02 Feb Understanding PVDF Aluminum Composite Panels

Table of Contents

You can find a pvdf aluminum composite panel in many new buildings. Each panel has layers that make it strong and bendable:

Layer | Description |

|---|---|

Protection Film | Protects the panel when people move or install it. |

PVDF Coating | Makes the panel tough and keeps out bad weather. |

Aluminium Skin | Gives support with light metal sheets. |

Polyethylene Core | Makes the middle strong and light. |

Service Coating | Gives more protection so it lasts longer. |

The PVDF coating ACP is what makes pvdf aluminum composite panels special. This coating helps the panels last a long time. It keeps the colors bright and safe from acid rain and sunlight. You can see that pvdf-coated ACP panels stay shiny for over 20 years and do not need much cleaning. The world wants more pvdf aluminum composite panel products every year. People want panels that do not crack, fade, or wear out fast. When you pick pvdf-coated ACP panels, you get panels that can handle bad weather, dirty air, and many years of use.

Key Takeaways

PVDF aluminum composite panels are tough and light. This makes them great for buildings and outdoor signs. The PVDF coating keeps panels safe from UV rays, rain, and chemicals. This helps them stay bright and last more than 20 years. You can pick from many colors and finishes to fit your design. These panels also cost little to take care of. They are cheap and need only a little cleaning. You do not need to repaint them, so you save time and money. PVDF-coated panels are safe in places where fires can happen if you use a fire-resistant core. This gives extra safety.

PVDF Aluminum Composite Panel Basics

Structure and Materials

PVDF aluminum composite panels have a clever design. They are strong but also light. Each panel has two thin aluminum sheets outside. These sheets protect the panel and make it smooth. The core sits in the middle of the panel. It is between the aluminum layers. There are different kinds of core materials:

Polyethylene core makes the panel light and easy to carry.

Fire-resistant core helps stop fire from spreading.

Both cores keep the panel stiff and hard to bend.

These core materials help the panel stand up to bad weather. They also help the panel handle bumps and hits. That is why PVDF aluminum composite panels are good for buildings and signs outside.

You may want to know about the sizes and thickness. Here is a table with the usual measurements:

Specification | Range |

|---|---|

Aluminum skin thickness | 0.21mm – 0.50mm |

Total panel thickness | 3mm – 6mm (recommended 4mm) |

1220mm × 2440mm |

These numbers show you can pick the right panel. You can choose thin panels or thicker ones for more strength. This choice is why PVDF aluminum composite panels work in many places.

PVDF Coating Overview

The PVDF coating makes these panels special. It is a layer on the outside of the panel. This layer keeps rain, sun, and dirt away from the aluminum. The PVDF coating uses strong chemicals that last a long time. The colors stay bright because the coating stops fading.

Let’s look at how PVDF coating is different from powder coating. Here is a table to compare them:

Feature | PVDF | Powder Coated |

|---|---|---|

Wear Resistance | Excellence | Good |

Shelf Life | 7–8 years | |

Price | Expensive | Economic |

Coating Thickness | 30–35 μm | 50–60 μm |

Process | Air spraying, thermal spraying, high pressure spraying | Electrostatic spraying |

Color Options | RAL color chart or customize | N/A |

PVDF coating lasts longer and keeps its color better. You get more choices for colors and finishes. The PVDF coating uses air spraying or thermal spraying. This helps the coating stick to the aluminum. Your panels will not peel or crack, even after years outside.

Tip: Pick PVDF aluminum composite panels with PVDF coating if you want panels that stay nice for a long time and do not need much cleaning. You get both good looks and strength.

The PVDF coating does more than add color. It protects the panel from bad weather, chemicals, and scratches. When you choose PVDF aluminum composite panels, you get panels that stay bright, clean, and strong for many years. That is why builders and architects use these panels for big projects.

