10 Feb How to Choose the Right ACP Panel for Your Project in 2026

Table of Contents

You need to pick the right ACP panel for your project. Match the ACP Panel’s features to what your project needs. First, check if the ACP panel has the right safety and certification. Think about where you will use the ACP panel. Some projects, like electronics or healthcare, need static control. Other projects need strong and easy-to-change finishes. Make sure your ACP panel is safe from fire and helps the environment. Check the thickness and core of each ACP Panel. This helps you know if it is strong enough. Choose an ACP panel that fits your design and how you will install it. Take your time with each step so your ACP panel works well for your project.

Key Takeaways

Always look for certifications when picking ACP panels. Certifications show the panels are safe and good quality. They help you follow building rules.

Think about the material and core quality of ACP panels. A strong core and nice surface make the panels last longer. They also help keep people safe.

Pick the right thickness for your ACP panel. Thicker panels are stronger. They work better for tall buildings or windy places.

Choose ACP panels with protective coatings. Good coatings stop scratches and weather damage. This helps your panels stay nice for a long time.

Look at the design choices you can get. Pick colors and finishes that make your project look better. This can also make your project worth more.

ACP Panel Selection Criteria

Certification and Standards

Certification and Standards

Start by checking if the aluminum composite panels have the right certifications. These show the acp panel follows safety and quality rules.

Pick aluminum composite panels with strong certifications. These prove the panels are safe and good quality.

Here is a table of important certifications and what they mean:

Certification | Description |

|---|---|

EPD Certification | Validates environmental sustainability and recyclability. |

UL Certification | Confirms compliance with safety standards. |

ASTM Standards | Tests for burning and adhesive strength. |

NFPA 285 | Assesses fire spread on walls. |

ISO 9001:2015 | Indicates quality management practices. |

ISO 14001:2015 | Demonstrates environmental management efforts. |

LEED Certification | Supports green building initiatives. |

Miami-Dade Approval | Ensures wind and impact resistance. |

Factory Mutual Approval | Meets loss prevention standards. |

Certified acp panels help you follow building codes. They also make it easier to get insurance for your project. Using the right acp sheet keeps your reputation safe and lowers risks.

Material and Core Quality

Look at the material and core of each acp sheet. Good aluminum composite panels use pure aluminum and a strong core. The core can be fire-retardant or regular. For buildings with strict fire rules, pick a fire-retardant core. This keeps your project safe and follows local laws.

Check the surface finish. A good finish helps the acp sheet last longer and look nice. Ask the maker for test reports. These reports show the sheet meets quality rules.

Thickness and Structural Needs

The thickness of the acp panel changes its strength. Pick the right thickness for your project. For tall buildings or windy places, use thicker sheets. This helps the cladding stay in place and keeps people safe.

Think about the size of each sheet. Big panels cover more space but may need extra support. How you install the panels matters too. Some projects need special fixing systems for better safety.

Thermal and acoustic features are important too. Good acp panels help keep buildings cool and quiet. This makes them a smart choice for homes and offices.

Tip: Always match the thickness and size of the acp sheet to your building’s height, wind load, and climate.

Surface Protection and Scratch Resistance

You want your acp sheet to look nice for a long time. Pick panels with a strong surface coating. This coating protects against scratches, stains, and weather. Some acp panels have extra UV protection. This keeps colors bright even in strong sunlight.

Ask the supplier about the coating type. PVDF and FEVE coatings are popular because they last long. A good coating also makes cleaning easier.

