27 Jul What You Need to Know About PVDF Aluminium Composite Panels in 2025

Table of Contents

A pvdf aluminium composite panel features lightweight aluminum and a durable core, topped with a resilient pvdf coating. By 2025, pvdf aluminium composite panel products are widely used, with architects, builders, and property owners relying on them for challenging environments. The construction industry favors pvdf aluminium composite panel solutions because they offer long-lasting performance in harsh weather, resist chemicals, and maintain their color exceptionally well.

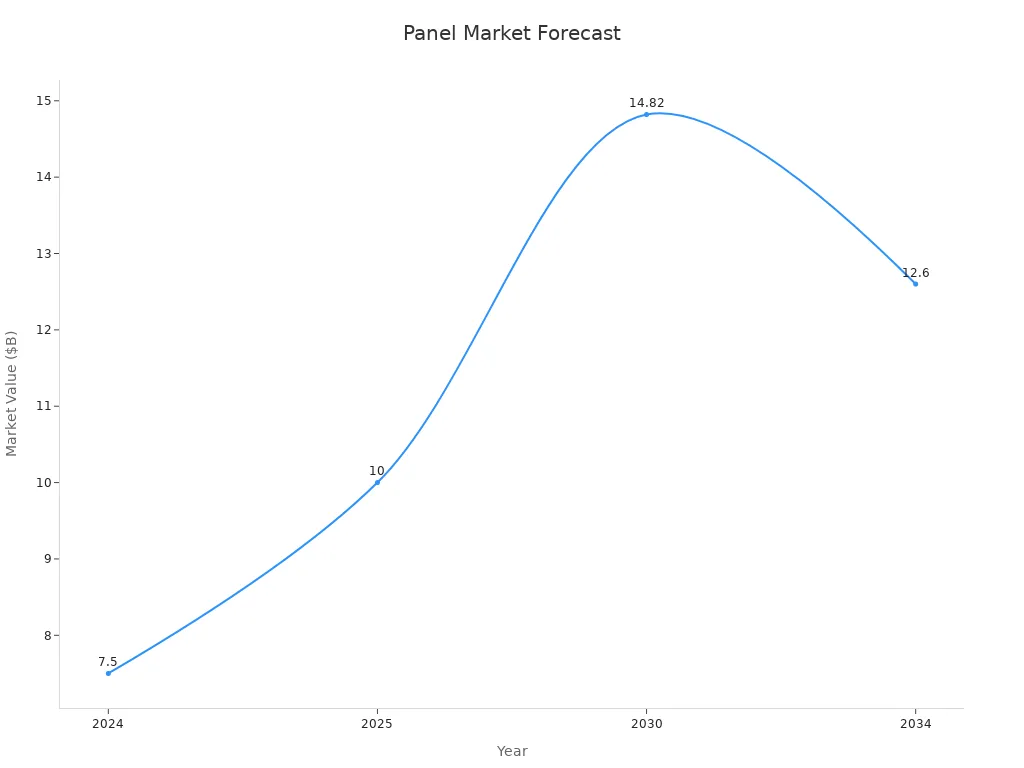

The global market for aluminium composite panels reached $6.6 billion in 2024, with pvdf aluminium composite panel products accounting for over 34% of this market.

Pvdf aluminium composite panel systems provide lasting visual appeal, energy efficiency, and require minimal maintenance due to their unique properties.

These panels give buildings a modern appearance, enhance structural durability in adverse weather, and reduce maintenance needs, making pvdf aluminium composite panel a top choice for contemporary construction.

Key Takeaways

PVDF aluminium composite panels protect buildings from weather, chemicals, and fire. This makes buildings safer and last longer. The PVDF coating keeps the panels bright and colorful for many years. You do not need to do much to keep them looking nice. These panels help save energy. They keep buildings cool in summer and warm in winter. This helps with green building goals. PVDF panels are light and easy to put up. They do not cost much over time because they last long and need little care. You can use them outside or inside. They work for building fronts, signs, and decorations.

