25 Jul How PVDF Aluminium Composite Panels Enhance Building Performance

Table of Contents

- 1 Key Takeaways

- 2 Key Properties

- 3 Benefits of PVDF Aluminium Composite Panel

- 4 Applications of Aluminium Composite Panel

- 5 Maintenance for PVDF Aluminum Composite Panels

- 6 FAQ

- 6.1 What makes PVDF aluminium composite panels different from regular panels?

- 6.2 How do PVDF-coated ACP panels improve energy efficiency?

- 6.3 Can PVDF aluminium composite panels be used for any building facade?

- 6.4 What are the main benefits of PVDF coating on ACP panels?

- 6.5 How should owners maintain aluminium composite panels for maximum longevity?

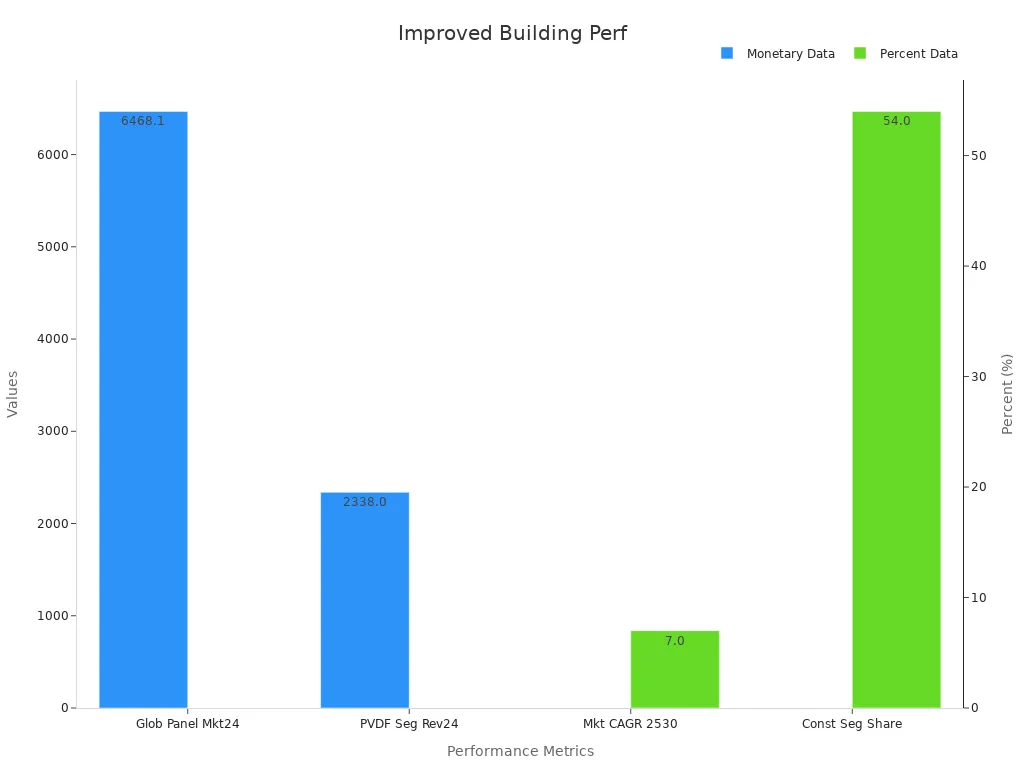

PVDF aluminium composite panels help buildings work better. They have strong mechanical quality, resist bad weather, and block UV rays. This makes them last longer and save energy. The pvdf coating on acp panels gives them high strength. It also lowers the number of panels thrown away by over 40% when making them. These panels keep looking good and stay strong in tough weather. Builders use them in many ways for new buildings.

Metric/Attribute | Value/Statistic | Building Performance Aspect |

|---|---|---|

PVDF Segment Revenue (2024) | USD 2,338.0 million | Preference for PVDF coating in aluminium composite panel |

Key Features of PVDF ACPs | High insulation, superior sealing, air & water barriers, durability, high tensile strength, lightweight | Enhanced thermal/acoustic insulation, structural integrity, energy efficiency |

More people around the world want pvdf aluminum composite panels. They are important for building things. These panels are easy to take care of and last a long time. They also help make buildings greener. This makes pvdf aluminium composite panel a smart choice for many uses.

