14 Aug Step-by-Step Guide to Applying Aluminum Composite Material in Building Design

Table of Contents

- 1 Key Takeaways

- 2 Applications of Aluminum Composite Panels

- 3 Understanding Aluminum Composite Material

- 4 Benefits of Aluminum Composite Panel

- 5 Installation Guide for Aluminum Composite Panels

- 6 Tips and Mistakes to Avoid

- 7 FAQ

- 7.1 What tools do you need to cut aluminum composite panels?

- 7.2 Can you use aluminum composite panels for both indoor and outdoor projects?

- 7.3 How do you clean aluminum composite panels?

- 7.4 Are aluminum composite panels safe for tall buildings?

- 7.5 Can you paint or print on aluminum composite panels?

Aluminum composite material is changing how we build today. In 2023, people used almost $6.8 billion worth of it. Experts think this number will keep growing. You can use aluminum composite panels on building outsides, inside walls, or for special signs. These panels are very useful and can be used in many ways. That is why builders and skilled DIYers like them. Many people pick these panels because they are light but strong. They are also easy to put up and can match almost any style. The table below shows how the aluminum composite material market is changing:

Aspect | Details |

|---|---|

Market Size 2023 | Approximately USD 6.8 billion |

Projected Market Size 2032 | Approximately USD 11.2 billion |

CAGR (2023-2032) | 5.5% |

Largest Consumer Sector | Building and construction sector |

Key Regional Market | Asia-Pacific |

Key Takeaways

Aluminum composite panels are light and strong. They are easy to put up. This makes them great for outside and inside buildings. They also work well for signs.

These panels help save energy because they insulate well. They also help block noise. The panels meet fire safety rules too.

You can pick from many colors and finishes. This lets you make modern and cool designs. The panels do not rust or fade for a long time.

Good planning is important. You need to cut the panels carefully. Use the right tools and materials to install them. This keeps the panels strong and looking nice.

Clean the panels often and fix them quickly. This keeps them in good shape. It helps your building stay safe, work well, and look nice for many years.

Applications of Aluminum Composite Panels

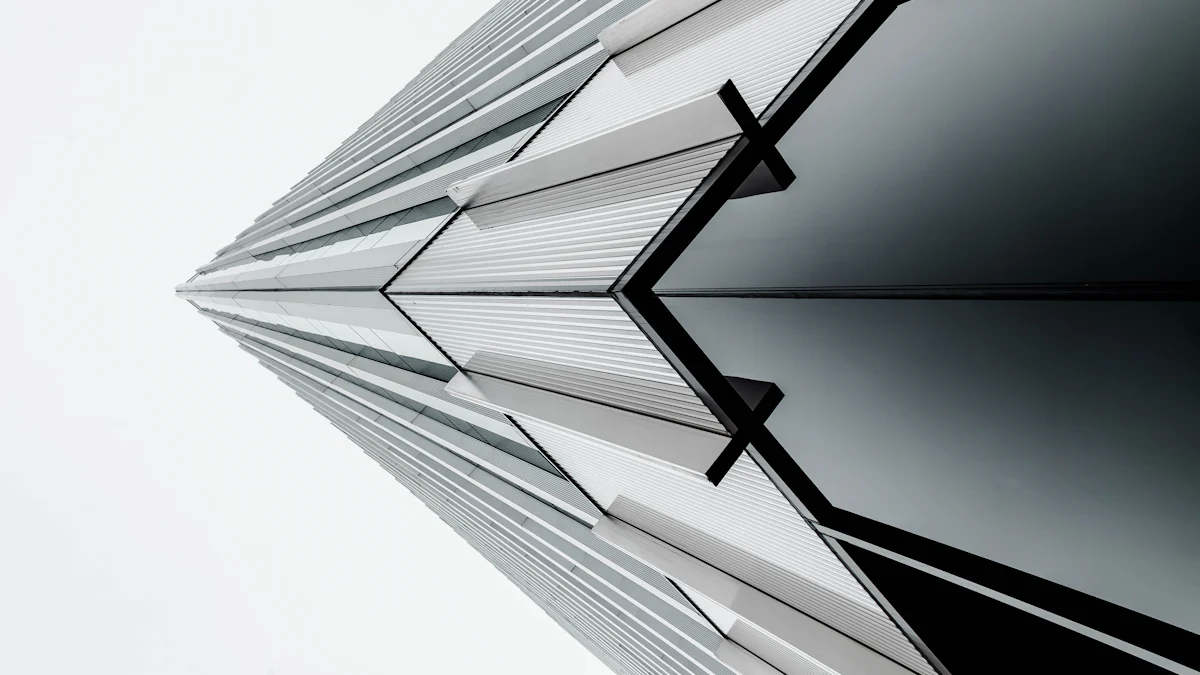

Exterior Cladding

Many buildings use composite aluminum panels on the outside. You can see them on offices, schools, and hospitals. More than half of commercial buildings have these panel systems. Builders like them because they are light and strong. They also stand up to bad weather. These panels protect buildings from rain, wind, and sun. They help save energy by adding insulation. Some ventilated cladding systems can cut power bills a lot. You can use these panels for new or old buildings. This is why they are a popular choice for building projects.