PVDF Aluminium Composite Panel Overview

Structure and Composition

A pvdf aluminium composite panel has layers for strength. Two thin aluminum sheets are glued to a core. The core is made from polymers and mineral fillers. This core helps stop fires and keeps heat in. The aluminum layers are hard and do not rust. This makes the panels last longer. The outside layers get a pvdf coating. This coating stops fading and damage. Factories use careful controls to make each acp. They check the thickness very closely. This makes sure every panel is high quality. Because of this, aluminum composite panels are light but strong. They work well for many building jobs.

PVDF Coating Features

The pvdf coating is also called kynar. It gives special features to acp panels. The coating uses polyvinylidene fluoride, a strong resin. First, the aluminum is cleaned and prepared. Then, a primer is put on to help the coating stick. Next, a top coat with pvdf paint adds color and protection. A clear coat is added last to seal in color and shine. Kynar coatings block UV rays, chemicals, and scratches. Tests show that pvdf-coated acp panels keep their color and shine for a long time. They do not fade in sunlight or bad weather. The coating also makes the panels hydrophobic. This means water and dirt slide off easily. Kynar helps the panels stay clean and bright with little work.

Note: Tests show that pvdf coatings stop flames, bend without breaking, and clean themselves. These things make pvdf aluminium composite panel products safe and useful for many jobs.

Test Type | Feature Validated | Key Findings |

|---|---|---|

UV resistance, durability | Color and shine stay the same after sunlight | |

Mechanical Stability | Physical durability | Only small changes after sand and rubbing |

Water Contact Angle | Hydrophobicity | Water beads up, showing strong self-cleaning |

Flame Retardant Test | Fire safety | Panels do not burn easily, so buildings are safer |

Flexibility Test | Adaptability | Panels can bend and twist without breaking |

2025 Relevance

In 2025, pvdf aluminium composite panel products are still very popular. The pvdf coating part leads because it lasts long and does not rust or wear out. New tech like AI helps with fixing and planning costs. Digital tools like BIM make building easier. People care more about the planet now. Makers use green materials and parts that can be recycled in aluminum composite panels. Many projects want green building awards. Pvdf-coated acp panels help reach these goals. Special finishes and textures let people design new looks. The market for polyvinylidene fluoride aluminum composite panels keeps growing. More people want them for building, travel, and ads. Kynar coatings last a long time. They help the market grow and meet tough safety and earth-friendly rules.

Benefits of PVDF Aluminium Composite Panels

Durability and Weather Resistance

PVDF aluminium composite panels are very strong and last a long time. They can handle bad weather and tough conditions. Factories test how well they hold together and how thick the coating is. They also check if the panels shine and if they can take a hit. The panels should not break or peel when hit. They are tested with strong acids and bases for a whole day. The panels do not change after these tests. They are also put through hot and cold cycles to see if the coating stays strong. Tests outside, like on Hainan Island, show the panels keep looking good for years.

Flexural strength and modulus tests

Coating thickness measurements (fluorocarbon coating ≥ 25μ)

Gloss test with strict error limits

Impact resistance test (no cracking under 50kg·cm)

Acid and alkali resistance (5% hydrochloric acid and sodium hydroxide for 24 hours)

Abrasive resistance tests

High/low temperature cycling (80°C and -40°C)

Natural weather exposure tests

These tests show PVDF ACP panels can last in hard weather. They keep working well even in very tough places. The panels also meet fire safety rules like GB8624-2012 for safe core materials. This makes them a safe pick for many buildings.

Chemical and Fire Resistance

PVDF aluminium composite panels can stand up to strong chemicals. The PVDF coating keeps acids and bases from hurting the panels. This makes them good for factories, hospitals, and places with lots of pollution. The panels do not rust or get old fast. The core has flame retardant and fireproof parts. This helps the panels pass hard fire safety tests. These tests include ASTM E84, NFPA 285, and EN 13501-1. The panels meet world fire safety rules, so builders use them in tall buildings and other important places. Certifications like SGS, CE, and ISO 9001:2008 prove the panels are safe and high quality.