Key Takeaways

PVDF aluminium composite panels are very strong and last long. They do not get damaged by weather. Their color and shine stay for many years. This helps buildings last longer and look nice.

The PVDF coating keeps panels safe from UV rays. It also protects them from acid rain, dirt, and pollution. This means you do not need to clean or fix them often.

These panels help save energy by keeping heat out. They insulate buildings well. This lowers energy bills and keeps rooms comfortable.

PVDF panels are light and bend easily. You can use them for many designs. They are easy to put on different buildings.

Clean the panels with mild soap to keep them nice. Check them every year to make sure they last long. This helps them work well for many years.

Key Properties

PVDF Coating Advantages

PVDF coating gives acp panels their best features. It helps the panels resist chemicals, fire, and damage over time. PVDF-coated acp panels keep their color and shine for many years. The pvdf coating protects the surface from UV rays, acid rain, and strong chemicals. This makes pvdf aluminum composite panels great for outside walls and cladding.

Manufacturers use a special mix to make the pvdf coating on acp panels. This mix makes the surface flat and keeps dirt away. PVDF-coated acp panels do not get dirty or marked by graffiti easily. They also resist pollution, so buildings stay clean with less work. The pvdf coating helps the panels last through bad weather and stops rust. These features help buildings look good and work well for a long time.

Note: PVDF aluminum composite panels can last over 50 years. The pvdf coating keeps the panels strong and bright in tough weather.

PVDF coating is not just for looks. PVDF-coated acp panels block sound and help control heat. This makes them good for schools, hospitals, and offices. The pvdf coating helps buildings look nice and work better.

Mechanical Strength

PVDF aluminium composite panel is strong because of its special structure. Each sheet has two thin aluminum layers with a core in the middle. The pvdf coating on acp panels makes them even tougher. Adding fillers like barium titanate and nanocellulose makes pvdf stronger and stiffer. Some pvdf-coated acp panels are much stronger than panels without these fillers.

PVDF-coated acp panels have:

High strength

More stiffness

Good flexibility

Strong impact resistance

These features help pvdf aluminum composite panels handle wind and hits. The panels do not crack or break easily. This makes them safe for tall buildings and busy places. The pvdf coating keeps the surface smooth and flat, which helps with how they look and how they are put up.

Weather and Corrosion Resistance

PVDF aluminum composite panels stand up to all kinds of weather. The pvdf coating on acp panels protects against rain, sun, snow, and pollution. The pvdf coating stops rust, so the panels do not fade or break down. This is important for buildings near the sea or in cities.

Test Type | Standard/Test Method | Quantitative Result/Performance | Comparison/Notes |

|---|---|---|---|

ASTM B117 | ≤1mm corrosion expansion after 3000 hours | Ordinary painted steel corrodes in 500 hours | |

UV Aging | ASTM G154 / QUV | ΔE ≤ 2.0 after 4000 hours (equivalent to 10 years) | PVC board ΔE > 5.0; PVDF coating light retention ≥90% |

Freeze-Thaw Cycles | GB/T9268 | 50 cycles without cracking | Micro-cracks appear in stone |

Acid Rain Corrosion | ISO 9227 | 30 days immersion in 5% H₂SO₄ without discoloration | Ordinary aluminum shows pitting |

Wind Load Resistance | GB/T17748-2016 | Deflection < L/180 at 30m/s wind speed (4mm board) | Exceeds L/100 standard |

Mechanical Durability | Wind Load Test | Bending strength ≥100MPa; deflection < L/180 at 90m/s wind speed | Equivalent to level 17 typhoon |

Color Retention | Field Data | 82% gloss retention after 12 years outdoor exposure | Acrylic panels yellowed in same period |

Peeling Strength | Field Data | Maintained 4.5N/mm after 15 typhoon seasons (initial 5.0N/mm) | High durability under extreme wind conditions |

Temperature Adaptability | EN 485 / Field Test | Stable service from -50°C to +80°C; bending radius 3× thickness at -50°C without cracks | Aluminum single plate fractures at -20°C |

The pvdf coating on acp panels keeps color and shine, even after years outside. PVDF-coated acp panels do not get damaged by acid rain or salt spray. This makes them good for cities and places near the ocean. The pvdf coating also stops dirt and stains from sticking. This means less cleaning and lower costs.

