14 Aug What is a PE Aluminium Composite Panel and How is it Made

Table of Contents

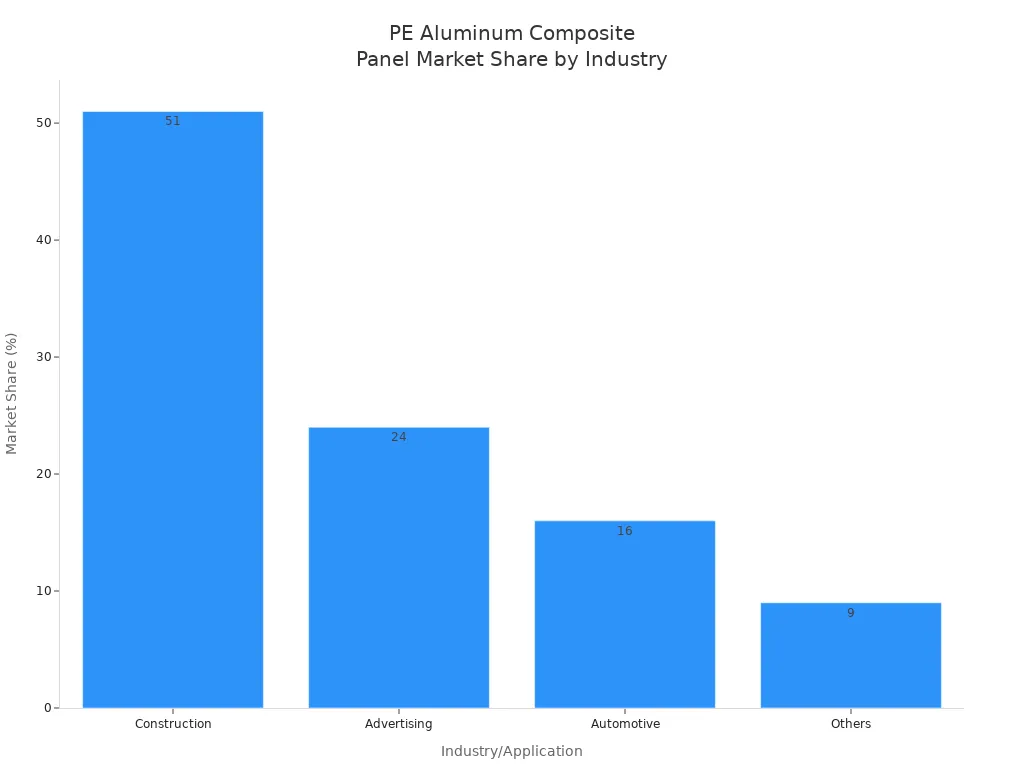

A PE aluminium composite panel has a sandwich structure. It has two thin aluminum sheets. These sheets are stuck to a polyethylene core. This design makes the panels strong and flexible. The panels are also light in weight. Verified Market Reports say these panels are about 60% of the global market. This shows they are popular for being cheap and tough. Many industries use these panels. They are used in construction, advertising, and cars. The chart below shows their main uses:

Industry/Application | Market Share (%) | Key Applications and Notes |

|---|---|---|

Construction | 51 | Building outsides, insides, hospitals, wound care areas |

Advertising | 24 | Outdoor signs, billboards, hospital signs |

Automotive | 16 | Car body panels, insides, medical transport vehicles |

Others | 9 | Kiosks, elevators, medical stations, cleanroom walls |

Knowing about aluminium composite panel properties helps people pick the right panels. This information helps make better choices in building and design.

Key Takeaways

PE aluminium composite panels have two thin aluminum sheets stuck to a polyethylene core. This makes them strong, light, and easy to bend.

People use these panels for indoor walls, signs, and short buildings. They are not safe for tall buildings because the core can catch fire.

Fire-resistant (FR) core panels have mineral-filled cores. These cores do not burn easily. FR panels are needed for tall or public buildings.

PE panels are simple to put up and last a long time. They come in many colors and help save energy. Always check local fire safety rules before using them.

Picking the right panel and a good coating keeps buildings safe and looking nice for a long time.