PVDF ACP panels are safe from chemicals and fire, so people trust them inside and outside.

Color and Gloss Retention

PVDF coated ACP panels keep their color and shine for many years. Factories use special tests to see how well the panels last. Long tests in places like south Florida show the panels change color very slowly, even after 10 or 15 years. Lab tests also check if the panels keep their shine and color. Standards like ASTM D2244, ASTM D4214, and AAMA 2605 are used for these tests. Good panels keep 85% to 90% of their shine after five years of hard weather. The color change (ΔE) is small, usually between 3 and 5 or less. Some famous buildings, like the Burj Khalifa, use PVDF ACP panels and still look almost the same after more than ten years.

Test Type | What It Checks | Result After 5-10 Years |

|---|---|---|

Natural Exposure | Color retention | Gradual, small color change |

Accelerated Aging (QUV) | Gloss retention | 85%-90% gloss kept |

Salt Spray (ASTM B117) | Corrosion resistance | No rust or blistering |

Adhesion (Cross-cut) | Coating strength | Minimal decrease, strong rating |

These results show PVDF ACP panels can handle bad weather and keep looking nice for a long time. The panels do not get chalky or dusty, so they stay bright and clean.

Energy Efficiency and Sustainability

PVDF aluminium composite panels help buildings save energy. The panels help keep buildings cool in summer and warm in winter. This means people use less electricity. Many builders pick PVDF ACP panels to meet green building goals. The panels use materials that can be recycled, which helps the planet. Makers try to use earth-friendly materials and follow ways to reuse things. More people want PVDF ACP panels because they help save energy and are good for the environment.

PVDF ACP panels help save energy and protect the planet, so they are a smart choice for new buildings.

Other good things are that the panels stop graffiti and germs. They are easy to clean and do not need much care. Dirt and water slide off, so buildings look new for a long time. This saves money on cleaning and keeps the building looking nice.

Applications of Aluminum Composite Panels

Building Facades and Cladding

Building Facades and Cladding

Architects and builders like to use ACP for building outsides. These panels are strong and light. They keep their color for a long time. PVDF coatings protect the panels from bad weather and sun. The coating also stops rust. This is why many big buildings use them. The panels let people make cool shapes and patterns. For example, the Quai9 Cultural Center in France used over 2,000 ACP panels with a special PVDF coating. The building is close to the sea, so it gets strong winds and saltwater. The panels do not lose color or shape, even in these hard places. The outside looks like folded paper and lets sunlight in during the day. At night, the building shines from the inside.

Project Name | Quai9 Cultural Center, France |

|---|---|

Material Used | |

Challenge | Coastal location, high UV, salt exposure |

Design | Origami-like, perforated, daylight and night glow |

Outcome | Durable, beautiful, long-term warranty |

These things show why ACP is a favorite for building outsides in many places.

Interior and Signage Uses

ACP panels are good for inside buildings and for signs. They stay flat and smooth, which helps with printing and design. Many companies use ACP for walls, ceilings, and room dividers. The panels come in many colors and finishes, so designers can match any style. For signs, ACP stands up to sun, rain, and dirt. The panels do not fade or stain easily. They are easy to clean and last a long time. Fire resistance and soundproofing make buildings safer and quieter.

The panels do not chalk or fade, even outside.

ACP is great for places that need to look good and last.

Performance Aspect | Benefit | Application |

|---|---|---|

Flatness & Printability | Easy to print, smooth surface | Signs, displays |

Durability | Long-lasting, low maintenance | Interiors, public spaces |

Fire Resistance | Safe for indoor use | Schools, hospitals |

ACP is a smart pick for both inside and outside jobs.

