06 Sep Pros and Cons of Using ACP Aluminum Composite Panels in 2025

Table of Contents

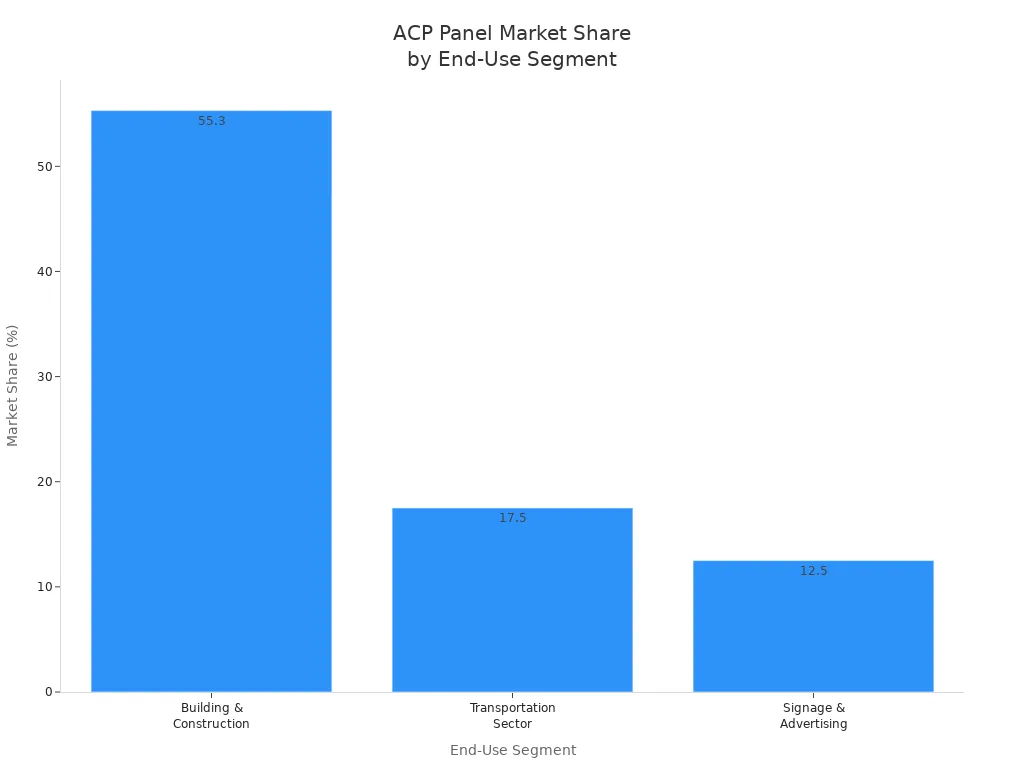

In 2025, opinions about acp aluminium composite panel are mixed, with both advantages and disadvantages noted. ACP aluminium composite panel is known for being cost-effective and durable, making it a popular choice for a variety of design applications. Homeowners appreciate acp aluminium composite panel because it resists rust and offers a sleek, modern appearance. Builders and architects often select acp aluminium composite panel due to its quick installation process and its resistance to fire. Additionally, acp aluminium composite panel requires minimal maintenance. Over 80% of homeowners report that acp aluminium composite panel helps them achieve their desired aesthetic. ACP aluminium composite panel also contributes to energy savings and enhances building safety. The global market for acp aluminium composite panel is valued at nearly USD 7 billion, with the majority of demand coming from the building and construction sector.

Statistic | Value/Detail |

|---|---|

Global Market Size in 2025 | |

Market Size in 2024 | USD 6.50 billion |

CAGR (2025-2034) | 6.4% – 7.03% |

Major End-Use Sector | Building & Construction |

Dominant Panel Thickness | 4mm thickness panels |

Key Takeaways

ACP aluminum composite panels help save money. They are light, strong, and simple to put up. This makes them good for many building jobs.

These panels stop fire, water, rust, and noise. They help keep buildings safe, dry, and quiet.

ACP panels come in many colors and finishes. This lets people make creative and modern buildings.

