04 Sep Impact Resistance of ACP in High-rise Curtain Walls

Table of Contents

Aluminum Composite Panels (ACP) are good at stopping damage from impacts. This is very important for tall building curtain wall systems. Impact resistance means a material can take a hard hit without breaking or ripping. This is needed for outside walls that face strong weather and accidents. ACP is light, but it has strong aluminum layers and a polyethylene core. These parts help keep tall buildings safe and strong. ACP is used in many places around the world. It is part of more than 2,300 tall building projects. ACP gives long-lasting results for high-rise buildings.

Key Takeaways

ACP panels are strong and light. This makes them great for tall buildings. They help protect against weather and accidents. Good impact resistance means the panels stay safe. They also protect buildings from getting damaged. This saves money on repairs. Picking the right core material is important. The thickness of the panel also matters. These choices help ACP panels handle hits better. They also help the panels last longer. ACP cladding is tougher than glass. It is also safer than many other materials. This makes it a top choice for curtain walls. Proper installation is important. Regular inspections are needed. Using certified panels keeps buildings safe. It also helps buildings look nice.

ACP Impact Resistance

Performance in High-Rise Applications

Aluminum composite panels are strong against impacts in tall buildings. Many architects pick ACP for high-rises because it can take hits from flying objects and accidents. ACP has two aluminum sheets and a core made of polyethylene or rigid PVC foam. This makes the panels strong and bendy at the same time. The panels also have a fluorocarbon resin coating. This coating keeps them safe from weather and sunlight. Because of this, the panels stay tough for many years.

ACP is better at handling impacts than wood, stone, or concrete. It is also much lighter than those materials. This makes it easier to put up and does not make the building heavy. Tall buildings need materials that can stand up to strong winds and things that hit them. ACP is good for this because it is tough and light. The panels do not break or crack easily. This helps keep the building safe and looking nice.

Note: ACP and other composite panels, like aluminum honeycomb panels, do not bend or change shape easily from pressure or force. This is why they are a great pick for very tall buildings that get strong winds.

What Impact Resistance Means

Impact resistance means the panels can take a hit and not fail. In tall buildings, this is very important for safety. The panels must keep the inside safe and protect people. For example, during storms, wind can throw things at the building. If the panels break, water and wind can get inside and cause problems.

Impact resistance also helps the building last longer. Panels that do not break from impacts do not need to be changed often. This saves money and keeps the building looking good. In tall buildings, strong impact resistance means the walls can handle both daily use and big storms.

Impact resistance depends on how good the materials are and how the panels are made. The fluorocarbon resin coating, especially with lots of polyvinylidene fluoride, gives extra protection from weather and rust. Good ways of making the panels, like baking and careful checks, help the coating last a long time.

Tip: When picking materials for tall building curtain walls, always look at the impact resistance rating. This helps make sure the building stays safe and strong for a long time.

Factors Affecting Impact Resistance

Material Composition and Core Types

What the cladding is made of is very important for impact resistance. ACP has two aluminum sheets with a core in the middle. The kind of core changes how well the cladding can take hits. Breakable PE cores are not tough and break fast, so they do not protect well. Unbreakable PE cores are tough and do not break, so the cladding stays strong. The LDPE core’s quality is important too. If it can stretch a lot, over 400%, the surface stays strong and flat. Recycled PE that only stretches about 100% makes panels that break and lose their flatness. Picking PE cores with a melt index from 0.4 to 0.8 g/10min helps make the panels better and stronger. Big buildings like the Burj Khalifa and Petronas Twin Towers use good ACP cladding to stand up to bad weather and hard hits.

Breakable PE cores: lower impact resistance

Unbreakable PE cores: higher impact resistance

LDPE quality: affects surface strength and flatness

Recycled PE: reduces impact resistance

Panel Thickness and Structure

How thick and strong the panels are changes how they handle hits. Most ACP cladding is between 4 and 6 mm thick. Thicker panels can take more force and do not dent as easily. The sandwich design with aluminum sheets and a core makes the cladding stiff and strong. Corrugated acp panels bend less and soak up more energy. Honeycomb panels have an aluminum honeycomb core. This makes them lighter by about 30% but still strong after many hits. The table below shows how different ACP panels handle impacts:

ACP Panel Type | Impact Resistance Description | Additional Notes on Core and Performance |

|---|---|---|

Ordinary ACP | High impact resistance; resists small missile impacts | Lightweight, strong strength-to-weight ratio, suitable for high-rise buildings |

Fire-Rated ACP | High impact resistance, focus on fire resistance | Mineral core, excellent fire resistance |

Honeycomb Panel | Very high impact resistance, superior energy absorption | Aluminum honeycomb core, maintains strength after repeated loads |

Metal Composite | Very high impact resistance and durability | Metal core, suitable for demanding cladding and facades |

Installation and System Design

How the cladding is put up and designed changes its impact resistance. Designers pick core materials for each project. Polyethylene cores are good for light cladding. Fire-retardant cores make the cladding safer. The sandwich design keeps panels from bending and breaking. PVDF coatings help the panels fight weather, heat, and damage. PVDF also stops fading and peeling, so the cladding looks new. ACP cladding is light, so it does not put much weight on the building. This helps with impact resistance. Designers can pick panel thickness, finishes, and shapes to make the cladding strong and nice looking. Corrugated acp panels and honeycomb panels are extra tough for hard jobs.

Tip: Good installation helps cladding work well and last longer. Always follow the maker’s rules for fixing and sealing to get the best impact resistance.

Curtain Wall Systems Comparison

ACP vs. Glass Panels

Aluminum Composite Panels are strong against impacts on curtain walls. These panels can bend and do not get damaged by sandstorms or flying things. Glass panels are used a lot, but they are not as tough. Glass can break or crack if hit hard. This can be dangerous and cost more to fix. ACP cladding does not break after many hits. It keeps the building safe and looking nice. Many architects pick ACP for tall buildings. It protects better from bad weather and accidents.

Note: ACP cladding is tougher than glass panels. It is safer for outside walls on tall buildings.

ACP vs. Solid Aluminum Panels

Solid aluminum panels are even stronger than ACP cladding. They do not have a core, so they do not dent or rust easily. These panels also last longer in busy places. ACP cladding has a core that is not aluminum. It can get weaker if hit hard or gets wet for a long time. Still, ACP cladding is liked because it is lighter and easier to put up. It also costs less money. The table below shows how ACP and solid aluminum panels are different:

Panel Type | Cost Range (per m²) | Impact Resistance & Durability | Installation & Weight Considerations | Typical Applications |

|---|---|---|---|---|

Aluminum Composite Panel (ACP) | $20 – $60 | Moderate impact resistance; good durability but concerns with combustible cores and fire safety | Lightweight, easier installation, reduces structural load | Commercial facades, high-rises, interiors |

Solid Aluminum Panel | $40 – $80 | Superior impact resistance and durability; excellent fire resistance; fewer issues with delamination or water damage | Heavier, requires stronger support and more complex installation | High-traffic areas like schools, hospitals, airports, canopies |

Solid aluminum cladding costs more and needs stronger support. It lasts longer in hard places. ACP cladding saves money and is faster to install. This makes it a good pick for most tall curtain walls.