Tip: Using composite aluminum panels on buildings makes them look modern and helps save energy.

Interior Design

Composite aluminum panels are good for inside spaces too. You can use them for walls, partitions, and ceilings. They come in many colors and finishes. You can pick any style you like. The panels are light, so you can put them up fast. They do not get dirty or wet easily, so cleaning is simple. These panels last a long time and do not rust. They follow fire safety rules and help keep people safe. You can use them in homes, offices, stores, and hospitals. They also help make rooms quieter.

You can shape composite aluminum panels for special designs.

They are good for the environment because you can recycle them.

Signage and Displays

Composite aluminum panels are used for signs and displays. Their smooth surface makes printing easy and colors bright. These panels can handle sun, rain, and wind, so signs last longer. Many companies use them for ads and branding. You can also use them for displays in malls or airports. The panels are light, so you can move and set them up easily. They are tough, so your signs will look good for a long time.

Note: Using aluminum composite panels for signs helps businesses make messages that stand out and last.

Composite aluminum panels are useful for cladding, interiors, and displays. They save energy, last long, and let you be creative with design. You can trust this material for many building needs.

Understanding Aluminum Composite Material

What Is Aluminum Composite Material

You may wonder how aluminum composite material is not like regular metal panels. This material has two thin sheets of pre-painted aluminum. These sheets are stuck to a plastic core, often made of polyethylene. The layers make a panel that is light, flat, and strong. The plastic core helps keep the panel stiff and gives insulation. The surface is smooth and does not bend out of shape. You can cut or shape it for your project with ease.

Traditional aluminum panels are just solid metal sheets. They are heavier and often need extra coatings to stop rust. Aluminum composite panels give better insulation and are easier to use. You can put them up faster and with less work. The design choices let you make modern styles for any building. These panels also stand up to weather, UV rays, and moisture. You can use them inside or outside and trust they will last.

Note: Aluminum composite material was first made in the 1960s. Over the years, makers made the core safer from fire and more durable.

Why Use Composite Aluminum Panels

There are many reasons to pick composite aluminum panels for your building. Here are some of the main benefits:

Weather Resistance & Lightweight: Composite aluminum panels can handle rain, heat, and cold. They are light, so you can move and install them easily.

Durability: These panels do not break, get wet, or rust easily. They stay strong and keep their shape for a long time.

Thermal and Sound Insulation: The plastic core helps stop heat and noise. This makes your building more comfy and saves energy.

Fire Safety: New aluminum composite panels have fire-safe cores. They meet tough rules like ASTM E84 and EN 13501-1. You can use them in schools, hospitals, and tall buildings.

Low Maintenance: You can clean the panels with a cloth. They do not need paint or polish.

Cost-Effectiveness: You save money on materials, shipping, and putting them up. The panels last long, so you do not spend much on fixing them.

Sustainability: Many composite aluminum panels can be recycled. They help lower your building’s carbon footprint.

Tip: Always look for fire safety certificates from other groups when you choose an aluminum composite panel. This keeps your building safe and follows the rules.

You can see why architects and builders like composite aluminum panels for many projects. You get strength, style, and safety all in one.

Benefits of Aluminum Composite Panel

Lightweight and Durable

Lightweight and Durable

When you pick up an aluminum composite panel, you see its benefits fast. Each panel weighs about 2.5 pounds for every square foot. This makes them easy to lift and move. You do not need big machines to put them in place. Being light helps you work faster and keeps you safer. This is very helpful for inside jobs or tall buildings. The panels are also very strong. They do not dent or bend easily. They can handle bumps and hits better than many other materials. You can count on them to last, even in bad weather. The panels meet tough rules for strength and safety. They pass tests for peel strength, flexural strength, and impact resistance. They also pass fire safety tests. This means you can use them where safety is very important. These panels can last up to 50 years. You will not need to fix or replace them often.

Tip: Clean your panels often and fix small problems fast. This helps them stay strong and look nice for many years.

Energy Efficiency and Insulation

Aluminum composite panels help your building use less energy. They bounce back up to 95% of heat from the sun. In summer, this keeps your building cooler. In winter, it helps keep heat inside. This means you do not need as much heating or cooling. Your energy bills will go down. The panels also block sound and stop moisture from getting in. This makes rooms quieter and more comfy. The panels are also good for fire safety. This is extra important for places like schools, hospitals, and offices. You can recycle these panels when you are done with them. This helps the planet and supports green building. You also help lower your building’s carbon footprint.