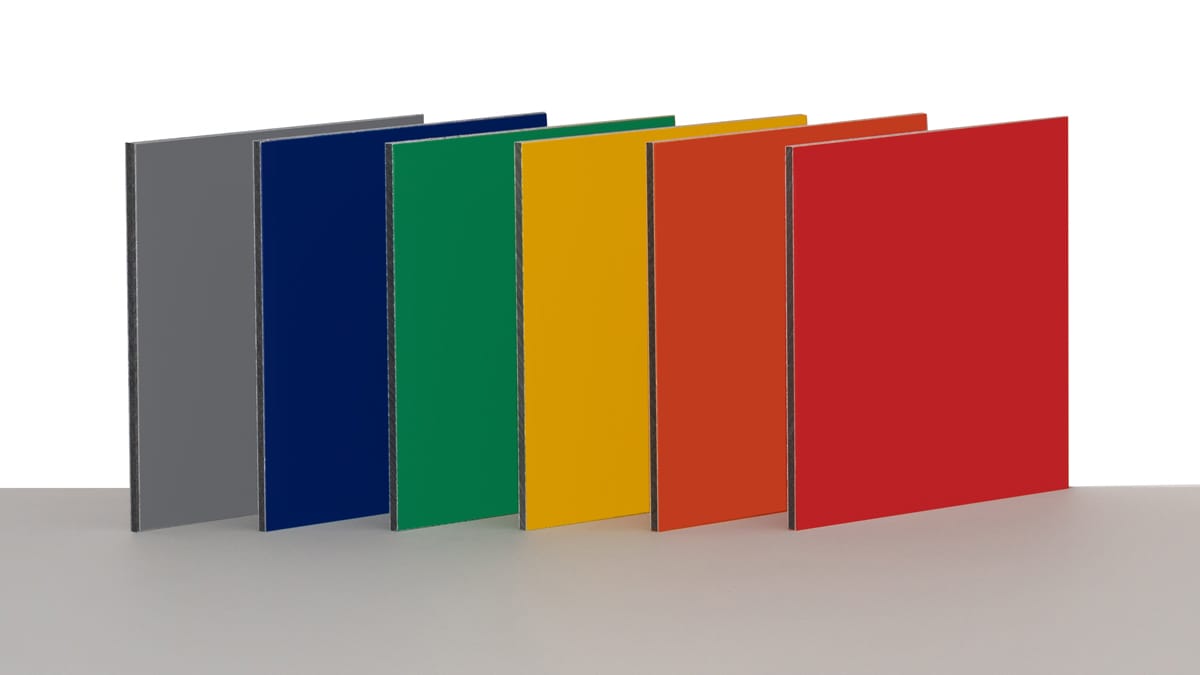

Color and Design Options

You can choose from many design options with acp panels. These panels come in many colors, finishes, and patterns. Pick a style that fits your project’s look. Some acp sheets look like wood or marble. This gives you lots of choices for creative projects.

ACP panels come in many colors, finishes, and patterns, so architects can be creative and make buildings look better.

Buildings with nice acp panels can sell for more money, because people like attractive buildings.

Color guides help architects pick finishes that match their design goals, which can make a project look even better.

Use color guides to help you pick the best finish. Always think about how the color will look in sunlight and over time. The right color and finish can make your building worth more and help it stand out.

How to Assess ACP Manufacturers

Quality Assurance

Quality Assurance

You should check how the acp sheets manufacturer tests their products. Good manufacturers follow strict rules for safety and quality. This means each acp sheet is safe and works well. You can look at the table below to see what top manufacturers do:

Quality Assurance Process | Description |

|---|---|

Compliance with ASTM | Adherence to American Society for Testing and Materials standards for safety and quality. |

Compliance with EN | Following European Norms for product safety and performance. |

Compliance with NFPA | Meeting National Fire Protection Association standards for fire safety. |

Guidance from AAMA | Utilizing recommendations from the American Architectural Manufacturers Association for performance and installation. |

Non-combustible grade A1 | Standards set by manufacturers for fire protection in high-risk construction. |

Ask for test reports and certificates before you buy any acp sheet. This helps you know the product is safe and good.

Sustainability Practices

Many acp sheets manufacturers care about the environment. You can check if they have special certifications for being green. These show the manufacturer tries to help the planet. The table below lists some common certifications and what they mean:

Certification | Significance |

|---|---|

Leadership in Energy and Environmental Design (LEED) | Supports recycled material credits, local sourcing, and reduces installation waste. |

BREEAM | Aligns with material selection criteria and energy efficiency requirements. |

Green Star | Enhances recyclability and energy performance, contributing to multiple credit categories. |

Living Building Challenge | Focuses on material recyclability and durability to meet advanced sustainability standards. |

WELL Building Standard | Promotes low-emission materials for better indoor air quality. |

Pick an acp sheets manufacturer that cares about the environment and has these certifications.

Design Variety

You want your acp sheet to look good on your project. Top acp sheets manufacturers give you lots of choices. You can pick from:

Metallic acp sheets that shine like silver or copper.