PE Aluminium Composite Panel Basics

What is a PE Aluminium Composite Panel

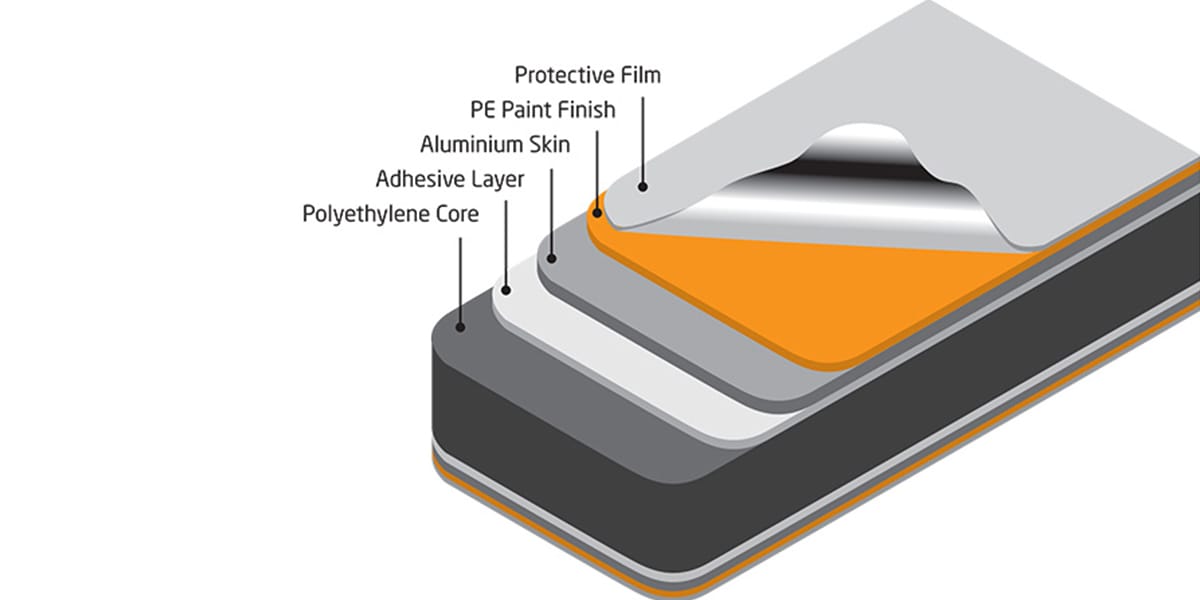

A PE aluminium composite panel is a building material. It is made from different materials put together. The panel has a sandwich-like shape. Two thin aluminum sheets cover a plastic core called polyethylene. This core makes the panel strong and light. The aluminum sheets often have paint or special coatings. These coatings protect the panel and give it color or patterns.

Industry groups say a PE aluminium composite panel mixes the lightness and rust-resistance of aluminum with the strength of a polyethylene core. Sometimes, the core has minerals to help stop fires. The outside of the panel can be painted, printed, or treated. This lets designers use many styles.

A PE aluminium composite panel is popular because it is easy to use and lasts long. The panels do not bend easily and can handle bad weather. They look nice on buildings and signs. But the polyethylene core can catch fire. Because of this, there are rules about where these panels can go, especially in tall buildings.

Note: The core inside aluminum composite panels changes how safe and strong they are. Always check your local building rules before picking a panel.

Comparison with Other Aluminium Composite Panels

There are different kinds of aluminum composite panels. The main difference is the core material. A PE aluminium composite panel uses a polyethylene core. Other panels use fire-resistant or mineral-filled cores. These differences change how the panels act in fire, their price, and where you can use them.

Here is a table that shows the main differences:

Feature | PE Aluminum Composite Panel (Polyethylene Core) | Fire-Resistant (FR Core) Panel | Aluminum Honeycomb Panel |

|---|---|---|---|

Core Material | Polyethylene (PE) | Mineral-filled or fire-retardant core | Aluminum honeycomb |

Fire Resistance | Low | High | Very high |

Weight | Lightweight | Slightly heavier | Even lighter |

Flexibility | High | Moderate | Moderate |

Cost | Lower | Higher | Highest |

Typical Applications | Interior walls, signage, low-rise facades | Exterior cladding, high-rise buildings | High-end facades, transport, ceilings |

A PE aluminium composite panel with a polyethylene core is bendy and not expensive. It is good for inside walls, ceilings, and signs. It is also used for ads.

Fire-resistant panels have an fr core with minerals. These panels slow down fire and follow strict safety rules. Many places need fr core panels for outside walls or tall buildings.

Some panels have an aluminum honeycomb core. These are very strong and do not burn easily. They are used in places like airports or big buildings where safety is important.

Panels with a PE core are best when fire safety is not a big worry. FR core panels are better for places that need more fire protection. The choice depends on what the building needs, the law, and your budget.

Tip: Always check if your project needs an fr core or if a regular PE aluminium composite panel is okay. Rules can be different in each country and for each building.

