31 Oct The Pros and Cons of Anodized Aluminium Composite Panels

Table of Contents

When you want strong and good-looking building materials, the anodized aluminium composite panel is a great choice. It has a light core and a tough anodized aluminum top that does not wear out easily. Here are some reasons why architects like these panels:

Reason | Description |

|---|---|

Stays shiny and clean for a long time. | |

Customization | You can choose colors and textures for cool designs. |

If you know the good and bad sides, you can pick the best one.

Key Takeaways

Anodized aluminium composite panels last a long time. They can handle bad weather well. This makes them a good choice for building things. These panels are easy to take care of. You do not need to spend much time or money on them. Other materials like wood or stone need more work. Anodized panels look modern and are not heavy. But they might not be as strong against hits as solid aluminium. Think about what your project needs before you choose.

What Is an Anodized Aluminium Composite Panel

Structure and Materials

An anodized aluminium composite panel is more than just shiny. It has layers that work together. There are two thin aluminum sheets on the outside. In the middle, there is a core that is not aluminum. The core can be LDPE or fire-resistant types like FR B1 or FR A2. This mix makes the panel light but strong.

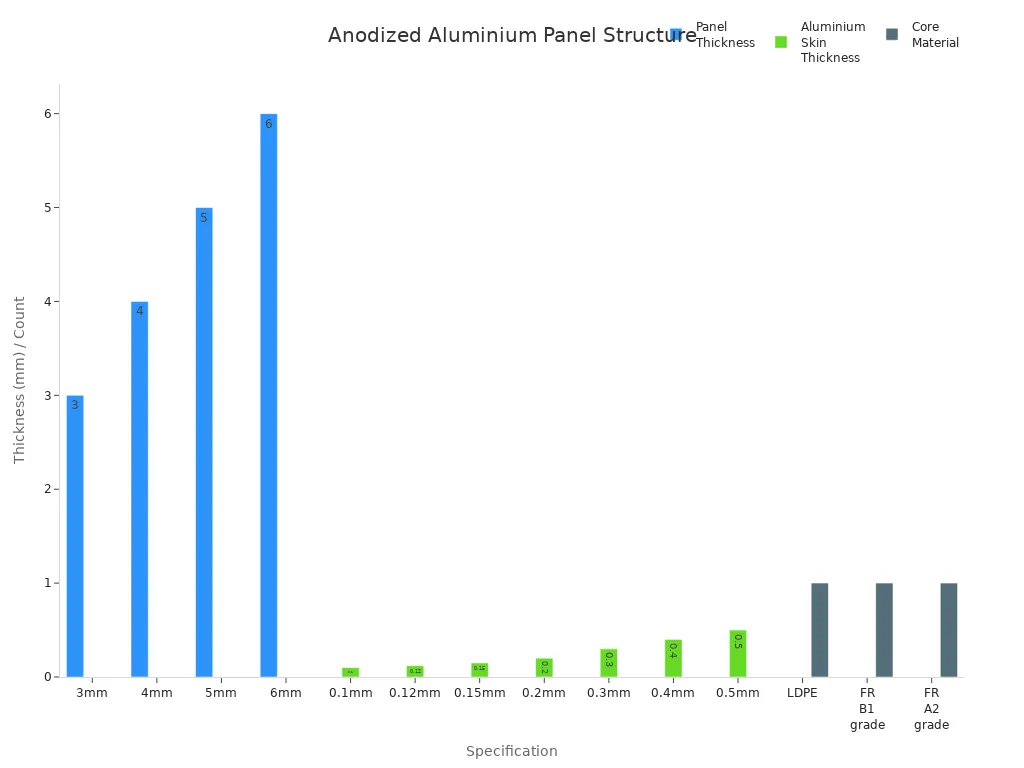

Here’s a simple table about the structure:

Specification | Values |

|---|---|

Panel thickness | 3mm, 4mm, 5mm, 6mm |

Aluminium skin thickness | 0.1mm, 0.12mm, 0.15mm, 0.2mm, 0.3mm, 0.4mm, 0.5mm |

Composite core materials | LDPE, FR B1 grade, FR A2 grade |

The top layer of aluminum gets a special coating. This coating is called an anodized oxide layer. It sticks well to the metal. It helps the panel last longer and look nice.