Good installation and regular checks stop damage. This keeps panels from bending, leaking, or cracking. It helps them last longer.

Picking panels with fire-safe cores and recycled parts is smart. It also helps if they follow local rules. This makes buildings safer and saves energy.

ACP Aluminium Composite Panel Overview

Structure and Materials

Structure and Materials

An acp aluminium composite panel has layers. Two thin aluminum sheets are glued to a middle core. The core is usually polyethylene or a fire-safe mineral. In 2025, many panels use recycled aluminum and green cores. This helps the environment. The aluminum layers make the panel strong and bendy. The core gives support and keeps heat in.

Modern acp panels have special coatings. These coatings, like PVDF or polyester, protect from sun, chemicals, and scratches. Nano-coatings help stop stains and rust. Some panels bounce sunlight away. This saves energy. Fire-safe cores and weatherproof designs make acp aluminium composite panel safe for many uses. These upgrades also make panels lighter and easier to put up, but still strong.

A table below shows the main parts:

Component | Material/Feature | Purpose |

|---|---|---|

Outer Layers | Aluminum sheets (often recycled) | Flexibility, durability, cladding |

Core | Polyethylene or fire-retardant mineral | Insulation, structure |

Coatings | PVDF, polyester, nano-coatings | UV, chemical, and scratch resistance |

Special Features | Fire resistance, weatherproofing | Safety, resilience |

Common Applications

People use acp aluminium composite panel in lots of ways. In business buildings, acp panels cover outside walls and big glass walls. You see them on schools, offices, and factories. ACP cladding helps block noise and saves energy. At home, acp panels go on outside walls, balconies, and even inside rooms. Homeowners like acp cladding for its wood, stone, or metal looks. It adds style and keeps homes warm.

ACP panels are used in public places too. They cover airports, hospitals, and schools. ACP cladding helps with noise and saves energy. Designers use acp panels for signs and billboards because they last in bad weather and are easy to shape. Furniture makers use these panels for cabinet doors and custom items. ACPs are also found in buses, vending machines, and elevators, where safety and rust-proofing are important.

Tip: ACP cladding is strong, easy to design with, and needs little care. This makes it a great pick for new and old buildings.

Advantages of ACPs

Cost Savings

Many builders and homeowners pick acp panels because they save money. ACP panels cost less than wood cladding. They do not need much care. ACP panels do not get damaged by bugs or bad weather. Stone cladding is heavy and needs strong support. It also needs skilled workers, so it costs more. ACP panels are light. This makes them cheaper to move and install. They help lower labor and transport costs. ACP panels are a good choice for small budgets. They save money compared to brick, stone, or concrete. ACP panels do not fade or rust easily. They do not need many repairs. This saves money over time. ACP panels are smart for big and small projects.

Durability

Aluminium composite panels last a long time. They can last 30 to 50 years. Good coatings like PVDF or FEVE make them last longer. ACP panels do not rust or stain. They do not get damaged by the sun. Their smooth surface is easy to clean. ACP panels look new for years. In wet places, acp panels last 15 to 30 years. Cleaning and installing them well helps them last longer. ACP panels are strong and reliable for cladding.

In wet places, acp panels last 15 to 30 years.

Panels with special coatings last over 20 years.

Good cleaning and installation help panels last longer.

Thick aluminum and fire-safe cores make panels tough.

Waterproof and Moisture-Proof

ACP panels keep water out. Their design stops leaks and mold. The coatings protect against rain and wet air. ACP cladding works inside and outside. ACP panels do not stain or grow fungus. They stay clean in wet places. ACP panels help buildings stay dry and strong.

Fire Resistance

Safety is very important for buildings. ACP panels can stop fire from spreading. Many acp panels have fire-safe cores. These slow down flames. ACP panels have fire ratings like A2, B1, and B2. Class B panels block flames and look nice. Builders in many countries use these panels for safety. ACP cladding with fire-safe features is common in tall buildings.

Note: Fire-safe acp panels cost more, but they keep people safe and follow building rules.