Bounces heat away and keeps rooms comfy

Blocks noise and stops moisture

Gives fire safety for safer buildings

Aesthetic Versatility

You can make many different looks with aluminum composite panels. You can pick solid colors, wood or stone looks, shiny metal, or special textures. You can match the panels to any style you want. You can also cut, bend, or shape them for cool designs. You can pick glossy, matte, or other finishes to make your building stand out. Many designers like these panels because they are flexible and look modern. The panels do not fade, rust, or get ruined by graffiti. Your building will look new for a long time. You can use them for outside walls, ceilings, room dividers, or any place that needs to look good and be strong.

Finish Type | Description |

|---|---|

Solid Colors | Even, bright, or soft shades |

Wood/Stone Look | Natural styles that are also tough |

Metallic | Shiny, modern, and grabs attention |

Matte/Glossy | Pick soft or bright shine |

Note: You can be creative with many design choices. You still get strong panels that are safe from fire.

Installation Guide for Aluminum Composite Panels

Planning and Preparation

You need a good plan before you start putting up panels. Planning helps you not make mistakes and makes the job easier. Here are the steps to install aluminum composite panels:

Look at the arrows on the film to see which way each panel goes.

Cut, roll, and drill from the back so the front stays safe.

Draw a sketch of your project. Mark windows, doors, and corners.

Start putting up panels at corners to keep them straight.

Measure each panel carefully. This stops gaps and crooked lines.

Take off the film only after you finish each part.

Seal the panels in order so water does not get in.

You should also make the base wall waterproof with a barrier or wrap. Overlap the sheets and smooth out any bumps. Put flashing at the bottom to move water away. Use chalk lines and a laser to mark where each panel goes. This helps you put up panels in the right place.

Tip: Always start at corners and openings. This keeps your panels straight and even.

Material Selection

Picking the right material is very important for your project. You want panels that last and fit your needs. Here is a table to help you compare what matters:

Criteria | Why It Matters | Example Brands and Features |

|---|---|---|

Keeps panels flat and strong | DIBOND® resists bowing and wrinkling | |

Weight | Makes for easy installation and less load on the building | C-TEK® panels are half as heavy as solid aluminum |

Fabrication Ease | Allows for easy cutting, bending, and shaping | Alumanate is easy to route and cut with CNC machines |

Surface Finish | Impacts look and print quality | DIBOND® offers mirror finishes; Alumanate is ultra-smooth |

Color Options | Lets you match any design | Alumanate comes in many colors and finishes |

Fire Rating | Meets safety codes | DIBOND® and Alumanate meet top fire safety standards |

Warranty | Protects your investment | Alumanate offers up to 10 years for indoor use |

Application Suitability | Fits your specific use (indoor, outdoor, signage, cladding) | DIBOND® for exterior, Alumanate for signage, C-TEK® for cladding |

Pick panels that are safe, look good, and last long. Always check fire ratings and warranties before you buy.

Substructure Setup

A strong substructure holds your panels up for many years. Use aluminum framing like TimberTech Aluminum Framing for best results. This framing is strong, flat, and does not rust or get moldy. It works well for long spaces and overhangs. The framing meets building rules and is easy to put together. You need fewer screws and less work on site. The framing is also good for the planet and has a long warranty.

Use aluminum framing for strong and easy setup.

Make sure the substructure is flat and level before you start.

Use the right screws and washers to stop leaks.

Note: A good substructure makes your job easier and helps panels last longer.

Cutting and Handling

Cutting and handling panels the right way keeps them looking nice and safe. Here is how to work with aluminum composite panels without damage:

Do not walk on panel stacks or put them on rough ground.

Use enough people and tools to move big panels.

Wear gloves, goggles, and boots to stay safe.

Use sharp, fine-toothed blades for cutting. Dull blades can hurt the edges.

For straight cuts, use metal shears. For shapes, use laser or waterjet cutters.

Hold panels steady with stands or fixtures when cutting.

Keep your work area dry and away from things that can catch fire.

Plan your work to handle panels less. Keep your jobsite neat so panels are safe and easy to find.

Panel Installation

Now you can start putting up the panels. Get your tools: tape, chalk line, level, saw, drill, screwdriver, clamps, suction cups, and safety gear. Clean and check the wall. Make sure it is dry and strong.

Start at a corner and move out. This keeps panels straight and stops gaps.

Use spacers or shims for even spaces between panels.

Attach panels loosely first. Adjust them to line up right.

Use stainless steel or aluminum screws. Do not make them too tight.

