23 Dec The Difference Between ACP and ACM Panels

Table of Contents

You might wonder about the difference between ACP and ACM panels. ACP, which stands for Aluminum Composite Panel, features a core made of polyethylene. On the other hand, ACM, or Aluminum Composite Material, encompasses a broader range of panel types and can have various cores and applications. Understanding the difference between ACP and ACM is crucial for selecting the appropriate panel for your needs. Builders consider factors such as weight, strength, insulation, and price when making their decisions.

The global ACP market was valued at approximately USD 7,188.4 million in 2023, with the building industry utilizing more than half of these panels.

Fire retardant ACPs accounted for 68.5% of the market, highlighting their significance in safety-related projects.

By learning these details, you can make more informed choices for your building projects.

Key Takeaways

ACP panels are light and not expensive. They work well for easy building jobs. ACM panels are safer in fires because of their special cores. They are good for tall buildings. Both types of panels keep heat and cold out. This helps rooms stay comfy all year. Think about what your project needs before you pick a panel. You should also check safety rules and the weather. Cleaning the panels gently can help them last longer. Both ACP and ACM panels need this care.

Difference Between ACP and ACM

ACP Overview

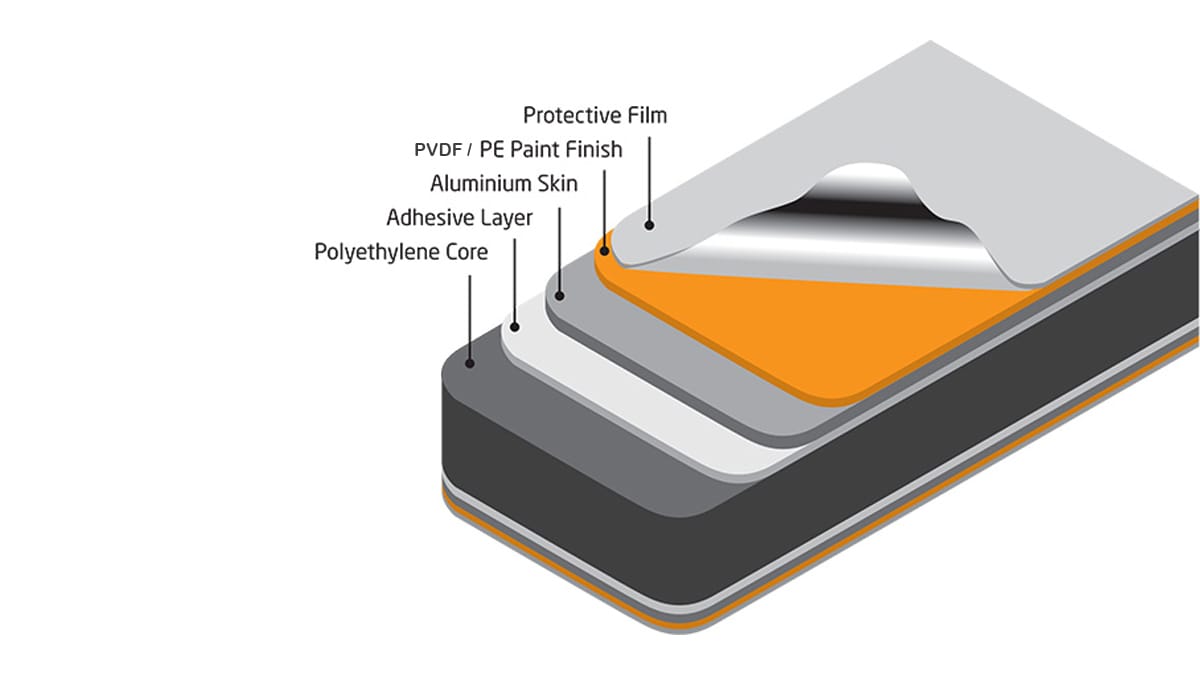

When you look at building materials, you will see ACP panels in many places. ACP means Aluminum Composite Panel. These panels have two thin aluminum sheets on the outside. The middle part is made from polyethylene or sometimes a mineral-filled material. The aluminum makes up about 30% to 50% of the panel’s weight. The core makes up the rest of the weight. ACP panels are light, strong, and easy to use. They help keep buildings warm in winter and cool in summer. The core works as a thermal insulator. ACP panels do not rust or get damaged by weather. This means they last a long time outside. You can pick from many colors and finishes. This lets you make your building look special.