Structure and Materials

Layer Composition

Layer Composition

PE aluminum composite panel has three layers. Two thin aluminum sheets are on the outside. A solid polyethylene core is in the middle. This design makes the panels strong and bendy. The panels are also light. The outside layers use painted aluminum. This paint protects the core and adds color or texture. Many industries pick these panels. They mix the good parts of metal and plastic. The panels stay flat and stiff, even when big. Builders use these materials to make modern and nice-looking surfaces.

Polyethylene Core

The core is made of polyethylene, which is a plastic. Makers use both low-density and high-density polyethylene. This mix keeps the panels strong but not heavy. The core makes the panels light and tough. It also stops water, acids, and alkalis from getting in. This helps the panels last longer. The core does not change much in hot or cold weather. It does not soak up much water. Here is a table with some main properties:

Property | Value/Description |

|---|---|

Density | 0.90 – 2.30 g/cm³ |

Water Absorption | 0.01 – 2.0% |

Chemical Resistance | Excellent |

Impact Resistance | High |

Thermal Conductivity | 0.21 W/m-K |

Flammability | V-2 (UL94) |

A high-density pe core is stronger and safer in fire than a low-density or recycled core. Good quality cores pass hard tests for bending, heat, and weather. The core also blocks sound and keeps the panels safe inside and outside.

Aluminum Sheets

The outside layers use thin aluminum sheets. These sheets are usually from the 1100 or 3003 alloy series. These alloys are strong, bendy, and do not rust easily. The sheets get coated with polyester (PE) paint. This paint makes the panels smooth and protects them from sun and rain. PE coatings come in many colors and patterns. This makes the panels good for decoration. The aluminum layers help the panels stay flat and strong. They also make the panels easy to cut, bend, or shape for different jobs.

Tip: Always check what kind of aluminum and coating you get. The right choice makes the panels last longer and look better.

Manufacturing Process of Aluminum Composite Panels

Production Steps

Making aluminum composite panels takes many careful steps. Each step helps make the panels strong and useful. Here is how manufacturers make panels with a polyethylene core:

Workers put aluminum coils into the machines.

Machines wash the aluminum sheets to get rid of dirt and oil.

A special chemical layer goes on the aluminum. This helps the aluminum stick to the core.

The aluminum gets a paint coating, like polyester or PVDF. This paint gives color and protects from weather.

The polyethylene core is made into sheets or rolls.

The core goes between two aluminum sheets. Heat and pressure press the layers together.

The panels cool down fast to keep the layers stuck.

A plastic film covers the panel to stop scratches during shipping.

Machines cut the panels to the right size and shape.

Workers check the panels for problems before packing them.

Tip: You can pick special finishes like matte, shiny, or brushed to match your design.

Quality and Standards

Factories check the panels to make sure they are good. They test the aluminum for how hard it is and what metals are in it. The polyethylene core must be strong and melt the right way. Every batch gets tested for how well the layers stick and how much they bend. These tests help keep the panels safe and strong.

Many factories follow rules from around the world. Some important certifications are:

ISO 14000 for caring about the environment

OHSAS18001 for health and safety

CE for selling in Europe

ASTM and EN for fire safety and lasting a long time

Tests by groups like SGS and INTERTEK

These rules help make sure panels are safe and high quality everywhere. Factories also check the materials and finished panels before sending them out. This careful work helps builders and designers trust the panels they use.

Features and Limitations of PE Aluminum Composite Panel

Key Benefits

PE aluminum composite panels have many good points for builders and designers. These panels mix the best parts of aluminum and plastic. Their main features make them liked in lots of jobs.

Lightweight: PE core composite panels weigh about 2.5 pounds per square foot. They are much lighter than stone or solid aluminum sheets. This makes them easy to move and install.

High Rigidity: The sandwich structure gives the panels strength and keeps them flat. They do not bend or warp easily, even after many years.

Flexibility: These panels can bend and shape into curves or angles. Designers use them for creative building shapes and signs.

Durability: The aluminum layers protect against sun, rain, and pollution. The panels last over 20 years with little damage.

Easy Installation: Workers can cut, drill, or join the panels with simple tools. This saves time and money during construction.

Low Maintenance: The powder coating resists dust, water, and stains. Cleaning is easy, and the panels stay bright for years.

Sustainability: Many panels use recycled aluminium. They are 100% recyclable and help save energy by reducing heat loss and blocking noise.

Versatile Design: Panels come in many colors, patterns, and finishes. They fit many applications, from cladding to decoration.