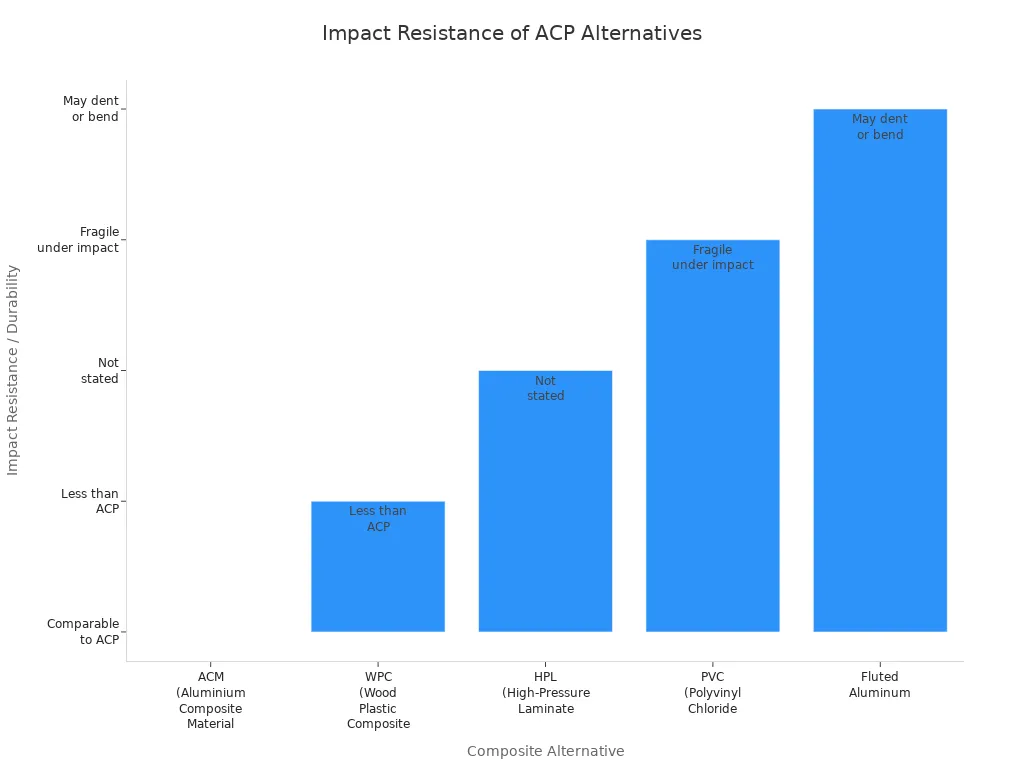

ACP vs. Other Composites

There are many types of composite cladding for curtain walls. ACP cladding is special because it is strong, light, and bends well. Other types, like ACM, WPC, HPL, PVC, and fluted aluminum, have their own good and bad points. ACM is heavier but does not burn easily. WPC looks like wood but gets bigger in heat and is not as strong. HPL does not scratch but is not very bendy. PVC is light but breaks if hit. Fluted aluminum is strong but can dent or bend.

ACP cladding is usually stronger than PVC and acrylic cladding. It is also as strong or stronger than wood and fluted aluminum. ACP cladding is lighter and bends more than ACM and HPL. This makes it a top choice for outside curtain walls on tall buildings.

Impact Resistance Standards

Relevant Codes and Certifications

Many countries have rules for impact resistance in curtain walls. These rules make sure aluminum composite panels protect tall buildings. Groups like ASTM International and ISO make testing rules. ASTM E330 and ASTM E695 are used for impact and strength tests. ISO 7892 is also about impact tests for building facades.

Building codes say ACP panels must pass these tests before use. Certification from trusted labs proves the panels can take real impacts. Local officials may want test reports to check the panels are safe from flying objects and accidents. Architects and builders use these certifications to pick safe materials for tall buildings.

Note: Always look for current certifications when picking ACP for curtain walls. This helps keep the building safe for a long time.

Testing Methods

Engineers do lab tests to check how ACP panels handle impacts. These tests show how the panels will work in real life. The most common tests are:

Testing Method | Description | Application to ACP / Aerospace Impact Resistance |

|---|---|---|

Charpy Impact Testing | Standard test that checks how much energy a panel takes before breaking; used for metals and composites. | Used a lot in aerospace to see how tough composite materials are, which matters for ACP. |

Izod Impact Testing | Test with a notched panel to see how much energy it takes; used for polymers and composites. | Often used for polymers and composites, gives impact resistance info for ACP. |

Drop Weight Testing | Drops a weight from above to copy fast impacts. | Used in aerospace to copy things like bird hits on composite panels. |

Puncture Impact Testing | Checks how well a panel stops a sharp object from going through. | Important for seeing if composite materials can stop punctures in aerospace parts. |

The Izod impact test, set by ASTM D256 and ISO 180, checks how much energy a notched panel takes during a hit. This test gives key info about how ACP panels handle sudden hits. Engineers also use drop weight and Charpy tests to copy real events, like flying things in storms.

Lab results often match what happens outside. For example, models made from lab data show the same damage as panels tested outdoors. This strong match helps builders trust ACP panels will protect buildings in real life.

Innovations in ACP

Advanced Core Materials

New changes in ACP cladding focus on better core materials. Makers now use aluminum core composite panels with honeycomb or corrugated shapes. These panels have aluminum cores between two aluminum skins. This design makes the cladding stiffer and stronger. It helps panels stop warping, cracking, and swelling when it gets hot or cold. Aluminum core cladding is better at stopping shaking and hits than old polyethylene core panels. Builders see that high-rise buildings last longer and save more energy. Using less polymer in the core means less heat and slower fire spread. This makes cladding safer during fires. Some countries, like Australia and the UK, now ban cores that can burn. This pushes companies to make safer, non-combustible cladding.