PVDF Coating Science

Chemical Properties

Chemical Properties

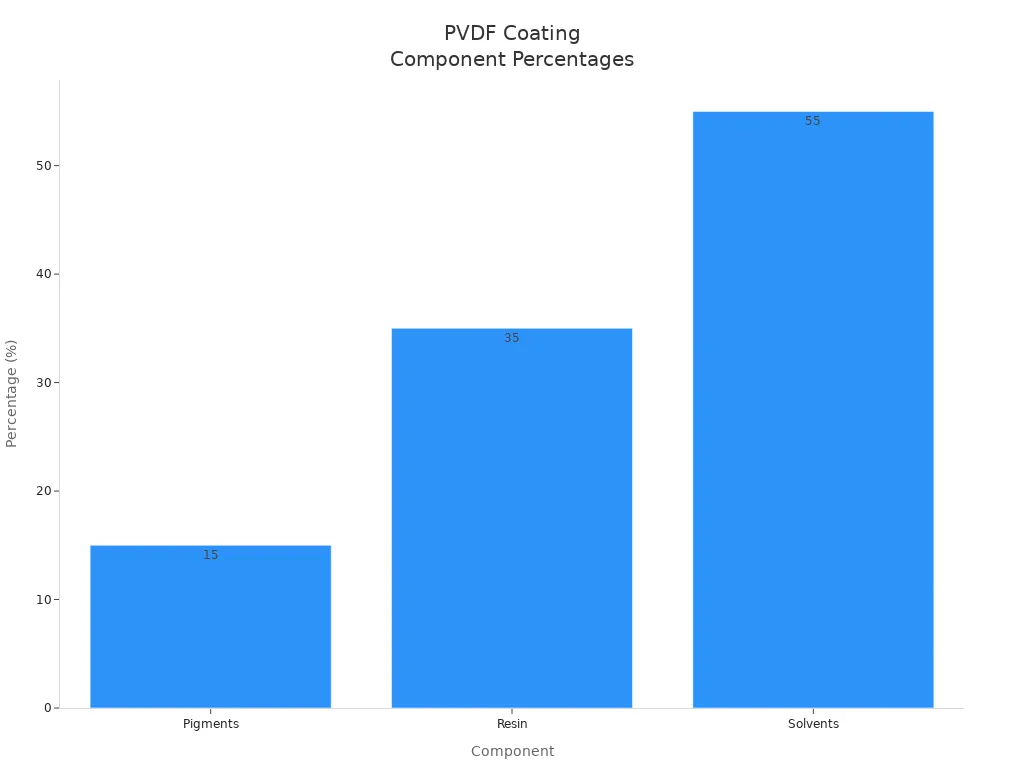

You may wonder why pvdf coating is so strong. The answer is in its special chemical makeup. PVDF means polyvinylidene fluoride. This material is the main part of the coating. It uses resins, pigments, and solvents. Each part helps protect the panels.

Component | Role in Weather Resistance | |

|---|---|---|

Pigments | 15% | Give color and help resist chemicals. |

Resin | 35% | Holds pigment to the panel and protects from weather. |

Solvents | 55% | Help spread the coating on the panel. |

Pigments add color and help with fire resistance. Resin keeps everything together and protects from rain and sun. Solvents help the coating cover the aluminum smoothly.

PVDF’s strength comes from carbon-fluorine bonds in the resin. These bonds are very hard to break. They stop the panel from fading or chalking. Your panel stays bright and strong for years. PVDF is also flexible and works well in tough weather.

Application Process

Factories use a careful process to put pvdf coating on panels. This makes sure the panels last long and look good. Here are the steps:

Surface Preparation: Workers clean the aluminum. They remove oil and dust. This makes the surface smooth.

Primer: A primer goes on first. It helps the next layers stick and adds protection.

PVDF Top Coating: The colored pvdf coating is sprayed on. This layer protects from scratches and water.

PVDF Clear Coating: A clear layer goes on last. Heat cures it to lock in color and make it strong.

This process gives you panels that resist stains and fading. Careful steps help the coating stick well and stay even.

Tip: Panels with pvdf coating go through strict checks. Workers check thickness, color, and how well layers stick. You get only the best panels.

Adhesion and Stability

You want panels that do not peel or crack. PVDF helps with this. The process bonds the coating tightly to the aluminum. High heat melts the resin and forms a strong shield. This shield stands up to wind and rain.

Step | Description |

|---|---|

Surface Preparation | Cleaning the metal helps the coating stick well. |

Primer and Base Coat | Primer stops rust and pvdf base coat makes thickness even. |

Curing Process | High heat bonds the resin and makes a tough layer. |

Checks for thickness and finish make sure coatings are good. |

PVDF coatings keep their shape after years in sun or cold. They do not react with most chemicals. You get panels that resist UV rays and heat. Scientists tested pvdf and found it stays strong for many years. It has better strength than other coatings. Your panels will not crack or break easily.

PVDF uses special agents to help the coating stick better. These agents make the surface harder. The panels do well in weather and erosion tests. PVDF coating protects your building for a long time.

You also get great chemical and fire resistance. PVDF does not react with acids or cleaning products. It stands up to high heat and does not burn easily. This makes it safe for tough places.

PVDF has excellent chemical resistance.

It is strong against UV rays.

The material stays stable in heat.

Note: When you pick pvdf aluminum composite panels, you get panels that stay safe, strong, and nice for many years.

Benefits of PVDF-Coated ACP Panels

Durability and Resistance

Durability and Resistance

You want panels that last for years. PVDF aluminum composite panels are very strong. The coating protects the panels from many things. You get:

High resistance to UV rays, so panels do not fade.

Strong protection from rain, wind, and bad weather.

Excellent abrasion resistance, so panels do not scratch.

Defense against corrosion, acid rain, and chemicals.

These benefits make PVDF aluminum composite panels a smart pick. They work well for buildings in cities or near factories. The panels keep their shape and color for a long time. You can trust PVDF-coated ACP panels to last and handle tough weather.