Trends for 2025

More people want pvdf acp in 2025. Builders pick ACP because it saves energy and is safe from fire. Outside panels are the most popular, especially for building fronts and signs. Asia-Pacific uses the most, but North America and Europe are growing fast too. New rules for fire safety and green buildings make companies choose better panels. New ideas like nanotechnology coatings and smart sensors make ACP even better. The market could reach $10 billion in 2025 and keep getting bigger.

ACP panels now have more colors, finishes, and designs. They help buildings look new and save energy. As cities get bigger, people need strong and nice-looking building materials. ACP gives strength, beauty, and is easy to care for.

PVDF-Coated ACP Panels vs. Other Materials

Performance and Maintenance

PVDF-coated acp panels work well and are easy to care for. Builders like them because they last many years. They do not need much fixing or painting. The PVDF coating keeps out sun, rain, and harsh chemicals. This helps the panels keep their color. They do not rust or break easily. Wood and vinyl need more repairs and painting. Steel can get rusty if not protected. Fiber cement sometimes needs to be fixed. The table below shows how pvdf-coated acp panels do better than other cladding materials:

Aspect | PVDF-Coated ACP Panels | Alternative Cladding Materials |

|---|---|---|

Durability | Lasts 40-50 years, resists corrosion | Wood: 10-20 years, rots; Steel: rusts; Vinyl: cracks; Fiber Cement: moderate |

Maintenance | Low, simple cleaning | Wood: high; Steel: rust prevention; Vinyl: repairs; Fiber Cement: repainting |

Weather Resistance | Superior, UV and moisture protection | Wood/vinyl: less resistant; Steel: rusts |

Fire Safety | Meets strict codes | Varies, wood less safe |

This shows pvdf-coated acp panels are stronger and need less work than most other choices.

Environmental Impact

Caring for the earth is important today. PVDF-coated acp panels help the planet in many ways:

They can be recycled, so less trash goes to dumps.

They are light, so trucks use less fuel to move them.

The panels last a long time, so buildings do not need new panels often.

Studies say metal panels, like pvdf-coated acp panels, make less pollution than concrete or brick walls.

The PVDF coating helps the panels last longer and keeps them safe from weather and chemicals.

These things make pvdf-coated acp panels a good pick for green building projects.

Cost Comparison

Builders think about price and value. PVDF-coated acp panels cost more at first than some other panels. But they save money later because they last longer and need less care. The panels help save energy by keeping buildings cool or warm. PVDF-coated acp panels are liked because they are strong, last long, and are worth the price. New tech makes them cheaper and easier to put up. Builders see that these panels help lower the total cost of owning a building.

Tip: PVDF-coated acp panels can be put up 40% faster than old materials, which saves time and money.

PVDF aluminium composite panels are popular in 2025 because they are strong and keep their color. They also help save energy. Builders and architects like these panels because they last a long time and do not need much care.

These panels can handle bad weather and strong chemicals.

They help with green building plans.

They come in many styles and looks.

If you want to know more, you can read guides from makers or talk to local sellers. PVDF ACP panels make new projects work well.

FAQ

What makes PVDF aluminium composite panels different from regular ACP?

PVDF aluminium composite panels have a special PVDF coating. This coating helps protect them from sun, rain, and chemicals. Regular ACP panels might not last as long. They may also lose their color faster.

Can PVDF ACP panels be recycled?

Yes, you can recycle PVDF ACP panels. The aluminum and the core can go through recycling. Many builders pick these panels for green building projects.

How do you clean PVDF aluminium composite panels?

You can clean PVDF ACP panels with water and mild soap. The panels do not get dirty or stained easily. You do not need strong cleaners or special tools.

Are PVDF ACP panels safe for tall buildings?

PVDF ACP panels follow strict fire safety rules. Builders use them on tall buildings because they resist fire and bad weather. Certifications show these panels are safe.

Building Facades and Cladding

Building Facades and Cladding