31 Jan How PVDF Coating Improves Weather Resistance in ACP Panels

Table of Contents

PVDF coating ACP panel weather resistance is a key feature that helps acp PVDF panels withstand harsh weather conditions. The PVDF coating has a compact molecular structure, forming a durable shield on the panel surface. This acp PVDF layer blocks harmful UV rays, preventing fading and chalking, so your panels retain their vibrant color for years. The PVDF coating ACP panel weather resistance is enhanced by the use of KYNAR500 resin, which provides superior resistance to acid and alkali, making your panels last longer with minimal maintenance. Choosing acp PVDF panels ensures your building remains protected and durable in tough weather.

Contribution to Weather Resistance | |

|---|---|

Compact molecular structure | Makes panels extra strong after baking |

Strong carbon-fluorine bonds | Stops UV rays, fading, and chalking |

KYNAR500 fluorocarbon resin | Fights acid and alkali, keeps panels looking good |

PVDF coating ACP panel weather resistance protects panels from UV rays, acid, and alkali.

With acp PVDF, you prevent fading and chalking, keeping panels strong and long-lasting.

Key Takeaways

PVDF coating keeps ACP panels safe from UV rays, acid, and alkali. This helps the panels keep their color and stay strong for a long time.

Pick PVDF-coated panels if you want easy care. They do not need much cleaning or fixing. This saves you time and money.

PVDF panels work well in tough weather. They do not rust or get damaged by weather. This makes them good for places near the sea or in cities.

PVDF-coated ACP panels help stop fires and keep heat inside. This makes your building safer and more comfortable.

Buying PVDF panels means you get strong panels. They can last up to 30 years if you take care of them. They keep looking good and stay strong.

Science of PVDF Coating on ACP Panels

What Is PVDF and How It Works

You may ask why pvdf is good for ACP panels. pvdf means polyvinylidene fluoride. It is a strong plastic. This material makes a hard layer on the panel. pvdf has tough carbon-fluorine bonds. These bonds help it fight sunlight and bad weather. If you pick pvdf, your coating stays strong outside.

pvdf is not like polyester or powder coatings. Polyester uses fake resins and works best inside. pvdf is made for outside and keeps its color and shine for a long time.

pvdf sticks well to panels and keeps its shine. Powder coatings can lose color as time goes by.

pvdf costs more, but it lasts much longer than other coatings.

pvdf stops UV rays, heat, and chemicals. You do not need to fix it often.

Manufacturers add special colors and use many layers of pvdf. This makes the coating even tougher. Your ACP panels stay bright and clean with less work.

Molecular Bonding and Protective Film

pvdf protects panels at the tiny molecule level. The carbon-fluorine bonds in pvdf are very strong. These bonds make a shield that blocks UV rays and stops fading. pvdf stays safe when it gets hot or touches harsh stuff.

pvdf coatings bend well and fight bad weather. Your panels do not crack or peel.

pvdf does not get hurt by chemicals, salt, or pollution. It works great near the sea or in cities.

pvdf keeps its color longer than other coatings. This is because of its strong bonds and good colors.

Studies show pvdf works better than polyester and polyurethane in tough weather. You can trust pvdf to keep ACP panels looking new after years of sun, rain, and wind.

Tip: If you want panels that last and need little care, pvdf coating is the best choice for weather resistance.

PVDF Coating ACP Panel Weather Resistance

UV and Color Retention

UV and Color Retention

You want your building to look nice for a long time. pvdf coating on acp panels helps keep it bright. The pvdf coating acp panel weather resistance protects from strong sunlight. When UV rays hit, pvdf coating blocks them. This stops fading and chalking. Your acp panels keep color and shine for years.

Lab tests show how pvdf-coated acp panels do in sunlight. You can see the results in this table:

Test Type | Feature Validated | Key Findings |

|---|---|---|

UV Aging Test | UV resistance, durability | Color and shine stay the same after sunlight |

Natural Exposure | Color retention | Gradual, small color change |

Accelerated Aging (QUV) | Gloss retention | 85%-90% gloss kept |

pvdf coating on acp panels keeps your building looking new. You do not need to worry about weather damage. pvdf coatings keep color bright for up to 20 years. They give great UV protection, stopping fading and chalking. pvdf coating acp panel weather resistance is better than other coatings.

Note: pvdf coating on acp panels gives better UV protection than anodized or PE coatings. You get color that lasts longer and less work to keep it nice.

Feature | PVDF Coating | Other Coatings |

|---|---|---|

Color Retention | Excellent, lasts up to 20 years | Limited, fades faster |

UV Resistance | High | Moderate |

Chalking Resistance | Very High | Low |

Moisture and Corrosion Protection

Rain, humidity, and pollution can hurt buildings. pvdf coating on acp panels gives strong weather and corrosion resistance. The pvdf coating makes a tight shield. Water cannot get inside the panels. You avoid rust, blistering, and peeling.