Some common uses for ACP panels are:

False ceilings

Soundproofing

Signage

Furniture

Exterior curtain walls

Cladding or facades

Building column covers and wraps

Walls of parapets and roof edges

Dado panels

You will see ACP panels used inside and outside buildings. They are good when you want something light and not too expensive.

ACM Overview

ACM stands for Aluminum Composite Material. This name covers more types of panels, including ACP. ACM panels also have two aluminum sheets with a core in the middle. The core is often made from fire-resistant minerals. This makes ACM panels safer for tall buildings and places where fire safety is important. You will see ACM panels in business buildings, homes, and for decoration inside.

ACM panels have many good points:

Light and simple to put up

Strong and can handle bad weather, rust, and sun

Many colors and finishes for different looks

Easy to clean and take care of

Fire-resistant choices for extra safety

Here is a table that shows the main things about ACM panels:

Characteristic | Description |

|---|---|

Material Composition | Two aluminum sheets joined to a fire-resistant mineral core |

Durability | Handles very hot and cold weather, dirt, and hits |

Fire Resistance | Slows down fire and stops heat from moving through |

Aesthetic Appeal | Comes in lots of finishes and colors |

Low Maintenance | Only needs simple cleaning |

Lightweight | Easy to move and install |

You will find that ACM panels are often picked first by architects who want safety and style.

Key Distinctions

You might wonder what really makes ACP and ACM different. The main difference is the core material and how well it stops fire. ACP panels usually have a polyethylene core. This core is lighter and costs less but can catch fire. ACM panels often use a mineral-filled core. This core does not burn easily and meets higher safety rules.

Here is a table to help you see the difference between ACP and ACM:

Aspect | ACP | ACM |

|---|---|---|

Core Material | Polyethylene (PE) | Fire-resistant minerals |

Fire Resistance | Lower (flammable) | Higher (fire-resistant) |

Weight | Lighter | Slightly heavier |

Cost | Less expensive | More expensive |

Application Scenarios | Interiors, low-rise | High-rises, high-risk areas |

You will also see people use these words in different ways. ACP means a panel with a polyethylene core. ACM is a bigger group that includes all aluminum composite panels, especially those with fire-resistant cores.

Some important things to remember about the difference between ACP and ACM:

ACP panels are light and strong, so they work well for many building jobs.

They help save energy by keeping buildings comfy in all seasons.

ACM panels give the same good things but are better where fire safety is needed.

Some countries do not allow ACP panels with polyethylene cores because of fire rules.

ACM panels are usually allowed in more places because they resist fire.

Tip: When you pick between ACP and ACM, always think about where you will use them and what safety rules you must follow.

By knowing the difference between ACP and ACM, you can make better choices for your building. You will know which panel is best for safety, price, and design.

Composition and Structure

Core Materials

Core Materials

The core inside each panel is very important. ACP panels usually have a polyethylene core. ACM panels often use a fire-retardant mineral core like ATH or MDH. The core changes how the panel acts in a fire. It also affects how safe your building will be.

Some ACP panels use a special core to stop fires.

These panels are made like sandwich panels.

The core helps the panel resist fire much better.

A2 fire retardant ACM panels use materials that do not burn. These panels do not catch fire easily and are hard to burn. You can trust them to keep your building safe from fire and heat. The table below shows how the core changes fire safety:

Panel Type | Core Material | Fire Resistance Features |

|---|---|---|

ACM Panels | Fire-retardant core (ATH or MDH) | Makes the panel safer, meets NFPA 285 rules |

ACP Panels | Fire-retardant core | Helps stop fire from spreading |

Aluminum Layers

Both ACP and ACM panels have two thin aluminum sheets on the outside. The thickness of these sheets depends on where you use the panel. Thicker aluminum gives more strength and keeps things safer.

Aluminum sheet thickness choices: 0.1mm, 0.12mm, 0.15mm, 0.2mm, 0.3mm, 0.4mm, 0.5mm.

The table below shows the usual thickness for different uses:

Application Type | Minimum Aluminum Thickness | Total Panel Thickness |

|---|---|---|

Exterior Wall Decoration | 0.2mm | > 4mm |

Indoor Panels | 0.1mm | ~ 3mm |

Curtain Wall Panels | 0.5mm | > 4mm |

You can pick the right thickness for your job. Thicker aluminum is best for outside walls and curtain walls. Thinner aluminum works well for inside panels.