Enhanced Coatings and Finishes

New coatings and finishes help ACP cladding work better. Makers offer shiny, wood, metal, stone, and mirror finishes. Each finish makes the panels last longer and fight bad weather. Nano-coatings and strong polymers protect cladding from sun and hits. Aluminum panels make a natural oxide layer that stops rust, even in wet or seaside places. Coatings like PVDF and polyester help panels stand up to rain, heat, and sun. These coatings keep the panels bright and lower how much care they need. The table below shows how coatings help cladding work better:

Feature Aspect | Explanation |

|---|---|

Protective Coatings | Aluminum sheets use PVDF or polyester finishes to stop rust and sun damage. |

Weather Resistance | Coatings help cladding last through tough outdoor weather. |

Durability & Low Maintenance | Cladding stays strong and needs less care because of coatings. |

Aesthetic Preservation | Coatings keep cladding colors bright and finishes looking good. |

Case Studies

Real buildings show how new ACP cladding helps stop damage from hits. Tall buildings in hurricane areas use strong cladding and windows to block wind and flying things. Engineers make roofs and frames with backup parts so one break does not cause a fall. Cities like Hong Kong use cladding shapes and wind tests to lower wind force. Japan’s earthquake-safe buildings use bendy cladding to spread out stress. Towers in Dubai use real-time checks and special cladding to handle tough weather. Strict rules like IS 17682:2021 set limits for cladding thickness, core type, and impact resistance. Builders now pick certified cladding to avoid problems from bad materials. These projects show that good design and testing help cladding take hits and keep buildings safe.

Practical Recommendations

For Architects and Designers

For Architects and Designers

Architects and designers should pick the best cladding for each job. They need to check impact resistance ratings and follow local building rules. It is smart to compare cladding systems for strong protection and long life. Using certified products lowers risks and keeps people safe. Designers can use mock-ups to see how cladding looks and works before putting it on the building.

Tip: Talk with your team about the good things each cladding system offers. This helps get the best results for tall buildings.

For Builders and Installers

Builders and installers are important for making cladding work well. They must follow the maker’s steps for fixing and sealing panels. Good installation helps cladding take hits and last longer. Workers should use the right tools and check each panel for damage before putting it up. Training teams on safe handling and correct ways to install can stop mistakes.

A simple checklist for installers:

Check all panels before putting them up

Use only approved fasteners and sealants

Follow the layout plans closely

Make sure panels line up and have the right space

Tell someone if there is a problem right away

For Property Owners

Property owners should know how cladding keeps their building safe. Regular checks help find damage early. Owners can make a plan to clean and check the cladding often. Quick repairs keep the building safe and looking nice. Owners should keep notes about all work done on the cladding. This helps with future fixes and insurance.

Maintenance Task | Frequency | Who Should Do It |

|---|---|---|

Visual Inspection | Twice a year | Building staff |

Cleaning | Every 6 months | Professional cleaners |

Minor Repairs | As needed | Certified contractors |

Note: Taking good care of cladding can make it last longer and keep the property valuable.

Aluminum composite panels keep tall buildings safe from hits. Architects and builders must pick the best panel for each job. They should follow the right steps when putting up panels. Checking panels often helps keep buildings safe. Using certified panels makes safety better.

Look at impact resistance ratings before picking materials.

Teach teams the best ways to install panels.

Learning about new ACP technology helps every project work better and stay safe.

FAQ

What makes ACP panels impact resistant?

ACP panels use two aluminum sheets and a strong core. This design helps the panels absorb force from impacts. The outer coating also protects the surface from scratches and dents.

How does ACP compare to glass in curtain walls?

ACP panels resist impacts better than glass. Glass can crack or shatter when hit. ACP panels bend and stay strong, which helps protect buildings from flying debris and accidents.

Can ACP panels handle extreme weather?

Yes. ACP panels withstand strong winds, rain, and hail. The panels do not break or warp easily. Many high-rise buildings in storm-prone areas use ACP for this reason.

How often should building owners inspect ACP cladding?

Experts recommend checking ACP cladding twice a year. Regular inspections help spot damage early. Quick repairs keep the building safe and extend the life of the panels.

For Architects and Designers

For Architects and Designers