Salt spray tests show pvdf-coated acp panels stay strong. No rust or blistering shows up after a long time. The coating stays smooth and tough. pvdf coating acp panel weather resistance helps protect buildings near the sea or in cities. You do not need to worry about corrosion or water damage.

pvdf coating on acp panels resists acid and alkali.

You get panels that last longer and need less fixing.

pvdf-coated acp panels keep their shield even in bad weather.

Fire, Heat, and Sound Insulation

pvdf coating on acp panels does more than stop weather damage. You also get fire, heat, and sound insulation. pvdf-coated acp panels reach a B1 fire protection level by GB 8624-2012. This means your panels slow fire and keep your building safer.

Heat and sound insulation help make rooms comfortable. pvdf coating acp panel weather resistance gives these benefits too. You get better thermal and sound insulation than with other cladding.

Property | PVDF-coated ACP Panels | Other Cladding Materials |

|---|---|---|

Thermal Insulation | Excellent | Varies |

Sound Insulation | Excellent | Varies |

You can use pvdf coating on acp panels in schools, offices, and homes. The panels help keep rooms cooler in summer and quieter all year. pvdf coating acp panel weather resistance gives you peace of mind and better living.

Tip: pvdf-coated acp panels are great for places with tough weather. You get strong protection, safety, and comfort.

Practical Benefits of PVDF Aluminium Composite Panels

Durability and Long-Term Performance

Durability and Long-Term Performance

If you pick pvdf aluminium composite panels, you get strong panels. These panels can last 15 to 20 years. Some panels last even longer if you take care of them. You see the pvdf coating advantages every day. The panels do not crack, chip, peel, or flake. They keep their shape and color for many years. Bad weather does not hurt them. Hail, wind, and temperature changes are not a problem. The panels stay tough in rain, snow, ice, and heat. You get panels that look good and last a long time inside or outside.

pvdf aluminium composite panels handle rough weather.

You get strong panels with little chance of damage.

The panels keep their shape and color for years.

Low Maintenance Needs

pvdf aluminium composite panels help you save time and money. The pvdf coating means you do not fix or repaint often. Cleaning is simple. In places with lots of pollution, you clean the panels once a year. This stops dirt and grime from building up. Simple cleaning keeps the panels looking nice and strong. pvdf aluminium composite panels cost less to take care of than other panels.

Performance Parameters | PE Aluminum Composite Panel | PVDF Aluminum Composite Panel |

|---|---|---|

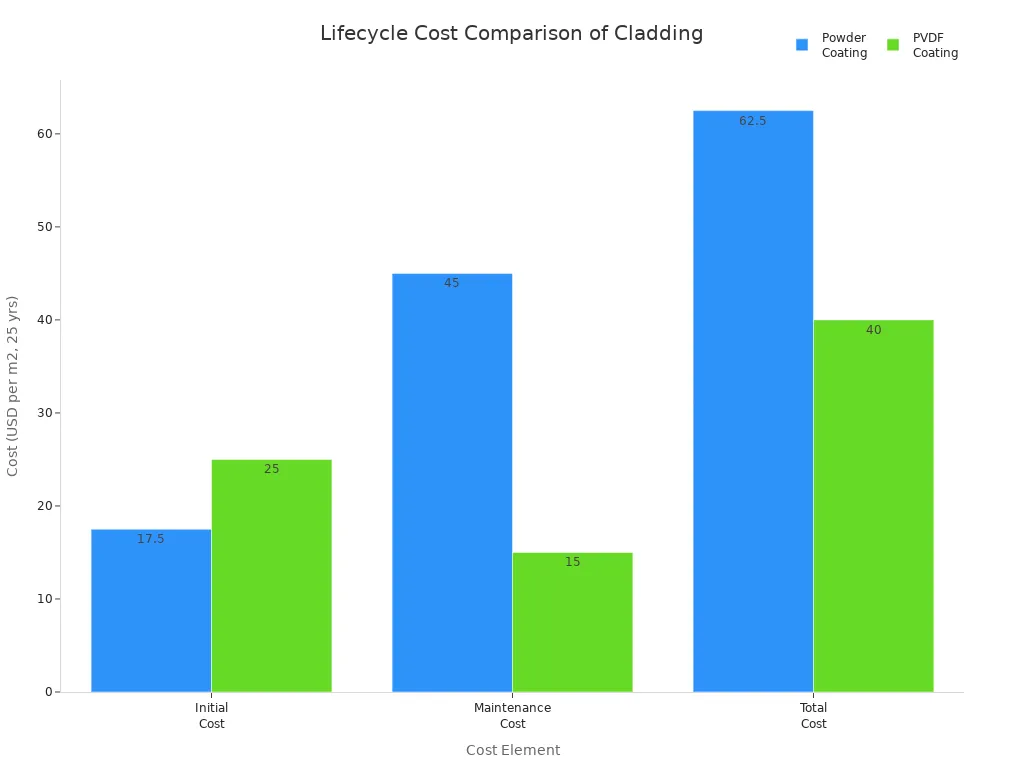

Maintenance Cost | Low to Medium | Low |

Tip: Clean your panels often to keep them looking new and lasting longer.