Weight Differences

ACP and ACM panels are much lighter than old building materials. Their light weight makes them easy to move and put up. You can lower the weight on your building and save time when you build.

ACP | Traditional Materials | |

|---|---|---|

Weight | Low | High |

Handling | Easy | Hard |

Structural Load | Less | More |

Light panels help you work faster and spend less money. You can use smaller supports because the panels do not weigh much. The main difference between ACP and ACM panels is the core, which can change the weight and safety.

Tip: Always check the weight and thickness before you pick a panel. This helps you find the best panel for your building.

Appearance and Customization

Surface Finishes

There are many surface finishes you can pick for ACP or ACM panels. These panels usually come ready to use, so you do not need to paint them. This saves time and makes your project look the same everywhere. The surfaces can have bright colors and smooth lines. This helps your building get noticed. You can choose finishes that look like metal, woodgrain, or stone. These finishes are not just for looks. They also help protect the panels from weather and damage. Special coatings keep the panels strong and help them last longer, even when it is tough outside.

Color Options

You get lots of color choices with both ACP and ACM panels. ACP panels come in more than 50 colors, patterns, and finishes. You can find shiny metallics, bright colors, or textured styles. ACM panels also have many standard and custom colors. If you want a special color, you can ask for it, but it might cost more. The table below shows some choices you get with ACM panels:

Feature | ACM Panels |

|---|---|

Standard Colors | Primary colors, metallics, matte shades |

Custom Colors | Bespoke service to match specific shades |

Finish Options | Gloss, matte, metallic, wood-like |

Texture Customization | Tailored to specific design requirements |

Note: Custom colors usually cost 10-30% more than regular ones, but they help you match your brand or design.

Design Flexibility

You can use ACP and ACM panels to make almost any look you want. These panels can look like wood, metal, marble, or granite. You can bend, cut, and shape ACP sheets easily because they are light. This lets you make special shapes and patterns for your building. ACM panels also give you lots of choices in colors, finishes, and textures. You can use them for bold designs or simple details. Architects and designers like these panels because they let them try new ideas and styles.

You can make curves, waves, or sharp corners.

You can mix finishes for a special look.

You can use panels inside or outside for many projects.

Tip: Try using different finishes and colors together to make your building stand out and show your style.

Performance

Weather Resistance

You want your building to look nice and last long. ACP and ACM panels help with this because they can handle bad weather. These panels do not get ruined by rain, snow, or heat. They keep their color and shape even when the weather changes fast. The PVDF-based paint on top stops fading and damage. The panels can look new for 15 to 20 years.

Here is a table that shows how these panels work in different weather:

Feature | Performance Metrics |

|---|---|

Temperature Resistance | Withstands -40°C to 80°C |

UV Stability | Keeps color under strong sunlight |

Fire Resistance | High fire-resistance ratings |

Sound Insulation | Blocks outside noise well |

Weather Resistance | 15–20 years without fading due to PVDF-based paint |

Tip: You will save time and money on fixing the panels because they stay nice all year.

Durability

You need panels that last a long time. ACP and ACM panels are tested to show they are strong. They do not change color, get damaged by water, or rust. For example, ACM panels only change color a little after 10 years in the sun. They do not bubble after 4000 hours in wet air. Salt spray tests show almost no rust.

Panels last 15 to 20 years if you take care of them.

They pass tests for sun, sticking, and shine.

Wet air and salt spray do not hurt them.

These things make the panels a good pick for places with tough weather.

Impact Resistance

You want panels that do not break when hit. ACM panels have a sandwich-like build that makes them strong. They do not bend or twist easily. The panels stay flat and steady, which is good for looks and safety. They are light but very tough.

Feature | ACM Panels Description |

|---|---|

Strength | Strong, keeps shape when pushed |

Elastic Limit | Bends less than single-layer aluminum |

Dimensional Stability | Stays flat and steady |

Durability | Light but strong |

When you look at ACP and ACM, both work well, but ACM panels are often stronger and last longer. This makes them a great choice for places where safety and lasting value are important.

