02 Sep How Strong Is a 3mm Aluminium Composite Panel?

Table of Contents

You can trust a 3mm aluminium composite panel to be strong and tough. The aluminum layers and polyethylene core work together. They help stop bending, warping, and denting. This is true even when the weather is bad. A 3mm aluminium panel is lighter than steel. But it still protects well from impacts.

The light weight (about 3 to 8 kg/m²) makes it easy to carry and put in place.

Aluminum is flexible, so you can shape and cut panels for special projects.

Knowing these things helps you pick the best 3mm aluminium composite panel for safety, design, and lasting use.

Key Takeaways

3mm aluminium composite panels are light and strong. They do not bend easily. They do not dent easily. They can handle bad weather.

The panels have layers of aluminum and a polyethylene core. This sandwich structure makes them flexible. It helps them resist impacts. It makes them last a long time.

These panels are good for walls, signs, and indoor use. They are strong enough for these jobs. You can cut and shape them easily.

If you need to hold heavy things, use thicker panels. For fire safety, use fire-retardant panels. For tough outdoor places, thicker or fire-safe panels work better.

Clean the panels often to keep them nice. Fix dents early so they look good. This helps them work well for many years.

3mm Aluminium Panel Strength

Load Capacity

Load Capacity

A 3mm aluminium panel can hold a lot for its weight. It weighs about 3 to 8 kg for each square meter. This makes it simple to lift and put in place. Even though it is light, 3mm acp panels are very strong. The aluminum layers have a tensile strength up to 250 MPa. This means the panel can handle pulling without breaking.

When builders use 3mm acp panels, they get both strength and lightness. The 3mm thickness keeps the panel flat and firm. It stays strong even in wind or under pressure. In windy places, these panels bend less than thinner ones. The special composite structure helps the panel hold more weight. It has two aluminum sheets and a polyethylene core. You can see this in buildings and big signs. These panels stay steady and safe for many years.

Tip: The 3mm thickness makes the panel last longer and stand up to weather better than thinner panels. This is good for places where strength is very important.

Flexural Strength

Flexural strength shows how well a panel can bend without breaking. For a 3mm aluminium composite panel, flexural strength is between 83 and 100 MPa. This high number means the panel can bend without cracking or losing its shape.

Thickness (mm) | Flexural Strength (MPa) |

|---|---|

3 | 100 |

3 | 83 |

The flexural yield strength is about 26 ksi. The flexural modulus is 1700 ksi. These numbers mean the panel stays stiff and flat, even with heavy loads. You will see this when using 3mm acp panels for cladding or signs. The panels keep their shape and look smooth. They do not get ripples or dents. This is important for buildings and signs that need to look nice and last long.

New ways of making panels have made flexural strength better. Modern panels have exact thickness and better coatings. This helps them resist bending, twisting, and weather. These changes make the panels even more useful for tough jobs.

Impact Resistance

3mm acp panels are great at handling impacts. Lab tests, like the Charpy impact test, show these panels soak up a lot of energy before breaking. The composite design helps the panel resist dents and damage from hits better than solid aluminum.

3mm acp panels can take hits from hail or flying things without denting easily.

The coatings protect against UV rays, water, and rust, so the panels stay strong in bad weather.

The panels are light, so you can use big pieces without worrying about sagging or warping.

You can see impact resistance in real life. For example, Artefex 3mm aluminium panel passed hard tests. It did not warp or crack after years of use. Artists and builders like these panels because they stay steady in changing weather. In building design, brands like DIBOND and Alucobond use 3mm acp panels for cladding and signs. These panels must resist hits and stay flat.

Note: 3mm acp panels are tougher and last longer than solid aluminum. The composite structure lets the panel bend a little without breaking. This helps stop lasting damage.

3mm acp panels also do well against strong winds. The layers and folded edges help them bend less and last longer. This makes them a top pick for outside building jobs where wind can be strong.

3mm Aluminum Composite Board Structure

Core Material

Core Material

You will find that the core material is the heart of a 3mm aluminum composite board. Most boards use a polyethylene (PE) core. This core sits between two thin sheets of aluminum. The PE core keeps the board light and easy to handle. It also helps the board stay flat and strong. Some boards use a fire-retardant core made from minerals like aluminum hydroxide or magnesium hydroxide. These minerals make the board safer in case of fire. If you need a board for a high-rise or public building, you should look for a fire-retardant core. This type of core can slow down fire and reduce smoke.

Common core types:

Polyethylene (PE): Light, flexible, but not very fire-resistant.

Fire-retardant mineral core: Safer for buildings, resists fire, and reduces toxic smoke.