Suitability for Harsh Climates

You can use pvdf aluminium composite panels almost anywhere. They work well in coastal, city, desert, or cold places. The panels fight salt spray, oxidation, and UV rays. They keep most of their color after many years in the sun. In coastal areas, you do not see pitting, blistering, or flaking. In deserts and cold places, the panels stay strong and look good. You get panels that work well in places with very hot or cold weather.

pvdf aluminium composite panels are good for the sea, cities, and places with strong weather.

Your building is safe from salt, pollution, and big temperature changes.

The panels last a long time and need little care, no matter where you put them.

Applications of PVDF-Coated ACP Panels

Commercial and Residential Uses

PVDF-coated ACP panels are used in many places. They work for homes and businesses. Builders pick these panels because they last long and look nice. The panels cover the outside of buildings. You see them on malls, offices, schools, and hospitals. People also use ACP panels for houses, balconies, and kitchens.

PVDF panels made up 45.3% of the ACP market in 2024. This means many people use PVDF-coated ACP panels outside.

Builders like these panels because they stand up to weather. They keep their color for a long time.

You can choose from many colors and finishes. This helps ACP panels match any building style.

Tests show PVDF-coated ACP panels keep over 90% of their shine after 10 years outside.

PVDF aluminium composite panels help save energy. They stop heat from leaving your building. A test showed these panels can cut heat loss by 54%. Your building stays cooler in summer and warmer in winter. You spend less money on energy.

Using aluminium ACP panels is good for the planet. The aluminium is easy to recycle. Many panels use recycled materials. This lowers waste and helps the environment. Their strong insulation means you use less energy.

Performance in Challenging Environments

PVDF-coated ACP panels are strong in tough places. They protect buildings from acid rain, pollution, and strong sun. The PVDF coating keeps panels looking new for years.

Feature | Benefit |

|---|---|

UV Resistance | Stops damage from strong sunlight |

Acid Rain Resistance | Protects against acid rain |

Air Pollution Resistance | Keeps panels safe in polluted cities |

Longevity | Keeps color and shine for over 20 years |

Maintenance | Lowers cleaning needs and costs |

PVDF aluminium ACP panels do not fade or bloom.

They protect against acid rain and pollution.

The panels work well in places with bad weather.

PVDF aluminium composite panels have strong insulation. They block air and water. The PVDF coating reflects sunlight. This keeps your building from getting too hot.

You can use PVDF-coated aluminium ACP panels in many places. They work in coastal cities, deserts, and rainy areas. These panels meet green building rules like LEED, BREEAM, and WELL. They help with recycled material credits and better energy use.

PVDF-coated ACP panels give you strong protection. They do not fade or rust easily. These panels can last up to 30 years. You do not need to fix them often. The color stays bright for a long time. The panels also help keep heat and cold out. Tests show PVDF coatings stay tough in bad weather. Owners say cleaning is quick and repairs are easy.

Key Benefit | What You Gain |

|---|---|

Durability | Panels last decades |

Color Retention | Bright, fresh look year after year |

Low Maintenance | Simple cleaning, fewer repairs |

Weather Resistance |

PVDF-coated ACP panels are good for many places.

You can use them in cities or near the sea.

Picking these panels is smart for saving money and keeping buildings strong.

FAQ

What makes PVDF coating better than other types?

You get stronger protection with PVDF coating. The coating blocks UV rays and resists chemicals. Other coatings fade faster and need more repairs. PVDF coating keeps your panels looking new for years.

How often should I clean PVDF-coated ACP panels?

You should clean the panels once a year. The coating stops dirt from sticking. Simple washing keeps the coating smooth and bright. You spend less time on maintenance because the coating works hard for you.

Can PVDF coating help in coastal or polluted areas?

Yes, PVDF coating protects panels from salt, pollution, and acid rain. The coating forms a shield that keeps panels safe. You see less rust and damage. The coating works well in cities and near the sea.

Does PVDF coating affect fire safety?

PVDF coating helps panels reach a B1 fire rating. The coating slows fire spread and adds safety. You get better protection for your building. The coating also keeps its strength in heat.

How does PVDF coating impact panel longevity?

PVDF coating increases panel longevity. The coating resists fading, cracking, and peeling. You get panels that last up to 20 years. The coating keeps color and shine, so your building stays beautiful.

Tip: PVDF coating gives you strong, long-lasting panels with less work.

Feature | PVDF Coating Benefit |

|---|---|

UV Protection | Stops fading and chalking |

Corrosion Block | Shields from salt and acid |

Fire Safety | Slows fire spread |

Longevity | Lasts up to 20 years |

UV and Color Retention

UV and Color Retention Durability and Long-Term Performance

Durability and Long-Term Performance