Wooden acp sheets that look and feel like real wood.

Marble acp sheets with lines like real marble for a fancy look.

Stone acp sheets for a strong and tough style.

Architects say having many designs helps them make cool buildings. You can use acp panels to make your project special and modern.

Reputation and Customer Feedback

You should find out if the acp sheets manufacturer is trusted. Look for reviews and ratings from other people. If the manufacturer has a good reputation, they make good products and help customers. Happy customers are important. You can ask for examples or visit finished projects to see how the acp sheet lasts.

Price Considerations

You need to think about price when you pick an acp sheets manufacturer. The price changes based on the core, thickness, and finish. Here are some average prices for 2026:

PE Core, 3mm: $15 – $20 per sq ft

PE Core, 4mm: $18 – $25 per sq ft

FR Core, 4mm: $22 – $30 per sq ft

FR Core, 6mm: $28 – $35 per sq ft

Special features like fire rating or coatings can make the price higher. You can save money if you buy a lot at once or sign a long contract. These deals help you spend less and always have enough acp sheet for your project.

Tip: Always check prices and ask about discounts before you choose an acp sheets manufacturer.

Matching ACP to Project Requirements

Residential vs. Commercial Use

Pick the right acp sheet for your building type. Homes and businesses have different rules. Homes can use regular acp panels. Offices, malls, and hospitals need special fire codes. The table below shows how rules change your choice:

ACP Panel Type | Fire Performance Requirement | Cost Implication | Usage Context |

|---|---|---|---|

Fire-Retardant | Slows fire spread | Higher | Mid-rise buildings, public spaces |

A2 Non-Combustible | Passes toughest tests | Premium | High-rises, critical buildings |

Always check local rules before you buy aluminum composite panels.

Interior vs. Exterior Applications

You can use acp inside or outside. Outside, acp panels protect buildings from weather. Inside, acp sheet works for walls, ceilings, and furniture. You get smooth designs and save money. Remember these points:

ACP is light and has many colors and finishes.

Outside panels must handle sun, rain, and wind.

Inside panels let you pick cool finishes like matte or shiny.

Custom sizes help acp sheet fit furniture or special spaces.

Climate and Environmental Factors

Think about your local weather. If you get strong sun, rain, or wind, pick acp with special coatings. The table below shows how coatings help:

Coating Type | Application Type | UV Resistance and Durability |

|---|---|---|

PVDF | Exterior Applications | 10–15+ years of color stability, resists UV and weathering |

Polyester | Interior/Low-Exposure | Moderate resistance; may fade after 3–5 years in harsh sun |

ACPs fight moisture, rust, and heat changes. This helps them last longer in tough weather.

Installation and Support

Install acp sheet the right way. Clean, smooth surfaces help it stick better. Measure well so you do not waste material. Use screws, glue, or rainscreen systems for cladding. Leave space for the sheet to grow or shrink with temperature. Getting help from experts gives you better results and longer warranties. Many makers give guides and support to help you finish your project and save money.

Tip: Pick acp sheet thickness based on building height, wind, and weather. Thicker panels are stronger and keep buildings warmer.

You can pick the best acp panel by using easy steps. First, look at the quality and check for certifications. Compare different aluminum composite panels to see which is better. Ask the acp sheets manufacturer for test results. See how each sheet matches what you need. Good support from the acp sheets manufacturer helps you choose well. Always talk to the acp sheets manufacturer before you buy. Choose with confidence and make sure you focus on quality.

FAQ

What is the best way to clean acp panels?

You should use a soft cloth and mild soap with water. Avoid harsh chemicals. Rinse with clean water. Dry with a soft towel. This keeps your acp panels looking new.

Can you use acp panels for both inside and outside projects?

Yes, you can use acp panels for interior walls, ceilings, and furniture. You can also use them for building exteriors. Always pick the right type for your project.

How do you know if an acp panel is fire safe?

Check for fire safety certifications like NFPA 285 or A2 ratings. Ask your supplier for test reports. These show if the acp panel meets fire safety rules.

Do acp panels help with noise and heat?

Yes, acp panels can reduce outside noise and help keep rooms cooler. Choose panels with good thermal and acoustic properties for better comfort.

Certification and Standards

Certification and Standards Quality Assurance

Quality Assurance