Honeycomb core: Used in special cases for extra strength and less weight.

The core material affects how the board handles heat, cold, and impact. A mineral core can keep its toughness even at very low temperatures. The choice of core also changes the fire rating. For example, a board with a mineral core can reach A2 fire safety, which is important for strict building codes.

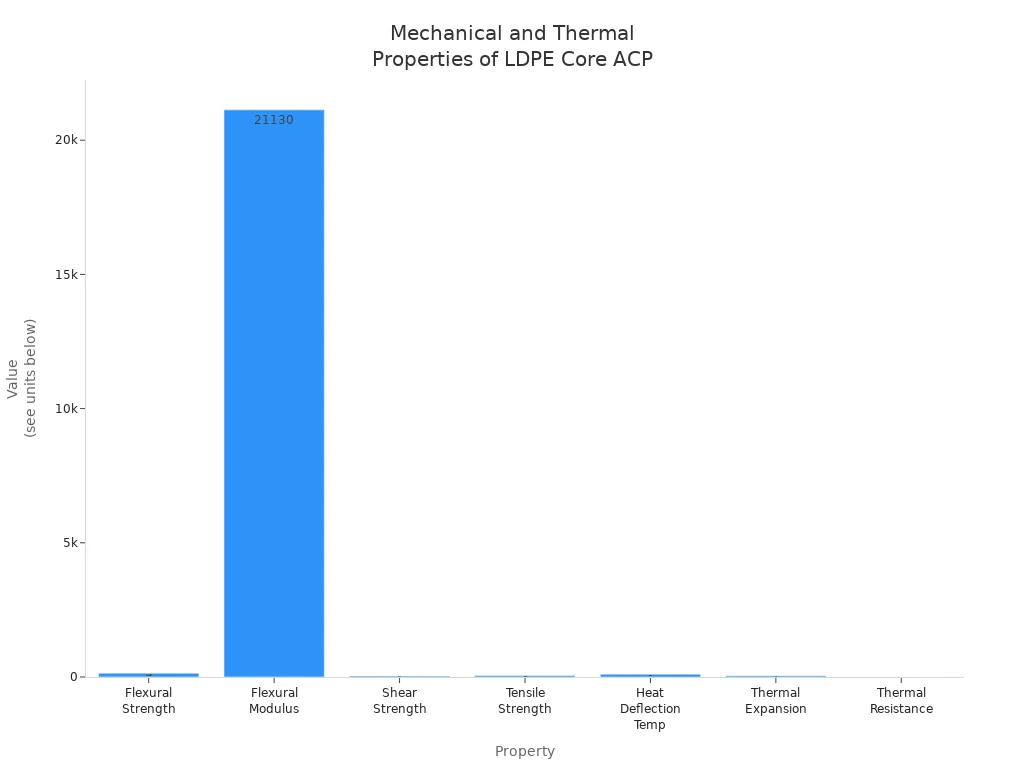

Property | Test Method | Result |

|---|---|---|

Flexural Strength | ASTM D790-10 Procedure A | |

Flexural Modulus | ASTM D790-10 Procedure A | 21130 MPa |

Shear Strength | ASTM D732-10 | 33.1 MPa |

Tensile Strength | ASTM E8/E8M-11 | 52.2 MPa |

Heat Deflection Temperature | ASTM D648-07 Method B | 107 °C |

You can see how the core material changes the board’s strength and safety.