Fire Safety

Fire Ratings

It is important to know how ACP and ACM panels act in a fire. The core inside the panel matters a lot. ACP panels with polyethylene cores catch fire fast and help flames spread. ACM panels with mineral-filled cores do not burn easily and follow strict safety rules. The table below shows the difference:

Panel Type | Fire Rating Description |

|---|---|

ACP Panels (Polyethylene Core) | Very easy to burn, helps fire move quickly. |

ACM Panels (Mineral-Filled Core) | Made to meet tough fire safety rules, much harder to burn. |

If you use ACP panels with polyethylene cores, fire can grow fast. ACM panels with mineral-filled cores slow down fire and help keep people safe.

Core Material Impact

The core inside each panel changes fire safety. Polyethylene is a kind of plastic that burns fast. If fire touches it, the panel can melt and flames can spread quickly. Mineral-filled cores do not burn like plastic. These cores block heat and flames. This gives your building better protection.

ACP panels with polyethylene cores are not good for places where fire safety is needed.

ACM panels with mineral-filled cores are good for schools, hospitals, and tall buildings.

You can trust mineral-filled cores to keep your building safer.

Tip: Always check the core before you pick a panel for your project.

Compliance Standards

You have to follow fire safety rules when building. Many countries have strong laws for panels in tall buildings and public places. More people want fire-resistant materials now. ACM panels with mineral-filled cores meet world fire codes. You see these panels in airports, train stations, and other big places.

Fire-rated ACM panels stop flames from spreading and meet world rules.

Green building rules now want materials that are safe and can be recycled.

Safety groups want you to use panels that protect people and nature.

If you want your building to pass checks and keep people safe, use panels that meet these rules. You help make your city safer and better for everyone.

Installation

Handling and Transport

Handling and Transport

You need to be careful with ACP and ACM panels. Store panels in a dry place. Wetness can hurt the metal. Cover panels to keep out rain. Do not let covers trap water drops. Put a protective film on the panel’s surface. This stops scratches. Put foam sticks in the slots. This keeps panels from bending. Wrap panels with foam film. This lowers pressure and rubbing. Use a wooden frame when moving panels. This helps stop bumps and hits.

When you move panels, teach your team to be gentle. Give workers gloves and safety glasses. Pack panels in strong wooden boxes for more safety.

Use protective film to stop scratches.

Put foam sticks in slots to keep panels straight.

Wrap with foam film to lower pressure.

Use wooden frames for safe moving.

Teach your team to handle panels gently.

Pack panels in strong boxes.

Installation Methods

There are different ways to put up ACP and ACM panels. Each way works best for certain places and needs. The table below shows some common ways to install panels:

Installation Method | Description |

|---|---|

Wet Sealant Joint | Attach panels to the frame. Put sealant in the joints to keep water out. |

Hanging Method | Hang panels from the frame. This lets panels expand and makes work faster. |

Dry Gasket Joint | Use gaskets instead of sealant. This keeps panels clean and strong. |

Narrow Open Joint | Use for panels that look like stone or wood. This gives neat, thin joints. |

Internal Wall Cladding | Hang panels on inside walls. |

Interior Column Cover | Use the Z-flange system for columns. |

Interior Ceiling | Put ceiling panels up with rivets that do not go through. |

Tip: Pick the way that fits your project and place.

Maintenance Needs

You should clean ACP and ACM panels often. Cleaning gets rid of dirt and pollution. Use gentle soap and a soft cloth. This keeps the finish safe. Do not use rough tools. They can scratch the panels.

Check panels often to find damage early. Clean by hand even if it rains a lot. Rain does not wash off all dirt. Do not clean panels when the sun is very strong. This can hurt the surface.

Clean panels with gentle soap and a soft cloth.

Check panels for damage.

Do not clean when sunlight is strong.

Note: Taking care of panels helps them last longer and keeps your building looking nice.

Cost

Material Pricing

You want to know how much ACP and ACM panels cost. ACP panels usually cost less than ACM panels. The price depends on the core material, thickness, and finish. ACP panels use a polyethylene core, which makes them cheaper. ACM panels use mineral-filled cores, which add to the price. You can choose from many finishes and colors, but custom options may increase the cost. If you pick a fire-resistant ACM panel, you pay more for extra safety.