Thermal and Acoustic Insulation

Aluminium composite panels help keep buildings warm and quiet. ACP panels have a core that blocks heat and sound. Tests show acp panels keep heat in and noise out. They help buildings stay warm in winter. They keep buildings cool in summer. ACP cladding makes homes and offices peaceful.

Property Tested | Test Standard | Result |

|---|---|---|

ASTM C 518 | 0.071 m²·K/W | |

Thermal Conductivity | ASTM C 518 | 14.085 W/m²·K |

Airborne Sound Transmission | ASTM E 90 | Passed |

Sound Insulation Rating | ASTM E 413 | Passed |

Design Flexibility

ACP panels let designers create cool and modern looks. Makers offer more than 50 colors and textures. You can get mirror, wood, metal, or marble finishes. ACP panels can be cut and bent into shapes. You can order special colors and sizes. ACP cladding helps with creative projects. It works for outside and inside designs. ACP panels are good for signs, furniture, and walls.

Easy Installation

Installing aluminum composite panel is quick and simple. ACP panels are light. Workers can carry and put them up easily. This means less heavy equipment is needed. Labor costs go down. Projects finish faster and save money. ACP cladding can be fixed or replaced fast. Builders like acp panels because they make work easier.

Low Maintenance

ACP panels are easy to take care of. Good coatings protect them from stains and weather. PVDF coated panels have a 20-year guarantee. PE coated panels have a 5-8 year guarantee. Cleaning is easy with water and mild soap. ACP panels look good after cleaning. Buildings stay fresh for years. Makers sometimes give free replacements for bad panels. ACP panels last long and need little care. Busy owners like them.

Other Key Benefits

ACP panels do not rust because aluminum protects itself.

The panels do not stain or get damaged by the sun.

ACP cladding is safe in earthquakes. It is light and bends instead of breaking. This helps buildings stay safe during shakes.

Tip: ACP panels save money, last long, stop fire, insulate, look good, install easily, and need little care. These features make acp panels great for modern buildings.

Disadvantages of Aluminium Composite Panels

Impact and Deformation Risk

Aluminum composite panels can get damaged if hit hard. Problems happen if panels are not put up right. Strong wind or big temperature changes can hurt them. Some common problems are:

Panels can bend or twist.

Cracks or bending can show up.

The sealant at the joints can break.

Panels might come loose from the building.

Joints may not line up right.

These issues often come from stiff connections or wrong panel direction. Not leaving space for panels to move can cause trouble. For example, a tall building in Southeast Asia had to change panels after three years. The panels bent because the joints were too tight and anchors were stiff. In another case, a public building in Northern Europe had cracked sealants. This happened because there were no thermal breaks. To stop these problems, builders should use flexible fixings and right joint sizes. They should also follow rules for thermal movement.

Tip: Careful work and checking panels often helps stop damage. This keeps the panels looking nice for a long time.

Heat Resistance Limitations

Aluminum composite panels cannot handle very high heat. Makers use special fire-safe cores to make them safer. These cores are things like alumina trihydrate or magnesium hydroxide. The panels meet fire safety rules like NFPA 285 and ASTM E84. But the highest heat they can take is about 107°C, as shown here:

Property | Test Method | Result |

|---|---|---|

Heat Deflection Temperature | ASTM D648-07 Method B | 107°C |

Panels with fire-safe cores protect better, but not forever. If the panels get too hot for a long time, the core can get weak. The panel might lose its shape or strength. This means ACP panels are not good for places with lots of heat or open flames.

Water Ingress Issues

Water can cause big problems for aluminum composite panels. Leaks happen if waterproof steps are skipped or bad sealants are used. Water can get inside the panels and make them last less time. Some water problems are:

Moisture can cause mold or rust.

Water stains and leaks can show up at joints or inside walls.

Rust can form around fasteners and panel edges.

The aluminum can peel away from the core.

Using the right sealants and backer rods helps stop these problems. After putting up the panels, checking them often is important. If water gets in, it can cause mold, rust, and damage that cannot be fixed.