Use clamps or suction cups to hold panels while glue dries.

For ventilated facades, leave a gap behind panels for air flow.

Tip: Always use a level and chalk line to check if panels are straight. This helps you avoid mistakes and makes the job easier.

Finishing and Inspection

Finishing and checking your work are the last steps. These steps help your panels look good and last long.

Step Category | Key Actions and Why They Matter |

|---|---|

Put on sealant, wipe off extra, and smooth joints. This keeps water and air out. | |

Trim and Edge Finishing | Trim edges neatly and use trims or paint. This protects from weather and looks nice. |

Ventilation and Drainage | Make a space for air and add drainage mats. This stops mold and keeps panels dry. |

Expansion Joints | Add joints for movement. This stops buckling and keeps panels flat. |

Quality Assurance | Check if panels are straight and safe. Fix problems right away. |

Look at your work closely. Take off the film right after you finish so it does not stick. Check for gaps, crooked panels, or scratches. Fix any problems before you are done. Check and clean panels often to keep them strong and easy to care for.

Note: Careful finishing and checking help your panels last and look good for many years.

Tips and Mistakes to Avoid

Best Practices

Best Practices

You want your aluminum composite panel job to last and look good. Follow these tips to get the best results:

Always wear safety gear and use the right tools. Gloves, goggles, and ear protection keep you safe.

Measure each spot carefully before you start working. Mark where each panel will go.

Work in a clean area with no dust. Dirt can scratch the panels and ruin how they look.

Store panels flat and dry. Keep them wrapped until you are ready to use them.

Use sharp, fine-tooth blades to cut panels. This gives you smooth edges for inside and outside jobs.

Follow the instructions from the maker for each step. Some brands have special steps you must follow.

Pick the right way to attach panels. Use screws or glue, depending on your project.

Leave small spaces between panels. This lets them move when it gets hot or cold and stops warping.

Put weatherproof sealant on all joints and edges. This keeps water out and protects your work.

Check your work after you finish. Take off the film and look for scratches or panels that are not straight.

Clean panels with mild soap and water. Do not use strong cleaners that can hurt the surface.

Check and clean your panels often. This keeps them looking new, even in busy places.

Tip: Always ask for samples and check the color and finish before you start. This helps you pick the right look for your design.

Common Pitfalls

Many people make mistakes when putting up panels. These mistakes can cause problems later. Watch out for these common errors:

Not sealing joints and edges the right way. Water can get in and cause mold or rust.

Using the wrong panels for inside or outside. Indoor panels can fade or bend if used outside.

Not leaving space for panels to move. They can buckle or crack if there is no room.

Picking bad glue or screws. Panels can fall off or get damaged.

Not cleaning or checking panels often. Dirt and damage can build up and make panels wear out faster.

Handling panels too roughly. Scratches and dents can happen when moving or installing them.

Not following the maker’s guide for installation. Each system may need special steps for inside or outside use.

Note: Careful planning and paying attention to details help you avoid repairs. This keeps your panels looking good inside and outside.

You can see that aluminum composite material helps make buildings better. The table below lists the main steps and what they do:

Key Steps in ACM Manufacturing | Benefits in Building Design |

|---|---|

1. Aluminum sheet production | Strong but not heavy |

2. Core material selection | Lasts long and stands up to weather |

3. Bonding process | Lets you pick many styles |

4. Finishing and coating | Saves money and energy |

These panels are easy to put up and very strong. You can use them in many ways for your design. Putting them up is quick and does not cost a lot. The panels will last a long time after you install them. Pick aluminum composite panels for your next building job. Talk to an expert to find the best way to install them.

FAQ

What tools do you need to cut aluminum composite panels?

You need a fine-tooth saw, metal shears, or a CNC router. Always use sharp blades for clean edges. Wear gloves and goggles for safety.

Tip: Use a clamp to hold the panel steady while you cut.

Can you use aluminum composite panels for both indoor and outdoor projects?

Yes, you can use these panels inside and outside. Pick panels with the right finish and fire rating for your project. Outdoor panels resist weather and UV rays.

How do you clean aluminum composite panels?

Use mild soap and water with a soft cloth. Avoid harsh chemicals or rough sponges. Rinse panels well to remove soap.

Clean panels regularly to keep them looking new.

Are aluminum composite panels safe for tall buildings?

Yes, many panels meet strict fire safety codes. Always check for certifications like ASTM E84 or EN 13501-1 before you buy.

Note: Fire-rated panels are best for schools, hospitals, and high-rise buildings.

Can you paint or print on aluminum composite panels?

You can paint or print on these panels. The smooth surface works well for digital printing and custom designs. Use paint or ink made for metal surfaces.

Lightweight and Durable

Lightweight and Durable Best Practices

Best Practices