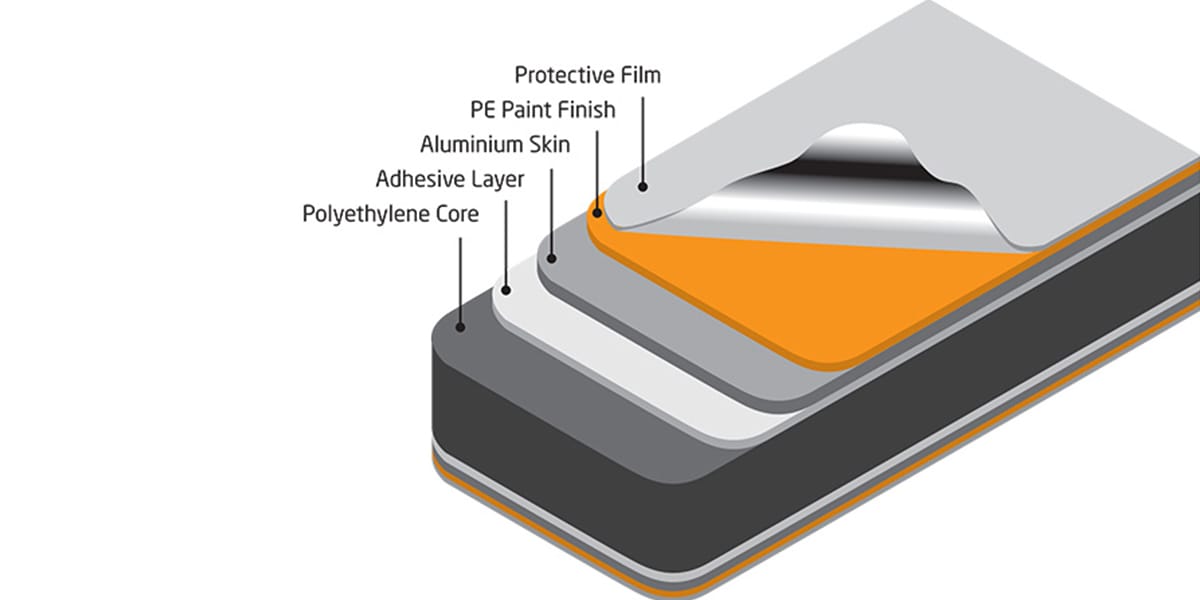

Construction

A 3mm aluminum composite board uses a sandwich structure. You get two thin aluminum sheets, each about 0.2 to 0.5 mm thick. These sheets cover the core. The layers bond together with strong adhesives. This design gives the board its famous strength and flexibility. The aluminum layers protect against dents and bending. The core adds insulation and keeps the board light.

The construction process follows careful steps:

Clean and degrease the aluminum sheets.

Apply a chemical treatment to stop rust and help paint stick.

Coat the sheets with special paint for weather and UV protection.

Sandwich the core between the aluminum sheets using heat and pressure.

Cool the board and add a protective film.

Cut and package the finished boards.

This process makes sure every board has the same quality and durability. The sandwich structure lets you cut, bend, or punch the board for many uses. The board stays strong, even in tough weather or heavy use.

The aluminum layers give impact resistance and help the board last longer.

The core absorbs energy, making the board flexible but tough.

You can use these boards for building walls, signs, or even inside trains and buses.

Tip: The right core and careful construction give your 3mm aluminum composite board the best mix of strength, flexibility, and durability.

Applications for 3mm Aluminium Composite Panel

Common Uses

3mm acp panels are used in many places. They are strong, light, and last a long time. Builders use them for curtain walls in offices and hotels. You also see them at airports and exhibition centers. These panels protect buildings from wind, rain, and sun. You can use them inside for walls, ceilings, and hallways. They make elevator rooms and public spaces look modern.

Advertising companies use 3mm acp panels for signs and billboards. The panels stay flat and do not fade or bend outside. You can cut or shape them for special designs. Factories use these panels for vending machines and equipment covers. The panels do not rust and keep machines safe.

Here is a table that shows where people use the panels and what they need:

Application Area | Common Uses | Performance Requirements |

|---|---|---|

Building Curtain Walls | Offices, hotels, airports, exhibition centers, industrial plants | Lightweight, high strength, corrosion resistance, weather resistance, fire retardant |

Interior Decoration | Indoor walls, ceilings, elevator rooms, corridors, public spaces | Aesthetic versatility, easy cleaning, low maintenance |

Advertising Signs & Logos | Outdoor signs, logos, billboards, light boxes | Excellent flatness, weather resistance, customizable, no fading or deforming |

Industrial Applications | Vending machines, elevator shells, equipment housings | Material safety, corrosion resistance, easy processing |

You can pick marine grade aluminum for tough places like near the sea. This type does not get damaged by saltwater and lasts longer.

You save money on work and shipping because they are light.

The panels need less cleaning and last longer, so you fix them less.

Tip: Clean 3mm acp panels with mild soap and water every few years. Use a soft cloth to keep them shiny and smooth.

Limitations

You should know what 3mm acp panels cannot do. These panels can bend or sag if you put too much weight on them. If you need to hold a lot, steel or thicker panels are better. 3mm acp panels bend more than solid aluminum or honeycomb panels. For big signs or walls, you need extra support to keep them flat.

Steel is stiffer than 3mm acp panels. Steel bends less but is heavier and costs more to use. There are small differences in wind resistance between 4mm and 6mm panels. Both need support for big jobs.