Surface Damage

Aluminum composite panels can get dents or scratches. This happens in places with hail, strong wind, or lots of use. Thicker panels do better, but even they can get marks after many hits. Scratches can happen if sharp things drag across the surface. Scratches look bad and can let water or dirt in. This can cause more damage later. Protective films help during shipping and putting up the panels. But these films must come off at the right time or they leave sticky stuff behind.

Aspect | ACP Panels (Aluminum Composite) | Solid Aluminum Panels |

|---|---|---|

Scratch Resistance | High due to coatings, but can scratch with sharp objects | Susceptible to scratches, hard to repair |

Dent Resistance | Can dent from hard impacts or hail | More prone to dents and deformation |

Maintenance | Low, but needs careful handling | Repairs are difficult, color matching is hard |

Cleaning gently and handling with care keeps panels looking new. If panels get damaged, fixing them is hard and may not make them look the same.

Strength Compared to Solid Aluminum

Solid aluminum panels are made from one thick sheet. This makes them stronger and better at stopping fire. They hold up well under heavy loads and do not peel or soak up water. Aluminum composite panels have two thin aluminum layers and a plastic core. This makes them lighter and easier to put up. But they are not as strong as solid aluminum panels.

ACP panels do not bend or twist easily because of their design. Their strength depends on how thick the aluminum is and how good the glue is. They can take some wind and hits, but not as much as solid aluminum. In tough places, solid aluminum lasts longer.

Note: ACP panels are strong enough for most jobs and are light. But solid aluminum is better for projects that need the most strength and fire safety.

Environmental Impact

Aluminum composite panels can be good and bad for the environment. Many new panels use recycled aluminum and skip harmful chemicals. This makes them safer and better for the earth. Making these panels tries to lower carbon emissions. They do not give off bad VOCs, which helps air inside buildings. ACP panels also help save energy by keeping buildings warm or cool.

But recycling ACP panels is hard because of their layers. Special places are needed to take the aluminum out of the plastic core. Making the panels uses a lot of energy, which adds to greenhouse gases. If not thrown away right, ACP panels can fill up landfills and give off bad fumes.

Eco-friendly ACP panels use recycled stuff and help green building goals.

They last a long time, so less waste is made from replacing them.

They help lower heating and cooling, which cuts down on carbon.

Recycling is still hard, but new ways are making it better.

Callout: Picking ACP panels with recycled parts and good disposal plans helps the planet. This supports green building and lessens harm to the environment.

Practical Considerations for 2025

New Technologies

New Technologies

In 2025, ACP aluminum composite panels have many new upgrades. Factories use better machines to make panels the same every time. AI checks the panels and tells when they need fixing. Architects use computers and BIM to plan and test panels before building. New coatings and insulation help panels last longer and block bad weather. Factories use recycled stuff and save energy to help the planet. Fire-resistant cores follow strict safety rules. Some panels even have smart things like solar power or better insulation.

Better machines for good quality

Computer design with BIM

New coatings and insulation

Fire-resistant cores

Smart features like solar power

Tip: Picking panels with these new upgrades helps buildings last longer and saves energy.

Building Codes

Building codes in 2025 want safer and greener panels. Many cities say tall buildings must use fire-resistant ACP cores. Codes also have rules for putting up panels to stop leaks and keep people safe. Some places want proof that panels use recycled stuff or save energy. Builders must check local rules before starting work. Using panels that follow these rules helps avoid problems and fines.

Requirement | Common Standard in 2025 |

|---|---|

Fire Resistance | A2 Non-Combustible Core |

Energy Efficiency | High insulation value |

Sustainability | Recycled content, low emissions |

Installation Quality | Certified installers required |

Application Suitability

ACP panels are good for many projects. Office towers and malls use shiny panels for a modern look. Schools and hospitals pick solid colors and safe cores for easy cleaning and safety. Tall buildings need panels with A2 non-combustible cores. Homes use ACPs because they block bad weather and can look different ways. Airports, factories, and big projects use ACPs for strength and a clean look. Inside, designers use ACPs for walls, ceilings, and columns. Light panels are good for places with earthquakes or tricky shapes.

Office towers, malls

Schools, hospitals, tall buildings

Homes, apartments

Airports, factories, big projects

Inside walls, ceilings, columns

Note: Always pick the right panel and core for the building and follow local safety rules.