Installation Costs

You need to think about installation costs when planning your project. The price can change based on the type of panel and the size of your building. Here is a table that shows the average installation costs for commercial projects:

Panel Type | |

|---|---|

ACM | $40 – $55 |

ACP | $20 – $60 (per square meter) |

ACM panels cost more to install because they need special handling and meet strict safety rules. ACP panels can be cheaper, but prices go up if you choose thicker panels or custom finishes. You should ask your installer for a quote before you start.

Long-Term Value

You want your building to last a long time. ACP panels usually last 10 to 30 years. ACM panels can last up to 40 years. You save money over time with ACM panels because they need less maintenance. You mostly just clean them. ACP panels may need more repairs and replacements because they can get damaged more easily.

ACM panels come with a five-year warranty against delamination.

You get finish warranties up to 30 years with ACM panels.

ACP panels may need to be replaced more often, which costs more in the long run.

ACM panels help you save money because they are strong and need little care.

If you want the best value, choose panels that last longer and need less work. Solid aluminum cladding can last even longer and gives you peace of mind. You make a smart choice when you look at both the upfront cost and the long-term savings.

Applications

Building Facades

Building Facades

You often see ACP panels on building facades. These panels give buildings a modern and sleek look. Architects choose them because you can pick from many colors, textures, and finishes. This helps you create unique designs for both commercial and residential buildings. ACP panels do more than look good. They protect your building from rain, sun, and wind. The panels resist UV rays and moisture, so your facade stays bright and strong for years. You also get better thermal insulation. This means your building stays cooler in summer and warmer in winter. ACP panels help save energy and lower costs.

Interior Uses

You can use ACM panels inside buildings in many ways. These panels work well for walls, ceilings, and partitions. You get lightweight panels that are easy to install and customize. Designers like ACM panels because you can choose different finishes to match your style. Here are some common uses:

Ventilated facades that improve insulation and reduce noise.

Decorative cladding for walls and ceilings.

Support for advertising signs and banners.

Quick upgrades during renovations without heavy construction.

ACM panels make spaces look clean and modern. You can change the look of a room fast and with little effort.

Specialty Projects

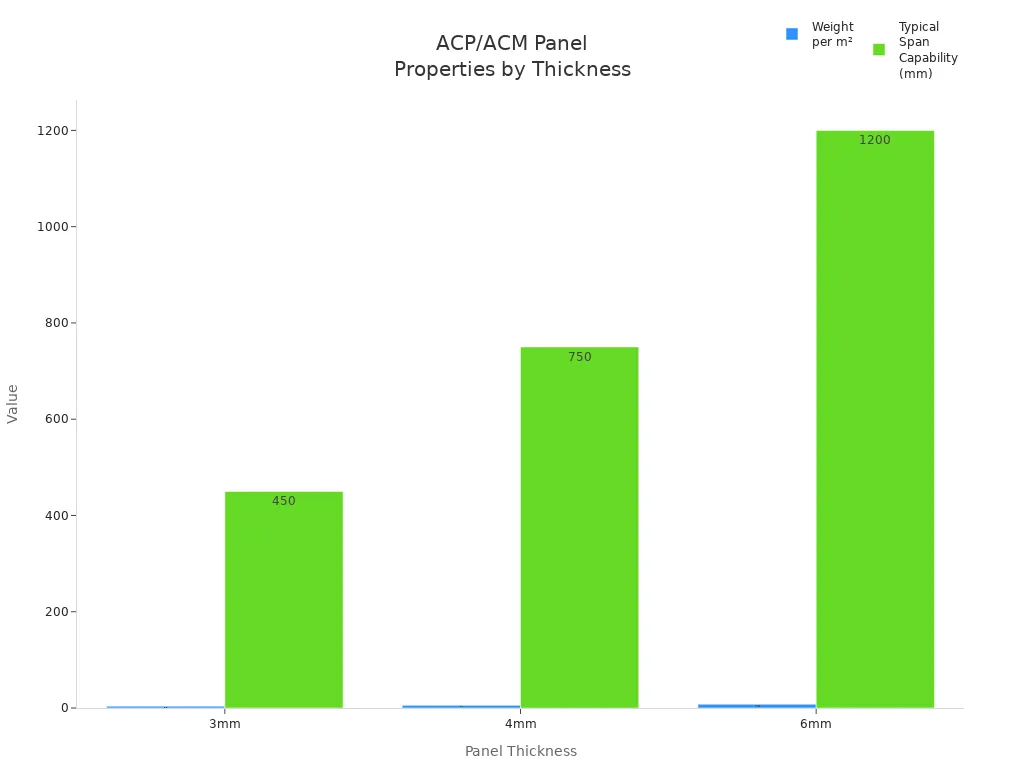

You can pick ACP and ACM panels for special projects by looking at their thickness and strength. The table below shows how different panel sizes fit different needs:

Thickness | Weight per m² | Typical Span Capability | Wind Load Resistance |

|---|---|---|---|

3mm | 3.8 kg | Up to 450mm | Low-Medium |

4mm | 5.5 kg | Up to 750mm | Medium-High |

6mm | 7.8 kg | Up to 1200mm | Very High |

You can use 2mm-3mm panels for indoor projects like wall art or displays. Choose 4mm panels for outdoor signs and cladding. For high-rise buildings or large outdoor structures, use 5mm-6mm panels. Always select flame-retardant cores for public or high-safety projects. This helps keep your building safe and strong.

Choosing Panels

Project Needs

You need to pick the right panel for your project. First, think about what your building needs most. Do you want panels that are easy to carry and put up? ACP panels are light, so you can move them easily. Both ACP and ACM panels have layers that keep water out. Some panels have special cores that make them last longer in tough places.

You should also check the finish. Fluoropolymer coatings protect panels from sun, wet air, and dirt. This helps your building look new for a long time. The aluminum on these panels helps with hot and cold weather. It keeps your building comfy all year. Always look at the warranty. A good warranty means the panel will last longer, even in bad weather.

Here is a table to help you compare important things:

Factor | |

|---|---|

Lightweight | Easy to manage, helps with transport and installation |

Moisture Barrier | Stops water from getting behind panels |

Specialty Cores | Made for better durability in tough environments |

Coating Finishes | Resist UV, humidity, and pollution |

Thermal Resistance | Handles big temperature changes |

Warranty Considerations | Compare warranties for expected lifespan |

Durability | Lasts long without cracking or peeling |

Tip: Write down your top needs before you choose a panel. This makes it easier to pick the best one for your project.

Suitability Factors

You also need to think about where and how you will use the panels. The weather in your area is important. If your building is near the sea, you need panels that can handle salty air and strong winds. For tall buildings in cities, pick panels that can take big changes in temperature and wind. The kind of building matters too. Factories may need panels that do not get hurt by chemicals.

Rules can change what you pick. Building codes change a lot. You should check the rules early so you do not have problems later. Safety rules like fire safety and strength help you choose the right panel.

Here is a table that shows how these things affect your choice:

Influence on Material Choice | |

|---|---|

Climate | Coastal areas need panels for salt and wind; cities need panels for temperature and wind |

Building Type | Industrial sites need chemical resistance |

Regulatory Requirements | Early code checks prevent costly changes |

Performance Specifications | Exposure, loading, and fire safety guide your selection |

Remember: The right panel depends on where your project is, what it is for, and what safety you need. Always pick the panel that fits your special needs.

You now know how ACP and ACM panels are different. ACP panels have a polyethylene core. ACM panels use mineral-filled cores for more fire safety. ACP panels are easier to put up and cost less money. ACM panels last longer and follow tough safety rules.

Use ACP panels for easy jobs and to save money.

Pick ACM panels for tall buildings or places that need fire safety.

Always ask a building expert before you choose. This helps you get the best results for your project.

FAQ

What is the main difference between ACP and ACM panels?

You will find that ACP panels use a polyethylene core. ACM panels often use mineral-filled cores. ACM panels offer better fire safety. ACP panels cost less and work well for simple projects.

Can you use ACP panels for high-rise buildings?

You should avoid ACP panels with polyethylene cores in high-rise buildings. These panels do not meet strict fire safety codes. ACM panels with mineral cores are safer for tall structures.

How long do ACP and ACM panels last?

You can expect ACP panels to last 10 to 30 years. ACM panels often last up to 40 years. Regular cleaning helps both types stay strong and look good.

Are ACP and ACM panels easy to install?

You will find both panel types easy to handle and install. Their lightweight design makes transport simple. You can use basic tools for most installations.

Do ACP and ACM panels require special maintenance?

You should clean panels with mild soap and a soft cloth. Avoid harsh chemicals. Check panels for damage every few months. This keeps your building looking fresh.

Core Materials

Core Materials Handling and Transport

Handling and Transport Building Facades

Building Facades