Tip: Using aluminium composite panels saves money and time. They are easy to clean and look nice for a long time. These panels also help buildings use less energy.

Fire Safety and Other Limitations

PE core composite panels have some limits. The biggest worry is fire safety. The polyethylene core is a kind of plastic that can burn. If there is a fire, these panels can help flames spread fast on buildings.

PE core panels can catch fire. Flames can move up a building quickly.

Many building rules do not let these panels on tall buildings. The Grenfell Tower fire in London showed the danger of PE core panels on high buildings. The fire spread fast and caused many deaths.

Some countries now want fire-resistant (FR core) panels for tall or public buildings. These panels have mineral-filled cores that do not burn easily.

Sometimes, panels are labeled wrong. Builders used PE core panels thinking they were fire-resistant. This caused big fires in places like Dubai and London.

Building codes like the International Building Code (IBC) and NFPA 285 have strict rules for using materials that can burn. Panels must pass fire tests before use on tall buildings.

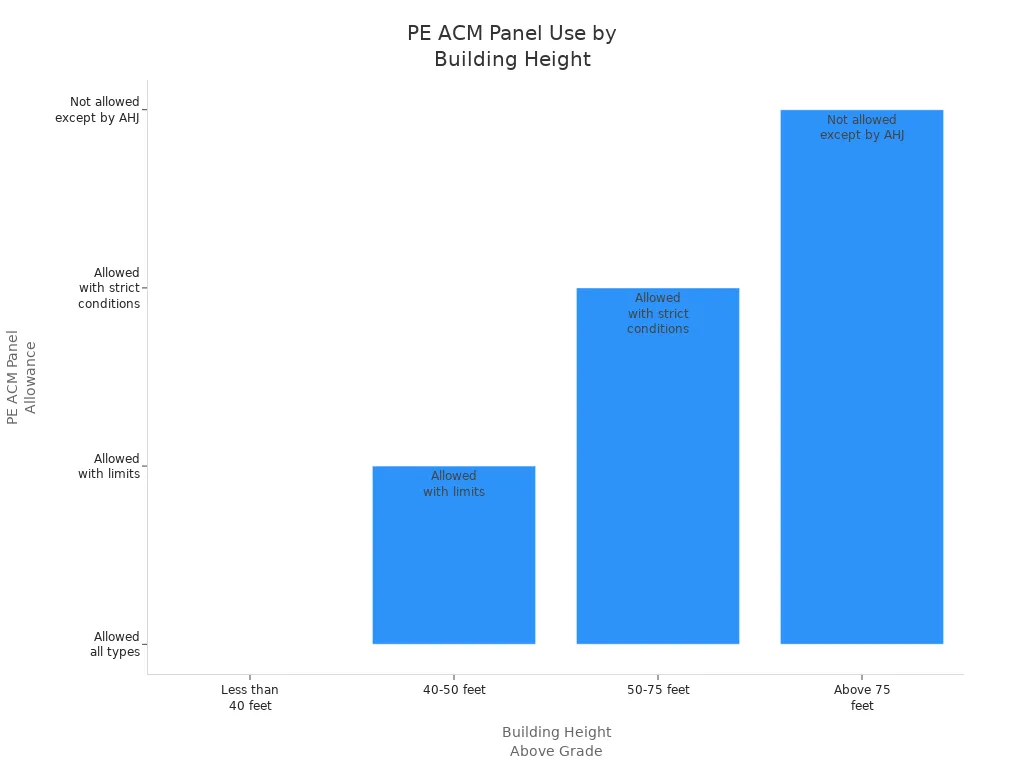

Allowed Use of PE Core ACM Panels | Conditions and Limitations | |

|---|---|---|

Less than 40 feet | Allowed on all construction types | Needs fire separation distance of at least 5 feet |

40-50 feet | Allowed under Section 1407.11.2 | Based on plastic veneer rules; limits on section size and vertical separation |

50-75 feet | Allowed with conditions from 2012 IBC | Options based on occupancy type or fire separation distance; sprinklers may change limits |

Above 75 feet | PE core generally not allowed | FR core required or approval from authority |

Other limits are:

Not good for places that need strong fire safety.

Cheaper panels may not last as long or handle weather well.

Some panels may not follow all local building rules.

Note: Always check local rules before using PE core composite panels. For tall or public buildings, FR core panels are often needed.

PE vs FR Aluminum Composite Panels

PE core and FR core aluminum composite panels look the same, but they act very different in fire. PE core panels have a plastic core that burns easily. FR core panels have a mineral-filled core that stops fire.