Anodizing Process

You might wonder how anodizing works. It is a process that makes aluminum stronger. First, the aluminum is cleaned and roughened. This removes dirt and gives it a dull look. Next, it goes into a bath with sulfuric acid. Electricity is used to make a thick oxide layer. This layer is like armor for the panel.

The anodized oxide layer keeps away rust, scratches, and chemicals. It is much stronger than paint or other coatings.

Here is what anodizing does for the panel:

Makes it resist rust by adding a thick shield.

Makes the surface harder so it does not wear out fast.

Keeps the panel looking good and colors bright.

Gives it some ceramic-like strength.

Helps the panel handle water, sun, and strong chemicals.

When you pick an anodized aluminium composite panel, you get something strong and easy to care for.

Pros and Cons

When you look at the good and bad sides of using anodized aluminium composite panels, you can see why many builders and designers pick them for cladding. Let’s talk about what makes these panels special and where you might want to be careful.

Pros of Anodized Aluminium Composite Panels

There are many good things about choosing an anodized aluminium composite panel for your project. Here is what you get:

Durability and Weather Resistance

These panels are very strong. The anodized layer works like a shield. It keeps the aluminum safe from rain, sun, and pollution. You do not need to worry about rust or fading. The surface stays tough and keeps its color for a long time.The durability of anodized aluminum composite panel means you will have less trouble later.

Low Maintenance

If you want something easy to take care of, aluminum composite panel is a good choice. You only need to clean them sometimes. You do not have to fix them a lot, unlike wood or stone.

Here is a quick table that shows how much it costs to keep different materials in good shape over ten years:Material Type

Maintenance Cost

ACP

Lower because it is durable

Wood

Needs repairs often

Stone

Costs more, but not as much as wood

Glass

Needs care, but not as much as wood

Lightweight and Easy to Install

Aluminum composite panel is lighter than solid aluminium panels. This makes it easier to move and put in place, even on big buildings.Anodized aluminium composite panels are not heavy like solid aluminium panels.

You can carry and install them without special tools.

This helps save time and money when building.

Cost-Effectiveness

The starting price of anodized aluminium composite panel is usually less than other cladding choices. You also save money because you do not need to spend much on repairs or cleaning.

The cost stays low over the years because they last long and do not need much care.Sustainability and Recycling

If you care about the planet, aluminum composite materials are a smart pick. These panels use recycled aluminium and can be recycled again when you are done with them.By picking panels made with recycled content, you help cut down on waste and save energy.

Quality and Appearance

The anodized finish gives the panels a smooth, modern look. You can pick from a few textures and colors, but not a lot. The finish stays bright and does not peel off like paint.Enhanced Fire Resistance

Some aluminum composite panel types have fire-resistant cores. These help keep buildings safer and follow strict building rules.

Here is another table that shows why these panels last a long time:

Advantage | Description |

|---|---|

Corrosion Resistance | Anodization makes a barrier that keeps the aluminum safe from weather. |

The anodized layer is hard and does not wear out fast. | |

Longevity | Anodized aluminum lasts longer than aluminum without this layer. |

Cons of Anodized Aluminium Composite Panels

Now, let’s talk about the bad sides. Every material has some problems, so it is smart to know them before you choose.

Lower Impact Strength

Anodized aluminium composite panel is strong, but not as tough as solid aluminium panels. If something heavy hits it, the panel might dent or crack.You may need extra support in places where panels could get hit a lot.

Potential Core Weaknesses

The core inside the panel can be weak. If the core is not fire-resistant, the panel can catch fire. Water can also get in if the joints are not sealed well.Panels can let water in if the joints are not waterproof.

Some panels can burn if the core is not made to stop fire.