PVDF aluminum composite panels work in very hot or cold weather. They stay strong from -50°C to +80°C. The panels do not crack or lose strength in extreme weather. The pvdf coating keeps the panels flexible and tough, even after many freeze-thaw cycles.

PVDF aluminium composite panel is a smart choice for buildings that need to last. The pvdf coating protects the panels from damage, so buildings look new for years. PVDF coating is used in harsh places and polluted cities, where other materials might not work.

Benefits of PVDF Aluminium Composite Panel

Durability and Longevity

PVDF aluminum composite panels are known for being tough and lasting a long time. The pvdf coating on acp panels keeps the surface safe from bad weather, UV rays, and pollution. This helps the panels keep their color and shine for many years. These panels have passed hard tests, like salt spray and UV light, showing they can last over 20 years outside. In real life, these panels often look new after many years, even at airports and power stations. Long studies show pvdf aluminum composite panels stay strong and look good for 30 to 50 years. The pvdf coating on acp panels stops fading, chalking, and cracking, so buildings stay nice and safe. This means less fixing or replacing, which saves time and money for owners. The pvdf coating also protects against chemicals, acid rain, and very hot or cold weather. These things make pvdf aluminum composite panels a smart pick for cities and places near the sea.

Note: PVDF coatings last 30-80% longer than other coatings, so they are a good choice for buildings that need to last.

Low Maintenance

A big benefit of pvdf coating is that it is easy to take care of. PVDF aluminum composite panels only need simple cleaning to stay nice. Most of the time, you just wash the panels with soap and water. The pvdf coating on acp panels stops dirt, graffiti, and stains from sticking, so the panels stay clean with little work.

Owners should check joints and sealants once a year to keep water out and keep the panels strong.

Cleaning off bird droppings and dirt quickly helps protect the pvdf coating on acp panels.

Do not drill, cut, or use strong water sprays on the panels after they are put up, to keep them safe.

Makers often give 10-15 year color warranties and up to 25 years for the panel’s strength.

With good care, pvdf aluminum composite panels can last 20 to 30 years without needing new paint or big repairs. These things help owners spend less money and time on taking care of their buildings.

Energy Efficiency

PVDF aluminum composite panels also help save energy. The pvdf coating on acp panels and good air sealing help stop heat from escaping buildings. A one-year test by Oak Ridge National Laboratory showed that aluminum composite panels with pvdf coatings can cut heat loss by up to 54%. This means buildings stay cooler in summer and warmer in winter, so energy bills go down.

PVDF aluminum composite panels have high insulation and strong air and water barriers. These things help keep rooms comfortable inside. The pvdf coating on acp panels also bounces sunlight away, so the building does not get too hot. This energy saving helps make buildings greener and saves owners money over time.

Design Flexibility

PVDF aluminum composite panels are great for design because they are flexible. Architects and designers can pick from many colors, textures, and finishes. The pvdf coating on acp panels lets people use custom patterns, digital prints, and even high-quality pictures. This makes it easy to make buildings look special and cool.

PVDF aluminum composite panels can look like stone, wood, or metal.

Digital tools like AR and VR help architects see what buildings will look like before they are built.

Famous buildings like the Burj Khalifa and Guangzhou International Finance Center use pvdf aluminum composite panels for their modern style and long-lasting beauty.

The pvdf coating keeps colors bright and shiny, even after many years. New ideas like nanocoatings add self-cleaning and anti-graffiti features, making the panels even better. These benefits let architects make bold and creative buildings that stay nice and safe.

Applications of Aluminium Composite Panel

Building Types

PVDF aluminium composite panels are used in many buildings. Builders put these panels on the outside and inside of tall towers, malls, schools, and houses. The panels cover the front of stores and offices to make them look new. Factories use these panels because they are strong and easy to clean. Architects like these panels for curtain walls and building fronts. The panels are light and simple to put up. You can also see these panels in ads and public places. They help block noise in busy cities. These panels are useful for many building jobs.

People use them for:

Outside walls on homes and stores

Making old and new buildings look better

Inside walls and ceilings

Factory and work building fronts

Signs and ad boards

Climate Adaptability

PVDF aluminium composite panels work well in tough weather. The panels stop UV rays, water, acid rain, and hot or cold air. Nano PVDF coatings give more protection and help the panels clean themselves. These panels do not rust or lose color in salty, snowy, or hot places. The PVDF coating sticks well to the aluminum, so the panels look good for a long time. These panels are good for inside and outside use in places with bad weather. They also meet fire safety rules, which keeps buildings safer.