PE core panels are usually rated as Class B2 or B1 (flammable or flame retardant). They can catch fire at about 341°C.

FR core panels often reach Class A (non-combustible) ratings. They use minerals like magnesium hydroxide to stop fire.

Many countries only allow FR core panels on buildings above 75 feet. PE core panels are used for short buildings or inside walls.

FR core panels cost more than PE core panels. The higher price is because of better materials and fire safety.

FR core panels last longer and protect better from fire, weather, and noise.

Feature | PE Core Panels | FR Core Panels |

|---|---|---|

Core Material | Polyethylene (plastic) | Mineral-filled (fire-resistant) |

Fire Rating | Class B2/B1 (flammable) | Class A (non-combustible) |

Allowed Building Height | Up to 40-75 feet (with limits) | Above 75 feet (required) |

Cost | Lower | Higher |

Durability | Good | Excellent |

Applications | Signs, interiors, low-rise | High-rise, public buildings |

Callout: FR core aluminum composite panels are safer in fire and meet more building rules. They are best for tall or public buildings, even if they cost more.

PE core composite panels are good for signs, inside walls, and short buildings. FR core panels are safer for tall and public places. Builders should always pick the right panel for the building and follow the law.

Applications of Aluminium Composite Panels

Indoor and Outdoor Uses

Aluminum composite panels are used in many places inside and outside. They are light and strong, so people use them for lots of jobs. Inside, these panels are used for wall designs in malls, hospitals, and subways. They are also used for office and hotel walls and ceilings. People put them in elevators and busy hallways. Some furniture, like cabinet doors and wardrobes, use these panels too. They are good for home decorations and room dividers.

These panels come in many looks, like mirror, brushed, wood, or stone styles. They are easy to clean and do not need much care. This makes them great for busy places inside.

Outside, people use aluminum composite panels for building covers and outside walls. They are used on stores, homes, and big signs. You can see them on billboards and ads. They are also used for canopies, columns, balconies, and kiosks in public places.

These panels work well outside because they can handle sun, rain, and wind. They do not rust, so they are good near the sea or in factories. In places with storms, the panels can take strong winds and hits. This helps keep buildings safe.

Selection Tips

Picking the right aluminum composite panel is important for your project. Here are some tips to help you choose:

Make sure the material is good quality. Good aluminum and cores last longer and handle weather better.

Pick a thick panel if you need it outside. Thicker panels, like 4mm or more, are best for outside walls.

Choose a strong coating. PVDF coatings protect from sun, rain, and dirt.

Think about fire safety. For tall buildings, use panels with mineral-filled cores.

Check if the maker is trusted. Good companies give better panels and help.

Other things to remember are:

Pick colors and finishes that match your building and weather.

Think about cost, how long the panels last, and how much care they need.

Try to use panels made from recycled stuff if you want to help the planet.

Make sure the panels have the right safety and quality certificates.

Tip: Always ask for sample panels or visit places where they are used before you decide. This helps you see if the panels are right for your project.

PE aluminum composite panels have two thin aluminum sheets. These sheets are stuck to a polyethylene core. This makes the panels light and strong. They are easy to shape and can handle bad weather. You can pick from many colors and finishes. But fire safety is a big worry, especially for tall buildings or outside walls.

Pick the right panel for your project.

Use fire-retardant cores for tall buildings or strict rules.

Talk to experts and look at samples before you choose.

Picking the right panel keeps people and buildings safe. It also helps your project last a long time.

FAQ

What is the main difference between PE and FR aluminum composite panels?

PE panels have a core made from polyethylene. This core can catch fire. FR panels have a core with minerals inside. These minerals help stop fire. Builders pick FR panels for tall or public buildings. This is because FR panels are safer.

Can PE aluminum composite panels be used outdoors?

Yes, you can use PE aluminum composite panels outside. They can handle sun, rain, and other weather. Builders use them for walls, signs, and canopies. Always check your local fire safety rules before using them outside.

How long do PE aluminum composite panels last?

Most PE aluminum composite panels last more than 20 years. The aluminum and paint protect them from rust and sun. Cleaning them often helps them stay nice for a long time.

Are PE aluminum composite panels safe for homes?

PE panels are safe for most homes. They work well for inside walls and ceilings. For tall apartments or places with strict fire rules, FR panels are safer.

Can you recycle PE aluminum composite panels?

Yes, you can recycle these panels. Factories can take apart the aluminum and plastic core. Recycling saves resources and helps cut down on waste.

Layer Composition

Layer Composition