Limited Color Range and Finish Options

You do not get as many color choices as with painted finishes. The anodized finish is strong, but there are fewer colors. Over time, the color might change a little because of the weather.

The finish is not as steady as paint, so you might see small color changes after a few years.Environmental Factors

Humidity and pollution can affect how long the panels last. The anodized layer helps stop rust, but tough weather can still cause damage over time.Factor

Impact on Sealing

Humidity and pollution can change how long the panels last.

Susceptibility to Storms and Hurricanes

These panels can get damaged in strong storms unless they are made stronger. Some companies add extra strength, but you should check if your project needs that.Upfront Cost Considerations

The price is usually lower than other cladding, but you still need to think about the starting cost. The price difference is not big, but it is good to compare with other materials.Recycling Challenges

Recycling aluminum composite materials needs special machines. The process separates the aluminium from the core, but it is not as easy as recycling pure aluminium.

When you look at the good and bad sides, you can see that anodized aluminium composite panel has many good points for cladding, but you should think about the possible problems for your project.

Applications

Building Facades and Aluminium Cladding

Building Facades and Aluminium Cladding

Aluminum composite panel is used a lot on buildings. Architects like aluminium cladding because it looks new and lasts long. The anodised aluminium cladding makes buildings shiny and clean. It protects from rain, sun, and wind. Look at this table to see why people choose aluminium cladding for outside walls:

Characteristic | Description |

|---|---|

Enhanced Durability | Stays strong against scratches and weather |

Aesthetic Versatility | Many colors and finishes for cool designs |

Lightweight & Strong | Easy to install and move |

Low Maintenance | Needs little cleaning or repair |

Aluminum cladding is lighter than other wall materials. You save money because you do not need big tools or many workers. The panels help keep buildings cool or warm.

Interior Uses

Aluminium cladding works inside buildings too. You can use it for walls, ceilings, and furniture. Some aluminum composite panel types have a fire-retardant core. This makes rooms safer. The metal skins push heat away. The core can stop burning fast. This helps meet fire safety rules in offices and stores.

The panels are easy to clean.

You get a modern look for your space.

Aluminum cladding keeps rooms safe and stylish.

Signage and Branding

Aluminum composite panel is good for signs. These panels stay bright and do not fade in sunlight. They work for indoor and outdoor signs. Here is a table showing why aluminium cladding is great for signs:

Feature | Benefit |

|---|---|

Polished Look | Signs look new for years |

No rust or fading outside | |

UV Protection | Colors stay strong in sunlight |

Fire Resistance | Safer for public spaces |

You can cut and shape aluminum cladding for logos or designs. This makes it good for branding.

Aluminum Cladding in Transportation

Aluminum cladding is used on buses, trains, and airplanes. The panels are light, so vehicles use less fuel. The strong aluminium skin protects from bumps and bad weather. You get a smooth look that lasts.

Aluminum cladding lowers the weight of vehicles.

It stands up to rain, sun, and dirt.

The cost is worth it because repairs are fewer.

You see aluminium cladding on buildings and vehicles. When you pick aluminum composite panel, you get style, safety, and savings.

Anodized aluminium composite panels give you many good things. They are strong, simple to clean, and look nice. You should think about what you need. Look at this table before you choose:

Factor | Why It Matters |

|---|---|

Quality | Stays nice and lasts longer |

Fire Resistance | Helps keep your building safe |

Budget | Lets you save money over time |

Choose the one that works best for your project!

FAQ

What makes anodized aluminium composite panels different from painted panels?

You get a tougher surface with anodized panels. The color stays longer. The finish does not peel or chip like paint.

Can you use these panels in wet or humid places?

Yes, you can. The anodized layer protects against water. Just make sure you seal the joints well.

How do you clean anodized aluminium composite panels?

You only need mild soap and water. Use a soft cloth. Avoid harsh cleaners or rough sponges.

Building Facades and Aluminium Cladding

Building Facades and Aluminium Cladding