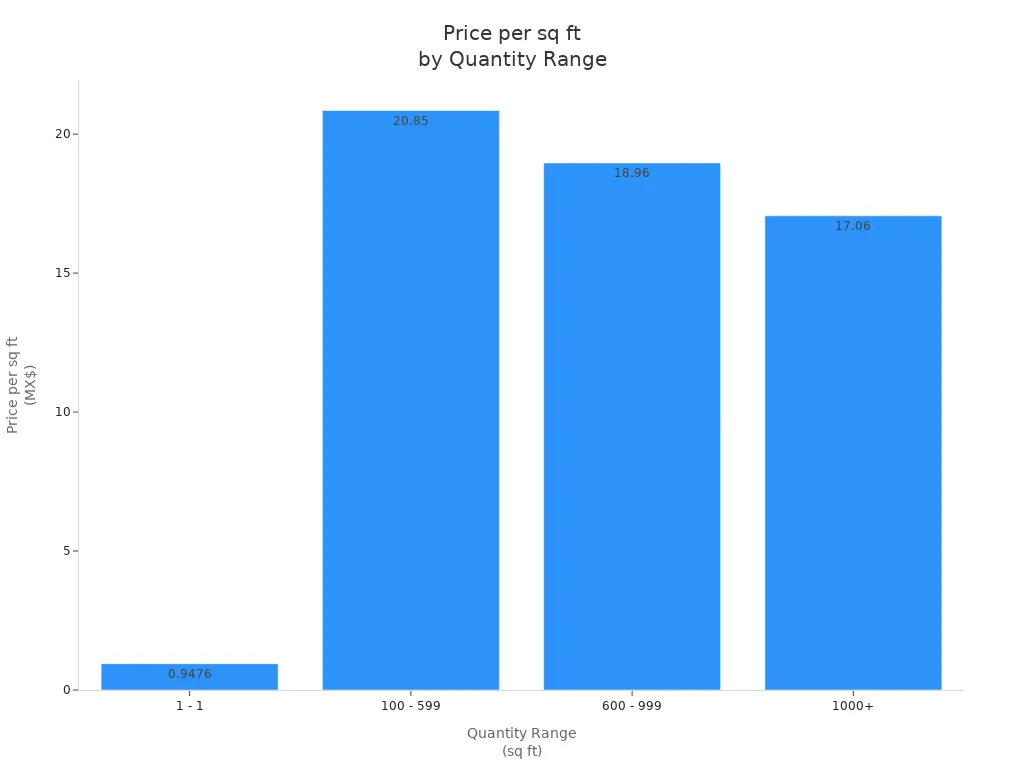

Think about the price too. 3mm acp panels cost more than wood or vinyl at first. The price goes down if you buy a lot, but it is still higher than some other materials. The chart above shows how the price changes when you order more.

You should also think about the environment. It is hard to recycle 3mm acp panels because they mix aluminum and plastic. Some companies have new ways to recycle, but many panels still go to landfills. If you want to be greener, look for panels that are easier to recycle.

Note: Always check your panels for dents or scratches. Fix small problems early to keep your panels strong and looking nice.

When you pick 3mm aluminium composite panels, you get panels that are strong and light. These panels can handle bad weather. They do not break easily if something hits them. They do not rust or get damaged by the sun. You can put them up without much trouble. You can also choose from many looks for your project.

3mm panels work well for inside walls, signs, and places that do not need to hold much weight.

Use thicker or fire-retardant panels for tall buildings or places with tough safety rules.

Panel Type | Best Use |

|---|---|

Inside, places with little stress | |

4mm/5mm ACP | Outside, places that need to be strong |

Fire-retardant ACP | Places where fire safety is very important |

Always check what your project needs. Pick the right panel so your project is safe and lasts a long time.

FAQ

How much weight can a 3mm aluminium composite panel hold?

You can expect a 3mm panel to support light to moderate loads. For wall cladding or signs, it stays flat and strong. You should add extra support for heavy objects or large panels.

Can you cut or shape a 3mm aluminium composite panel easily?

You can cut or shape these panels with basic tools. Use a saw, router, or utility knife. The panel does not crack or split. Always wear safety gear when you work.

Is a 3mm aluminium composite panel waterproof?

You get good water resistance with these panels. The aluminum layers and coatings block rain and moisture. You should seal the edges for outdoor use to keep water out.

Does a 3mm aluminium composite panel rust?

You do not need to worry about rust. Aluminum does not rust like steel. The panel stays shiny and smooth, even in wet weather.

Can you paint or decorate a 3mm aluminium composite panel?

You can paint or decorate the surface. Use special paints for metal. The panel holds color well and does not peel. You can also add stickers or vinyl graphics.

Load Capacity

Load Capacity Core Material

Core Material