. This helps stop rough edges and makes finishing easier.

Troubleshooting and Tips

Common Mistakes

When you cut aluminum composite panels, mistakes can happen. Knowing these mistakes helps you do a better job.

If you use the wrong speed, the edges can get rough or damaged.

Cutting too deep or too shallow can make the panel warp or look bad.

If you do not hold the panel tight, it can shake or bend.

Dull or wrong blades can make aluminum stick to the tool and cause uneven cuts.

If you do not take care of your tools, they can break and cut badly.

If you remove the protective film too soon, the panel can get scratched or change color.

If you do not fix the panel right, it might come loose or fall.

Tip: Always check your setup before you cut. Hold the panel tight, use sharp blades, and pick the right speed for your tool.

Pro Tips for Precision

You can make clean and exact cuts if you follow these tips:

Use special cutting machines, not just hand tools. This makes your cuts safer and more exact.

Pick cutters that cut and finish at the same time. This saves time and gives smooth edges.

Use dust-free tools to keep your air clean and protect your health.

Choose machines that are easy to line up and clamp. This helps you make straight cuts every time.

Use cutting heads that stop the panel from bending. This keeps your panels flat for printing or mounting.

Try cutters that are easy to hold and slide. These help you cut many panels without getting tired.

For big jobs, use machines that can cut large panels. This helps you work faster and save money.

If you need to cut different shapes or materials, use machines that can do v-grooving or cut steel composite panels.

Note: For smooth edges, use jigsaws with lots of teeth or sharp cold chisels for thick panels. Always hold your panel tight before you cut aluminum composite panels.

You can cut aluminum composite panels safely and neatly by following some steps.

Pick the best tool for your job, like a circular saw, electric shears, or tin snips.

Put on safety goggles, gloves, and a mask to stay safe.

Hold the panel tight and keep the protective film on the finished side.

Smooth the edges and add waterproofing so your panels last longer.

Look at the troubleshooting tips before you begin to help you avoid mistakes.

FAQ

What is the best blade for cutting aluminum composite panels?

You should use a fine-toothed carbide blade with 60–80 teeth. This blade gives you smooth, clean cuts and helps prevent chipping. Always check that your blade is sharp before you start.

Can you cut aluminum composite panels with a utility knife?

Yes, you can score and snap thin panels (up to 4mm) with a utility knife. Make several gentle passes along your marked line. Do not use too much force. This method works best for straight cuts.

How do you prevent scratches on the panel surface?

Keep the protective film on the finished side while you cut. Place the finished side face down if possible. Use masking tape along the cut line for extra protection.

What safety gear should you wear when cutting?

You need gloves, safety goggles, and a dust mask. If you use power tools, add ear protection. These items protect you from sharp edges, dust, and loud noise.

How do you get smooth edges after cutting?

Use a metal file or sanding block to remove rough spots.

Start with medium-grit sandpaper, then switch to fine-grit for a polished finish.

Wipe away dust before installing the panel.

Marking and Measuring

Marking and Measuring