Tip: Nano PVDF panels need less cleaning and last longer, even in places with strong sun or heavy rain.

Environmental Impact

Many builders want to use green materials now. PVDF aluminium composite panels help make buildings better for the planet. The panels save energy and help lower heating and cooling bills. Makers design these panels to be recycled and to give off less bad gas. Some companies use old materials to make new panels. More people want these panels because they are good for the earth. Builders pick these panels to follow new green rules and make buildings better for nature.

Environmental Benefit | Description |

|---|---|

Energy Efficiency | Reduces energy use for heating and cooling |

Recyclability | Panels can be recycled after use |

Low VOC Emissions | Improves indoor air quality |

Supports circular economy practices |

People like PVDF aluminium composite panels because they help make modern buildings greener.

Maintenance for PVDF Aluminum Composite Panels

Cleaning Tips

Cleaning Tips

Cleaning PVDF aluminum composite panels often keeps them bright and strong. Most panels need only water and mild soap for washing. Use a soft sponge or cloth to wipe away dust and stains. Special coatings on these panels make cleaning simple. Dirt and stains do not stick easily. These coatings also help stop scratches and fading.

Superhydrophobic coatings help panels clean themselves. Water drops roll off and take dust with them. Studies show these panels stay cleaner and work better than panels without coatings. Superhydrophobic surfaces remove dust well, even if the panel is steep or the dust is tiny.

In dry places, you can clean panels without water. PVDF piezoelectric films shake dust off with gentle electric vibrations. This saves water and keeps panels clear and flexible. For tough stains, use sodium hypochlorite, but be careful. Too much or leaving it on too long can hurt the panel. Always rinse the panels well after using any cleaner.

Tip: Clean panels at least two times each year. If your area is dusty or polluted, clean more often to keep panels looking new.

Maximizing Service Life

Taking care of PVDF aluminum composite panels helps them last longer. Owners should check for cracks, loose edges, or broken sealants every year. Fixing small problems early stops bigger ones later. Special coatings help stop fading, scratches, and even germs. This helps panels work well for a long time.

Do not use sharp tools or strong water jets on the panels. These can scratch or dent the surface. Always use soft brushes or cloths for cleaning. When using chemicals, follow the maker’s instructions to protect the finish.

Good care helps panels last for many years. Clean them often, check them carefully, and handle them gently. These steps keep buildings looking nice and working well every year.

PVDF aluminium composite panels make buildings work better in many ways. They can handle bad weather, rust, and scratches. These panels come in lots of colors and styles, so they match any look. Builders like them because they are light and simple to put up. This saves time and money on the job. The panels help keep heat out or in, so buildings use less energy. More people around the world are choosing these panels for new buildings.

They stay strong in tough weather.

There are many finishes for different designs.

They are light, so they go up fast.

They help keep buildings warm or cool.

They look good for a long time and need little care.

PVDF aluminium composite panels are a smart pick for new buildings or fixing old ones.

FAQ

What makes PVDF aluminium composite panels different from regular panels?

PVDF aluminium composite panels have a special pvdf coating. This coating helps them stand up to bad weather. It also keeps their color bright and stops pollution from sticking. These things help the panels last longer. They also help buildings look new for many years.

How do PVDF-coated ACP panels improve energy efficiency?

PVDF-coated acp panels bounce sunlight away. They also block heat from getting inside. This keeps buildings cooler in summer. It also keeps them warmer in winter. The panels give good insulation. This lowers energy bills and helps the planet.

Can PVDF aluminium composite panels be used for any building facade?

Yes, aluminium composite panels with pvdf coating fit many facades. Builders use them on homes, offices, and factories. The panels are strong and last a long time. They also resist bad weather. This makes them good for many jobs.

What are the main benefits of PVDF coating on ACP panels?

PVDF coating makes panels last longer. It stops rust and is easy to clean. The coating protects the aluminium composite panel sheet from acid rain and UV rays. It also keeps dirt off. This means less work to keep them nice and they last longer.

How should owners maintain aluminium composite panels for maximum longevity?

Owners should wash aluminium composite panels with mild soap and water. They should check for damage or loose parts every year. Do not use sharp tools or strong chemicals. Good care keeps the panels strong and helps them last longer.

Cleaning Tips

Cleaning Tips