Color and Finish Options

You can pick from many colors and finishes. PVDF aluminum composite panels let you choose the look you want. Here is a table with some options:

Finish Type | Color Options |

|---|---|

Matte | Many colors available |

High Glossy | Many colors available |

Wood | Many wood finishes available |

Marble | Many marble finishes available |

Brushed | Many brushed finishes available |

Mirror | Many mirror finishes available |

Chameleon | Many chameleon finishes available |

You can select standard colors, special colors, or custom shades. PVDF-coated ACP panels match RAL or PANTONE colors. This means you get the style you want. The coating keeps colors bright for years. Kynar 500® coatings help panels stay shiny and resist fading. PVDF’s chemical structure gives long-lasting durability and weather resistance.

Maintenance and Cost

You save time and money with PVDF aluminum composite panels. The coating does not need repainting or re-coating. You only clean the panels sometimes to keep them looking new. Other materials, like stone, cost more and need more care. PVDF-coated ACP panels cost less than $100 per sheet. This makes them a budget-friendly choice.

You do not need to worry about sealant renewal or heavy cleaning. The panels stay strong and colorful for many years. This means you spend less money over time. PVDF aluminum composite panels give you low maintenance and high value. You get long-lasting durability without extra work or cost.

Tip: Pick PVDF-coated ACP panels if you want a building that looks good, lasts long, and saves money.

Applications and Comparisons

Uses in Construction and Design

Uses in Construction and Design

PVDF aluminum composite panels are used in many places. These panels protect buildings from rain, chemicals, and fire. You see them on the outside walls of buildings in cities and airports. They work well for covering buildings and making curtain walls. You also find them in malls and big stores. Designers use them for signs and inside decorations.

Used for outside walls and building covers

Common in malls, airports, and big stores

Great for signs and decorating inside buildings

Help save energy by keeping buildings cool or warm

These panels last a long time. You do not need to clean them often. They help keep buildings comfortable by holding in heat or cool air.

Tip: Pick PVDF panels if you want colors that last and strong protection.

PVDF Panels vs. Other Materials

You might wonder how PVDF panels are different from other materials. Aluminum composite panels are light and easy to put up. Other materials like HPL are heavier and need stronger support.

Material | Weight | Installation |

|---|---|---|

ACP | Light | Easy to cut and install |

HPL | Heavy | Needs strong support |

Fire safety is important for panels. Mineral-filled core ACP panels stop fire better than regular PE-core ACP panels.

Panel Type | Fire Resistance Characteristics |

|---|---|

PVDF-coated ACP | |

Mineral-filled core ACP | Stops fire better than regular PE-core panels. |

Standard PE-core ACP | Does not stop fire well. |

Performance and Cost Comparison

You want to know how PVDF panels work over time. Aluminum composite panels are strong and do not need much care. Here is a table to compare:

Feature | PVDF-Coated Panels | Non-PVDF (Anodized) Panels |

|---|---|---|

Durability | Resist UV rays and chemicals well | Hard surface, does not scratch easily |

Weather Resistance | Do not fade or chalk easily | Good, but not as strong against UV rays |

Maintenance | Clean every 1 to 3 years | Needs little care |

Warranty | Up to 25 years | Can last longer with good care |

PVDF panels help save energy and are good for the environment. The coatings meet green building rules. They help lower heating and cooling bills. You can trust these panels to last and look nice for many years.

You get many benefits when you choose pvdf-coated acp panels for your building. These panels last a long time and keep their color and shine. The PVDF coating protects against UV rays, rain, and chemicals. You can see pvdf-coated acp panels on stadiums and city landmarks because they stay strong in harsh weather.

PVDF-coated acp panels resist fading and damage.

They offer many colors and finishes for design.

You spend less time and money on cleaning.

Benefit | Why It Matters |

|---|---|

Durability | Panels stay strong for many years. |

Aesthetic Flexibility | Many styles fit your project needs. |

You can trust pvdf-coated acp panels to keep your building safe and looking new.

FAQ

What does PVDF stand for?

PVDF means Polyvinylidene Fluoride. This material is in the coating on aluminum composite panels. It helps protect the panels from weather, sunlight, and chemicals.

How do you clean PVDF aluminum composite panels?

You clean these panels with mild soap and water. Use a soft cloth or sponge to wipe them. Do not use strong chemicals or rough brushes. This keeps the panels smooth and shiny.

Are PVDF-coated panels safe for fire-prone areas?

Yes, PVDF-coated panels with a fire-resistant core are safe. These panels help slow down fire. Always look for fire safety certificates before buying.

Can you recycle PVDF aluminum composite panels?

Yes, you can recycle these panels. The aluminum and core materials get separated during recycling. This helps cut down on waste and supports green building.

Chemical Properties

Chemical Properties Durability and Resistance

Durability and Resistance Uses in Construction and Design

Uses in Construction and Design