Choosing Aluminum Composite Panel

Decision Checklist

Picking the best ACP for a project in 2025 takes planning. This checklist helps people look at choices and pick the right one:

Look at the technical details. Check the grade, thickness, fire rating, and finish. Grades like 5005 and 3005 are common. Thickness can be from 2mm to 6mm. Fire ratings such as A2 and FR are important for safety. Finishes can be shiny, painted, or have texture.

Think about the core material. Polyethylene cores are cheaper but not good with fire. Fire-retardant cores are safer. Mineral cores are safest but cost and weigh more. Aluminum honeycomb cores are strong but light.

Make sure the panels are good quality. Look for ISO 9001 and CE marks. Ask for factory checks and reports. Good testing means the panels are safe.

Pick a good manufacturer. Think about how much they can make and if they have a good name. Check if they can make special panels. Look at order size, payment, and shipping.

See if the panels are green. Panels with recycled stuff and energy-saving ways help the earth. ISO 14001 shows they care about green building.

Make sure the panels follow local rules and fire laws.

Pick panels that fit the job. Some are best for stores, factories, signs, or transport.

Learn how the panels are made. How they are put together changes how long they last and how they look.

Finish all checks. Factory visits and paperwork help make sure the panels are good. Local rules may change what is needed.

Tip: Using a checklist helps people pick ACP panels that are safe, green, and fit their budget for building projects.

Factor | What to Check | Why It Matters |

|---|---|---|

Material Grade | 5005, 3005 | Strength, durability |

Thickness | 2-6mm | Impact resistance, weight |

Fire Rating | A2, FR | Safety, code compliance |

Surface Finish | Anodized, painted, textured | Appearance, maintenance |

Core Material | PE, FR, Mineral, Honeycomb | Fire safety, weight, cost |

Certifications | ISO 9001, CE, ISO 14001 | Quality, sustainability |

Manufacturer | Reputation, customization, logistics | Reliability, flexibility |

Installation Support | Local code compliance | Safety, legal approval |

Application Suitability | Commercial, signage, transport | Performance, longevity |

Industry experts in 2025 say ACP aluminum composite panels save money. These panels last a long time and can be used in many designs. Some types stop fire well and are good for the planet. Other types may not be as safe or strong. Some are harder to put up. The table below lists the main points for each ACP type:

ACP Type | Main Pros | Main Cons | Best Use Cases |

|---|---|---|---|

Low-Density Polyethylene | Light, cheap | Not very fire safe | Inside, safe places |

Fire-Retardant Core | Stops fire, lasts long | Costs more, heavier | Tall buildings, hospitals, schools |

Mineral Core | Best fire safety, strong | Very costly, needs experts | City, places needing fire safety |

Eco-Friendly Panels | Good for the earth | Not many design choices | Green projects, eco-buildings |

Before picking ACP panels, readers should ask:

Does the panel follow fire rules?

Will the design work for the building?

Is the panel green or has a certificate?

Does new tech make it safer or last longer?

Tip: Always look for new rules and tech before you start. This helps keep buildings safe and makes them last longer.

FAQ

What is the lifespan of ACP aluminum composite panels?

Most ACP panels last 20 to 30 years. Good coatings and proper installation help them last longer. Regular cleaning keeps panels looking new.

Are ACP panels safe for tall buildings?

Yes. Panels with fire-retardant or mineral cores meet strict safety codes. Builders should always check local rules before using ACP panels on tall buildings.

Can ACP panels be recycled?

Some ACP panels use recycled aluminum. Recycling the full panel is hard because of the mixed materials. Specialized recycling centers can separate the layers.

How do you clean ACP panels?

Use mild soap and water. Soft cloths work best. Avoid harsh chemicals or rough brushes. Regular cleaning prevents stains and keeps panels shiny.

Do ACP panels help save energy?

Yes. The core in ACP panels provides insulation. This helps keep buildings warm in winter and cool in summer. Energy bills often go down.

Structure and Materials

Structure and Materials New Technologies

New Technologies